To ensure the stability and durability of the operation of an autonomous private well, it is necessary to select equipment for pumping water that is as simple as possible in design, but at the same time reliable and functioning in any conditions. A screw pump is perfect for this. Let's look at its structure, principle of operation and purpose, what types there are and what their specifics are, what pros and cons it has, what are the features of its operation and installation rules.

The screw pump effectively pumps water even with a high sand content Source strategic-zone.ru

Screw pump - device, principle of operation, purpose

Pumping equipment, the main working unit (rotor) of which is in the form of a screw or auger, is intended primarily for pumping liquid media with a high viscosity index. For example, it can easily pump water with sand or oil within the specified operating characteristics.

Therefore, they are often equipped not only with various production cycles, but also with private autonomous wells that are not characterized by stable performance indicators - that is, at the bottom of which deposits of silt, clay or sand often occur. These are primarily Abyssinian wells, low-flow wells, ordinary wells or reservoirs. In addition, the equipment is of the submersible type, which means that it has maximum pressure and is optimally suited for installation in a well, especially in regions where winter occurs.

A household screw pump has the following device:

- A separate compartment for placing a vertical single-phase electric drive with a dry-type rotor. It is separated from the hydraulic part by an oil chamber. The start capacitor is located in the lower area.

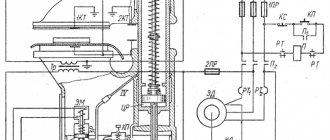

Schematic design of a screw pump Source dfogorod.ru

- Hydraulic compartment of the housing. Inside it there is a working auger with a coupling in a rubber cage and a water filter. In the body itself there are water intake holes, passing through which water is pushed by a screw mechanism to the pipe.

- Perforated stainless steel cylinder for water intake.

- Cover with eyes - it contains loops for attaching a lifting cable and an outlet tube with threads for fixing a check valve and a water-lifting hose.

The pump housing is made of stainless steel, cast iron or plastic.

Mechanism of action

The principle of operation of a screw pump for a well comes down to the following simple algorithm:

- Water from the well channel penetrates into the working chamber through the perforated part of the housing.

- A rotating auger takes in water and directs it to the outlet pipe.

- The helical axis formed between the body and the auger protrusions prevents water from escaping out.

Moreover, the higher the frequency the rotor and screw rotate, the higher the feed speed, and the greater the volume of water pumped per unit time.

The main working element of the pump is a rotor with a screw Source sadovij-pomoshnik.ru

See also: Catalog of companies that specialize in water supply, sewerage and related work

Purpose

Screw pumps are used in everyday life when the following pressing issues need to be resolved:

- Permanent or seasonal water supply for a private house, cottage, bathhouse.

- Filling and emptying artificial reservoirs - swimming pools, ponds, containers for watering the garden or heating the house.

- Irrigation of green areas, garden, vegetable garden.

- Drainage of low terrain areas, as well as inside buildings during seasonal rising water or flooding.

- Initial pumping of the well after drilling.

- Cleaning wells and wells from bottom sediments.

Important! When choosing a screw type pump, you need to pay attention to the dimensions of its main working element - the screw. The longer its length, the more productive the equipment is.

Review of popular models

Judging by the reviews, the most purchased in our country are the Russian screw-type submersible pumps Aquarobot and Unipump ECO VINT, the Ukrainian Aquarius and the Belarusian Belamos.

So:

- The Aquarius submersible screw pump can be used to supply water from open reservoirs, wells and wells with an internal casing diameter of more than 100 mm. And also for cleaning wells and wells, pumping contaminated water from flooded basements and containers, watering and irrigation. It is secured in an underground source using the included synthetic cable. It is easy to install, operate and repair.

Submersible pump Aquarius NVP

- Unipump ECO VINT - these pumps are assembled in Russia and China. They provide decent pressure, but do not have very high productivity, which is unlikely to be enough to provide water to a large farm. However, for a summer cottage or a small country house it is quite enough. Its advantages include compact size and lack of vibration during operation.

Photo of a pump from the ECO VINT series

- Among the many models of pumps from a well-known Belarusian manufacturer, screw units include the Belamos SP series units (see Belamos borehole pump: model review). They belong to high-pressure devices designed for work in wells and mine wells. The instructions also allow you to use them in tanks and open water bodies. Their main advantages are a reliable stainless steel case and the presence of built-in thermal protection that turns off the device when the engine overheats critically.

