The use of copper pipes allows you to create an efficient and durable heating or water supply system. The simplest and most common way to connect such products is soldering technology. It involves the presence of solder - a thermoplastic substance that seals the joint by melting and flowing under the influence of high temperature. After cooling, it hardens and fixes the connection.

Soldering of copper pipes is carried out with different types of solder

Preparing copper pipes

These products are strong, durable, can withstand high pressure and temperature, and are not afraid of ultraviolet radiation.

To solder copper pipes you will need a pipe cutter, an expander, a hammer, a tape measure and a chamfer. The choice of pipe cutter is determined by the diameter of the products used. It allows you to get an even cut that is perpendicular to the axis of the pipe. Chamfer removers are used to remove burrs and chamfers from the edges of products. Removing burrs from the outer and inner edges of the pipes makes it easier to fit them into each other. Chamfer removers come in a round body (with a pipe diameter limit of 3.6 cm) or in the form of a pencil.

If the connection of copper pipes does not involve the use of fittings, then a pipe expander is used.

Important! The copper product to be expanded must be either soft or annealed.

There should be no flammable or combustible substances in the copper pipe soldering room. It is also necessary to ensure good ventilation and ventilation.

For a quality connection, an even cut is important, so the pipe must be cut with a special device - a pipe cutter

Classification of copper products

Copper pipes in Europe are mainly metric; 6, 8, 10, 12, 15, 22, 28, 42 and 48 mm are also found in larger diameters, but they can also be inch:

| inches | mm |

| 1/4 | 6.35 x 0.8 |

| 3/8 | 9.52 x 0.8 |

| 1/2 | 12.7 x 0.8 |

| 5/8 | 15.9 x 0.8 |

| 3/4 | 19.1 x 0.8-0.9 |

Copper marking in Russian marks: the letter “M” is used to denote copper. Next are numbers showing the degree of purity in% (00 - highly pure, 0 - pure, 1, 2, 3 - technically pure). The last element of the marking is a letter indicating the method of copper production: (k - cathode, y - cathode remelted, b - oxygen-free, p - deoxidized, f - deoxidized with phosphorus).

| Copper grade | M00 | M0 | M1 | M2 | M3 |

| Purity | 99,99 | 99,95 | 99,90 | 99,70 | 99,50 |

Copper grades M1p, M2p and M3p, with a total impurity content identical to copper grades M, M2 and M3, differ from them in that they are more completely deoxidized and the oxygen content in them is reduced from 0.05 - 0.08% to 0. 01%. Therefore, they additionally contain from 0.002% to 0.012% phosphorus. The M1f copper grade differs from M1r in an even greater amount of phosphorus from 0.012% to 0.04%, for greater deoxidation and, accordingly, a complete absence of oxygen.

CHEMICAL COMPOSITION OF COPPER ACCORDING TO GOST 859 (%)

| Copper grade | Cu+Ag (%) | Impurities, no more (%) | ||||||||||

| Bi | Sb | As | Fe | Ni | Pb | Sn | S | Zn | O | P | ||

| M1f | 99,90 | 0,001 | 0,002 | 0,002 | 0,005 | 0,002 | 0,005 | 0,002 | 0,005 | 0,005 | — | 0,04 |

| M1r | 99,90 | 0,001 | 0,002 | 0,002 | 0,005 | 0,002 | 0,005 | 0,002 | 0,005 | 0,005 | 0,01 | 0,012 |

| M1 | 99,90 | 0,001 | 0,002 | 0,002 | 0,005 | 0,002 | 0,005 | 0,002 | 0,004 | 0,004 | 0,05 | — |

| M2 | 99,70 | 0,002 | 0,005 | 0,01 | 0,05 | 0,2 | 0,01 | 0,05 | 0,01 | — | 0,07 | — |

| M3 | 99,50 | 0,003 | 0,05 | 0,01 | 0,05 | 0,02 | 0,05 | 0,05 | 0,01 | — | 0,08 | — |

The use of various grades of copper in plumbing products is determined by GOST 52318, and in Europe - EN 1057. In construction products: GOST 495-92, in Europe - EN 1172. Typically, water pipes contain 99.90 copper and are excellent for home brewing purposes.

