The need for surface hardening and tempering

Surface hardening of parts is done to achieve better characteristics of the outer layer, while in the core the metal remains tough and ductile. In this way, it is possible to change the physical and mechanical properties of the metal.

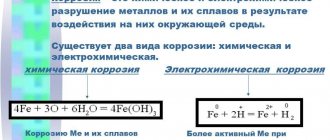

To reduce brittleness and residual stresses, the metal is then tempered, after which its hardness decreases slightly and its properties become more stable.

The steel surface hardening temperature is 820-900 0C. It can be distinguished by color.

To obtain the required depth of heat treatment, after rapid heating, the surface of the part is cooled with air or water.

Gas flame hardening

The temperature regimes associated with heating and cooling can be continuous or cyclical. Surface hardening is performed in four ways.

- Heating and cooling of a part area: hardening of wheel teeth, rail ends, valves, etc.

- Hardening of small rotating bodies with a small width of the treated area: axle and shaft journals.

- Continuous-sequential method: moving a flame along the surface, followed by a coolant. Sequential heating and cooling of narrow areas with water jets is carried out. The surfaces of large-diameter parts are similarly hardened with their slow rotation relative to stationary burners and nozzles. Temper zones remain at the edges of the strips during secondary heating from neighboring areas.

- Combined method: moving along the generatrix of the flame jets, and behind them - the cooling medium while rotating the cylindrical part. The technology is used for hardening long products. The method provides a uniform solid layer on the surface of the part.

Hardening a knife at home: video, instructions, tips

It is no coincidence that the question of how to harden a knife yourself at home is so relevant, because it is this technological operation that allows you to give the blade of a cutting tool the required strength and hardness.

If you neglect this procedure or perform it incorrectly, the cutting part of your knife will quickly become dull, which will make its use ineffective. The durability and cutting ability of a knife are determined by the hardness of the blade.

Even if a homemade knife is made of a solid metal product (file, spring, valve, etc.), it still requires hardening, since during the manufacturing process the blade was subjected to intense mechanical processing and, accordingly, heating.

It is quite simple to check how correctly the hardening of a homemade knife has been carried out at home. To do this, you need to hold its blade in a vice and begin to bend it vertically. If the knife breaks at a bend angle greater than 45°, it means the hardening was done correctly.

For those who do not like to go into the subtleties and details of the process, you can immediately watch a video with a detailed description and demonstration of one of the methods of hardening a knife at home. If you want to get acquainted with the technology in more detail, we recommend reading the entire article.

Temperature

It may seem that there is nothing complicated in hardening a knife, but, as in any other technological operation, a number of nuances must be taken into account when performing it. The first thing that should be controlled in order to properly harden the blade is the uniformity and gradualness of heating.

If you neglect this requirement and heat the knife too quickly, this will lead to the formation of too large grains in the metal structure, which will make the product brittle.

For steel alloys belonging to different categories, different temperature conditions are used to perform quenching operations:

- steels belonging to the group of low-carbon alloys – 727–950°;

- high-carbon steel alloys – 680–850°;

- steels containing alloying elements – 850–1150°.

Processing modes for corrosion-resistant heat-resistant steels

At home, it is not always possible to use a device such as a pyrometer, which is used to determine the heating temperature of the metal.

Meanwhile, you can determine the degree of heating of a steel product if you use an ordinary magnet.

The essence of this simple technique is that every metal has a so-called Curie point, at which it turns from ferromagnetic into paramagnetic material, that is, it ceases to be attracted to the magnet.

Consequently, if the blade of a heated knife has ceased to be attracted to the magnet, its heating temperature has reached the Curie point (you can see its value for various metals in special tables).

Features of the technology

At home, if you approach the matter correctly, you can qualitatively harden any knife.

It can be a hunting or folding knife, a bayonet or a hook-shaped product, a blade made of a file or a bearing, a butterfly knife, etc.

It is somewhat more difficult to harden products made from stainless steel at home, but this problem can be solved if you carefully study the process technology and select the appropriate heating equipment.

Various materials are used as a cooling medium when performing hardening, both in production and at home. Thus, the most common cooling media - water and oil - provide the following cooling rates of a heated steel product:

- oil at room temperature – 150°/s;

- oil heated to a temperature of 200° – 300°/s;

- water, the temperature of which is slightly above 20°, – 450°/s;

- ice water – 600°/s.

