Chain oil

Almost all chainsaws come with an instruction manual. Such a manual states that in all cases it is necessary to fill in chain oil with a high adhesive effect.

Adhesion is an indicator characterizing the degree of adhesion of the lubricant to the surface of the chain bar.

Adhesive oil is required for chain operation for the following reasons:

- When the device is operating, the chain moves at high speed. If you use oil with a low adhesion index, then during operation it will be scattered due to inertia. You can check this yourself by simply adding a regular lubricant to the surface and adding gas.

- The oil must have high lubricating properties. At a high speed of movement of the tire, it can become very hot, due to which the metal used during manufacturing becomes soft and less wear-resistant.

Lubricating oil in various containers

It is worth considering the fact that when using a chainsaw for a long time, a large amount of oil will be required, since it is quickly wiped off the surface of the tire. A variety of companies are involved in the production of chain lubricants.

Advantages of higher-priced oils

Branded chain oils contain useful antioxidant, anti-corrosion, stabilizing components and additives that help maintain the operating properties of the oil and increase the wear resistance of working equipment in difficult operating conditions.

The quality of branded consumables is standard. Most of these are products from leading manufacturers Shtil, Husqvarna, Echo, Daewoo and a number of others. Over the past few years, the quality of Chinese chain oils produced at state-owned enterprises has noticeably improved.

Owners of chainsaw equipment independently decide which oil to use to lubricate the chainsaw chain. In the best case, this is a consumable material adapted to the climate of the region and recommended in the operating instructions for this model.

This is interesting: Design, setup and adjustment of a chainsaw carburetor - we tell you all the nuances

What parts of a chainsaw need oil?

A modern chainsaw is represented by a complex mechanism, which consists of a large number of different elements. The following elements require lubrication:

- A chain is an element on which blades for sawing wood are attached. It consists of a large number of individual elements movably connected to each other. When using the device, the surface may become very hot. In this case, the metal can rust due to high humidity, which significantly reduces its service life.

- The engine is the part of the chainsaw through which rotation is transmitted to the bar. Modern engines also need a lubricant that can significantly extend their service life. Different lubricating products are used to lubricate the chain and engine, which is worth considering.

Pouring oil into a chainsaw

The operating instructions also indicate which parts of the chainsaw need lubrication.

What oils can be used

Leading manufacturers of chainsaws recommend using their own lubricants in their equipment. However, these oils often cost several times more than simpler ones from third-party manufacturers.

note

If you are in doubt about the choice of lubricant, then in this case, the best solution would be to purchase lubricants from the equipment manufacturer.

But what to do if for some reason it is impossible to buy expensive original oil? Here, chainsaw owners resort to different options. Let's take a general look at each of the possible lubricants for saw chains.

Original oils

Often this is the best choice in terms of performance, but not price.

In addition to optimal lubricating properties, today manufacturers strive to make these lubricants biodegradable (based on rapeseed bases), which has almost no harm to the environment and human health. Stihl chainsaw chain oil is a biodegradable product. The only significant negative is the price.

Narrow profile

Special oils for chainsaw chains from third-party manufacturers. Also a good choice. They cost significantly less than branded lubricants, but are often almost as good in performance.

Cheap industrial oil

The most common option here is the domestic product, labeled I-20 or I-20A. One of the cheapest options. This industrial oil can be poured into a chainsaw to lubricate the chain without fear of negative consequences.

The lubricant has good properties regarding the operating conditions of the saw set and can reliably protect the chain and other elements of the set from wear.

In terms of performance, it is a little inferior to the original. But the price can be several times lower than for specialized products. Therefore, this option is used by many owners of chainsaws of all brands and models.

In hot conditions, it is recommended to monitor the lubricant level during sawing after half the gas tank has been used up.

Due to its very low viscosity, industrial oil is consumed quite quickly. There are known cases where industrial lubricants were used up faster than the fuel tank ran out.

