3 popular brands of electrodes that every welder should know about

No matter what skills a welder has, and no matter what category he has, a lot depends on the quality of the electrodes. There are good electrodes, and there are not so good ones.

It is also important to understand that each brand of electrodes is designed for welding specific metals and to obtain certain weld characteristics.

This article will talk about three popular brands of electrodes that are of high quality.

Characteristics

The characteristics of welds produced using LB-52U are shown in the tables. Chemical composition of the deposited weld metal (in percent).

| Ø, mm | C | Si | Mn | P | S | Ni | Cr | Mo | V |

| 2,6 | 0,06 | 0,52 | 1,0 | 0,011 | 0,005 | 0,01 | 0,03 | 0,01 | Track |

| 3,2 | 0,06 | 0,51 | 1,02 | 0,011 | 0,006 | 0,01 | 0,02 | 0,01 | Footprints |

| 4,0 | 0,06 | 0,49 | 1,01 | 0,013 | 0,004 | 0,01 | 0,03 | 0,01 | Footprints |

Diffusion hydrogen content at humidity 60% and air temperature 20 °C, ml/100 g: 1.5…1.9.

Mechanical properties of a weld metal weld

| Diameter, mm | Yield strength, N/sq.mm | Tensile strength, N/sq.mm | Elongation, % | RA, % |

| 2,6 | 441 | 546 | 31 | 75 |

| 3,2 | 446 | 540 | 34 | 77 |

| 4,0 | 455 | 530 | 35 | 75 |

Impact strength, J/sq.cm: 130.

Electrode sizes and welding current

| Diameter, Ø/Length, mm | 2,6/350 | 3,2/350…400 | 4,0/400 |

| Current, A | 60…90 | 90…130 | 130…180 |

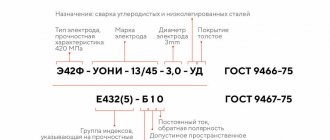

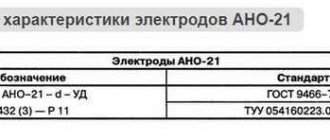

GOST compliance

Electrodes comply with the following standards:

- GOST 9466-75 “Coated metal electrodes for manual arc welding of steels and surfacing. Classification and general technical conditions";

- GOST 9467-75 “Coated metal electrodes for manual arc welding of structural and heat-resistant steels. Types".

Certification

LB-52U are certified by the National Welding Control Association (hereinafter referred to as NAKS) and are certified for use in the construction and repair of main pipelines. They are approved and recommended by VNIIST for welding work.

Certificates have the following validity periods:

- NAKS LB-52U 2.6 mm until 08/20/2017;

- NAKS LB-52U 3.2 mm until 08/20/2017;

- NAKS LB-52U 4.0 mm until 08/20/2017.

LB-52U Safety data sheet:

- NAKS LB-52U 2.6 mm until 08/18/2017 GO, NGDO, OKHNVP, SK;

- NAKS LB-52U 3.2 mm until 08/13/2017 GO, NGDO, OKHNVP, SK;

- NAKS LB-52U 4.0 mm until 08/13/2017 GO, NGDO, OKHNVP, SK.

Extract from the OVP Register of AK Transneft OJSC about LB-52U:

- NAKS LB-52U 2.6 mm until 09/01/2017 NGDO Transneft;

- NAKS LB-52U 3.2 mm until 09/01/2017 NGDO Transneft;

- NAKS LB-52U 4.0 mm until 09/01/2017 NGDO Transneft.

ESAB OK 46.00

Some of the most popular electrodes are coated with rutile-cellulose, which are not so sensitive to metal contamination. These electrodes are convenient for welding even unprepared metal with severe rust.

These electrodes are also not afraid of moisture, since they are completely undemanding to drying and calcination. Easy separation of slag in the weld pool and excellent strength characteristics of the seam have made OK 46.00 electrodes one of the most popular among welders.

Advantages:

- Optimal combination of cost and quality;

- Possibility of welding even poorly prepared metals;

- Ease of welding thin-walled products at minimum current.

Flaws:

- Despite the strength of the weld seam obtained with these electrodes is high, for welding critical structures it is still preferable to use electrodes with a basic coating.

Both beginners and welding professionals can weld with ESAB-SVEL OK 46.00 electrodes.