In some cases, hardening is performed by cooling the product in an intermediate medium, which can be molten lead. This technique, in particular, is used when hardening knives that are made from files.

Annealing a knife over an open fire requires close attention.

The most important problem that you may encounter when trying to harden a knife at home is overheating the metal, which leads to a significant increase in its fragility. It is also necessary to very carefully monitor the uniform heating of the knife being hardened, so as not to encounter the formation of transverse cracks on its blade.

There is a simple rule that should be followed in order not to encounter such a problem: the part of the blade that will not be sharpened is heated three times to a purple color, which corresponds to a temperature of 285 °, and the cutting part is heated only once to a yellow color, after which the degree Its heating is checked using a magnet. You can learn more about this technique by watching the corresponding video.

Colors of heat and tarnish of carbon and low-alloy steels

On stainless steels, tarnish colors appear in the same sequence, but at higher temperatures

Different cooling media also provide different depths of the hardened layer (hardenability).

Thus, when cooled with water, steel is calcined at a rate of 1 mm per second, and when oil is used as a cooling medium, this rate is almost halved.

To harden a double-edged knife, obtaining hard cutting edges and an elastic core, you need to do the following: the blade, heated to the required temperature, is first dipped in water for two seconds and then placed in oil.

Another technology that allows you to qualitatively harden the cutting edge of a blade with significant thickness is hardening the knife in graphite.

Using this technology, the details of which can also be easily studied in the video, you can qualitatively harden knives of various models and configurations (hunting knife, bayonet knife, butterfly knife, etc.).

At the same time, such hardening can be performed efficiently at home.

Homemade knife after hardening in graphite

It is often necessary to carry out zone tempering of an already hardened knife in order to make its middle part more elastic, while maintaining the hardness of the cutting blades. At home, such a technological operation is performed according to the algorithm below.

- The middle part of the blade is heated using a metal rod with a diameter of 10 mm, heated to maximum.

- After heating the middle part of the blade, it is dipped in boiling water and kept in it for 2 hours.

- After soaking in boiling water, the blade is dipped into ice water.

After completing all the manipulations described above, you will receive a knife whose middle part of the blade has been subjected to low tempering.

You can determine the tempering temperature by the colors of tarnish - a rainbow film that appears when the cleaned surface of the knife is heated: from light yellow (item 1) to bluish (item 6)

If you are trying to harden your knife at home, you should follow two rules that will allow you to get high-quality results.

- The volume of coolant used must be large enough (minimum 20 liters). Otherwise, the liquid will become very hot, which will change the temperature regime and cooling rate, and this in turn will negatively affect the result of the entire technological operation.

- In order for the heat transfer from the heated knife to be uniform and not to lead during the hardening process, it cannot be moved in the cooling environment - it must be kept motionless.

Rules for quality hardening

There are a few more simple rules that allow you to harden a knife at home to the highest possible quality.

- Before you begin surface or deep hardening of a knife made of a certain grade of steel, you can select the modes for performing such a technological operation using plates made of the same material. The first plate is used to more accurately select the required heating temperature. To do this, the metal plate must be heated unevenly: one part to the maximum temperature, the second to the minimum. Then the heated plate is dipped in water or oil and, after complete cooling, it is clamped in a vice, broken and the metal is examined for fracture. High-quality hardened metal, if the temperature conditions were selected correctly, should have a coarse-grained structure.

- The next stage of experiments with metal plates is the selection of the optimal cooling medium. Using various cooling media (water, oil, liquid lead, etc.), harden the plate to such a state that, when clamped in a vice, it breaks at a deflection of 30°. After this, it is necessary to temper the plate, also selecting various cooling media and temperature conditions. As a result of this operation, you should ensure that the plate, clamped in a vice, breaks at an angle of deflection of 45°.

- To avoid the appearance of surface cracks on the blade of a hardened knife, the product must first be annealed. When performing such a technological operation, for which it is desirable to use a muffle furnace with a temperature controller, the following rules must be adhered to: the knife is heated as long as possible, slowly and evenly.

By following these simple recommendations, you can even harden a knife correctly at home, resulting in a strong and durable tool with excellent cutting properties.

