- Application of tapes

- Typology of paintings

- Saw maintenance

- Features of breeding tape webs

- How to properly sharpen a blade? Method 1: Full profile sharpening

- Method 2: Sharpening the tooth edges

A properly sharpened band saw for metal and wood is the key to productivity and long service life of the tooling. As a rule, such services are provided by special organizations, but if you know the sequence of actions and features of the process, you can sharpen a saw that has become dull on your own.

Design features of band saws

- Band devices intended for cutting wood are made from alloy tool steel, which has a hardness of 40 to 46 HRC.

Elements of a tooth.

- The width of the cut (kerf) of band tools is much smaller than that of disk analogues. When cutting cheap wood, this point is not so noticeable, but when cutting valuable and exotic types of wood, it is critically important.

- The machine can cut workpieces of any size. At the same time, the band tool works quickly and creates a high-quality cut.

- There is very little waste (shavings, sawdust) when using this type of saw.

Note! In order for the machine to always work stably and efficiently, its maintenance should be approached with the utmost responsibility. Sharpening and setting of band saws for wood must be carried out in a timely and competent manner.

Profile, teeth and sharpening angle

International classification of tooth profiles.

Tape devices have different tooth geometries, which depend on the type and characteristics of the materials being cut. Wood tools can be carpentry or dividing. There is a third type, designed for sawing timber and logs. All these subspecies have their own parameters and shape of the teeth.

The sharpening angle of wood band saws is selected by the manufacturing company based on several points. The main one is that the harder the material, the smaller the rake angle should be. Below is a table with the main parameters of the saws.

Saw characteristics | Carpentry fixtures (1 profile) | Dividing analogues | For cutting logs and beams (4 profile) | ||

| 2 profile | 3 profile | ||||

| Thickness of the canvas, mm | 0.6-0.9 | 0.9-1.2 | 0.9-1.2 | 1.4-2.2 | |

| Width of the canvas, mm | 10-60 | 50-175 | 50-175 | 230-350 | |

| Teeth pitch, mm | 6-12 | 30-50 | 30-50 | 50-80 | |

| Height of teeth, mm | 2-6.5 | 9-13 | 7.5-15 | 16-24 | |

| Rounding radius at the cavity, in mm | 1.5-2.5 | 3-4 | 3-4 | 5-8 | |

| Rear angle, in degrees. | 35 | 20 | 15 | 12 | |

| Sharpening angle, in degrees. | 50 | 45 | 45 | 53 | |

| Front angle, in degrees. | 5 | 25 | 30 | 25 | |

This is interesting: How to make a spot welder from a regular microwave

When to sharpen a circular saw

There are very definite signs by which one can judge the condition of the instrument. Saw sharpening is necessary when the following clearly appears:

- During operation, smoke appears, a specific smell of burnt wood, the casing covering the saw teeth begins to heat up quickly.

- When moving the tool along the workpiece, you need to apply significant effort, as if pushing the saw forward.

- After cutting the material and visually inspecting the sawn edge, black deposits or many chips, fiber burrs, and chipped areas are visible.

- When you carefully examine the saw teeth through a magnifying glass, you can see that the cutting parts have rounded edges rather than sharp ones.

How to properly sharpen a band saw for a band sawmill! Master Class!

All this requires immediate cessation of work, otherwise there is a high risk of damage to the material and wear of the circular saw to a state where sharpening will no longer help it.

Use of machines

Using a special machine, circular saws are sharpened very easily and quickly. The main thing is that there is no need to monitor the angle of the disk feed. Once it has been set, the operator only has to move the teeth into the processing area and lightly press the tooth plane against the rotating diamond disk.

Sharpening a band saw efficiently and quickly

This equipment can be used to sharpen carbide-tipped circular saws and conventional circular saws. The simplest machine for sharpening operations of circular saws has the following structural elements:

- An electric drive with a grinding disc fastening system is a stationary part of the equipment.

- The stand, which moves along the guides, is responsible for feeding the saw blade into the processing area.

- A saw blade clamp on a stand, which is designed to hold the blade in a constant position when it is fed to the sharpening disk.

READ Is It Possible to Pour 95 Gasoline into a Chainsaw?

Pay special attention! Discs with different types of teeth require an individual approach to sharpening. When the front edge is beveled, it is fed into the processing area at an angle to the horizontal, for which one edge of the stand is raised accordingly.

If you have additional questions about saw sharpening or you have experience in carrying out such operations, please respond in the comments! Your comments are important to us!

The process of constructing private houses and various buildings will be quite complex without the use of a circular saw. It is significantly better than many wood saws because it surpasses them in accuracy and cleanliness of the cut.

Due to the fact that this tool is actively used, it wears out quite quickly, and therefore sharpening circular saws with your own hands becomes extremely necessary.

Self-sharpening

Many home craftsmen do an excellent job of sharpening circular saws without a special machine. Most owners of circular saws have long been accustomed to sharpening saw blades on the fly, using an ordinary file or other available sharpening tools. However, this method is very inconvenient and traumatic. In addition, when sharpening by hand, you can accidentally miss individual teeth. Therefore, this method should not be used.

Experienced sawmills usually make a round wooden stand for sharpening saws, on which the saw blade is placed. The operating principle of such mini-machines is approximately the same as the operating principle of industrially produced machines.

Masters believe that before sharpening saw blades should be slightly damp - this makes sharpening much easier. To do this, sharpeners wet the saw blades with water and various chemicals. However, experts say that in fact this method only brings harm. Any liquid corrodes the metal and causes it to corrode, that is, contributes to the appearance of rust.

When sharpening yourself, you need to be careful not to miss a single tooth. Even if only a few teeth have become dull and the rest remain sharp, absolutely all teeth need to be sharpened. It will work correctly only if all sawing elements are sharpened equally.

Sharpening yourself is not as difficult as it seems. How exactly to sharpen a saw, on an industrial machine or on a primitive stand, is up to each home craftsman to choose for himself. However, in any case, it is necessary to strictly observe basic safety precautions and sharpen the teeth as sharply as possible. If you encounter difficulties associated with sharpening a circular saw at home, you should consult a specialist. If you regularly maintain your circular saw, it will serve faithfully for many years.

A disk tool for cutting wood is always useful during construction. A circular saw is convenient because it allows you to quickly cut material with minimal effort and time. As for the quality of the cut, we can say that it is ideal, but only when the saw is in good working order and well sharpened. Otherwise, working with such a tool is even dangerous, so you should sharpen the circular saw.

