POS 61

The melting point of pos 61 is 183 degrees, which is the starting point. Complete melting is achieved at a temperature of about 190 degrees, which allows you to work with it using any household soldering iron or professional soldering station. Soldering temperature is 240 degrees. This is the lowest melting point solder of the entire group of tin-lead solders.

Compound

This filler material belongs to the soft category, contains 61% tin, 38-39% lead and may contain an acceptable percentage of impurities in the form of antimony, nickel, iron, sulfur and bismuth.

Within the tin-lead group, this material is the purest solder in composition and is more suitable for electrical installation and tinning, since due to the copper content in it, it reduces the rate of dissolution of copper wires and tracks and wears out the soldering iron tip less, and the relatively low melting temperature does not harm printed circuit board.

Material characteristics

- The melting point is 183 degrees.

- Melt temperature 190 degrees.

- Density 8.5 g/cm3.

- Resistivity - 0.139 µOhm/m.

- Tensile strength - 4.3 MPa.

Available in several varieties, which differ only in appearance:

- In the form of wire - section thickness approximately 2 mm, the most convenient and common option. Wire with flux inside can also be found. The role of a flux is played by pine rosin, which works well when soldering electrical connections, since it does not oxidize parts, unlike acid fluxes, after working with which the parts must be thoroughly washed.

- In the form of solder tape - solder in the form of a very thin long strip. Ideal for quick soldering of strands and tinning of wires. Like wire, it comes with or without flux.

- In the form of rods up to 8 mm thick and approximately 40 cm in length. These rods are convenient to use when soldering installation wires and tinning the soldering iron tip. If desired, you can make them yourself by pouring them into pre-made molds.

Use in everyday life and at work

This solder is widely used both in everyday life and in industry. The low cost of the material makes it very accessible, and its chemical composition and technical properties allow its use in solving many problems.

So, it was already said above that using POS 61 it is convenient to solder radio components, because its low melting point will not damage the printed circuit board tracks and radio components, especially microcircuits that can fail if overheated.

Also, using this material you can carry out high-quality soldering of twisted copper wires, which is actively used in electrical installations, and you can solder with both a soldering iron and a gas torch. In addition, pos 61 has very good fluidity and forms tight seams, which allows its use when welding pipes together using a gas torch.

But the low melting point also imposes some restrictions on the scope of its application - it cannot be used when working with materials that will subsequently be subject to strong heating. This can cause the weld to become distorted or even melt, ruining the entire job.

Classification of solders for copper pipes

Solders for high-quality and reliable soldering of copper pipes are made from different components. Products differ from each other in shape and chemical composition.

The type and parameters of the connecting elements are determined by the area of subsequent operation of the pipe system made of copper parts.

Melting point differences

Based on the level of temperature treatment, solders are divided into three types:

- low temperature;

- medium temperature;

- high temperature.

Low temperature options melt in the range from 150 to 450 °C. They do not change the original physical parameters of the parts. In the connection area, a neat but not too strong seam is created. Intended for use in heating and water supply networks that are not subject to heavy loads.

Ensure the tightness and integrity of pipes with a diameter of up to 10 cm installed in communication systems transporting coolant with temperatures up to 130 °C.

Medium and high temperature materials soften at temperatures ranging from 450 to 1100/1850 °C. They guarantee the most durable, strong connection, not sensitive to external influences.

The area connected by medium-temperature or high-temperature solder exhibits resistance to mechanical damage and calmly tolerates active thermal loads.

Separation by chemical composition

According to the chemical composition, modern, practical solders are divided into soft, fusible and hard, refractory.

The first category includes the following items:

- lead - contain only pure lead and melt at temperatures from 180 to 230 °C;

- tin - consist of tin and melt at 220 °C, creating a durable and ductile seam;

- lead-tin - can contain from 15 to 90% tin. The melting temperature of such elements is 183-280 °C;

- tin-copper - 97% consist of high-quality tin and 3% copper. They are among the most popular and are sold at a reasonable price. Form a strong connection with good corrosion resistance;

- copper and silver - 95% copper and 5% silver. They are characterized by high strength characteristics and provide reliable adhesion between fragments.