Flame hardening technology

Surface hardening is carried out on machines where the processes of moving heating and cooling devices and parts are mechanized. The process is widely used in industry. It requires simple devices. A mixture of acetylene and oxygen, natural gas or kerosene is used as an energy source. Sometimes gas-flame heating is more profitable to use than high-frequency heating. This especially applies to large-sized products for which it is difficult to manufacture inductors. The method is often used in small-scale production, when high demands are not placed on the quality of parts. Injection-type quenching burners contain replaceable tips for adjusting the flame power. Mouthpieces are made in accordance with the profile of the parts being processed. They are made with a large number of nozzles or slotted ones. Jet sprinklers supply water for cooling.

Mechanisms for moving tools and parts are used specialized or universal. Enterprises often manufacture them on their own using metalworking machines.

Hardening of metals depends on the composition, as well as on the size and shape of the products.

Hardening a knife - step-by-step instructions for hardening various types of metals (75 photos and videos)

Surface hardening of the knife provides additional strength to the cutting base. Heat treating a steel billet significantly improves the mechanical and physical properties of that item.

If you neglect this requirement, then the risk of quickly erasing the metal plate increases. In simple terms, the knife will constantly become dull, which will affect its performance.

In our material we will talk about how to harden a knife at home. Here are recommendations from professionals who know all the intricacies of working with metal.

What material are knives made of?

An alloy of carbon and iron is used to produce knives. When these components are heated, high carbon steel is formed.

This material is able to cope with sudden changes in temperature. In addition, it is characterized by high density and resistance to various mechanical influences.

Products made from pure carbon steel are quite expensive. To reduce the cost of materials and components, many craftsmen prefer to add special additives.

To do this they use the following substances:

- Molybdenum;

- Vanadium;

- Zinc;

- Tungsten;

- Calcium.

If the workpiece contains a minimum amount of carbon steel, then which products are elastic? They require proper hardening, which will provide them with additional strength.

We make a chamber for hardening metal

Before you begin processing the metal base, you need to prepare the appropriate equipment. It is recommended to pay special attention to the oven in which high-temperature processing will be carried out.

The oven chamber should have dimensions of 30 cm x 20 cm x 10 cm. It is made of refractory clay and brick. The clay composition should not contain any impurities.

The design of the furnace is a rectangle. The walls and back panel are on the same level. A metal door on hinges is installed in front. This will maintain the temperature inside the furnace structure.

To harden steel you will need from 300 to 900 degrees. This parameter directly depends on the material from which the metal product is made. For example, to harden a knife from a file, you will need a temperature of 500 degrees.

The composition of this material contains a high steel content and a minimal amount of tungsten. The finished item is quite strong and durable.

The process of hardening steel at home

The easiest way to harden a workpiece is an open fire. Our ancestors used a similar method more than 100 years ago. The processing process is carried out “by eye”.

For the work process you will need the following materials and tools. These include:

- Fire;

- Large container with oil;

- Bucket of cold water;

- Metal pliers with long handles. They will help you carefully remove and lower the iron for further heating.

The first step is to achieve the desired temperature. We send combustible material in the form of firewood and coal to the oven. The flame begins to change its hue from bright orange to crimson.

At this time, wood and combustible material are added to the fire. When the flames change their color to white, you can proceed to hardening the metal product.

Place the base of the knife on burning coals and leave until the metal turns red. On average, this will take from 5 to 15 minutes. When the product acquires a bright red hue, it is immersed in oil.

Tempering a knife with oil helps add ductility and strength. After the first dive, similar manipulations are carried out 5 more times. Next, he sends the metal blade back to the heating furnace

.

The next step is cold water quenching. This procedure is final. It adds strength to the metal product. The hot workpiece is placed in ice water for 20 minutes. A photo of knife hardening shows this manipulation.

We present to your attention a detailed video of knife hardening. Here is presented all the regular actions and manipulations with carbon steel.

Photo of knife hardening

Process parameters

The adjustable parameters are as follows.

- Heating power. It depends on the acetylene consumption and the speed of the flame relative to the product.

- The distance from the center of the torch to the heated surface is maintained at a level of 2 to 3 mm.

- Duration of heating or speed of movement of the heater. The depth of hardening and surface hardness depend on these characteristics, which are selected experimentally.

- Water with a temperature of 18-350C is mostly used as a coolant, and the flow rate is about 1 l/cm2.

- Time between heating and cooling (5-10 sec) or distance between heating and cooling zones (12-25 mm).

Steel hardening technology includes the processes of heating the metal, holding it to equalize the temperature while undergoing the necessary structural transformations, and cooling at a given speed. A distinctive feature of surface hardening is rapid heating.

