The profession of a jeweler requires not only creativity in work, but also certain skills. There are many points in this matter, the observance of which allows you to create truly beautiful and neat products.

Despite the emergence of modern working methods, many previous ones still remain the same unchanged. We are talking about the casting process. Since ancient times, molds have been used to create jewelry. It is necessary to understand the peculiarities of the manufacturing process in order to answer the question: “what is a flask and how does it simplify the work of jewelers?”

Features of the jeweler's profession

The profession of a jeweler requires not only a creative approach. A jeweler must be careful and patient. There are many nuances in this matter, the observance of which requires utmost precision. A jeweler works with high temperatures and hot metal; the danger of this profession requires endurance and physical strength. A master jewelry maker is not only a designer who comes up with sketches and works with a file under the bright light of a lamp. This is also a foundry worker, managing hot furnaces and molten metal, lifting heavy plaster molds and ensuring that technology is followed. The arsenal of a jewelry master is full of unusual devices that the average person has never even heard of. For example, flask. What is a flask and what is this device used for? Our article will talk about this.

Opoka in jewelry making

Despite all the innovations and high level of technology for making jewelry, many of the jeweler’s working methods remain unchanged since ancient times. The ring casting process, for example, has changed little.

To answer the question of what a flask is, you should find out how the jewelry casting process occurs. To make a ring from a precious metal, a jeweler uses a special fireproof cylinder into which hot metal, molding compound and wax blanks are placed. This is the flask.

This device serves to hold the molding sand while it is compacted during the process of obtaining a casting mold into which the precious metal is poured. You can make a flask yourself, the main thing is that it is made of fire-resistant material. Some craftsmen make a flask from a piece of pipe or roll it from a sheet of iron. The photo shows a modern metal flask.

This flask is already filled with molding mass, inside of which there are wax blanks. The next step is calcination of the flask in a hot furnace; this procedure takes place in the foundry.

How to make an aluminum casting mold

There are several aluminum casting techniques that are used in production on an industrial scale. But if we are talking about work at home, then the most acceptable way is to pour liquid aluminum into homemade molds. This is the technology we will talk about.

Before understanding the nuances of casting, it is advisable to remember some of the characteristics of this metal. Aluminum melts at a temperature of about 660 ° C (depending on its purity), and boils at 2,500. Another feature that needs to be taken into account is rapid oxidation upon direct contact with air.

There are quite a lot of different “engineering solutions” that can be implemented when casting aluminum yourself at home. “Craftsmen”, knowing its characteristics, select the necessary devices and materials themselves.

One of the main problems is what and how to make a mold for pouring. This is where people who have no practical experience most often stumble.

Therefore, we will consider only one of the simplest options, since it is unrealistic to cover all the methods in one article.

Let's start with what you need to prepare for casting:

Aluminum scrap

Each of us has encountered this metal. But has everyone noticed that, for example, aluminum wire can be different? One bends easily, like plasticine, and the other is harder, less pliable. For casting, it is advisable to choose the one that is softer, since such a material, relatively speaking, contains less oxides and more “pure” aluminum.

Gypsum

The easiest option for working from home. Its best brand is sculptural (marked “G – 16”). But it has yet to be found, and the cost of such a high-quality product is quite high. Therefore, in domestic conditions, white gypsum (designated “G - 7”) is more often used, which is not in short supply. It can be purchased at any specialized store that sells building materials.

It is very similar in appearance to alabaster, and the two can easily be confused. In addition, the seller, not knowing why the buyer needs plaster, may offer this “analog” instead. In the construction industry, materials often replace each other, since many of their characteristics are similar. But alabaster is definitely not suitable for making molds! This needs to be taken into account.

Wax

This material is mentioned in almost all recommendations for do-it-yourself metal casting. Indeed, this is the best option, but only if we are talking about the manufacture of small parts. Pure wax is quite expensive, and there is no point in buying it in large quantities. Moreover, it is unlikely to be used again.

In practice, you use ordinary candles, which are found in any household goods department. Whether they are stearic or paraffin is not important. The quantity depends on the dimensions of the required part, the “blank” of which will be prepared from them.

You'll need a few more things as you go along. This will become clear when considering casting technology, and the choice of specific materials depends on the ingenuity and capabilities of the craftsman.

Melting containers

You can also melt candles in a regular tin. But for aluminum, the cookware needs to be stronger, since it will have to be heated quite strongly.

Heat source

What can I use? Muffle furnace or homemade crucible/gas forge. The main thing is to achieve the required melting temperature. As for the last “device” (crucible), it is clear from the picture how it works. You just need to take into account that the brick must be fireproof.

When using a sufficiently powerful stove to heat materials, it is necessary to include some kind of temperature regulator in its power circuit (if it does not exist). Such modernization will save time, nerves and electricity. It is enough to install a simple rheostat or an adjustable transformer (LATR). Otherwise, you will have to constantly turn on/off the device so as not to “drive” the temperature.