Materials required for work

You can solder copper pipes yourself. To work you will need:

- solder;

- steel brush;

- flux;

- brush;

- soldering iron or gas torch.

Solder has the form of a wire with a melting point lower than that of copper. This allows products to be joined by heating. Using a steel brush during preparatory work, the inner surface of the fitting and the outer part of the pipe are cleaned.

Solder can be high-temperature, which is a thin wire made of copper with the addition of up to 6% phosphorus and has a melting point of 600-800 °C, and low-temperature - made of tin, melting at 300-400 °C.

Liquid flux is applied to the coupling and pipe before assembling the connecting unit, solid flux is melted in the soldering zone. Flux in the form of a paste is a thickened mixture that can be applied both before and after the joining process. Flux cleans the surface of the pipe from oxides, protects the soldering site from oxygen, promotes the spreading of solder and improves the adhesion of the parts being connected.

A gas torch is required to heat the metal and solder.

There are gas burners with a stationary cylinder or a disposable one. There is a separate type of burners - acetylene-oxygen, which differ in their design. The power of the soldering machine is selected based on the melting temperature of the solder. Professional tools are used to solder copper pipes with hard solder, and semi-professional tools are used to solder copper pipes with hard and soft solder.

Difference between soldering copper and brass

Soldering is a handy tool when it comes to bathroom plumbing repairs. Soldering is not a uniform operation, and different cases require different technologies. In particular, brazing brass pipes can be more difficult than brazing copper because brass fittings require higher temperatures.

The basic process of joining brass or copper water pipes is essentially the same, however the big difference between copper and brass is that brass requires much more heat for the solder to work properly. In fact, the metal would have to be heated five or six times hotter than copper before it would reach the point where the solder would melt. This will require a higher temperature from the torch, more time applying heat to the metal, and close attention to the behavior of the flame from all sides.

Brass pipes are somewhat unusual, so before starting soldering you need to make sure that pressure inside the soldering does not accumulate, but is freely released into the environment.

Experience has shown that propane torches are not hot enough to work with brass. Instead, when working with brass, a special gas is used, which is a mixture of methyl acetylene and propadiene, which reaches a higher temperature than propane. There is no need to skimp on using flux or solder paste when you need to install pipes.

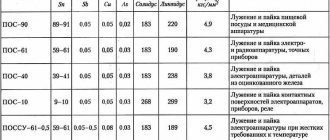

Features of solders and fluxes

There are a large number of hard and soft solders that can provide high-quality soldering of copper pipes. Low-temperature solders produce a seam with slightly worse mechanical parameters, but allow work to be performed at a temperature that does not have a strong effect on the strength of the pipe metal. About 95-97% of such solders are tin, the rest are other elements.

The best technological properties are found in compounds containing silver. There are three-component solders, which include tin, silver, and copper. Fluxes used for low-temperature soldering often contain zinc chloride.

Sufficient joint strength when soldering with soft solder is achieved by a large contact area of the elements. For gas pipelines, only high-temperature soldering is used, ensuring the best strength and reliability.

Low temperature solder is made of tin and has the appearance of a wire.

The permissible pressure in pipelines when using different types of soldering is given in the table.

Table 1

| Soldering type | Temperature of the medium being transported, °C | Pressure, atm |

| Low temperature | 30 | 16 |

| 65 | 10 | |

| 110 | 6 | |

| High temperature | 30 | 40 |

| 65 | 25 | |

| 110 | 16 |

For high-temperature soldering, copper-phosphorus solders are usually used. They are produced in the form of rods.

Note! Copper-phosphorus solder cannot be used when soldering cast iron, steel, and non-ferrous metals that contain more than 10% nickel.

It is recommended to use flux and solder from the same manufacturer for both low- and high-temperature soldering.

Conditions for ensuring strength

One of the conditions for the tightness and strength of soldered products is the appropriate width of the soldered joint. To ensure this condition, special devices of connectors, two-ended elbows, caps, and tees are used. Copper can be soldered:

- soft solders (melting point below 450 C);

- hard solders (melting point above 450 C).