Preparation of parts before hardening involves smoothing out sharp corners and cleaning in various ways: sandblasting, chemical, or manual brushes.

Surface hardening under the correct conditions ensures an increase in the durability of parts by 2-5 times. The choice of cooling modes allows you to smoothly increase the hardness of the hardened layer up to 700 HB. The process should go quickly. At the final stage, when the temperature is 200-3000C, the cooling rate slows down. As a result, the formation of cracks is reduced and the products do not warp.

When alloy steels are overheated, the hardness may decrease, which is considered as a defect. There is also no possibility of precise adjustment of the thickness of the hardened layer. In addition, when working with gas, additional measures are required to ensure safe working conditions.

How to harden a knife?

The technology for obtaining a durable, strong, reliable knife is impossible without hardening. In essence, this is the same technological process of metal processing as sharpening, milling and grinding.

Only instead of an emery wheel, a graver and a cutter, high temperature is used.

And if polishing gives the blade a mirror shine, emery gives the sharpness of the blade, and engraving gives an irresistible design, then hardening makes it durable, which is very important even for a home kitchen knife.

What steel to choose for making a knife?

Today, a brand of steel and alloys can offer metal in several thousand names and grades. In addition to iron, the steel alloy may contain tungsten, nickel, vanadium, and zinc.

The physical and chemical properties of the metal depend on this; with tungsten it becomes hard and durable, zinc makes it soft, and the aluminum component allows it to be drawn. But this is not important for a knife; the determining factor here is how much carbon the metal contains.

The higher the carbon component, the stronger it is, but it is also more fragile. But the less carbon, the more ductile the metal, no, not softer, but more ductile.

Therefore, when choosing a metal for a knife, it is recommended to pay attention to high-grade steels and high-alloy grades; a blade made of such metal will be both durable and flexible, remaining sharp for a long time.

What is the purpose of the hardening process?

High-temperature processing of a metal allows you to change its internal structure - when heated to a certain temperature, the carbon content in it changes, and when it cools sharply, the metal retains the acquired structure. When alternating the heating and cooling process, the metal acquires strength. But heating at a certain temperature allows you to maintain the elasticity of the metal.

However, hardening is only the first part of the metal heat treatment process. The second part is the gradual cooling of the metal after heating.

Tempering is necessary to relieve internal stress that arises in the crystal lattice of the metal and makes it brittle.

Thus, in order to harden a knife, it is necessary to perform a complete hardening technology and complete it with a metal tempering process.

What is needed for hardening?

The key point in the blade processing process is the process of heating and maintaining the metal at a high temperature for a certain time. For this we use:

- Muffle furnace;

- Gas-burner;

- Forge;

- Blowtorch.

Each method has its pros and cons. The advantages of the burner and lamp include their mobility, which cannot be said about the forge and furnace, but the burner and lamp do not make it possible to maintain the temperature for the required time. On the other hand, it is possible to adjust the heating temperature with an accuracy of up to 50 degrees only in an oven, and the process of working with it is more convenient.

Hardening in the classic form is carried out by heating to 700-1000 degrees, after which cooling is done in a container with mineral oil. Therefore, it is recommended to work in a specially prepared room where it is possible to install both a stove and an oil container.

Heating a workpiece in a forge is quite simple - when air is supplied, the coals become hot and the workpiece can reach the desired temperature. The main thing here is not to overheat the blade.

It is better to navigate using a special temperature scale, in which the temperature corresponds to a certain color of the metal.

True, in order not to make a mistake, the scale must be studied thoroughly, since when overheated, the steel loses its properties and becomes soft.

The cooling process of the workpiece is carried out in a container with mineral oil, without access to oxygen. The container needed is quite large - the blade should be completely immersed in the oil, but the oil should not boil.

To work with a red-hot workpiece, you will need blacksmith pliers with long handles and canvas or leather gloves. At home, for work, you need to provide clothing made of non-flammable material and a mask to protect your face.

The process of hardening a blade at home

When working with a forge or burner, the workpiece should lie on the coals when the flame acquires a crimson hue. A white or blue flame is not suitable for hardening - with a white color the temperature reaches 1000-1100 degrees, and the metal quickly overheats, and with a blue color of 500-600 it simply does not have time to warm up to the required temperature.