Electrodes Lincoln Electric Omnia 46

American-made electrodes, also with rutile coating. Affordable price, only 130 Russian rubles per 1 kg, and impeccable quality of the welding seam, have made electrodes of this brand very popular all over the world.

Lincoln Electric Omnia 46 electrodes include the absence of hot metal splashes and excellent quality of the welding seam. The deposited metal has high mechanical strength. Therefore, these electrodes are often used for welding pipelines under pressure.

Beware of fakes!

Counterfeit “LB-52U” brand electrodes made in China have appeared in our country. In order not to fall for the tricks of scammers, we suggest paying attention to the original packaging of “LB-52U” brand electrodes, made in Japan.

This is what the front of the package should look like.

This is what the back of the package looks like.

Please note that the electrode type “LB-52U” must be: AWS: A5.1 E7016.

Pay attention to:

- release date(Date.);

- batch number (No.);

- barcode appearance.

Big photo:

Useful video

See what real electrodes look like in packages:

Welding electrodes LB-52U: reviews from welders

Experts discuss Kobelco welding electrodes of the LB-52U brand (hereinafter referred to as LB-52U) on various forums and pay tribute to their advantages :

- high productivity and the ability to weld in any spatial position;

- maintain a stable arc (in low and high current modes) and produce minimal spatter;

- beautiful appearance of the weld bead;

- excellent mechanical properties:

- high impact strength at low temperatures;

- high resistance to cracking, etc.

But there are also negative reviews:

- the arc does not “light” well on an insufficiently cleaned surface;

- secondary “ignition” cannot be performed, etc.

If the first review is given by inexperienced welders (with the advent of experience among welders, this drawback of the LB-52U “disappears on its own”), then regarding overcoming the second, the welding “guru” says the following:

- firstly, they explain the reason for this phenomenon: after the electrode is torn off from the weld pool, its rod seems to “sink” inside the coating and, when trying to ignite, does not come into contact with the part being welded;

- secondly, they advise what needs to be done. All you have to do is chip off the coating on the tip of the electrode (clean it), and the arc will be ignited without problems.

Unboxing video

And, in all cases, you should strictly adhere to the “Operating Instructions” on the packaging of consumables:

- calcination of welding electrodes is mandatory. Its mode is as follows: T = 300...350 °C for 0.5...1 hour;

- the welding process must be carried out at the required welding current, etc.

Application of Kobelco LB-52U

Electrodes provide the welded products with high impact strength. Therefore, they are often used:

- when welding steel pipelines;

- tanks;

- various marine structures, structures, etc.

When using these welding electrodes, the following recommendations should be followed:

- electrodes with a diameter of 2.6 mm are intended for filling, facing or root layers of the weld;

- electrodes with a diameter of 3.2 and 4.0 mm are intended for the same layers, plus the so-called “underwelding seam”.

Where you should not use LB-52U electrodes

LB-52U is a very good, but also relatively expensive consumable. Therefore, in order to save the budget, it is advisable to use cheaper welding electrodes. It is recommended to use it only when replacement is not possible.

Electrodes OZS-12 (SpetsElektrod, Moscow)

There are a few electrodes of domestic manufacturers that have received the NAKS certificate. OZS-12 electrodes are intended for welding low-carbon steels. Welding work with the help of these electrodes can be carried out even at hazardous sites.

The advantages of electrodes of this brand include easy separation of the slag crust and stable combustion. The deposited metal is very durable and resistant to mechanical stress, it is indestructible and does not have slag inclusions.

Description

These electrodes are produced by one of the world's largest suppliers of high-tech equipment - Japanese. Over the past 35 years, LB-52Us have been used at the largest construction sites in our country:

- MN FRIENDSHIP;

- Yamal Europe;

- in the Arctic:

- New Urengoy;

- KTK, BTS and VS-TO.

The electrodes create an improved, stabilized arc, which ensures deep penetration of the parts being welded. This creates a perfectly deposited weld metal with a neat scaly root bead, which has no defective areas of parts connected only on one side.

Recently, the LB-52U has been replaced by more durable welding consumables:

- LB 62D;

- LB 62U;

- LB 106.

Electrodes OZL-8 (LEZ)

Specific electrodes that are used for welding chrome steels and steels with a high nickel content. These electrodes for welding stainless steel can only be used on welding inverters with direct current.

Their main advantage lies in the surfacing of metal that is not prone to corrosion processes. The welding seam is highly durable and does not crack after cooling.

Share on social networks