It is not difficult to determine the need for sharpening: a blunt tool cuts the workpiece poorly, which is immediately noticeable. There are two options here: either take the blade to a workshop, which is not always profitable in terms of time and money, or sharpen the circular saw yourself. This may seem complicated at first glance. But if you delve into the essence of the saw in more detail, it will not be difficult to service the tool at home.

Preparing the device for work

With constant use of the tool, a decrease in the quality of the cutting edge is inevitable. It becomes dull, and the width of the teeth is reduced. Based on this, sharpening a wood saw and setting it up are necessary components of the maintenance of a band saw machine.

It should be noted that the setting of the teeth should be carried out before sharpening them, and not vice versa.

Tool layout

Application of an adjustable machine.

Setting is the process of bending the teeth to the sides. This operation is necessary to ensure that the saw blade does not clamp in the workpiece, and also to reduce friction during operation.

There are 3 main types of breeding.

- With the classical method, the cloves are bent left and right in strict order.

- With the stripping method, every third of the teeth remains in its original position. It is optimal for devices designed for cutting particularly hard wood.

- With a wavy setting, each tooth is given its own separate bend value. In this case, the profile of the canvas takes on the appearance of a wave. This method is the most complicated.

Note! When setting, you should not bend the entire clove, but only a third or two-thirds of it from the top. Manufacturing companies advise performing the operation so that the bending range is within 0.3-0.7 millimeters. The work is carried out using a specialized spreading tool.

Sharpening the saw

Elbor circles having different shapes.

Before sharpening a saw blade for wood or a band tool, keep in mind that more than 80% of incidents with damage to devices (including their rupture) occur due to non-compliance with work standards.

- The need for surgery is determined visually. In this case, you should pay attention to the condition of the teeth and the quality of the cut walls (for example, their increased roughness).

- The circles for the point of the band tool are selected based on the degree of hardness of the teeth. To work with tools made of tool steel, corundum discs are required. Bimetallic saws are sharpened on borazone or diamond wheels.

- The shape of the emery for belt devices must be selected based on their parameters. Cup, profile, plate, and flat circles are known.

- Before carrying out the operation, it is necessary to turn the saw out and let it hang in this position for about 10-12 hours.

Manual tool maintenance.

The wood saw sharpening scheme should take into account the following provisions.

- Metal removal along the profile of the teeth should be uniform.

- Excessive pressure from the sharpening device must be prevented. It can lead to annealing.

- The profile of the blade and the height of the teeth must remain unchanged.

- Liquid cooling must be provided during the operation.

- There should be no burrs on the teeth.

Pay attention! The theoretical instructions for sharpening band saws on wood indicate that it should be done either on the front side of the teeth, or on both the back and the front. In real life, most specialists and amateur craftsmen perform the operation only on the back side, because it's more convenient.

Sharpening methods

The photo shows automatic full-profile sharpening.

You can prepare a tool for work using special sharpening devices (for example, machines with wheels of different materials and shapes) or manually. Before you properly sharpen a wood saw, you should learn the basic methods for carrying out this operation.

The first method is full-profile sharpening.

- It is of the highest quality, the operation is carried out on an automatic machine.

- Elbor emery, chosen exactly in shape, passes the entire surface of the interdental cavity along with the accompanying planes of adjacent teeth in one movement.

- The creation of angularities at the tips of the teeth is completely eliminated.

- A relative disadvantage of such sharpening is the need to have at your disposal the appropriate number of wheels for blades with different profiles.

A tool sharpened along the edges.

The second method is to sharpen the edges of the teeth.

This can be done either manually or using a professional machine.

- Having chosen a machine, you need to decide on the wheel to be used. As a rule, it is flat. Specialized sharpening devices should only be used when there is a lot of work to be done.

- In domestic conditions, sharpening is best done with your own hands - using regular mechanical sandpaper or using an engraver. When performing the operation, do not forget about personal protection and use gloves, a mask or special glasses.

Working with an engraver.

- When you and your neighbors don’t have an engraver, machine, or emery, you can sharpen a band saw using the traditional folk method - using a needle file.

Recommendations for sharpening

During operation of the canvas, its rupture is very often observed. This is explained by the fact that its sharpening is poorly carried out. This is explained by the concentration of stress in the profile of the blade if sharpening is carried out at a poor level. The need for the procedure is determined by the condition of the band saws. If the roughness of the cut surface increases, this leads to dulling of the tool.

Tool sharpening is carried out using diamond, electrocorundum, and CBN discs. Their choice directly depends on the characteristics of the material being processed. Sharpening of blades, the production material of which is tool steel, is carried out with corundum wheels. The procedure for bimetallic tools is carried out correctly if a diamond or CBN wheel is used. The instructions will tell you how to carry out this procedure. The most important thing is that the angle does not change during the process.

Wheels of various diameters can be used for sharpening. The choice of one of them is determined by the parameters of the device. For this purpose, profile, flat, dish-shaped, cup circles are most often used. Sharpening is carried out correctly if the peripheral speed is from 20 to 25 meters per second.

Application of tapes

The key component of every band saw is the band saw (blade). Band saws are widely used when working with wood, metal, rubber, plastic and various flexible materials.

There are three types of these products.

- Manual tape devices - these machines can be called household ones; they are most often used at home.

- Desktop modifications - these units are often purchased for small industrial facilities, woodworking companies, and workshops.

- Stationary units - such installations are classified as professional; they are used in large industries, factories, factories, large workshops, and so on.

How and how to sharpen chain teeth

The saw chain teeth have a non-standard shape. They consist of a base, a blade and a depth stop. The blade has a vertical blade and a horizontal blade that falls at an angle. It is thanks to these blades that a chainsaw cuts wood. They work on the principle of a plane, cutting off pieces, and the limiter regulates their thickness (the difference in height between it and the horizontal blade will be the thickness of the chips). You can sharpen a chainsaw chain manually or using a machine.

3.2 Use of manual and automatic machine

Files are not suitable for all chains. When the cutting edge loses its original appearance, you have to use a machine.

The operating procedure for the manual unit looks like this:

- unscrew the adjusting screw of the chain clamp,

- install the chain, turning the links in the direction of the grinding wheels,

- set the recommended angle,

- The teeth are processed in two ways: sequentially (with reversal of polarity) or alternately.

The degree of sharpening is determined by the bluntest tooth. Grinding is done shallowly to avoid reducing the strength of all elements. At the end of work on the machine, the chain is blown with compressed air and dipped in machine oil for several hours.