When the blade is uniformly painted purple-red and then yellow, and visible dark spots on the surface disappear, the workpiece can be removed and dipped in oil.

The workpiece is first dipped in a container with oil for 3-4 seconds, after which it is again sent for firing in a furnace or forge. When the metal reaches a dark red color, it is removed again and lowered for 4-5 seconds. The process is repeated 4-6 times, with the time increasing by 1-2 seconds.

The last time the workpiece is lowered into a container of water for cooling - you need to be especially careful here, since water can cause the droplets of oil remaining on the blade to splash.

To what temperature should the workpiece be heated?

Depending on the steel grade, heating is carried out in the following temperature ranges:

- Low carbon alloys and steels – 730-945 degrees;

- High carbon steels 678-851 degrees;

- Alloy steels – 850-1150 degrees;

Release of blanks

High temperature treatment creates internal stress in the metal. This negatively affects the flexibility and strength of the metal. The workpiece becomes fragile - if the pressure is incorrect or skewed, it begins to crumble or burst.

In order for the metal to become more ductile, a tempering procedure is carried out - bringing the temperature of the workpiece to the point of maximum ductility of the metal and its gradual, natural cooling. To do this, the metal is heated in a muffle furnace to the required temperature, and then, with the door closed, it is gradually cooled for 2-3 days.

It is quite simple to check whether the blade has been properly hardened - just run a file over the blade - if the blade slides, the hardening was successful, but if it touches the metal, then the procedure will have to be repeated.

Hardening with high frequency currents (HFC)

High-frequency heating is one of the most effective ways to harden a surface. The use of high frequency frequencies up to 10 thousand kHz significantly reduces the heat treatment time. A high-frequency current is passed through a water-cooled copper inductor. The resulting electromagnetic field penetrates the steel part, forming eddy currents in it, thereby causing heating. The main energy is concentrated in the surface layers. The depth of heating depends on the magnetic permeability of the steel, electrical resistance and current frequency. By adjusting these parameters, you can change the size of the hardened layer.

Advantages of the induction method

- high productivity and economical heating when it is necessary to heat only certain areas of parts;

- the surface of the part is slightly oxidized, there is no decarburization;

- products warp less, fewer cracks form;

- The depth of hardening is precisely adjusted;

- possibility of process automation.

The disadvantages of the HDTV hardening method include the high cost and complexity of manufacturing induction devices.

Copper inductors are manufactured with or without damping devices.

There are the following types of surface hardening.

- Simultaneous. After heating, the part is cooled with water. The part being hardened is heated inside the inductor. After a predetermined time, the electric current is turned off and water is supplied in strong jets through the heater holes to cool the product. Ring inductors are used for hardening gears, and loop or zigzag inductors are used for flat parts.

- Continuous-sequential. A heating inductor moves along the stationary part, followed by a showering device.

HDTV heating makes it possible to create automated units in the flow of machining shops. Due to this, there is no need to transport parts to heat treatment shops.

Induction installation

The HDTV induction heat treatment unit is a high-frequency generator and inductor for HDTV hardening. The part to be hardened can be located in or near the inductor. The inductor is made in the form of a coil, with a copper tube wound on it. It can have any shape depending on the shape and size of the part. When alternating current passes through the inductor, an alternating electromagnetic field appears in it, passing through the part. This electromagnetic field causes eddy currents known as Foucault currents to occur in the workpiece. Such eddy currents, passing through layers of metal, heat it to a high temperature.

HDTV induction heater

A distinctive feature of induction heating using HDTV is the passage of eddy currents on the surface of the heated part. This way, only the outer layer of the metal is heated, and the higher the frequency of the current, the smaller the depth of heating, and, accordingly, the depth of hardening of the high-frequency frequency. This makes it possible to harden only the surface of the workpiece, leaving the inner layer soft and tough to avoid excessive brittleness. Moreover, you can adjust the depth of the hardened layer by changing the current parameters.

The increased frequency of the current allows you to concentrate a large amount of heat in a small area, which increases the heating rate to several hundred degrees per second. Such a high heating rate moves the phase transition to a higher temperature zone. In this case, the hardness increases by 2-4 units, to 58-62 HRC, which cannot be achieved with volumetric hardening.

For the correct implementation of the HDTV hardening process, it is necessary to ensure that the same clearance is maintained between the inductor and the workpiece over the entire hardening surface, and mutual touching must be avoided. This is ensured, if possible, by rotating the workpiece in the centers, which allows for uniform heating, and, as a consequence, the same structure and hardness of the surface of the hardened workpiece.