Soft, low-melting components are used to combine pipes with a diameter of 6 to 108 mm into a single complex. In the joint area, a neat seam with a width of 7 to 50 mm is formed.

Lead is considered an element harmful to human health. The use of lead-containing solders is strictly prohibited in networks supplying water to apartment or private buildings, enterprises or public institutions. This prohibition does not apply to other types of communications.

Hard, refractory materials are suitable for high-temperature processing:

- copper in combination with silver and zinc - contains 30% copper, 44% silver and 26% zinc. The adhesion area has good strength, retains ductility, effectively resists corrosion and demonstrates increased thermal conductivity;

- copper with phosphorus - an alloy of 94% copper and 6% phosphorus. The soldering process does not require the use of flux. Makes a strong and reliable connection, but partially loses its elasticity at low ambient temperatures;

- silver – during soldering requires the mandatory use of flux. Creates a strong, reliable seam with good ductility and high corrosion resistance. It is much more expensive than analogues made of simple metals and is not widely used. It is used where there is economic feasibility and increased demands are placed on the quality of the pipe connection.

Using refractory solders, complexes of pipes with a diameter of 12 to 159 mm are installed, including gas communication networks, heating lines and water mains with a diameter of 28 mm.

The use of classic copper-phosphorus or any other elements is allowed when creating overlap joints. This coupling option ensures maximum structural strength and increases the operating life of the pipeline.

Read also: What kind of oil is poured into the rotator

Soft solders are usually made in the form of coils for ease of use. Solid elements are supplied in the form of wires of different lengths.

Solder paste

Mainly used for soldering surface-mounted components (SMDs), as well as leadless chips in BGA packages.

It looks like a gray paste, consists of tiny balls of Sn62Pb36Ag2 alloy (silver 2%, lead 36%, tin 62%), and also contains no-clean flux. The fact that the flux is no-clean is indicated by two letters on the packaging: NC (No Clean). The flux containing solder balls dries in air, so the paste is stored in a closed container.

This product is used for complex cell phone repairs and for soldering microcircuits in BGA housings. Its use involves the use of additional equipment for repairing mobile phones, for example, special stencils. The paste is quite expensive because it contains silver.

Lead-free solders are now widely used in electronics production.

Solder Material Selection

One of the main criteria for choosing an alloy for creating a solder joint of metal parts is its melting point.

That is, the filler material must melt earlier than the base material. But this is not the only condition for choice.

The liquid melt should well wet the surface of the base metal. In addition, certain strength requirements are imposed on the soldered joint.

It is for this reason that when soldering any metal product, they try to use an additive based on the same metal as the metal of the product.

At the same time, the lower melting temperature of the solder is ensured by the additional components included in its composition.

However, it should be noted that it is never possible to equalize these characteristics when soldering. That is, during mechanical fracture tests, fracture will always occur at the joint.

In some specific types of soldering, the strength of the connection does not play a major role. For example, when soldering jewelry, the main thing is the aesthetic part of the work. Therefore, products made of gold, silver and platinum are soldered only with solders based on the same metals, and of the same standard.

Manufacturers

Several manufacturers in different countries produce silver soldering wire. Sales are carried out wholesale and retail. Any property of a product is regulated by regulatory documents. Experts did not notice any significant differences between the products of different companies.

The performance characteristics of the joints of parts created by soldering, in most cases, depend on the correct choice of brand of solder, flux and soldering iron temperature.

In the country, wire is mainly used from manufacturers:

- Felder is a German company located in Germany, with several branches in other countries;

- Sparta is an LLC known in Russia for the production of hot-rolled wire, including materials for soldering;

- Ukrinterstal - unites several large steel rolling enterprises located in Dnepropetrovsk, Nikopol and Mariupol;

- Donmet - Donetsk region, produces wire from non-ferrous and high-alloy steels.