New engine or transmission lubricants

Not a very reasonable choice in economic terms. Suitable for cases where the saw is rarely used, and there is no point in buying a canister of special lubricant separately.

These oils contain a huge amount of unnecessary and useless additives for saw operation, which will only pollute the processed lumber and the environment.

Which oil is better to use for a chain - video

Here you also need to take into account viscosity indicators. The rate of oil supply to the chainsaw chain can be greatly reduced as the temperature increases the viscosity.

Greases may lose their fluidity in winter conditions and may not effectively protect the chain and tire running surfaces from wear.

In the case of motor oils, when working in winter, it is recommended to use low-viscosity options. In general, internal combustion engine lubricants can be used in saws.

Used oils

Using used oils to lubricate a chainsaw chain is the worst idea possible.

Firstly, the specific nature of the operation of a chainsaw implies the creation of an oil mist in the work area, which spreads to the surrounding nature and is partially inhaled by humans.

And the waste is a recognized carcinogen and is generally extremely toxic. Therefore, in many countries, entire industries have been created to recycle used motor and transmission oils, and unauthorized discharge into the environment is punishable by serious fines.

Secondly, the lubricating qualities of the waste are extremely low. They are tight enough for medium load conditions. If you cut a thick log or hardwood, the chain and the rest of the saw set will suffer, even to the point of irreversible destruction.

Answering the question of how to replace chain oil for a chainsaw if it is too expensive to buy the original, you can answer this way: almost any oil with a suitable viscosity. But not with detention. It is better to fill the chainsaw with products specially designed for this purpose to lubricate the chain.

How and when to pour lubricant into the reservoir? Here the answer is simple: pour gas every time you fill up to the mark on the neck.

When to use special chain oil?

Manufacturers recommend using special oil to lubricate the chain in all cases of using a chainsaw. This recommendation is related to the following points:

- The oil pump may fail. This is due to the special properties of the lubricant.

- The use of waste or other oils for other purposes reduces the tool’s ability to perform at high speeds.

- If the tire is heavily worn, you cannot install a new chain on it. This is due to increased surface wear. It is recommended to purchase at least four chains for frequent work.

- It is strictly forbidden to work without oil poured into the tank. When refueling the chainsaw, the tire must be lubricated.

When using special oil to lubricate the chain, you need to pay attention to its quality, since the composition should not contain various impurities or debris. Otherwise, the oil pump may quickly fail.

Chainsaw chain lubrication

Almost all manufacturers of chainsaws and components produce lubricants. Chainsaw chain oil protects the metal from rapid wear and corrosion. In addition, chain oil stays on the surface for a long time even during long-term operation of the device.

Chainsaw oil

A chainsaw is a rather complex device that requires constant care and maintenance. The owner of the tool can perform some of this work independently; if complex malfunctions occur, we recommend contacting experienced mechanics.

Chainsaw oil

The performance of a chain saw and electric saw depends on many circumstances. The power of the motor, the experience of the operator, the quality of the saw set and fuels and lubricants should be taken into account. In addition, modern chainsaws are equipped with automatic chain lubrication, without which it is now difficult to imagine even the cheapest tool.

Main components of a chainsaw

We will tell you in our material what the automatic chain lubrication system is, how it functions and what its serviceability depends on. We will pay special attention to the problem of choosing lubricating oil and introduce you to the recommendations of leading manufacturers in this matter.

A little about lubrication of a chainsaw chain by working off

Used oil is oil that has already served its useful life in an engine or gearbox. It is often used to save money, including when servicing the chainsaw.

It is worth considering that working out can lead to rapid wear of the structure.

This can be associated with the following points:

- Often the breakdown is associated with a large amount of metal shavings in the composition. It gets there during the operation of the engine and gearbox, then accumulates in the pan.

- When metal shavings come into contact with a tire, they become like an abrasive. Due to this, the process of surface wear is significantly accelerated. The sprocket and bearing are worn out.

- Mining also has a negative impact on the connection points of the moving elements of the chain. Due to severe wear, the likelihood of its breakage during operation increases.