The main advantage of this method is to achieve maximum accuracy, which is impossible when using a file or grinder.

Sharpening is often done on automatic machines. Similar machines are installed in workshops and factories, but some owners can afford such a device at home. It is presented as a small “box” with a built-in sharpening stone. The saw is inserted inside, fixed and closed.

The electric mechanism is adjusted to full power, as a result of which the chain is automatically sharpened on the stone. This process takes a few minutes, but the owner of the machine needs to purchase additional chains from the manufacturer that produced this device.

Typology of paintings

The basis for the division of saws of this type is the material of manufacture and the elements being processed. In accordance with such aspects, the following types of canvases can be distinguished.

- Wood saws. The key materials for their manufacture are carbon and alloy steels; their hardness reaches 40–45 HRC. All teeth are subject to mandatory hardening with high-frequency currents. It should be noted that this blade material can be used for cutting thin non-ferrous metals or carbon steels.

- Canvases for metal. Such tools are made from high-speed or spring steel (cobalt and tungsten are added to the structure). These saws already carry a strength of up to 69 HRC. To obtain high hardness and broad capabilities, stellite or other types of durable alloys can be welded onto the teeth.

Common mistakes

If a person tries to sharpen a saw for the first time, it is difficult for him to fulfill all the requirements and remember the nuances of the technological process. However, violation of these rules leads to the fact that the efficiency of using a band saw is noticeably reduced, the load on the blade increases, which leads to premature rupture.

Professionals recommend avoiding the following mistakes:

- during mechanical sharpening, the abrasive stone is positioned incorrectly relative to the saw profile. In this case, the sharpening of the teeth will be uneven;

- excessive force when contacting the saw and the grinding wheel. As a result, the metal overheats, scale appears, which leads to premature wear of the cutting edge;

- burrs remain on the canvas. After sharpening, all roughness must be eliminated, otherwise microscopic cracks will appear on the metal during operation;

- using your own sharpening angles. Many inexperienced craftsmen believe that only sharpness is important for saw teeth, so they shamelessly violate the geometry of the cutting edge profile recommended by the manufacturer. It is important to understand that the shape of the tooth has been tested over the years; it is useless to try to experiment here.

Instead of a conclusion, we will add that each band saw has a certain resource, so the blade cannot be sharpened indefinitely. Manufacturers guarantee correct operation of the tool until the total width of the blade is reduced to 65% of the original size.

Sources:

https://crast.ru/instrumenty/kak-zatochit-diskovuju-pilu-v-domashnih-uslovijah https://samastroyka.ru/zatochka-pily-po-derevu.html https://ventanaspb.ru/info/ kak-zatochit-cepnuju-pilu-v-domashnih-uslovijah/ https://drevogid.com/instrumenty/pily/zatochka-lentochnoj.html

Teeth and sharpening angles

Band saws have different tooth geometries due to the different types and properties of the material being processed.

If we consider wood, then the teeth are divided into:

- - carpentry;

- - divisive;

- - for sawing logs.

As for sharpening angles, the manufacturer determines this parameter. Basically, it is accepted that the harder the material, the smaller the rake angle.

For metal band saws, the teeth are usually shaped either standard or with a positive rake angle. Let me clarify this point a little: the standard tooth shape is used for sawing thin-walled material, and the shape with a positive rake angle, as you might guess, is used for cutting thick-walled material.

I suggest looking at a small picture that can explain what profiles a tooth can have and where they, these same profiles, are applicable.

In addition, the pitch of the teeth is important. So, for example, for a thin-walled material you should use a tool with a small number of teeth, and for thick-walled material, on the contrary, with a large number of teeth per inch.

Now let's take a look at the picture, in which we can clearly see how saws with variable tooth pitch differ from saws with a constant tooth pitch.

Often, saws are made with variable pitch in order to eliminate the resonance effect.

Next, I propose to find out what types of band saw layouts there are.

This is interesting: Characteristics and passport of the 2M112 desktop drilling machine

How to sharpen a wood saw

Sharpening a saw on wood is not a difficult task, but at the same time it requires some knowledge and experience, and most of all perseverance and patience.

READ Assembly of the Stihl 180 Saw

The latter, by the way, is very useful if you need to sharpen the saw with a file manually. As for sharpening a saw with a grinder, this kind of work can be done the fastest, but there are also some nuances here.

How to sharpen a saw with a file

So, in order to sharpen a wood saw with a grinder, you should clamp the saw in a vice or clamps to a solid base. Then, using a grinder, the teeth are carefully sharpened. Here it is important not to overdo it, feel how the grinder works, and do all the work of sharpening the saw, slowly and carefully.

Do not forget about precautions, since working with an angle grinder can harm your own health. Before sharpening a saw with a grinder, be sure to wear safety glasses over your eyes to prevent scale from getting into your eyes. It is also worth securing the saw firmly and only after that you can begin to sharpen the saw.

So, as you can see, sharpening a wood saw with your own hands is not so difficult. For these purposes, you can use both a file and a grinder. But be sure not to forget about your own precautions, act as carefully as possible and, of course, take your time.

Characteristics

Sharpening a band saw has a number of the following features:

- It is prohibited to use abrasive discs and hand-held sharpening tools with uneven wear on the working surface;

- when turning, it is important to perform all movements evenly, without jerking or uneven movement of the tool, since there is a high probability of violating the geometry of the teeth;

- the machines used must have liquid cooling to prevent overheating of the equipment and tape;

- after completion of the work, there should be no burrs or chips on the surface, as they can negatively affect the quality of cutting;

- when sharpening a tool for winter use, it is important to increase the angle of inclination of the teeth to 900, however, it is unacceptable to use such a tape for woodworking in the summer due to increased loads on the cutting edge;

- when sharpening on machines, you need to make sure that the disk is positioned correctly relative to the belt profile;

- the speed of the grinding disc is selected so that the metal is not heated red hot, since in this case it will lose its strength properties;

- if the band saw has been operated without maintenance or the recommended service life has been exceeded, then when turning you will need to remove a larger layer of metal in one pass;

- to control the quality of tool sharpening, it is recommended to use a new tape as a standard;

- It is prohibited to change the factory shape of the teeth, as the saw will become unsuitable for use;

- the need for sharpening is determined by the degree of wear of the teeth by 35% of the original dimensions.

Recommendations from experts

- If a tool sharpening machine is used, it should be inspected before use to determine whether the wheel is in the correct position relative to the saw.

