Sometimes at home you need to make holes in blanks made of wood, metal, chipboard or other material.

And the presence of a screwdriver does not help and does not allow making holes strictly at an angle of 90, we are not talking about oblique holes at different angles.

To facilitate the processing of materials, a drilling jig is used.

These devices are widely used in the furniture industry.

[contents]

What is a hole jig?

In the article below we will talk about a hole drilling jig - a simple tool that will help you easily and accurately drill the desired hole in parts (or products) of both wood and metal.

What is it? This drilling device looks like an ordinary strip, in which holes of different diameters are made, and at different angles. It's easy to work with. All that is needed is to position the jig at the required angle to the surface to be processed, and it will serve as a kind of “guide” for the drill. As you might guess, such a device for drilling at an angle is simply irreplaceable in any furniture production workshop, but it can also be used at home.

Jig conductor with pneumatic clamp

Installation and securing of the workpiece is the same as in the previous jig. Pneumatic piston drive 1, together with the distribution valve, is moved to the side. Lifting and lowering of the cover 4 is carried out through the gearing of the column 3 with the roller 2 .

The clamping force at air pressure in the network piz=4 kgf/cm2 is 550 kgf.

Up

Design and types

So, we figured out that a jig is a template strip, the main purpose of which is to ensure accuracy when drilling holes in a variety of materials.

There are two types of conductors:

- A jig designed for drilling holes located perpendicular to the surface of the product.

- A jig made for drilling holes at an angle. It allows you to make a hole at the desired angle.

But this is a very rough and generalized classification. In fact, there are more types of conductors, differing in their design and purpose. In particular, the following types of these devices are distinguished.

Invoices

As you can easily guess from their name, such jigs are applied to the surface of the part or workpiece to be processed. They can be secured with special clamps or simply held with your hand while working.

Rotary

These are specially made templates that are intended for processing cylindrical workpieces. With the help of such jigs, it becomes possible to make not only perpendicular holes, but also to drill holes at different angles, since the rotating devices are equipped with special bushings that allow the jig to be installed at different tilt axes.

Universal

Here too the name literally speaks for itself. These drilling jigs are suitable for most types of work (except for specialized ones), so they are loved by workers in small industries, and even by those who do work at home.

Sliding

This type of jigs does not require their attachment to the surface in which the hole needs to be drilled. You just need to hold them with your hand (which can often not be very convenient).

Pinned

Unlike the previous type, such jigs are rigidly attached to the workpiece being processed. Although it is more convenient to work with, this type of device limits freedom of action.

Tiltable

And the last type of conductors is quite similar to the universal type. They are used when it is necessary to drill in different planes or at an angle.

Stands for overhead conductor with hand fastening

The workpiece can be installed directly on stand 1 or on an intermediate spacer. The overhead jig is centered along the mounting diameter dC3 of pin 2 and is held in place by a quick-release washer when fastened. The jig and the workpiece are secured simultaneously by lowering a finger connected through a helical clutch to the roller carrying the handle 3 .

Locking with a cone lock.

Dimensions in mm

| D | H | h | d (additional deactivation according to C) | d1 | b | |

| min | max | |||||

| 125 | 75 | 20 | 75 | 20 | 12 | 21 |

| 200 | 90 | 20 | 85 | 25 | 16 | 21 |

| 300 | 105 | 25 | 120 | 28 | 20 | 25 |

Up

Materials from which conductors are made

There are many conductors that are made from completely different materials. There are even plastic and glass conductors.

However, the generally accepted opinion is that the best devices are made of metal (the best option is stainless steel).

This is not surprising, because a metal drilling jig can provide a number of advantages. Mainly among them, it is worth highlighting the clearest directionality of the drill, virtually no deformation, and also the fact that metal conductors do not heat up during operation.

Stand for overhead conductor with pneumatic mounting

Installation of blanks is similar to the previous one.

Fastening the overhead jig - from a pneumatic drive.

The axial force on the pneumatic actuator rod at an air pressure in the riz network of 4 kgf/cm2 for a stand D = 190 mm is ~260 kgf, for a stand D = 315 mm — ~400 kgf.

Advantages and disadvantages

The main advantage of conductors is that not even highly qualified specialists, but “ordinary” people at home can work with them. And they will produce clear and precise holes (both perpendicular and inclined).

You will not need to perform any calculations and markings, and this reduces how

labor intensity and work time.

The following advantages of using this type of device can be highlighted:

- The drilling jig is capable of providing perfect accuracy for both straight and inclined drilling.

- To use them, markings and preliminary scrupulous calculations are not required.

- Speeding up the assembly of furniture parts and other structures.