Waste oil

The above information indicates that in all cases you need to use a special product that is designed for this purpose. Processing that was previously used in the engine or gearbox is not suitable for a chainsaw.

Chainsaw sprocket lubricant

To increase service life and reduce friction on the drive sprocket, the manufacturer equips this mechanism with a needle bearing, which must be periodically lubricated. Stihl Multi-Purpose Grease can be used for lubrication.

If you do not want to overpay, it is better to use an inexpensive, but no less high-quality option, Litol or Litol 24 lubricant. Due to its viscosity, Litol will easily replace the original one.

You can lubricate the chainsaw tire sprocket with the same lubricants as the drive one, using a special syringe for this. This allows grease to be pressed through the technological holes in the tire to the sprocket bearing.

How should a chain oil lubrication system work?

To ensure reliable operation of the chainsaw, a special chain oil lubrication system is installed. An example is the following information:

- Fuel tanks are selected by volume, taking into account that when the fuel is completely used up, some oil should remain. In addition, it is important to correctly set the carburetor so that fuel is not quickly produced.

- With a slow decrease in oil at the time of use of the saw, the lubrication efficiency decreases several times, and the conductivity of the channels also decreases. Over time, a malfunction may appear that will be quite difficult to fix.

- It is recommended to check the condition of the oil pump from time to time. If necessary, you can adjust the performance using a special screw.

- You can check the correct operation of the pump yourself. To do this, the tire is brought to an illuminated surface. If oil splashes appear on it, then the design is working correctly. Lubricant consumption is adjusted depending on the specific situation.

Saw chain lubrication system

A sign that an insufficient amount of lubricant is getting into the cutting zone is strong heating and the appearance of smoke and an unpleasant odor when cutting wood. When heated strongly, the metal expands, causing the chain to become pinched in the groove. The effectiveness of the lubrication rate decreases when the tire gets into the ground. That is why, if the saw is not used carefully, it will quickly wear out. When chain oil comes into contact with the ground, it collects various substances, due to which the heating of the metal accelerates.

The structure of the chainsaw and where to fill the oil

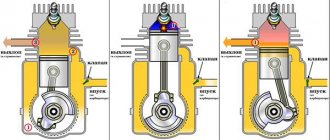

Now we will “plunge” into the very core of this tool, so that you can at least have a general idea of what your “assistant” consists of, in order to be able to determine the malfunction of a particular part in case of problems with the chainsaw. In fact, this kind of tool can be responsibly attributed to classical mechanisms that operate by activating an internal combustion engine.

Without exaggeration, we can say that this type of tool is the simplest of all other mechanisms, since the saw does not have a gearbox and is equipped with a conventional two-stroke engine, which has one cylinder and runs on gasoline. The main advantage of a chainsaw is that it is designed quite simply, which helps to increase reliability, as well as trouble-free operation in difficult and difficult conditions. Next, let's look at the design of the saw in more detail, so:

- engine;

- clutch;

- ignition system;

- carburetor (see carburetor setting);

- fuel system (see ratio of gasoline and oil);

- air purification system;

- starter;

- chain (see how to sharpen a chain with your own hands);

- tire;

- chain brake;

- chain tension mechanism;

- chain lubrication system.

In essence, we have sorted out the device, but now an important issue remains the lubrication of the chainsaw parts. Many people do not understand why it is needed at all? The answer is quite simple, like all mechanisms, a chainsaw, especially its individual parts, require special care, including periodic lubrication.

This is necessary in order for your tool to serve you for many years , since during operation, the chainsaw spare parts produce a movement that must be smooth, smooth, so as not to damage nearby spare parts.

Just as everyone knows that the friction force disrupts the surface, so here, if you do not lubricate the chainsaw as necessary, the spare parts will simply wear out quickly and the tool will fall out of tune. You need it? Don't think. Therefore, it is necessary to take care of your chainsaw so that it “has the strength” to serve you for many years.