The production of rolled products containing silver and copper is an energy-intensive production that requires complex equipment.

PSR series solder is in great demand. It is universal when soldering materials with a high melting point, which are difficult to weld and solder in other ways.

Warming up

Depending on the melting point of the filler material used, different heating methods are used during soldering. In the case of soft materials containing tin, zinc, and lead, the main tool for soldering can be a regular soldering iron.

An example is the assembly and repair of electronic circuits containing components that are critical to overheating. In this situation, lead-tin materials with a low melting point and low-power electric soldering irons are usually used.

The mechanical strength of the connections plays a secondary role here; the main thing is to ensure reliable electrical contact.

When it comes to soldering with high-temperature materials, the soldering iron is powerless. In these cases, heating is carried out using gas burners and special installations using high-frequency currents.

This applies to industrial soldering in production workshops and the use of hard solders.

In some cases, when the parts to be soldered are very massive, and using conventional heating means it is not possible to achieve melting, special furnaces are used, where the workpieces are placed entirely. This is the only way to ensure reliable soldering.

General information about soldering

What is more important in a soldering job: the tool or the material? Everything is important: the soldering iron, the solder, and the flux. The variety of soldering irons is related to the object of soldering. Massive parts are heated with powerful soldering irons, and microscopic circuits of chips are heated with low-power ones. Professional soldering workers use several types of these heating tools.

Classification of soldering irons by power:

- A soldering iron with a nichrome insert with a power of 25 watts is a common household tool used by craftsmen, radio amateurs, and electronics engineers. They are still popular to this day, quite cheap, and last up to 10 years. A metal insert in the form of a copper rod, the tip of which is cut at 60 degrees. It is used in 90% of cases that arise in business situations; even many repair shops use them.

- The second type is more powerful with a 40-watt heater and a nichrome insert, twice as heavy and larger than its 25-watt counterpart. Used for more complex work. The tip is sharpened into a wedge, similar to a screwdriver, but it cannot be used for screwing screws. This sharpening is made for the convenience of soldering massive parts, for heating up to 190 C. They are used by professionals, but not recommended for home use.

- The third type is a gas soldering iron, three in one. The soldering iron itself has a copper core sharpened for a needle. The second function is a hair dryer that can heat an object up to 600 degrees. Gas burner - in this case the nozzle is changed, the tool performs the functions of a gas burner, heats the parts to a temperature of 1300 degrees.

- The fourth type is a modern ceramic soldering iron. Champion compared to all presented instruments. It has a very thin tip, capable of soldering millimeter dots, and is used to perform very precise work. Power - 100 watts. It is equipped with a soldering station with a temperature range from 200 to 480 degrees. Among specialists it is used as a universal tool.

Group of special alloys

When antimony is added to metal compositions in small quantities, the strength of seam joints significantly increases.

The material is marked “POSSU” and has a melting point from 189 ℃ (for a composition with a trace antimony content) to 270 ℃ (for a solder with an antimony content reaching 4%, in some even 6%).

Materials of the first subgroup with an additive concentration measured in hundredths of a percent are low-antimony grades.

Such solders are used in the aircraft and automotive industries, in the production of refrigeration equipment, and food utensils that are subject to subsequent tinning.

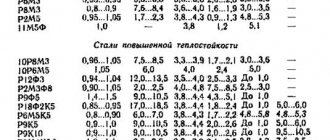

Table 1. Low antimony solders:

| Brand | Content, % | Application area | ||

| Sn | Sb | Pb | ||

| POSSu 61-0.5 | 59-61 | 0,05-0,5 | Rest | Soldering parts sensitive to overheating |

| POSSu 50-0.5 | 49-51 | 0,05-0,5 | Rest | Aviation radiators |

| POSSu 40-0.5 | 39-41 | 0,05-0,5 | Rest | Galvanized parts of refrigerators, radiator tubes, windings of electrical machines |

| POSSu 35-0.5 | 34-36 | 0,05-0,5 | Rest | Cable sheaths for electrical products, thin-sheet packaging |

| POSSU 30-0.5 | 29-31 | 0,05-0,5 | Rest | Radiators |

| POSSu 25-0.5 | 24-26 | 0,05-0,5 | Rest | Radiators |

| POSSu 18-0.5 | 17-18 | 0,05-0,5 | Rest | Heat exchanger tubes, electric lamps |