- The ability to drill several holes at a time without making preliminary markings.

disadvantages of drilling jigs ; to be more specific, there is only one: the rather high price of this device. That is why some carpenters make their own jigs.

Benefits of using the device

The device in question performs the functions of a template. With its help, you can obtain an unlimited number of holes with equal parameters and characteristics. Using the tool increases productivity by eliminating the need to take measurements after each work pass.

Thanks to the guide sleeves, the accuracy does not depend on the drilling depth.

Steel or plexiglass are usually used as construction materials. Metal devices have better quality and performance characteristics.

The main advantages of using a conductor:

- ease of operation - an excellent alternative to complex equipment;

- high quality holes;

- productivity increase;

- simplification of the operation.

To be fair, we note that this device will help a beginner more. With its help, even an untrained person can make a hole of acceptable quality. A professional can do without it in most cases.

Scope of application

Jigs designed for drilling holes are widely used in furniture manufacturing, but their use is by no means limited to this industry.

Let's take a closer look at where this useful device is used.

Furniture manufacture

When making furniture, it is constantly necessary to drill holes for accessories, fasteners, and fittings. After all, it’s enough to make a mistake with the hole by literally a couple of millimeters, and the cabinet or bedside table will turn out skewed during assembly. The finished product will have to be thrown away or it is unlikely to be sold.

Therefore, jigs are simply necessary in the production of furniture, because they “correct” the incorrect angle of the drill entering the part. Also, when assembling furniture, a jig for drilling holes for dowels or a template for drilling holes for confirmation has proven itself to be excellent.

Mechanical engineering

Here, jigs are used for drilling holes in a variety of workpieces made of various materials. Since everything is standardized in this industry, the slightest discrepancy in dimensions leads to rejection of the part. Therefore, there is simply no way to do without conductors in this area.

Construction

During any construction work, you always have to make holes in walls, ceilings, and fasten various parts. If you do not use templates, the drilling process will be delayed, since it is much more difficult to make holes in the walls or ceiling at exactly the right angle. Therefore, builders often use a jig to drill holes at an angle.

Serial or mass production

Mass production requires unification of components. Accordingly, conductors will come in handy here too. When using these tools, you are confident that all holes will be the same.

Household use

Every home needs repairs from time to time. In this case, you often have to pick up a drill and make holes in walls or furniture, and here, just like air, conductors will be needed.

Rock jig with mechanical clamp for drilling holes in cylindrical workpieces

The workpiece is mounted on prisms 1 and 2 . Supporting prism 1 is movable. To adjust to a given distance from the mounting end to the drilling center, use stop 3 .

- The workpiece is clamped by lowering the conductor plate.

- Locking with a cone.

- Dimensions of blanks: diameter 12-30 mm.

- The shortest length is 15 mm.

Up

Homemade conductors

Since drilling templates aren't exactly cheap, many people make their own. Yes, a jig for drilling holes with your own hands is not a fantasy, but a reality.

In order to make a conductor, you will need:

- drawing or diagram of the device;

- drill;

- welding machine;

- Bulgarian;

- locksmith tools;

- “blank” for the future conductor (reinforcement with a square section of 10x10 millimeters is good).

First, we cut the reinforcement with a grinder (a hacksaw is also suitable) into pieces of the required length, which are cleaned with sandpaper. Then marking of future template holes is done and their subsequent drilling. There are some nuances here. The centers of the holes should be marked 8 millimeters from the edge, the distance between the holes should be (according to generally accepted standards) 32 millimeters, and the diameter of the holes should be 5 millimeters.

At the end, we add a stop made of a metal plate (25 millimeters wide and 1 millimeter thick), bent at a right angle. We fasten all parts of the contraction together - and the jig for drilling with your own hands is ready.

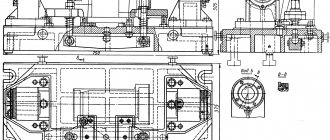

Double-column conductors with mechanical clamp

Installation and securing of workpieces are similar to the previous one. The workpiece is clamped by lowering the top cover 1 using handle 2, locking in the lowered position with a cone lock.

| A | A1 | B | IN 1 | N | H1 | H2 min | WITH | C1 | C2 | d (additional deflection according to C) | |

| min | max | ||||||||||

| 75 | 170 | 120 | 155 | 60 | 90 | 40 | 145 | 75 | 125 | 38 | 13 |

| 105 | 215 | 170 | 215 | 90 | 130 | 55 | 200 | 110 | 180 | 58 | 16 |

| 140 | 120 | 240 | 290 | 125 | 175 | 70 | 265 | 150 | 250 | 70 | 20 |

| 185 | 350 | 320 | 380 | 170 | 230 | 80 | 330 | 200 | 335 | 85 | 24 |

Up