Types of solder used on copper water pipes:

- 40 percent lead / 60 percent tin, for example POS-61;

- 95 percent tin-antimony/5 percent lead;

- 50 percent lead solder is recommended on copper alloy lines, which should not be used for potable water;

- lead-free solder for pipes used in water supply.

Soft soldering

Low-temperature soldering is used when installing water supply and heating networks with coolant temperatures up to 130 °C and pipe diameters up to 10 cm.

Soldering at low temperatures is suitable for installing water pipes

The technology for connecting copper products with soft solder involves preliminary cleaning of the surfaces, applying flux paste with a brush and inserting the elements into each other. Next, the joint is heated with a gas burner to 200-250 degrees. Solder is applied to the edge of the joint.

When soldering, it is important to remember that the temperature of the burner flame can reach 1 thousand degrees, so 15-20 seconds are enough to heat up the elements. To ensure uniform heating, the flame must be constantly moved. The degree of heating is controlled by the color of the flux. After it darkens, you need to take solder.

After introducing soft solder into the soldering zone, in contact with a heated copper pipe, the tin wire begins to melt and slide along the flux into the seam. Gradually the heated mass fills the space between the socket and the pipe.

Types of Copper Solder Fittings

In general, there are more than two dozen different shaped elements for copper pipes - fittings, but three types are most often used:

- couplings - for connecting two pipes;

- corners - for turning;

- tees - for creating branches in the pipeline.

Couplings for soldering copper pipes

The number of fittings used can be minimized - copper can be bent, which will reduce the number of angles needed. Also, if desired, you can do without couplings: one end of the pipes can be expanded (using an expander) so that the pipe goes into it and there is a gap for solder to get there (about 0.2 mm). When creating an expansion, the pipes must overlap by at least 5 mm, but more is better.

What’s hard to do without is tees. There is equipment for inserting a branch - a beading machine, but it is professional and costs a lot. So in this case it’s cheaper and easier to get by with tees.

There are fittings for soldering copper pipes with soldered solder

There are two types of fittings - conventional, with sockets, which provide the required clearance for solder to flow. Solder is supplied to the welding zone manually. There are fittings with built-in solder. Then a groove is formed on the socket, into which, during production, a piece of solder is installed, which makes the soldering process easier - you just need to heat the welding zone, but leads to an increase in the cost of fittings.

Brazing

Do-it-yourself soldering of copper pipes using hard solder is carried out if you plan to operate the system at temperatures above 110 °C. The connection requires a temperature above 700 degrees, so soldering is performed using a gas-flame method.

Copper-phosphorus solder is produced in the form of rods and is used for high-temperature soldering

Note! Brazing technology involves annealing the metal, which softens the copper.

The use of copper-phosphorus solder does not require flux. If you properly ensure uniform heating of the ends of the products, it will fill the gap. The readiness of the connection is checked with a solder bar - it should melt.

The soldering steps are as follows:

- The docking unit is assembled and warmed up.

- Solder is introduced into the connection point between the socket and the pipe, which is softened by a burner.

- After the first coupling, the pipe is rotated and the softened solder is wound onto the next section of the joint.

The advantages of brazing copper pipes technology are:

- good seam strength;

- possibility of reducing the connection width;

- applicability in systems operating at high temperatures.

Since proper soldering of copper pipes with hard solder should prevent overheating of the products, which leads to ruptures, it is better to entrust the work to specialists.

Brazed pipes are used in heating systems

How to prepare parts for soldering?

Before you start soldering with your own hands, part of the part must be properly prepared. The surface of the material should be degreased.

To do this, you can use gasoline, acetone, or any other solvent. To remove the oxide film, you need to apply physical force.

To do this, you can use various materials: stainless steel mesh, brush, abrasive wheels.

To remove the oxide film, you can use acids; this method is labor-intensive enough to be used at home.

After treating the metal surface using a stainless steel product, the old film will be removed, but a new one will form in its place.

It will be weaker and thinner. The flux will dissolve it much faster than the one that was previously removed. Surfaces made of brass and copper are much easier to clean.