Metal tin-lead compositions with an antimony concentration from 1.5% to 6% are called antimony. They are recommended for use in electric lamps, tubular radiators, and tinplate.

The addition of antimony makes the tin-lead material cheaper, but soldering is more difficult. A slight change in the tin-lead composite significantly reduces the wetting properties of the melt. Only professionals can work with this consumable.

Table 2. Antimony solders

| Brand | Content, % | Application area | ||

| Sn | Sb | Pb | ||

| POSSu 95-5 | Rest | 4.0-5.0 | No more | Pipelines operating at elevated temperatures, electrical products |

| POSSu 40-2 | 39-41 | 1.5-2.0 | Rest | Refrigeration devices, thin sheet packaging |

| POSSu 30-2 | 29-31 | 1.5-2.0 | Rest | Refrigerators, light bulb production, abrasive packaging |

| POSSu 25-2 | 24-26 | 1.5-2.0 | Rest | Automotive products |

| POSSu 18-2 | 17-18 | 1.5-2.0 | Rest | |

| POSSu 15-2 | 14-15 | 1.5-2.0 | Rest | |

| POSSu 10-2 | 9-10 | 1.5-2.0 | Rest | |

| POSSu 8-3 | 7-8 | 2-3 | Rest | Electric lamp production |

| POSSu 5-1 | 4-5 | 0.5-1.0 | Rest | Tubular radiators, parts operating at elevated temperatures |

| POSSU 4-6 | 3-4 | 5-6 | Rest | Car body putty, tinplate soldering |

| POSSU 4-4 | 3-4 | 3-4 | Rest | Automotive products |

TEST METHODS

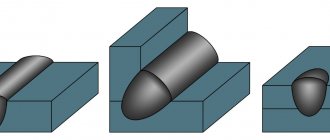

4.1. Inspection of the surface of pigs is carried out by visual inspection. 4.2. Sampling - in accordance with GOST 24231. The shavings selected from all pigs are crushed to a particle size of no more than 5 mm without control sieving, thoroughly mixed and reduced by quartering to a laboratory sample weighing 200 g. The laboratory sample is melted in a crucible and ground on a belting to particle size no more than 2 mm, stirred and treated with a magnet. The laboratory sample is divided into two parts: one part is sent for chemical analysis, the other is saved in case of disagreement in assessing the quality of the batch. Samples of liquid metal are taken in the form of splashes and rods with a diameter of 8 mm and a length of 75 mm. (Changed edition, Amendment No. 1,2, 3, 4)

.

4.3. Solder shavings containing more than 2.5% antimony are sifted through mesh No. 08 according to GOST 6613 to determine the fine fraction. The calculated data of the analysis results of both fractions are taken as the result of the analysis. (Changed edition, Amendment No. 1, 2)

.

4.4. The chemical composition of solders is determined according to GOST 1429.0-GOST 1429.15 or other methods that provide the required determination accuracy. In case of disagreement in assessing the chemical composition of solder, its determination is carried out according to GOST 1429.0 - GOST 1429.11. (Changed edition, Amendment No. 2)

.

Specifications

Solder for soldering POS 61 is quite common in our country. It is widely used both at the industrial level and in domestic conditions. Its distinctive feature is that due to the high percentage of tin in the chemical composition, its temperature point at which the material begins to melt is very low. It is worth noting that this solder can be classified as one of the most fusible consumables for soldering. This category includes all filler materials whose melting point is less than 450 degrees Celsius. POS 61 melts at temperatures below 200 degrees Celsius. This model is produced in our country in strict accordance with government standards.