Screw well pump Belamos SP 70/6

Advantages and disadvantages

A screw pump for a well has the following number of advantages:

- Quite high productivity – up to 70%.

- The minimum base price is much cheaper than centrifugal analogues.

- The simplicity of the device ensures easy operation, reliability, durability and, if necessary, quick and affordable repairs.

The main working elements of a screw pump are easy to buy and replace if necessary. Source burnavody35.ru

- The ability to pump water containing particles of sand, silt and clay without damaging the internal working elements. This allows pumps of this type to be installed in wells on sand, in the water intake of which bottom sediments often occur, and where pumps of other types quickly break down.

- The maximum depth of water intake is 8.5 m.

- Good performance characteristics - absence of noise and pulsation, small dimensions.

The disadvantages are as follows:

- High prices for high-quality models from well-known manufacturers. This is explained primarily by the complexity of production technology.

- Burnout during idle operation, that is, when the working part is out of the water.

- Lack of adjustment of water intake volume.

On a note! Screw models are characterized by a small diameter and elongated shape, which, however, does not limit their performance. Therefore, they are very convenient to use as submersible equipment for small-diameter wells.

The screw pump has a small diameter, but considerable power Source tssp.kz

Types and main technical characteristics

All devices of the type under consideration are divided into two main categories. Screw pumps for wells can be designed to operate at different well depths. There are two main types of device:

- Standard, designed for use under normal conditions.

- Designed for operation at great depths.

Representatives of the standard group are designed to work at well depths of up to 25 meters. Such pumps are installed with low productivity; well drilling can be carried out in country and suburban areas. In addition, equipment with different performance indicators is installed, while the pressure remains unchanged regardless of the composition of the water and many other points.

If necessary, you can purchase and install a deep-type device.

The key feature is the presence of an elongated screw, thereby expanding the scope of the device.

The key points are the following:

- The device has increased performance.

- Can be installed in artesian wells.

- Long service life is ensured through the use of wear-resistant materials.

A significant increase in performance determines an increase in price. That is why their installation is carried out when it is necessary to ensure increased productivity.

Models that belong to the middle price category have become quite widespread. They have the following characteristics:

- When choosing, attention is always paid to performance. In most cases, it varies from 1500 to 2000 l/hour. This is sufficient for most installations.

- Another important parameter is the indicator of the generated pressure. It varies from 40 to 60 meters. This parameter allows you to operate the device in suburban areas.

- The temperature of the transported liquid can vary in the range from 5 to 50 degrees Celsius. At low temperatures, the liquid crystallizes, causing wear and deformation of the structure.

- When choosing, attention is also paid to what the maximum particle size is. In most cases, it varies from 2 to 2.5 mm.

- The power of the installed electric motor, which is responsible for rotating the rod, varies from 1 to 1.5 kW.

In most cases, an electric motor is installed, which is powered by a 220 V network. You can also find more powerful versions powered by a three-phase network.

In specialized stores you can find models that are designed for installation in industry. They are characterized by higher performance properties. An example is the transportation of a medium with a higher temperature.

The classification is also carried out according to the type of material used in the manufacture of the case. In most cases it is made of stainless steel, in some cases it is made of plastic. To increase the degree of sealing, gaskets made of rubber or silicone are installed.

Varieties

Due to the fact that screw pumps can have different purposes and conditions of use, they can differ in design features and operating principles. There are the following main modifications:

- Screw . Designed for pumping water with solid particles, as well as chemically aggressive liquids. Installed in both vertical and horizontal positions. Suitable for both boreholes and wells. They are characterized by a simple design and low cost.

- Rod _ The main purpose is pumping viscous media, for example, in the oil refining industry. The device includes an external drive, a rotation column and a wellhead type gland. It is characterized by great power, but also a high price.

- Vacuum . The design has 2 rotors rotating in opposite directions. The principle of operation is based on the fact that water first enters the space between the cylinder and the chambers, and then exits into the outlet pipe.

Screw-type screw pump Source stroy-podskazka.ru

Note! Household screw-type models are divided according to the permissible depth of application. Standard units allow you to pump water from a depth of up to 25 m at a low flow rate. Their deep counterparts are distinguished by an elongated auger and are designed to lift water up to 100 m from artesian sources.