- This layer of steel must be removed from the sinuses to ensure that all microscopic cracks are removed.

- If the saw has been used without maintenance for longer than the period allowed by the manufacturer, the amount of metal removed during sharpening should be increased.

- To check the results of the operation, always use the new product as a reference.

The result of incorrect operation is burnt out tool teeth.

- The shape of the teeth is a characteristic developed and tested by specialists. If you change it, you will not be able to process parts efficiently. Based on this, sharpening must be done so that the shape of the teeth and the profile of the blade remain the original ones, manufactured at the factory.

- If all operating and maintenance rules are followed, the band tool will serve you faithfully until its width is worn down to 65 percent of its original size.

There is an opinion among amateur craftsmen that there is no particular need to remove burrs formed during processing. This is fundamentally incorrect, since microscopic cracks may appear on the canvas.

After completing the work, the tape device must be immediately cleaned of tree sap, sawdust, and resin. Before starting maintenance, the tool must be carefully inspected, otherwise the wheel will clog. This will lead to a significant reduction in sharpening efficiency.

Saw maintenance

To maintain the blades, it is not enough to sharpen the teeth; they also need to be set apart. These two procedures are performed in order of succession: they begin with setting the teeth, and end with sharpening them. This chronology of work must be strictly observed. Dilution is carried out in order to reduce saw friction in the process of cutting a particular material (wood, metal, plastic, etc.). There are several methods of breeding, which depend on what elements need to be obtained after processing and the strength of the starting piece.

How to know when it's time to sharpen your circular saw

Sharpening a circular saw should only be done when necessary. You can recognize the onset of such a moment by two clear signs. In particular, urgent sharpening of a wood circular saw is necessary:

- If strong heat regularly occurs on the safety guard of the saw in the area of the electric motor. In some cases, with such an increase in temperature, smoke is released under the casing.

- With strong pressure on the tool to obtain a good cut while processing the material.

- If dark marks appear, traces of soot on the wood and a characteristic smell of burnt wood. This occurs due to the fact that the teeth of the saws are dull.

Sharpening methods

Sharpening a band saw for wood can be done in one of the following ways:

- full profile;

- only edges.

Full profile turning has the following advantages:

- operations are carried out with high precision, as they are performed on automated machines;

- specially shaped emery passes the entire surface of the space between the teeth simultaneously with the planes of adjacent cutting edges in one movement;

- tops of regular shape without angularity are formed.

Sharpening of edges can be done in the following ways:

- A machine with a flat abrasive wheel or a special shape is selected, depending on the profile of the cutting edges.

- At home, it is recommended to carry out processing with an engraver or regular sandpaper of suitable sizes. To operate, you will need to wear goggles and gloves.

- In the absence of tools from points 1 and 2, the use of needle files is allowed.

Peculiarities

A saw of this type is a closed band of teeth. This design has a number of advantages over other saws.

A band saw is useful in situations where it is necessary to cut some expensive raw materials, as the teeth create a neat and narrow cut, thereby keeping the maximum amount of material intact. For example, you can use a wood band saw when working with valuable wood materials.

If you sharpen the teeth of such a saw correctly and at regular intervals, then the tool will efficiently perform its task, namely: instantly, accurately and with a small amount of waste, cut parts from almost any material.

There are two main ways to sharpen a band saw.

1 way

Referred to as full-profile sharpening. It is produced on an automatic machine, which immediately means that the sharpening will be of high quality. The principle of sharpening is based on passing the entire interdental cavity with the corresponding surfaces of adjacent teeth in one movement with a CBN wheel, which is directly selected according to the shape. It follows from this that we will not get angular shapes at the base of the teeth. This is simply out of the question.

Wheels are often used, the abrasive of which can be electrocorundum, CBN or diamond sputtering.

Perhaps the only significant disadvantage of this method is that different saws require different circles.

Method 2

Characterized by sharpening of the tooth edges. It can be done using a machine, then the circle is selected again. Manual processing is carried out by an engraver or on a conventional machine in compliance with safety precautions, or using a needle file (its essence is to make several movements along the front or back surface of the teeth)

To sharpen a band saw with your own hands, you need to:

- — eliminate strong pressure on the circle;

- — ensure uniform metal removal along the tooth profile;

- — ensure the preservation of the height, as well as the profile of the tooth;

- — control the absence of burrs;

- — use coolant.

If there are nicks on the surface of the tooth, the saw will quickly become dull. Therefore, it is important to have a smooth tooth surface. It is also necessary that the radius at the base of the tooth is maintained. This is necessary to prevent cracks and tearing of the fabric.

The saw should be sharpened as soon as there is noticeable force to move it in the wood. Most woodworkers are happy to sharpen their tools, but may call a professional if the teeth need to be set. The alignment should be done after 4-5 sharpenings or if the saw “moves away” from the intended direction due to incorrect alignment. Electrically hardened teeth cannot be sharpened by hand, and dull replacement blades for fine work are simply thrown away.

Sharpening and setting the saw

The main cutting element of any hand saw. a series of teeth cut on the blade and representing wedge-shaped cutters. Wood, in the manufacture of all kinds of products from it, is sawn along, across and at an angle Θ to its fibers; in this regard, transverse, longitudinal sawing and sawing at an angle to its fibers are distinguished, and in each case they use the appropriate type of saw, which differs from others in shape teeth

When cross-cutting, cross-cut saws are used, the cutting edges of the teeth of which, when moving in the wood, cut its fibers like a knife and form a cut. Longitudinal sawing differs from cross-cutting in that the direction of movement of the saw is parallel to the grain of the wood. The leading edges of the teeth of rip saws plan wood, like knives in planes, and, going deeper, form a cut. When sawing wood at an angle Θ, universal (mixed) saws with teeth that are an intermediate form of teeth for transverse and longitudinal saws are used to its fibers.

Sharpening the saw

Sharpening saw teeth. in its own way an art that requires faithful hands, a good eye, and attention. It is not difficult to learn this business, you must have the desire and strictly adhere to the following rules:

- The saw blade must be rigidly fixed in a special device made of wood, which is also firmly installed on a well-lit work table. Sharpening saw teeth on stools or knees does not give satisfactory results.