Due to the properties described above, the filler material of this model has increased fluidity. In some cases, this property is considered a disadvantage, but not in this case. Due to the low melting point and high fluidity of solder, you can work with it with almost any equipment, from an ordinary household soldering iron to professional specialized units. During the soldering process, solder is able to penetrate even the smallest cracks and recesses, which, of course, allows you to raise the level of quality of the final result of the connection, in particular its strength.

The filler material also interacts well with water. Due to good wetting, soldering using solder of this model does not cause any difficulties during operation. All chemical, physical and mechanical properties of a consumable material are determined by its chemical composition, or rather by a certain ratio of elements in it. Even if you change this value by just one percent, all the characteristics of the material can change dramatically. In addition to the main elements in the composition, additional substances can be added to its structure, which can improve one or another specific characteristic of the solder.

This filler material can be used when working with microcircuits, since the low melting point will not cause technical problems, and most importantly, it minimizes the risk of damage to the thin surface. Unlike other solder models, which work with high temperatures, which can damage the condition of the working surface, using POS 61, with the proper skill and equipment, is absolutely safe even for the thinnest metal.

The low temperature point at which the material begins to melt helps achieve another important property of the material. It lies in the fact that in addition to its main use as a consumable for soldering, it can be used as a substance for tinning a soldering iron and working surface

There is a characteristic feature, the essence of which is that the less lead is present in the chemical composition of the solder, the more various additional elements there are. The rarest element, which is found quite rarely in alternative models, is antimony. Its presence makes it possible to obtain connections with the maximum level of tightness, which significantly improves the quality of the final result of the connection as a whole.

Solder POS 61 GOST 21931 76 is very often used in the process of repairing pipelines and other products whose working activities are carried out in constant contact with water and other various liquids. The high level of popularity is due to the ease of use of this material model.

Flaws

- Difficult to use, as it requires a lot of experience from the master;

- The work requires special tools, which are not always available on the farm;

- Used exclusively for hard-melting metals.

Varieties

Solder for brass from the brass itself. It is often a metal with small additives that help make the melting point a little lower without significantly changing the properties. It is the most difficult to use, as there is a risk of burning the base metal. However, it is the strongest alloy and produces the highest quality joint.

Copper-phosphorus alloys are also used as brazing alloys for brass soldering. They have a lower melting point and are easier to use. This is one of the most popular options, as it combines simplicity and high quality, and also has anti-corrosion properties.

Solder with copper-phosphorus alloys

Silver solders. Grades with low silver content, around 40-60%, which are of the hard type. They lack the ability to withstand high temperatures, but can be easily used even by beginners. Their cost is higher than that of other brands used for this purpose.

Silver solders

Chemical composition

The composition of copper-phosphorus differs from silver and is as follows:

| Brand | Element content, % | ||

| Silver | Copper | Phosphorus | |

| PMF 102 | 2 | 91,3 | 6,7 |

| PMF 105 | 5 | 88,5 | 6,5 |

| PMF 115 | 15 | 80,2 | 4,8 |

Softer grades, such as POS 40, contain more silver, but at the same time contain a lot of other elements that make it possible to maintain a high strength of the compound.

| Element | Percentage |

| Silver | 40 |

| Cadmium | 28,5 |

| Zinc | 17 |

| Copper | 17 |

| Nickel | 0,5 |

| Iron | 0,1 |

| Lead | 0,05 |

| Bismuth | 0,005 |

Technical characteristics of popular brands

Copper-phosphorus grades have the following characteristics:

| Solder grade | Melting point, degrees Celsius | Spreading temperature, degrees Celsius |

| PMF 102 | 645 | 820 |

| PMF 105 | 630 | 780 |

| PMF 115 | 650 | 800 |

The silver-containing parameters are as follows:

| Property name | Meaning |

| Melting point, degrees Celsius | 590-610 |

| Specific resistance, Ohm | 70 |

| Specific heat capacity, J/kg degrees | 20 |

| Density, kg/cm3 | 9250 |

Features of choice

The selection of material depends on the purpose of soldering. For example, brass soldering wire is used in cases where it is necessary to connect parts of metal structures and repair cracks that have appeared. Due to its shape and relatively small diameter, it allows you to fill places of deep damage, and also does not run the risk of missing metal. This material is suitable only for critical structures, and is also recommended for use only by experienced craftsmen.