Universality problems

Universal oil for lubricating chainsaw chains has relatively unattractive performance properties. It is worth considering that even lubricant manufacturers do not indicate their 100% versatility.

An incorrect choice leads to the fact that the wear of the structure increases by approximately 10% and the working life of the saw set is reduced.

The information above indicates that there are no universal options for oils. That is why when choosing, you need to pay attention to operational properties, in particular, temperature conditions.

Types of oils for electric saw chains

Special oils for chains of electric and chainsaws are presented on the modern market in the main groups - these are mineral-based products, fully synthetic and semi-synthetic. The latter contains both synthetic and mineral components. Another group of chain oils for electric saws consists of special materials based on plant raw materials.

Each group of oils has certain advantages and disadvantages.

From the point of view of stability and the ability to work in the most severe conditions, synthetic oils are undoubtedly the leaders. They ensure operation of electric saws even in frosts down to -40 degrees. The main disadvantage of such products is their high cost.

Mineral oils are much cheaper, but their level of performance properties is also lower. Most of them, at subzero temperatures as low as -25 degrees, stop entering the friction zone and performing lubricating functions.

Semi-synthetic oils for petrol and electric saws, both in terms of characteristics and cost, occupy an intermediate position between mineral water and synthetics.

Based on temperature properties, oil for lubricating chains of electric saws is also divided into three groups:

- Summer oils work well at high temperatures, but become extremely thick as early as -15 °C

- Winter - retain their viscosity properties at -20 °C and below

- All-season suitable for use both in winter and during the warm season

To obtain specified performance characteristics, various additive packages are introduced into the formulation of such products. It is especially important for electric saws that the lubricant is not discarded from the friction units under the influence of centrifugal forces when the saw rotates. Therefore, adhesive additives play a vital role in chain oil.

Performance properties

When producing branded and standard oils, standards related to viscosity or density, as well as the concentration of foreign impurities, are taken into account. Among the features we note the following points:

- Organic and mineral compositions practically do not differ in their performance qualities. This is due to the fact that the lubricant flies off the surface of the tire quite quickly. There is no point in overpaying significantly for the purchase of expensive lubricants, since the difference is insignificant.

- The protective properties of mineral compositions are significantly higher than those of natural ones. That is why it is recommended to use such oils for one-time work.

- If there are only a few days between jobs, then it is recommended to use organic compounds. They are much cheaper than mineral ones and are characterized by high efficiency in use.

If you are using lubricant for the first time, you should hold the saw at medium speed for several minutes and check whether it is suitable for your specific model. Such oils are also characterized by the temperature at which they can maintain their performance characteristics.

Advice from experienced sawyers

- In order not to run into a fake, you need to check with the seller for a certificate stating that he is an official representative of this brand.

- Do not use used oil, diesel or sunflower, for your saw.

- It is strictly forbidden to add individual fuel additives. It is difficult to predict how they will interact with the other components of the oil.

- Do not mix oils of different brands or different compositions. It's cheaper to pour out the leftovers and fill in new ones.

The oil is specially painted in bright colors so that when mixed with fuel, the color of gasoline will change. Thanks to this, you can understand whether lubricant was added to gasoline.

Poor quality oil can lead to rapid wear of the entire piston group of the engine. The released carbon deposits will not allow the rings to shrink and snags will form on the crankcase. Due to poor quality lubrication, bearings can overheat and jam. Follow our advice, select only high-quality lubricants and the saw will last a long time.

- How to choose the best from the Patriot chainsaw model range: review of the 6 most popular models, their pros and cons, tips on selection, operation and care of the tool

- Lesnik chainsaws: what kind of brand is this, what advantages does it have, review of popular models, their pros and cons, expert advice

- Chainsaws Sturm: how to choose the best, their features, review of the 9 most popular models, their pros and cons, possible malfunctions

- Stihl chainsaws: how to choose the right one, popularity rating and review of the 6 main models, their pros and cons, design features, use and care

Choosing engine oil

Saw chain oil is not always used as an all-purpose option. Often, the option for the engine from which the tire receives rotation is also filled. When choosing it, the following points are taken into account:

- You should give preference exclusively to the options recommended by the saw manufacturer.