Making a blank

The task is to melt the paraffin and pour it into a mold with certain linear parameters. After it has cooled, it is easy to cut out an exact copy of the required part from the hardened mass. The easiest way is to take a shoebox. In principle, such “formwork” can be easily made from cardboard or plywood, securing the entire structure with adhesive tape.

Features of work

- The poured mass cools down for a very long time, and this process should not be forcibly accelerated. Hardening should occur naturally, then the structure of the blank will be uniform throughout its entire thickness. You will have to wait at least a day, since the top hard crust is not yet an indicator that the paraffin inside has hardened.

- The material used is characterized by significant shrinkage. In other words, in the central part of the mold the mass will “sag” somewhat during the cooling process. When calculating the dimensions of the required workpiece, this should be taken into account and paraffin should be poured with some reserve in volume.

Since you will have to manually cut out a part from a finished sample, it is clear that in the absence of experience (and perhaps even ability), it will not be possible to do everything accurately the first time, especially if you need to cast something of a rather complex configuration. But a rejected “blank” has only one path – to be melted down.

In order not to waste time, it is advisable to prepare two of them. If the first one is spoiled, then with the second one, taking into account the experience gained, the work will go more successfully. Considering that candles cost pennies, this will not “hit your pocket.”

Mold making

There are enough recommendations for its preparation. One simple way is to make it from plexiglass. This “aquarium” is assembled by fastening cut pieces of hardboard using plasticine. They also seal all joints.

Making a part template

A “blank” is placed at the bottom of the “aquarium”. To prevent it from moving during the process of pouring the solution, it is fixed with the same plasticine.

It should be taken into account that all other work is done quickly, since the plaster sets well. But this material is not used in its pure form. Its mixture with sand of the smallest fractions (50 to 50) is used. Otherwise, water will remain in the gypsum mass, which will begin to evaporate after pouring aluminum. This will cause pitting in the finished part.

The mixture is diluted to a medium-thick sour cream, after which the solution is loaded into the mold. You need to cook it so much that the “blank” is completely covered with it. In this case, it is not worth saving on material, especially since its price is low. To remove air bubbles, if there is no vibrating table, the mold must be shaken thoroughly by hand.

After the poured mass has hardened, the “aquarium” is dismantled. All that remains is to remove the paraffin from the plaster. It's easy to drown it out.

For example, place a plaster template, bottom up, on a sheet of iron, and place it on an open fire. But this does not guarantee the “cleanliness” of the insides of the form.

If the part is not just a metal plate or something similar, but has protrusions, cutouts, and so on, then a different method is used.

An unnecessary metal container is taken, into which a plaster template is placed and water is poured. The dish is placed on the fire, and when the liquid boils, the paraffin will begin to collect at the top (float). But it’s unlikely that you’ll be able to wash the container afterwards.

After the melting process is completed, the gypsum is dried. The temperature should be low, otherwise the material may “burn out” and become deformed, especially thin parts of the template.

Pouring aluminum

There is nothing complicated about this, just one nuance. It is necessary to keep a stainless steel spoon ready, which will immediately remove the resulting oxide film.

A few notes

- The “aquarium” shape can be made from any available materials. The main thing is that it does not fall apart during plaster pouring, and that it can be easily disassembled later.

- It is not necessary to look for a muffle furnace or install a crucible as a heat source. You need to try whether the prepared aluminum scrap will melt, for example, from a gas burner. Perhaps argon welding will be sufficient. Everything that is on the farm is sampled.

When casting yourself, it is necessary to experiment, since the essence of all operations is presented quite clearly, and the examples given on equipment and materials are not dogma.

Disposable flasks

Having learned what a flask is and how it is used, it is easier to understand the intricacies of the process. It no longer seems so complicated, but rather interesting and simple. Modern technologies allow you to try to make your own jewelry almost at home. The Chinese market offers a wide range of disposable molds with ready-made molds. All that is needed to work with such a form is the required amount of precious metal and the ability to melt it. They are used both by jewelers who do not have their own foundry, and by freelance craftsmen who make custom-made jewelry.

Author: Anastasia Razulite

Silver casting

The noble metal silver is one of the oldest metals mastered by mankind. Being in nature in its native form, as well as its low melting point - 962 °C, gave our distant ancestors the opportunity to use this metal in the 4th - 3rd millennium BC.

Silver

Silver is a soft, ductile metal, excellent for the production of jewelry, ritual objects, mirrors and for minting coins.

Silver has the best electrical conductivity among metals and is used in the most critical electrical appliances and components. Excellent thermal conductivity makes it possible to use it in heating engineering.