Brass solder with flux turns out to be more convenient to use, so for more comfort you should opt for it. Here you don’t have to use borax and other fluxes, since they are already contained inside. Such options have a higher cost, but this pays off during use, as fewer defects occur.

When choosing which solder to solder brass with, you should look at the most common option - copper-phosphorus alloys. They combine economic advantages and high resistance to high temperatures and physical stress. If there is no need for ultra-high strength, then options such as PMF series solders become the most optimal choice.

Grades with a high silver content are used in cases where the responsibility for joining is minimal, or where there are no tools to melt hard grades at high temperatures. The joining process itself is much faster than other types of brazing.

Soldering Features

One of the main features is the use of borax as a flux. Without it, nothing may stick and the connection will be at an extremely low level. Thanks to the borax, all films and deposits are removed, and the penetration of the filler metal into the pores is improved. It is also worth considering the peculiarity of the high melting temperature. Here only a gas burner is used, since other methods will not achieve a tedious result.

Manufacturers

These products are produced by both domestic and foreign companies:

- BrazeTec;

- Castoline;

- Unitor;

- UkriIntersStal.

Composition and characteristics

Chemical components

It was previously mentioned that PIC solder consists of an alloy of tin and lead. Tin has a lower melting point than lead, so by varying the percentage of these two components, you can select certain temperature characteristics. POS 60 has the following chemical compounds in its composition:

- Tin. The share is 59–60.5% of the total mass.

- Lead. The percentage content ranges from 39 to 40.5% by weight of POS.

- Impurities. They are represented by various elements such as copper, iron, antimony, nickel, zinc and others. Their mass fraction is no more than 0.3% of the total mass of the alloy.

Chemical composition of POS61 solder

Other metals also influence the technical properties of the solder alloy.

Physical properties

The large amount of tin contained in this brand of solder directly affects its temperature characteristics and physical properties. Thus, POS 60 has the following properties:

- Melting point 183-190 degrees Celsius.

- Density 8.5 grams per cubic centimeter.

- The resistivity is 0.137 ohms per meter, which is 9–15% of the conductivity of copper.

- The tensile strength corresponds to the limit for soft solders and is equal to 50–70 MPa.

- The Brinell hardness is 14.9 PV.

- Thermal conductivity is 0.117 W/(m×k). Tensile strength is 4.3 kg/mm.

Physical properties of POS 60 and other solders

It is worth noting that tin and lead are identical in both softness and viscosity. Both of these metals have a characteristic of 1.5 on the Moss scale, so their percentage does not affect the physical properties of the solder.

Varieties

Conventionally, solders can be divided into hard and soft. The temperature limit between them is approximately 300 degrees. Soft solders melt at temperatures below this limit, and hard solders, respectively, above. In addition to the melting point, hard and soft solders are distinguished by different strength limits. For soft ones this limit is below 100 MPa, and for hard ones it is higher.

Soft solders are mostly an alloy of lead and tin, depending on the percentage of which the melting point varies. The more tin there is in the alloy, the lower the melting point. Solid ones consist mainly of an alloy of copper and zinc or silver with various additives. Tin-lead solder POS 60 belongs to the category of soft solders.

Increasing environmental standards require the elimination or minimization of the amount of lead in materials used for soldering. Therefore, lead-free solders are entering the market, in which there is no lead at all. It is replaced by other metals such as silver, zinc, indium, copper.

In addition to the high price, such solders have very poor wettability or fluidity, so they have not yet become widespread.