- Mineral lubricants are more popular, as they are more effective in use.

- Products from well-known manufacturers are characterized by higher performance characteristics.

- The recommended temperature regime must also be taken into account. Some versions cannot be operated at too low a temperature, as this leads to an increase in viscosity. Too high a viscosity causes structural damage when operating at high speeds.

Various brands of chainsaw oils

If you do not add lubricant to the engine in a timely manner, it can quickly wear out or even fail.

What type of oil should I use for a chainsaw chain?

The working element of a gasoline saw is a sawing apparatus consisting of a guide bar, a driven sprocket and a chain. In order to ensure maximum operating time and maximum efficiency of these elements, it is necessary to carry out timely maintenance in accordance with the manufacturer’s regulations.

Choosing a chain oil is not as difficult as, for example, oil for a two-stroke engine. Many experienced gas saw users agree that chain lubricant can be any type of oil. The exception is mining, since its beneficial properties have already been lost, so its use is unacceptable.

When choosing a lubricant for a chainsaw chain, you need to take into account its chemical basis. As with two-stroke oil, the fluid can be mineral, semi-synthetic or synthetic.

When working in conditions of negative temperatures, it is better to focus on the last two options, since this type of lubricant is capable of maintaining low viscosity in the cold. However, a low viscosity coefficient can also play a negative role in the summer. Oils with this property will provide too high consumption.

Chain lube is poured into a separate tank for gasoline tools. During operation, it is necessary to monitor the level and, if the required volume is not available, add oil. On the reservoir of every gasoline saw, without exception, there is a transparent area with which you can monitor the level.

Oil is supplied to the chain using an oil pump, which creates pressure. If there is no liquid in a special tank, the pump, running idle, may burn out.

What types of chainsaw oils are there and how to use them - video

Many experienced people recommend using a lubricant of this kind for another useful purpose - placing the saw chain in a container with chain oil a few hours before use.

This procedure will give a beneficial effect. Penetrating into the connecting elements of the chain links, the oil helps protect against corrosion and ensures the mobility of each link.

In the modern construction market you can find many offers from various manufacturers of chain oils. Cheap options are quite suitable for amateurs, but for professionals there are more expensive products.

Huskvarna

Many manufacturers of gasoline saws do not shy away from producing all kinds of consumables. Huskvarna is no exception. Chain lubrication oils under this brand are of organic origin, which means they are highly environmentally friendly. Review of Huskvarna oil for chainsaws - video

Since oil, during the operation of a chainsaw, invariably ends up on the ground, this property is very beneficial for the environment. The products of this brand are in the middle price segment. A container with a volume of 1 liter can be purchased at a cost of 350-500 rubles.

Oregon

Despite the fact that gasoline sawing tools have never been produced under this brand, this brand is the leader in sales of consumables for chainsaws. This is facilitated by high quality at a reasonable price.

By forming a permanent film of oil, Oregon chain lube prevents corrosion from adversely affecting the saw chain, reduces vibration and prevents oil from splashing, which significantly reduces consumption. The cost of one liter of chain fluid will be about 300 rubles.

Stihl

The brand is famous not only for gasoline saws and other garden equipment. The company is closely involved in the production of consumables.

Chain oils under this brand are highly environmentally friendly, since the products are made on a plant basis. Despite the high price (a liter container costs from 500 rubles), professionals often opt for Stihl.

Self-selection criteria

Problems often arise due to the fact that it is impossible to find a suitable branded oil. Many experts recommend choosing an analogue from well-known manufacturers that will ensure long-term operation of the device. Among the features of choosing a chain lubricant, we note the following points:

- There are budget and expensive analogues on sale. The price may depend on a variety of parameters, for example, resistance to heat.