- You should use a personal file, followed by cleaning the sharpened edges of the teeth with a velvet file (with a fine notch) or a needle file. It is advisable that the file be new, sharp and with a mounted handle. If you don’t have one at the right time, you can use a second-hand one, but it must be cleaned with a steel brush and rubbed with charcoal so that the file does not become clogged or dull. When sharpening a tooth, the file must grip the metal and remove its layer depending on the force of pressure. And if it slides over the tooth without removing the metal, then the saw teeth are overheated or the file is worn out. In this case, it is necessary to repeat sharpening with a new file. If in this case it slides along the tooth, then you just have to take another saw.

- The handle of the file is clamped with your right hand, and its end is held with your left hand and the file is directed towards the teeth of the saw. How to use a file depending on the type of saw is described below.

- The pressure of the file on the teeth should be smooth and uniform and only in one direction away from you. When returning the file to its original position, it should not touch the teeth.

- You should try to grind the metal from the edges of the teeth to a minimum of the same thickness, moving the file the same number of times with the same pressure, which allows you to maintain the angles, pitch and height of the teeth after sharpening.

- Burrs form on the edges of the tooth on the side where the file exits, which reduce the sharpness of the tooth, and if they are not removed, then during the operation of the saw they chip and the teeth become significantly dull. To remove burrs, the edges of the teeth are sharpened with a file with a velvet cut and the burrs are removed from the side edges with a wet whetstone.

- After sharpening the teeth, you need to check their sharpness. Look at the point of the needle and the edge of the razor blade: although they are sharp, they do not shine in the light. And if they are dulled, then rounded surfaces appear on the tip of the needle and on the edge of the blade, which reflect light and shine well. This principle is used to check the quality of saw teeth sharpening. To do this, place the saw in front of your eyes and examine its teeth along the blade. If their cutting edges and tips do not shine, then the saw teeth are sharpened satisfactorily, and if some of the teeth are shiny (this often happens), then they need to be sharpened with a velvet file, remove the burrs and again check the reflection of light on their edges and tips.

Crosscut saws. The teeth of cross-cut saws are sharpened using a finely cut triangular file with an apex angle of 60°.

To sharpen the teeth, the saw is clamped into a special device that allows you to set its blade at an angle of 45-50° to the plane of the work table. The file is led parallel to the work table at an angle of 60-75° to the saw blade and thus the left edge of A1A2B2B1 is sharpened in the first tooth.

The saw teeth are sharpened in several stages. First, a file is passed along the left edges of the odd teeth located in the far row, tuning the hands for the same movement. Then they pass the file along the right edges of the same odd teeth, finishing sharpening the main cutting edges with very sharp tips. After sharpening the odd teeth is completed, the saw blade in the sharpening device is turned over and thus the even teeth that are in the far row are sharpened. When sharpening the teeth of cross-cut saws, it is necessary to carefully ensure that each tooth has sharp main cutting edges with a dihedral angle φ = 60-75°, a short cutting edge and a sharp tip.

Rip saws. The teeth of longitudinal saws, in which the angle π

What can you sharpen with?

A small blade with small teeth can be sharpened with a special needle file or a regular machine attachment. However, such sharpening is very time-consuming and low-productive, and also very often causes a number of saw breakdowns. Taking these problems into account, many craftsmen have long been using an electric sharpening machine, which quite quickly and equally sharpens all the teeth of a band saw.

Such machines are divided into several groups.

- Fully automatic centers , they use a specialized feeding and sharpening program; such machines are used mainly by large workshops for sharpening or restoring large and massive band saws. The process takes place using cooling chemical liquids and under strict control.

- Semi-manual machines with special tool consoles.

- Small automatic centers , in which the step of moving the web is adjusted and the process is controlled.

A sharpening machine is a unit that helps sharpen a saw efficiently using a sharpening wheel. Most often, a specific unit is selected for a certain type of saw.

The machine includes:

- base and external structure;

- tool holder;

- special drives used to move the blade and rotate the grinding wheels.

How to sharpen a circular saw at home

Sharpening saw blades for wood is one of the most important activities for caring for a circular or circular saw. If you don't sharpen it, it will quickly become dull and become unusable.

It is most convenient to sharpen on a special production machine. However, many home craftsmen make their own design for this purpose, which significantly saves time and money.

Saws made from high-quality materials become dull less often, which means they require sharpening infrequently. However, if the discs are made of low-quality material (and this happens quite often, and even an experienced master cannot always determine the quality of the metal “by eye”), most likely they will have to be sharpened often. Therefore, any home craftsman who uses a circular saw should know how to sharpen it.

Sharpening blades in winter

If everything is clear about sharpening blades under normal conditions, then sharpening in the cold season needs to be said separately. There is a difference in sharpening tape blades in summer and winter cold. It consists of changing the degree of sharpening. The angle that applies to blades in winter should be 90 degrees, in contrast to summer, when the sharpening angle is 120 degrees.

Recommendations from experts.

- When sharpening a blade using a machine, before starting the process, you need to ensure the accuracy of the location of the grinding wheel in relation to the tool.

- It is extremely important to remove such a volume of metal from the recesses so that all microcracks are reliably eliminated.

- If the blade has operated without normal maintenance for a longer time than the manufacturer allowed, the volume of metal removed in one pass must be increased.

- To test the effects of sharpening, always use a new blade as a sample.

- The tooth configuration of the blade is an indicator that has been worked out and adjusted over the years. Therefore, relying on the device to cut “without a hitch,” no matter what you do with the teeth, is a huge mistake.

- If operating standards are followed, the belt web will work conscientiously until the width is reduced to a value equal to 65% of the initial parameters. The width decreases, of course, during sharpening.

- There is absolutely incorrect advice that there is no particular need to remove burrs after sharpening. If you take this into account, then the occurrence of microcracks in the saw is guaranteed.

- Upon completion of the work, the tape blade must be cleaned of chips and resin without shelving, and carefully inspected before sharpening. Otherwise, the risk of contamination of the sharpening discs is very high. And this will certainly lead to a poor-quality sharpening process.

How to sharpen a chain saw at home

Proper use and care have a significant impact on the quality and performance of the tool. For comfortable work, you need to sharpen your STIHL chainsaw chain on time. A dull chain can be taken to specialists or you can sharpen it yourself, especially since the whole process is not particularly complicated. You just need to acquire a certain skill, since the teeth on it have an unusual shape.

Description of the sharpening process using files

The first step in straightening a saw chain on a saw is to place the tool on a flat platform or table. In forest conditions, a large diameter chock is well suited for this. Next, you need to inspect the saw chain for any defects, these could be cracks or completely broken teeth. After inspection, you need to set the brake to working condition, thereby blocking its movement on the tire.

The chain must be tensioned when sharpening with a file.