Mechanical part

The main components of the mechanical part of a screw pump can be considered the rotor (1), stator (2), pump housing (3), bearing housing (4), mechanical seal (5) and universal joint (6). All these parts are connected in series to each other and are located inside special supports (7).

The driveshaft, also called the “thrust”, has hinges at both ends. One hinge, through the adapter shaft, connects the “rod” to the gear motor, the second hinge to the pump rotor. The cardan shaft is the connecting link for transmitting torque from the engine to the rotor. In addition, since the cardan shaft has a hinged connection, torque can be transmitted at an angle relative to the axis of the electric motor shaft. To prevent the hinge mechanism from coming into contact with the pumped liquid during pump operation, they are placed in special sealed casings made of the same material as the “rod”.

The driveshaft is located inside a cylinder, which is the pump housing. The housing is connected by flanges, on the one hand, to the pump stator, and on the other hand to the bearing housing.

On top of the pump body there is a pressure pipe, which can have a threaded or flanged connection. Since screw pumps can pump liquid reversely, this pipe may well not be a supply pipe, but a suction pipe. In addition, the pump nozzle comes in the form of a loading funnel.

Loading funnels (or hopper) are used when the pumped product has a high viscosity, is pasty, and does not have flow properties. In these cases, the cardan shaft is replaced with an auxiliary transport (feed) auger, which also has a swivel joint. In addition to transmitting torque, the auxiliary screw moves the product loaded into the funnel to the gerotor pair.

The gerotor pair is the most important component of a screw pump, which consists of a moving part - the rotor and a stationary part - the stator. The stator is a steel sleeve in the inner part, which has a spiral-shaped uniform elastomer layer obtained as a result of the vulcanization process. The metal of the stator housing and the inner elastomer layer are inseparably connected to each other. Depending on the purpose of the gerotor pair, the stator can be made of various materials. In a screw pump, the stator is sometimes called a cage and sleeve, and the rotor is called a screw, auger, or worm. The rotor is a screw that rotates inside the stator.

The rotor is a single piece, but it can be roughly divided into two parts. The first part is the head for attaching the rotor to the cardan shaft. The second is the rotor body itself, which has the shape of a spiral and is in constant contact with the holder during pump operation. The stator and rotor are a friction pair with internal cycloidal engagement. The gerotor pair of the screw pump is attached with flanges to the pump body. At the end, depending on the direction of rotation of the rotor, it has a suction or supply pipe.

To seal the pump drive, the design provides a mechanical seal. It is located between the “rod” hinge and the bearing housing.

The bearing housing is a unit consisting of two angular contact bearings and an adapter shaft, which, on the one hand, is connected to the gear motor using a key or splines, and on the other hand, it is pivotally connected to the driveshaft.

A horizontal screw pump can be designed with a bypass. This modification of the pump is used when a flow control device (for example, a solenoid valve) is additionally installed in the pressure line. The bypass allows you to avoid switching off the pump motor every time the valve in the supply line closes. When the valve is closed, the pump continues to operate and pumps liquid in a circle from the pressure pipe back to the suction pipe, thereby avoiding excess pressure in the area from the pump to the valve.

Features of operation

A screw pump for a well can operate for decades in trouble-free condition thanks to the following operating features:

- The motor is cooled naturally - by the pumped water itself. Therefore, it is always located below the intake holes.

- The quiet operation of the equipment allows you to make a well as close to the house as possible.

- The absence of vibrations eliminates the impact of the motor on the walls of the borehole channel.

- Detection of breakdowns and malfunctions of equipment is accessible even to a non-professional, due to the simplicity of the device.

Screw-type models work equally effectively in vertical and horizontal orientations. This means that they can be used to pump water not only from a well, but also from a river, stream, well and any other suitable body of water.

Screw and vane pumps - what are the differences?

Most inexperienced buyers often make the mistake of mistaking a vane pump for a screw pump. The differences between these types of units lie in the areas of application and characteristics of the units.

Screw devices are mostly used for industrial purposes, much less often in everyday life. Among their advantages are:

- Uniform supply volume of the pumped liquid;

- Self-priming ability;

- Excellently balanced design;

- The unit operates efficiently even if there are solid impurities in the liquid;

- High strength of parts.

The disadvantages of screw pumps include the high cost of equipment, large dimensions, increased friction of its spare parts, high noise levels and ineffective cooling.