- The constant use of products from one brand allows you to open up all the possibilities of a lubricant. Having selected a high-quality product from a well-known manufacturer, you can purchase it regularly.

- You cannot purchase lubricant with bright sediment and fractional separation. Moreover, such an offer is often much cheaper than branded options.

- If a product of a little-known brand is purchased, then consumer reviews are studied before doing so. On the Internet you can find quite a large number of different blogs and services where you can find reviews. Of course, not everyone needs to be believed, as some will be placed as part of an advertising campaign. Do not forget that good oil will not be cheap.

- It is forbidden to mix mineral and organic oil, as their performance characteristics are significantly reduced. Therefore, it is recommended to drain the old substance, after which only a new one can be poured.

The operation of the lubrication system must be monitored in a timely manner. If you choose the wrong oil, the service life of the saw is reduced several times.

How to replace expensive oil

The disadvantage of special branded chain lubricants is their high price. Buying a liter of another expensive oil is not burdensome. And if there is work to be done that requires several liters, or even tens of liters, thoughts about saving will probably arise. The main thing is not to go to extremes when considering options. You can save on oil to such an extent that you will have to change the chain several times, or even the tire itself or the oil pump.

There are three replacement options. Firstly, you can use specialized products from little-known manufacturers to lubricate the chain. But we still need to look for such oils. In addition, there is a risk of stumbling upon a low-quality product.

Application of oils for automobile engines. They can be used as a temporary replacement, but they cannot boast of high adhesion, so the quality of their work will be clearly worse than special ones. For this reason, it is not recommended to use spindle and diesel oils - the worst in terms of adhesion.

And we definitely need to talk about one more option - working out. This is the name of oil that has spent its life in the engine and is drained from it when replaced.

In fact, this is not an option at all. Metal particles are always present in the waste. And if they may not damage the chain itself, then they certainly will not damage the oil pump and the entire lubrication system. On forums on the Internet you can find a “killer” argument in favor of testing - that the Soviet chainsaw “Druzhba” did not have chain lubrication at all and worked. So you can pour whatever you want - and it will do. Well, “Shtil” will also work with a working off or even with a non-lubricated chain. The question is how long it will work and how many chains will have to be replaced during this period.

A warning to those whose chainsaw is under warranty. Warranty workshop technicians are able to identify cases of poor-quality chain lubrication. Especially when using mining. Repairs under warranty will be rejected immediately.

Adjusting oil density to external temperature factors

The performance characteristics of the lubricant decrease when it is used when the ambient temperature drops to -20 degrees Celsius and below. Also, at low temperatures, the pump responsible for supplying oil does not work properly. The solution to this problem is often mixing the thickened composition with kerosene. Such an additive provides the required density of the substance, but it is still recommended to reduce the applied load. If the ambient temperature is too low, you need to monitor the effectiveness of lubrication of the main elements. This recommendation can also be attributed to the fact that the liquid in the wood begins to freeze, increasing the hardness and reducing the degree of workability. Too high a load causes rapid wear. An increase in viscosity makes engine operation more difficult. This is why many manufacturers indicate the conditions under which a chainsaw can be used.

The danger of using counterfeit oil

Cheap lubricants are inferior in properties to branded products. At the same time, manufacturers of expensive versions indicate that the saw should be used with the least load. In addition, you should consider:

- Counterfeiters accelerate the wear and tear of the material. Moreover, if the structure is severely worn, it cannot be repaired under warranty, since non-recommended oil was poured during operation.

- Rapid wear can cause the engine or tire to fail quickly. A fuel-powered engine is a combination of various moving elements. In order to reduce their wear, a certain amount of a special lubricant is added to the design, which also provides the required cooling. During operation, due to heating and slow wear of the metal, the properties of the oil change significantly. That is why from time to time it is necessary to completely replace it.

In order to eliminate the possibility of counterfeiters, it is recommended to purchase lubricant for chainsaws in specialized stores. Only in this case can you count on the fact that the information on the packaging will correspond to the real one.