It is advisable to place a stand under the bar; you can use a log, a piece of a branch of a suitable diameter as it, or manufacturers of sharpening tools have special clamps to hold the bar while sharpening the chain.

The chain is sharpened by moving the file from the inside of the tooth outwards. In this case, the file should be located parallel to the special mark on the chain. This mark is applied by the chain manufacturer to indicate the standard sharpening angle.

The tooth being sharpened should be located approximately in the middle of the bar, this is necessary for the convenience of work; during the sharpening process, you need to move the chain along the bar, not forgetting to set the brake to the working position each time.

The work of sharpening a chain on a chainsaw must be carried out using gloves made of rough material, otherwise it is quite easy to injure yourself, because the working surface of the teeth is very sharp.

Ideally, manufacturers advise performing the same number of file movements for each tooth, but in practice this is not always possible, because the teeth have varying degrees of damage to the working edge.

To facilitate sharpening the saw chain using a file, special holders with corner markings applied to them can be used. Markings are made not only for a standard transverse cut, but also for a longitudinal one.

Tool holders are also convenient to use if you do not have sufficient sharpening experience. Experienced craftsmen do not use holders for sharpening, but can only use special devices that support the file.

Another device designed for sharpening is a manual saw chain straightening machine. It uses a regular file as a sharpening tool, which you can replace yourself. The machine is mounted directly on the tire; it also has the ability to adjust the angle of sharpening the tooth and a special stop that holds the tooth being sharpened.

Manual sharpening machine, perfect for beginners. Along with electric models of sharpening machines, manual ones have their undeniable advantage in the form of a low price. Depending on the manufacturer of the manual machine, their appearance may vary, but the principle of operation is the same for all.

How to sharpen a band saw blade with your own hands, a simple device

Adjustment of the cutting depth is done using a flat file, so that there is a difference between the upper cutting edge of the tooth and the height limiter.

As can be seen from the figure, the depth stop is ground down in such a way as to bring the gap to the factory value. Below is a table that shows the main values of angles, as well as clearances for the most common types of chains.

As a rule, the gap size is adjusted using a special die. It is installed on the chain during sharpening, after which the depth stop is ground off.

2.1 Replacing the saw chain yourself

Companies that produce electric saws do not prohibit their owners from replacing chains with their own hands. The most common design of a budget unit has lateral tension. To replace the chain, perform the following steps:

- move the protective shield and at the same time release the brake,

- turn the tension screw with a screwdriver, unscrew the nut,

- release the cover and separate the tire from the sprocket,

- remove the old chain and install a new one,

- repeat all steps in reverse order.

After this, the chain should be smoothly tensioned. The final tension is done when the plastic cover is closed.

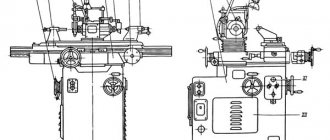

Sharpening machine for band saws - its structure, tooth alignment and instructions

The use of a sharpening machine for band saws allows you to quickly and efficiently restore the working surface of the tool and ensure the volume of wood cutting declared by the manufacturer before the blade breaks.

Mechanisms and machines for sharpening bandsaws

The use of band saws for sawing wood and other materials ensures minimal losses during the processing process and increases labor productivity. Circular saws have lower productivity and lower material efficiency.

The average cutting tool performance declared by various band saw manufacturers before breaking should correspond to a sawing volume of more than 60 m³ of round timber.

If the working part of the saw tooth is blunted or improperly sharpened, the productivity of the process drops sharply. After cutting, a large wave appears on the surface of the wood being processed and the saw breaks. Which negates all the advantages of such saws.

To properly sharpen a band saw, you must first restore the alignment of the teeth of the working blade. For this operation, an adjusting machine is used, which allows you to accurately adjust each tooth to the required angle. It allows you to bend a third or 2/3 of the tooth height, restoring the original profile of the tool.

To ensure high strength and wear-resistant properties, the saw blade consists of 2 parts welded together. The main blade is made of spring steel, capable of withstanding strong dynamic loads. The cutting surface of the tool is made of tool steel, increased strength and wear resistance, with a high content of tungsten and cobalt.

Since the hardness of the saw cutting edge material is above 45 HRS, corundum, diamond and CBN wheels are used for sharpening it. When sharpening, a borazon (CBN) wheel is preferable to a diamond one, although its hardness is 10-20% lower than that of a diamond one, but its chemical and thermal resistance is 2 times higher.

Borazon is a registered American trademark of technical cubic boron nitride, and elbor is a material synthesized in the USSR, having the same chemical formula, but manufactured using a different technology. Experts believe that grinding wheels made from Russian CBN are of higher quality and wear-resistant.

Design differences of machines for sharpening band saws:

- manually driven devices, which, through the action of a rotating abrasive wheel on a tooth, restore the sharpness of its edge;

- installations with a mechanical automation system for the sharpening process, which allows you to configure the necessary process parameters;

- automated centers controlled by computer systems.

A revolution in the technology of sharpening band saws was made by Wood-Mizer, which proposed a method in which a profiled borazone wheel restores both the tooth profile and its sharpness in one pass. The disadvantage of this method is that you need to have your own circle for each saw tooth profile.

The market offers sharpening devices for band saws in 3 price segments:

- 15,000-30,000 rub. - fairly cheap machines. These include sharpening mechanisms with flat wheels that sharpen the cutting edge of the tooth. A simplified version of the device with a disc for profile tooth sharpening.

- 85,000-130,000 rub. — expensive copies of Wood-Mizer devices and machines from the original company.

- 60,000-65,000 rub. - Russian machine developed in.

The first category of equipment does not provide full-profile grooving of the intertooth groove when sharpening with a flat wheel, thereby reducing the service life of the saw to sawing 15-20 m³ of round timber.

Simplified versions of machines for sharpening wood saws with a full-profile wheel suffer from the presence of large backlashes, which lead to the wheel beating and, as a consequence, incorrect sharpening and rapid failure of the CBN wheel.

In the second category, it is better to buy original Woodmizer machines.

The third group includes Russian machines manufactured at optimal cost and with characteristics exceeding foreign analogues:

- multi-profile CBN discs have wear resistance that is 30-40% higher than foreign analogues;

- ergonomic, thoughtful adjustment of the saw sharpening device, allowing you to correctly sharpen the tool’s tooth profile.