The inductor for hardening HDTV has several versions:

- single- or multi-turn annular - for heating the outer or inner surface of parts in the form of bodies of rotation - shafts, wheels or holes in them;

- loop - for heating the working plane of the product, for example, the surface of the bed or the working edge of the tool;

- shaped - for heating parts of complex or irregular shape, for example, the teeth of gear wheels.

Depending on the shape, size and depth of the hardening layer, the following HDTV hardening modes are used:

- simultaneous - the entire surface of the workpiece or a certain zone is heated at once, then also cooled simultaneously;

- continuous-sequential - one zone of a part is heated, then when the inductor or part is displaced, another zone is heated, while the previous one is cooled.

Simultaneous high-frequency heating of the entire surface requires large amounts of power, so it is more profitable to use it for hardening small parts - rolls, bushings, pins, as well as part elements - holes, necks, etc. After heating, the part is completely lowered into a tank with coolant or sprayed with a stream of water.

Continuous-sequential hardening of high-frequency particles allows you to harden large-sized parts, for example, the crowns of gear wheels, since during this process a small zone of the part is heated, which requires less power of the high-frequency generator.

Other methods of surface hardening of steel

- Quenching in electrolyte. If an electric current is passed through an aqueous electrolyte solution, the cathode is a part that heats up quickly. The method is convenient because after a power outage the part is immediately hardened. The electrolyte bath simultaneously functions as a heating furnace and a quenching tank.

- Laser hardening. Laser radiation heats the metal surface to a high temperature. The reinforcement thickness is less than 1 mm. The wear resistance of cast iron parts increases several times, and the endurance limit of steel increases to 80%. The method is often used to harden the cutting edges of a tool.

Hardening a knife at home

Many centuries ago, master blacksmiths wondered about the hardness of the blade. And many of them understood that steel must be cooled quickly after heating. Damascus craftsmen hardened steel in gorges where strong winds blew. They believed that the force of the wind was transferred to the blade, and it became elastic, hard and did not break.

Hardening the cutting edge of a knife.

A little more history

Some blacksmiths used sheep urine collected for three days for this purpose. And others used the boy’s urine for such a process, and he had to be red-haired. These are the tricks the masters of the past used. By the way, the use of urine can be partially justified, since the presence of salts in it accompanied the rapid absorption of heat from the hot metal.

There were even quite barbaric methods of hardening, a red-hot blade was stuck between the ribs of a slave, and it was believed that his strength was transferred into a metal blank. It's good that those days are over. But people gradually noticed that if, after heating the metal, it was placed in a salty environment, its quality and characteristics improved.

Time passed, and thousands of methods were tried before achieving a positive result. The young scientist metallurgist D.K. Chernov, who worked on this problem in 1866, achieved considerable success in determining certain values for each metal.

The plant where Mr. Dmitry Konstantinovich Chernov conducted the tests completely got rid of defects and this man can be called the progenitor of modern metallurgy. Today, any student, having a wealth of knowledge accumulated over centuries, can cope with the hardening of steel.

Choosing steel for knife hardening

As you know, steel is nothing more than an alloy of carbon and iron. Additives are added to them in small doses. They do not play a big role on the quality of the future blade. The most important element is carbon.

Additives can be such as zinc, chromium, molybdenum, calcium, etc. But the less carbon in steel, it acquires high strength, but wears out faster and corrosion develops faster. For proper hardening, you must know the composition of the future blade.

It is best to carbon analyze the steel.

Ideal hardening of a knife blade.

If the future product is, for example, made from a file or a car spring. Hardening in this case is simply necessary, especially since forging such a metal implies its mandatory heating. You can check the quality of hardening at home, but it is quite “cruel”.

You need to tighten the finished blade in a vice and begin to gradually bend it, and if the blade breaks at around 45 degrees. We can safely say that the hardening was carried out correctly.

But this should be done after your first independent hardening of the blade, you need to remember the whole process well and repeat it again.

Hardening methods

There are essentially 2 types of hardening methods. On an open fire and in the oven. But, unfortunately, in an ordinary fire it will not be possible to raise the temperature above 900 degrees. Then the oven comes to the rescue. You can make it yourself. This is a rather difficult process, but once you make it once, it will serve you for a long time. Moreover, if you are a beginner master, you simply need it.