Main question

It consists in maintaining the proportions of non-gasoline oil for the chainsaw. An extra first ingredient will cause carbon deposits to form on the spark plugs and pistons. Excessive gasoline causes scuffing on the pistons, which will cause rapid engine failure. The exact proportions are indicated by the Russian automobile industry itself.

Husqvarna and Stihl recommend taking four liters of gasoline per hundred ml of oil. This is typical for tools with motor power up to 1.5 kW. At higher power the proportion should be 1/50. What kind of oil to pour into a chainsaw to lubricate the chain. Approximately the same answer to the question “How to dilute gasoline for a chainsaw?” It is recommended to proceed from the following proportions: 20-50 ml of oil per liter of gasoline.

“Partner” Jonsered recommend using 3.3 liters of gasoline per hundred ml of oil.

As you can see, different domestic manufacturers have different approaches to maintaining the proportions of oil and gasoline. Therefore, it is necessary to strictly adhere to the instructions that come with the specific brands of tools in question.

Mixing must be carried out in special canisters, which are marked with measuring divisions and do not have two holes: one for oil, the other for gasoline. The components are poured into it, the container is tilted and does not mix when the lids are closed. Drops of water or other solid particles are not allowed to get into the mixture being prepared.

However, these containers have a minimum mark of one liter, so for smaller volumes there is an option to make the measure yourself. For this purpose, you have the option of taking a plastic bottle with a capacity of 0.5-1 liters. There we fill in water one hundred and two ml (up to eight hundred and sixteen ml) using measuring cups. After pouring each portion, a mark is made, on the indicator of which numbers from two to eighteen are written in increments of 4. In order to measure the oil, we use a syringe without a needle with a volume of 10-20 ml. A step of one hundred and two ml of water provides a proportion of 1/50. For other proportions, it must be changed accordingly.

The finished composition is stored for less than one month. It's even better to use it up over a few days. This is due to the fact that oxidation processes take place there, which change its chemical composition. The ideal mixture consumption option is a minute. If the engine breaks down due to overexposure to fuel, this will be considered a non-warranty event. If at the end of the season there is a prepared mixture left in the chainsaw, then you need to turn off the engine so as not to remove its remains.

Storage Features

It is recommended to store new and used chains in oil baths. This recommendation is due to the fact that prolonged exposure to humidity may cause severe corrosion on the surface. You can also use waste or motor oils for storage, since in this case it is important to protect the metal from corrosion.

Used oil storage

In conclusion, we note that only if the basic recommendations are followed, long-term operation of the structure can be ensured. The cost of a tire or chain, as well as the engine, is very high; if improperly lubricated, they can become completely unusable in just a few hours of operation. Therefore, you can save a lot by purchasing the right lubricant for the chain and engine.

How to determine the ratio of gasoline and oil

The fuel mixture used in 2-stroke engines is prepared from a certain amount of oil and gasoline. The latter must have an octane number of at least 90 and be unleaded. AI-92 fuel is best suited for these purposes.

Gasoline with an octane rating of 95 is not recommended because it contains many different additives that are harmful to two-stroke engines.

To prepare the mixture, you must use only motor oil from reputable manufacturers. The lubricant must be intended for high-speed engines with an air cooling system. This component, intended for low-speed engines (moped, motorcycle, snowmobile), is prohibited.

When preparing the mixture, you must strictly observe the proportion of gasoline and oil. As a rule, this is 1:50, that is, you need to take 100 ml of oil and dilute it in 5 liters of gasoline. This rule changes slightly if the engine or piston system is new and requires break-in. In this case, the oil-gasoline ratio can be 1:40. For break-in, you will need 2-3 full refuelings of the unit with a fuel mixture with this ratio. If you dilute the fuel mixture in a ratio of 1:30, carbon deposits will inevitably form on the piston and inside the cylinder, which, as already mentioned, leads to breakdown of the entire crank mechanism.

Below is a table that helps you quickly determine the gasoline-oil ratio if you need to prepare a large amount of fuel mixture.