Popular models

On the Russian market, in the ranking of popular models of saw sharpening machines, the prestigious positions are occupied by budget machines from Voronezh, which produces a line of equipment under the AZU-02 brand. The company also produces machines for setting teeth RU-04/08M, -05, -07. In the more expensive price segment, the leader is the PZSL30 60 PROFI model, developed in the Moscow region.

Sharpening machine device

A semi-automatic machine that allows you to sharpen the edges of saw teeth is a structure consisting of a base on which is mounted an abrasive tool with a drive, a copier that tracks the tooth profile, a pusher, a system of control rods, a liquid cooling system and a remote control with installation controls.

The abrasive tool produces a translational movement up and down; using an adjustment device, the operator can change the angle of inclination of the sharpening tool. The copier provides control of the movement of the abrasive wheel in accordance with the profile of the cutting edge of the tooth, and sets the longitudinal displacement of the saw blade depending on the distance between the teeth.

To sharpen the cutting edge of metal saws, you need to adjust the equipment by changing the tooth sharpening angle with the controls.

How to sharpen a saw on a machine?

At home, in order to properly sharpen saw teeth with your own hands, you need to:

- restore the setting of the teeth by bending 2/3 of the tooth length away from the generatrix of the blade, restoring the initial setting angle;

- Use an abrasive tool to sharpen the edges of the teeth, removing microcracks from the surface of the material.

Basic rules that must be followed when restoring the cutting edge of a saw on a machine:

- set the teeth using special equipment, restoring the initial set angle;

- set the machine to remove enough material from the cutting edge to remove all damage and microcracks;

- sharpen with the cooling system turned on, preventing the tooth material from turning blue;

- start the sharpening process from the place where the blade is welded into a ring.

Sharpening options

There are 2 ways to sharpen saw teeth:

- Full-profile, produced on an automatic machine for sharpening band saws. A borazon wheel, corresponding to the tooth profile, restores the profile of the interdental cavity in 1 pass and sharpens the cutting edges of the tool.

- Sharpening the cutting edges of the teeth. Can be done manually or on a machine with a flat sharpening disc. At the same time, the edges are sharpened and microcracks on the working surface of the tool that formed during the work are removed.

The instructions for sharpening band saws will show the sequence of correct actions when performing this process.

Tools

Band saws are cutting tools used in band saw machines. They are a closed belt with teeth. They have a lot of their own, characteristic only for them, advantages. Band saws leave a significantly smaller cutting width than circular tools: while this fact may not be significant when sawing budget wood, then when cutting elite metal and cutting valuable wood species it is critically important. With their help you can cut absolutely any workpiece. In addition, band saws demonstrate good operating speed. provide high quality cutting surface. Reducing chip waste through their use is an obvious thing. However, in order to consistently experience all of the above benefits of working with the tool in practice, it is necessary to take a responsible approach to its maintenance. Sharpening of band saws, as well as their routing, must be done efficiently and in a timely manner.

READ Which File For Sharpening Chainsaw Chain

The price of sharpening band saws in specialized offices is usually low, but the speed and accuracy of the work is not always pleasing. Is it possible to cope with the task yourself? Of course, if you know how to sharpen band saws correctly and have the necessary equipment.

Subtleties of band saw wiring

As the tool is used, the quality of its cutting edge decreases. Therefore, setting and proper sharpening of band saws is a natural part of the work process.

Note! The divorce must be done before sharpening, and not after it!

Setting is the operation of bending the teeth to the sides to prevent pinching of the tool blade and reduce its friction. There are three main types of wiring:

classic - the teeth bend to the right and left sides strictly alternately; stripping - every third tooth is left in its original position. “Relevant” for tools used for cutting especially hard materials and alloys; wavy - each tooth has its “own” bend value, thus forming a wave from them. This is the most complex type of wiring.

Worth knowing! During divorce, not the entire tooth is bent, but only part of it - a third or two-thirds from the top.

The values of the spread recommended by manufacturers fall within the range of 0.3-0.7 mm. The operation is carried out using special adjustable instruments.

How to sharpen a band saw correctly?

It has been proven that over 80% of tool breakage cases occur due to non-compliance with the rules for sharpening band saws. The need for manipulation is determined visually - by the appearance of the teeth themselves or the condition of the cut walls (increased surface roughness). Wheels for sharpening band saws are selected depending on the hardness of the teeth. To sharpen products made from tool steel, corundum wheels are used. Bimetallic saws require diamond or borazon samples. The shape of the grinding wheel for band saws should be determined based on the parameters of the tool. It can be profile, cup, flat, dish-shaped.

Before starting work, it is recommended to let the saw hang inverted for ten to twelve hours.

Requirements for sharpening band saws with your own hands:

ensuring uniform metal removal along the tooth profile; avoiding excessive pressure on the wheel (this can lead to annealing); ensuring the preservation of the height and profile of the tooth; mandatory presence of coolant; control of the absence of burrs.

Standard instructions for sharpening band saws state that sharpening should be done either on the front surface of the tooth, or on both the front and back. But this is a theory. In practice, many professionals, and even folk craftsmen, “perform” it exclusively on the back surface - in their opinion, this is more convenient.

In general, despite a lot of rules and requirements, these tools are quite unpretentious in terms of sharpening. You can work with them either using a special sharpening device for band saws or manually; use wheels of different shapes and materials for processing, etc.

Before sharpening a band saw, you need to familiarize yourself with the basic methods of performing this operation.

It is of the highest quality and is produced on an automatic machine. The CBN circle, precisely selected in shape, passes the entire interdental cavity in one movement along with the corresponding surfaces of adjacent teeth. Obtaining angular shapes at the base of the teeth is excluded. The only drawback of such sharpening is the need to constantly have at your disposal a certain number of wheels for “multi-profile” saws.

It can be done on a professional machine or manually. If preference is given to the machine, then, again, you should choose the wheel wisely - usually these are flat samples. In general, it is recommended to use specialized sharpening equipment only in cases where the volume of work is quite large. Occasional “home” manipulations are best done manually - using an engraver or on a conventional machine. When working, for safety reasons, be sure to use a mask or safety glasses.

If you don’t have a machine or an engraver in your arsenal, then you can sharpen a band saw using the usual old-fashioned method - using a needle file. Three or four confident movements along the back or front edge of each of the teeth - and it’s, as they say, “in the bag.” With regular and diligent execution of the operation, the skill of high-quality manual sharpening will quickly appear.

A little theory: what is the instrument made of?