Video:

Before soldering one part to another, it is worth heating them up. If steel objects are large, you should use a blowtorch or special gas burners for heating.

When heating with a burner, you need to be careful and monitor the operation of the burner at all times. The base material should not overheat, as it will melt and lose its shape.

Constant monitoring of the burner temperature is necessary. To do this, the solder rod must be briefly applied to the surface. When the temperature reaches operating temperature, the solder will melt.

It is worth paying attention to the burner flame that heats the parts.

The gas compositions of the mixture for the burner must be balanced and not have a lack/excess of oxygen.

If there is more oxygen than normal, the metal surface will oxidize. A similar situation will not happen if you work with surfaces made of steel, brass, and copper.

When working with small parts, burners are not used; soldering irons powered by mains power are usually used.

If multiple components need to be connected, wave soldering is used. The video shows how to work with soft and hard solders.

Basic mistakes when soldering yourself

Before soldering copper pipes, you need to make sure that there are no defects on their surface, which often appear when cutting products. The reliability of the seam largely depends on the purity of the materials used in the work. For pipes with a diameter of 6-108 mm, the width of the resulting connection can be 7-50 mm.

Important! If the copper pipe or solder is not heated sufficiently, the tin or copper wire of the latter will not stick to the flux and will not soften. This will cause leakage at the joint.

Sometimes, when applying flux, some sections of the pipe are missed, which results in poor adhesion of the solder to the product. A similar result is caused by overheating the pipe, which causes the flux to burn.

During soldering, it is important to comply with safety requirements, since the work involves the use of open flames and chemically active substances. Before soldering copper pipes, you need to take care of personal protective equipment: gloves, goggles, etc.

Properly organized and performed work on connecting copper pipes will ensure a long service life of the pipeline.

Safety precautions

- First of all, you need to remember that copper conducts heat strongly, and you should not solder a part shorter than 30 cm by simply holding it in your hands, this can lead to burns !

- When soldering, copper becomes very hot and acquires very unpleasant properties, causing very severe burns in a split second when touched! For example, many can pick up a coal from a fire and throw it from hand to hand without harming themselves, but with copper such a trick will not work, a burn is guaranteed!

- During soldering, flux may drip onto exposed parts of the body; rinse off immediately with water, otherwise there may be a chemical burn!

- While working, you should not be wearing synthetic clothing; do not forget that you are working with fire, hot metal, and flux containing acid! Synthetics tend to ignite and melt easily!

- Do not put flux in your eyes, nostrils, mouth, ears or genitals!

- When soldering, open the window, do not breathe in large amounts of smoke from the burnt Flux!

What physical and chemical processes is soldering based on?

Brazed copper pipes

When soldering, the solder, when heated, first softens and then turns into a liquid state. This temperature range is called the solder melting zone. During soldering, the parts to be joined are heated, but not brought to a liquid state. The process of fusion of liquid solder occurs when the temperature of the solder becomes higher than its melting point. This is the so-called operating temperature. The molten solder wets the metal being joined, spreads and eliminates gaps between the copper pipes being connected.

Soldering time, or the period from heating the soldering site until the solder transitions to a solid state and crystallizes, averages 4-5 minutes. It is also necessary that the soldering tool generates enough heat so that within 2 minutes of heating the molten solder reacts with the surfaces being joined. In this case, the flux and parts will not overheat.

During soldering, the solder enters into physical and chemical interactions with the copper pipes being connected. This ability is called solderability.

The very nature of all physical and chemical processes occurring during soldering is very complex and not fully understood. However, the entire soldering procedure can be briefly described as follows. The preparatory stages in forming a joint can be considered heating, melting and wetting, or contact of liquid metal with the heated surface of the part. As a result of wetting a solid metal with a liquid, the surface of the solid metal is replaced by the liquid-solid interface. In it, solution-diffusion, diffusion and chemical processes of interaction take place between liquid solder and the parts being connected (copper pipes). As a result, all gaps are filled and a strong connection is formed between the solder and the parts. The solder then crystallizes during cooling and a seam is formed.