Thermal conductivity of silver

Noble metal was widely used in photography in the 19th and 20th centuries.

Bactericidal properties of silver

Another important property has long been noticed - bactericidal properties. Silver vessels and filters are used to disinfect water. In Christianity and some other religions, the so-called is prepared in silver vessels. “holy water”, which helps with appropriate prayer against all ailments.

Silver casting technology

Silver casting in a factory environment is carried out using industrial technologies that require expensive equipment, significant energy consumption and the use of rare and dangerous components. Traditional technologies, proven over thousands of years, are more suitable for casting silver at home or in a workshop.

The most common of these is lost wax casting. The use of special modeling wax as a model material is also popular. The material used to create the mold is gypsum or clay-sand mixtures.

Silver ingots for casting

Silver for casting can be purchased at a savings bank or jewelry store in the form of ingots. In this case, its composition is precisely known and is stamped as a sample. If you decide to use grandma's spoons or scrap silverware, be prepared for the fact that you will have to carry out an operation to clean the scrap from impurities.

For example, silver is purified from impurities of base metals such as lead, copper and others by melting it in a crucible with the addition of saltpeter, borax and soda. Nitrate binds base metals, oxidizing them. Soda and borax transfer these oxides into solution, forming liquid slag.

The silver remains at the bottom of the crucible in the form of an ingot.

Lost wax casting. This silver casting technology is most accessible for beginners to master. The model is made of a material whose melting point is lower than that of the melt being poured. A mold of plaster or sand-clay mixture is poured or molded around the model.

Lost wax casting

The most common materials for lost wax models are wax and paraffin.

When the melt is poured into the mold, the model material melts and is forced out of the mold through a specially provided hole. The place of the model is gradually taken by silver.

There is a variation of this method in which the wax model is burned out by heating the mold to a high temperature, and casting silver is poured into the now empty mold.

To cast precious metal products at home you will need

- Crucible for melting or cleaning metal.

- Muffle furnace or gas burner.

- Steel tongs.

- Fireproof stand.

- Scales

- Modeling wax. Candle wax will not work.

- Molding sands

- Container for diluting the mixture

- Scalpel, knives and files for processing the model and for finishing the finished product.

- Casting mold

- Hammer for breaking the flask.

- Protective gloves, glasses and apron.

- Fire extinguisher.

- Dremel (mini drill)

- Vices, Crossbars and Mandrels

It’s worth going into a little more detail on making a mold for casting silver. First, a model of the future product is created from wax by sculpting and cutting out small parts with a scalpel, completely repeating its shape, but having a thin protrusion in the form of a round rod.

Wax model for silver casting

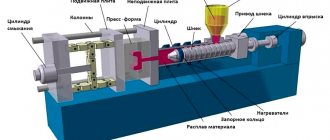

This is the sprue that will carry the molten metal into the mold. Next, the model is placed in the flask and the molding mixture is poured.

If dry molding mixture is used, then the vibration compaction method is used for molding. Next, the model wax is burned out, and the mold is ready for pouring the melt.

Model casting in earth molds

Casting in so-called earth molds is the oldest method, proven over thousands of years.

Molding mixtures do not actually consist of black soil, but are a mixture of fine-grained quartz sand and plastic clay in certain proportions.

For casting small products with thin relief and a large number of parts, mixtures containing 12-15% clay are used, for large castings - up to 25%. Gases generated during casting must escape freely through the walls of the mold.

Casting silver according to models in earthen molds

The model for casting into earthen molds is made absolutely exactly repeating the original, but a little larger in size. This is an allowance for shrinkage and subsequent processing of the product. Models were traditionally made from wood, wax and plaster. Today, plastic models are becoming increasingly popular. The plastic holds its shape well and is easy to process.

Lost wax casting technology

Lost wax silver casting equipment is relatively uncomplicated and available for home use.

The essence of the method is that a model made of a low-melting material, upon contact with the liquid metal being poured, melts and is forced out of the mold through specially provided holes.

The metal occupies the void formed in the place of the model and accurately repeats its spatial shape.

It is necessary to pour the metal in a thin stream to allow the material of the lost wax model to leave the mold, in order to avoid the formation of splashes of molten metal.

Silver casting at home

Important! Casting silver with your own hands is a complex and fire-hazardous process. Your workshop should have fireproof stands and fire extinguishers designed to extinguish live electrical equipment. Be sure to wear fire-resistant gloves, an apron and goggles.

For casting silver at home, beginning craftsmen usually choose the following technologies:

- wax modeling

- earth casting

- heating the crucible with a gas burner.

Of course, if you have a muffle furnace with adjustment and maintenance of a given temperature, a vibrating table and a centrifuge, your castings will only get better.

Casting silver at home is a complex process, but quite feasible with proper preparation and perseverance. Good luck in mastering this branch of metallurgy!