Vane pumps are used in everyday life. The centrifugal vane pump has the following advantages:

- Easy to operate and maintain;

- Possibility of connecting several vane pumps to one pipeline at once;

- Modest dimensions and weight;

- Low noise level during operation;

- Low cost of most models;

- Availability of an effective cooling system.

Among the disadvantages of a roller vane pump, the inability to work with contaminated water should be highlighted. The centrifugal vane pump has low efficiency, and when the flow channels are narrowed, most units overheat, which leads to their breakdown. For the production of most models, heavy steel parts are used, which, when paired with a light plastic body, impair the balance and stability of the devices.

An important characteristic of a vane pump is its performance. It greatly depends on the quality of the water and the power of the unit. If the pump does not have high power, then it will not pump the amount of liquid necessary to service a private home. Therefore, for suburban housing, you should choose more powerful equipment, the purchase of which will cost much more.

Installation Rules

In order for the submersible screw pump to last as long as possible, the following rules must be observed during installation:

- The water riser pipe must withstand the highest pressure in the system and match the dimensions of the outlet pipe.

- The flexible hose must prevent the formation of twists and kinks.

- Lifting and lowering of equipment should be carried out using nylon or steel cable. In any case, the pump must not be suspended by the electrical conductor.

- The diameter of the casing must allow the free passage of equipment, including cables and pipes.

- The pump should not be located less than 0.5 m from the bottom of the well.

- The unit should not pump water with the water shut-off valve closed.

- Pumping equipment must be equipped with a dry-running safety sensor.

- The electric cable should not be in a coil, as this will lead to overheating and melting of the insulation.

Advice! If the model is not equipped with a check valve from the factory, it must be installed during installation - on the outlet pipe in front of the water intake line.

How best to use

When purchasing a screw pump for an equipped source, you will have to take into account certain operating rules. By following simple recommendations, the homeowner will be able to significantly extend the life of the device.

To operate a screw pump in a well, it is advisable to select a pump that can be well mounted on the wall of the shaft. It is advisable to install the device at an optimal depth so that the likelihood of the water level dropping to a critical level is minimal. This will prevent the device from running dry.

It is advisable to maintain a distance of at least 1 meter from the bottom so that liquid mixed with sand is not pumped through the water supply. When purchasing a screw unit, you don’t have to worry about the reliability of the operation of such equipment. The design of the product and the basic principle of operation were specially developed in such a way that the water intake hole was located above the engine itself. The working unit, thanks to this design, can be cooled naturally. The probability of fire in this case is practically zero.

Features of water intake are decisive in the selection of functional characteristics of equipment. Before selecting a suitable pump, be sure to take into account all the required control parameters.

Briefly about the main thing

Screw pumping equipment pumps water due to the movement of a special working element of the screw. This device allows you to pump without damage not only water, but also more viscous media, including those containing sand, silt and clay. The pump consists of electrical equipment with a motor, a hydraulic part, a water intake cylinder, a cover with eyes and a pipe.

Water, entering through the holes, enters the screw, which, during rotation, lifts it and delivers it to the outlet pipe. A screw pump is used in everyday life to supply water to a house or bathhouse, fill or empty a swimming pool and other reservoirs, water plants, drain floods, as well as pump and clean a well. Its main advantages:

- Low base price.

- Great performance.

- Simple design.

- Possibility of pumping water with silt and sand.

- The greatest depth of the fence is 8.5 m.

- Acceptable operating parameters.

The disadvantages are associated with the high cost of high-quality models, rapid burnout when idling and lack of adjustment of the volume of water intake. Pumps are divided into 3 types - screw, rod and vacuum. Each of them has its own pros, cons and specific application. Durability and trouble-free operation are ensured by special operating conditions and compliance with special rules during installation.

Advantages and disadvantages of technology

Advantages of screw type well pumps:

- increased productivity;

- the absence of complex components in the design simplifies routine maintenance;

- there is no increased noise during equipment operation;

- small geometric dimensions;

- Pumping of liquids with different chemical compositions is allowed.

The disadvantages of a submersible pump for a screw-type well include increased cost and the inability to regulate the water supply. When installing the product, it should be taken into account that the device does not allow operation without a liquid supply.

The average price of an imported pump is 8-10 thousand rubles. Domestic equipment will cost slightly less. You can purchase submersible pumps in Moscow in specialized stores that supply components for water supply systems.