In the cell

Next we will talk about how to make your own muffle furnace for proper heat treatment of workpieces, and now we will simply and briefly describe the hardening process in it; the blade steel will be used 50Х14МФ:

- We heat the oven to the desired temperature, in this case 1070 degrees, and immerse the blades in the oven.

- Having loaded the blade into the oven, we heat the oven again to 1070 degrees, and at this temperature the countdown begins. The principle is simple: 1 minute 40 seconds for every millimeter of blade thickness.

- After the required time has passed, the blade is pulled out and cooled in air for 15 minutes under light pressure.

- Then the metal is tempered in the oven at 200 degrees.

Hardening a knife in a chamber made at home.

With this process, the steel gains a hardness of 56 HRC.

But keep in mind that in this case, hardening took place without immersion in liquid. Each steel has its own hardening conditions. And the result you want to achieve will depend entirely on the process itself.

On an open fire

The method, one might say, was tested by our ancestors and has been around for many years.

To properly harden steel, without any precise measuring instruments, so to speak “by eye”, you need to be attentive and patient. The only way to check is with a magnet.

When a metal reaches a certain incandescent point, the so-called Curie point, it stops interacting with the magnet.

And one more sign is the color of the workpiece itself, it should turn dark red. But you also need to make sure that no blue or black spots appear during the process, this indicates overheating. The workpiece should be placed in the coals when the color of the flame from them is crimson.

What you will need:

- mineral oil in a container (can be worked off);

- bucket with water;

- well prepared coals;

- long metallurgical pliers.

Hardening a knife over an open fire.

After the part has acquired the desired shade and is not magnetic, you need to carefully take it with pliers and lower it into the oil for 3 seconds, and this must be done several times. Keep the workpiece in the oil a little longer each time. And at the final stage we immerse it in water.

How to make a chamber for hardening metal

It is clear that when making such a camera, it is better to take the process seriously, since you will not be making it for one day or once. Let's try to briefly describe the manufacturing process of such a chamber; it is also called a muffle furnace.

- The main thing is to correctly manufacture the “body” of such a camera; here they resort to a simple process. The future neck is made from any hard paper material (such as cardboard) and coated with a thick layer of fireproof clay. Don't forget to make a thin layer of paraffin between the form-building paper material and the clay.

- In the second stage, the future chamber is dried for at least a day, and then placed in the oven and calcined at a low temperature of about 90-110 degrees Celsius. After this stage, the paper component can already be removed.

- The final firing of the structure occurs over an open fire at a temperature of about 900 degrees, then it is cooled under natural conditions. You need to wait until the camera cools down completely.

- After the workpiece has cooled, it acquires the properties of stone and becomes very hard, like a brick. Doors that open horizontally are attached to it.

- The final stage can be called wrapping the future furnace with nichrome wire, with a cross-sectional diameter of about 0.75 mm. The entire structure will require about 18 meters. To prevent short circuits during winding, it is better to immediately coat it with raw clay. We make two holes in the housing, one for a thermocouple (to measure temperature), and the second for visual control.

A self-made chamber for hardening a knife.

At this point, we can say that the furnace for heating metal is ready. As you can see, there is nothing difficult in making a muffle furnace for your home.

It is very good if there is a furnace for hardening steel. You can even purchase it in a specialized store, but the pleasure is not cheap. So how to harden a knife at home without a special muffle furnace? There is a way out, and to be honest, there is more than one.

But first, you need to conduct small experiments and remember in detail all your actions. If the result is positive, then the same manipulations can be performed with a real part.

This tricky technique will help you get better at working on small workpieces and acquiring the skills to heat and cool a blade. We must not forget that different alloys require different temperatures and cooling methods, otherwise cracks and brittleness of the workpiece cannot be avoided.

Heating source

Basically, several sources of heating the workpiece can be distinguished. It is better to exclude the muffle furnace, since according to all expert estimates, it is the best in this matter. But we will try to evaluate other fairly common heating devices.

The forge copes quite well with heating workpieces. A blowtorch or propane torch may be suitable for this purpose; by trial and error, you can achieve the desired result. By the way, for these two options, you can build a small oven from refractory bricks, and the process will be simpler and the result will be positive.

Fireproof brick furnace for hardening a knife.

Well, the last, one might say, completely unacceptable source of heating is a gas stove. If you want to spoil something, use this option.

Cooling and holiday

For proper hardening, you need to maintain the correct temperature during cooling. It is preferable to cool stainless alloys in mineral oil with additives. And low-alloy steels, in aqueous solutions with salt and other additions.

Cooling the knife with mineral oil with additives.

There are many cooling options:

- blades with double-sided blades are dipped first into oil and then into an aqueous solution;

- Red-hot workpieces are dipped into the oil three times, each immersion taking a little longer than the previous one. And only then they lower it into the water;

- To give elasticity to the middle of the blade, this part is heated, then dipped in boiling water for 2 hours, and then in ice water.

With all these manipulations, it is worth considering that metal cools twice as fast in oil.

A workpiece that has undergone hardening is subjected to a special process called tempering to restore the crystal lattice of the metal structure.

There is nothing complicated in this procedure: the blade needs to be warmed up for a couple of hours. For alloy steel 270-320 degrees, for plain steel 150-200 degrees.

Determining the quality of work

Having gone through all the stages described above, I would like to know what will come of it. How to check the quality of the work done is quite simple:

- sharpening should last for a long time;

- the blade should not wrinkle or crumble when in contact with dense materials;

- the blade must have plasticity, bending and restoring its previous shape;

- a normal tool, with regular sharpening and constant use, should last at least 10 years.

Don't forget that true mastery comes with experience. And experience, as we know, is the son of difficult mistakes.

If you didn’t succeed the first time, or the second, then be persistent - the tenth time it will turn out no worse than others. Study the material, practice and sculpt true beauty.

Tempering after hardening

Hardening and tempering are two processes that complement each other and ensure the production of high-quality parts. The purpose of tempering is the final operation after hardening, forming the final, more stable properties of the metal, ensuring the removal of internal stresses. A steel product of a certain grade is heated and maintained at the appropriate temperature, after which it is cooled in air.

- Low tempering at 120-2500C - processing of tools and other parts. The metal has a stable structure, high wear resistance and hardness.

- Average tempering at 350-5000C - for dies, springs, leaf springs. The structure has good plasticity and high elasticity.

- High tempering at 500-6800C - medium-carbon structural steels. Provides high strength, toughness, and plasticity.

Temperature selection

For the correct completion of the hardening process, the correct selection of temperature, which depends on the material used, is very important.

Steels based on carbon content are divided into hypoeutectoid - less than 0.8% and hypereutectoid - more than 0.8%. Steel with carbon less than 0.4% is not hardened due to the resulting low hardness. Hypoeutectoid steels are heated slightly above the temperature of the phase transformation of pearlite and ferrite to austenite. This occurs in the range of 800-850°C. Then the workpiece is quickly cooled. When cooled sharply, austenite transforms into martensite, which has high hardness and strength. A short holding time makes it possible to obtain fine-grained austenite and fine-needle martensite; the grains do not have time to grow and remain small. This steel structure has high hardness and at the same time low brittleness.

Microstructure of steel

Hypereutectoid steels are heated slightly lower than hypoeutectoid steels, to a temperature of 750-800°C, that is, incomplete hardening is performed. This is due to the fact that when heated to this temperature, in addition to the formation of austenite, a small amount of cementite, which has a higher hardness than martensite, remains undissolved in the metal melt. After rapid cooling, austenite transforms into martensite, and cementite remains in the form of small inclusions. Also in this zone, carbon that has not had time to completely dissolve forms solid carbides.

In the transition zone during high-frequency quenching, the temperature is close to the transition temperature, and austenite with ferrite residues is formed. But, since the transition zone does not cool down as quickly as the surface, but cools down slowly, as during normalization. At the same time, the structure in this zone improves, it becomes fine-grained and uniform.

Overheating the surface of the workpiece promotes the growth of austenite crystals, which has a detrimental effect on brittleness. Underheating prevents the complete ferrite-perrite structure from transforming into austenite, and unhardened spots may form.

After cooling, high compressive stresses remain on the metal surface, which increase the performance properties of the part. Internal stresses between the surface layer and the middle must be eliminated. This is done using low-temperature tempering - holding at a temperature of about 200°C in an oven. To avoid the appearance of microcracks on the surface, it is necessary to minimize the time between hardening and tempering.

You can also carry out the so-called self-tempering - cool the part not completely, but to a temperature of 200 ° C, while heat will remain in its core. Then the part should cool slowly. This will equalize internal stresses.