Wood saws are usually made of tool steel (hardness 45 HRC). For the production of metal products, Russian manufacturers turn to V2F, 9HF steels, and foreign ones. to C 75, etc. The teeth of such saws are “rewarded” with the highest hardness during the hardening process with high-frequency currents. Often when working with metal, a bimetallic belt tool is used: its blade is made of spring steel, and the belt with teeth is made of a high-m alloy of cobalt and tungsten. This high-speed steel is “attached” to the saw blade using an electron beam.

Tips from the professionals

If you sharpen a band saw using a machine, before starting work you must ensure that the sharpening disc is in the correct position relative to the tool. 2. It is very important to remove such an amount of metal from the sinuses so that all microcracks are guaranteed to be eliminated. 3. If the tool “functioned” without quality maintenance for longer than the manufacturer allowed, the amount of metal removed per sharpening should be increased. 4. Always use a new tool as a reference to check sharpening results. 5. The shape of the saw tooth is a parameter developed and verified over the years. Therefore, hoping that the tool will cut like clockwork, no matter what you do with the teeth, is a huge misconception. 6. If the operational requirements are met, the band saw will serve you conscientiously until its width is reduced to a figure equal to 65% of the original value. The width naturally decreases during the re-sharpening process. 7. There is a completely absurd recommendation that there is no particular need for deburring after processing. If you “listen” to it, then the appearance of microcracks in the canvas is guaranteed. 8. After use, the band saw should be immediately cleaned of resin and sawdust, and thoroughly inspected before sharpening. Otherwise, the risk of clogging the grinding discs is extremely high. And this inevitably entails a “clumsiness” of the sharpening procedure.

All about teeth and their sharpening angles

Band saws can have different tooth geometries: it is influenced by the type and properties of the raw materials being cut. As for tools for working with wood, they can be carpentry, dividing and intended for sawing logs - and the parameters and shape of the teeth for each “subspecies”, respectively, are different. The sharpening angle of band saws for wood is determined by the manufacturer based on a number of factors, but the key is this trend - the harder the material, the smaller the rake angle should be.

For metal saws with a constant pitch, two main tooth shapes are characteristic - standard and “positive rake”. Standard teeth are designed for cutting thin-walled material, while positive rake teeth are designed for processing thick-walled metal.

Now about the step size. For thin-walled workpieces (rolled sheets, pipes), saws with a small tooth pitch are used - otherwise there is a risk of damaging or even breaking the tooth. It is better to work with thick-walled materials using a tool with a small number of teeth per inch.

In order to eliminate the resonance effect that provokes vibrations of the blade, a number of saws are made with variable pitch.

Device for setting teeth

To cut teeth with a pitch of 0.5 mm, the ratchet wheel is replaced. The replaceable matrix 11 is attached to the body 1 with screws 12 and installed using a stop 13. When installing a new tape, the upper roller is moved away from the lower one using a special lever. With 116 strokes/min of the slider and a tooth pitch of 6 mm, the device cuts teeth on a 41.76 m long strip in 1 hour. Correct tooth spacing is of great importance for the productive operation of band saws. To set the teeth of band saws, a device is used, the operating diagram of which is presented in Fig. 14 [8]. The device is driven by the rotation of the flywheel 1, mounted on the crankshaft 2. On the latter, ring-bearings are freely located, in which curved levers 3 and 4 are attached to the threads. When the flywheel rotates, they receive a reciprocating motion. At the end of lever 3 there is a square with a freely hanging pawl 5. When lever 3 moves to the right, the pawl rests on the tooth of the saw blade 6. With one turn of the flywheel, the saw moves two teeth. The pawl and the square are hinged, so when the lever moves back, the pawl rises and slides along the teeth of the saw. Levers 4 are elements of the gear setting mechanism (the second lever is located on the back side of the housing). Levers 4 are pivotally connected to the crank axis of the cam 7. The levers return to their original position by springs 8. When the flywheel rotates, the levers 4 rotate the cams 7, which push the punches 9 towards each other. Two adjacent saw teeth bend in different directions (move apart). Springs 8 return cams 7 and punches 9 to their original position. The angle of the teeth is adjusted with nuts 10 and by deepening the threaded end of the levers into the rings on the crankshaft. The tooth set angle is 15° in both directions. The amount of feed of the pawl 5 is adjusted by nut 11. The mechanism for installing and securing the band saw has two plates that make up the body of the device, and a wedge 12 located between them. The wedge moves in the body, and the teeth of the set saw always protrude above the body by a certain amount. At the Volgograd Tractor Plant they use a device for setting the teeth of band saws. The device operates by hand drive and consists of two disks with shoulders on which a band saw is mounted. One of the disks is movable to tension the saw. The adjustment is carried out by two cams using a pawl, a lever with a roller, copiers, a handle and levers. An automatic machine is used for cutting and setting the teeth of band saws [54]. Teeth cutting is done on a steel strip of any length, which is then cut into measuring tapes. When refurbishment of band saws, the teeth are cut again. The machine can be installed on a separate frame, table or workbench; its overall dimensions are 380x320x250 mm, weight 16 kg; it is equipped with an electric motor with a power of 0.37 kW, with a shaft rotation speed of 1400 rpm. On the plate 1 of the machine (15) two brackets 2 and a support bar 3 are installed. Supports 4 are attached to one bracket, in which a worm 5 carrying ball bearings and a driven flywheel pulley 6 are installed. On the other bracket is mounted the eccentric 7 of the pusher 8 of the feed mechanism and gear wheel 9. The feeding mechanism consists of three supports 10-12, on which are placed a worm pair 13 and 14, a drive roller 15 for feeding the tape blank, a pressure roller 16, a pressure roller lever 17 and a screw 18 that regulates the degree of pressing of the pressure roller. To move the workpiece per saw step, a replaceable ratchet 19 is mounted on the worm 5. A drive gear 21 is installed on the shaft 20, which meshes with the eccentric gear of the feed mechanism pusher, cam disks 22-25, intermediate bushings 26 and 27, and a worm wheel 28. A combination stamp (16) is installed on the support bar 3; one of the stamps is used for cutting out teeth, and the other for setting teeth; the stamps are mounted on plate 1 between two posts 2 and 3. On the base of plate 1, together with the die-cutting die matrix, two strips 4 and 5 are installed. Between the die-cutting die matrix and the guide strip 6 there is a clamping device strip 7. The device is kinematically connected to the punch of the cutting die using two rollers 8 and 9 of guide bars 10 and 11, between which a spring 12 and a pushing head are inserted. A rubber ring 14 and a metal ring 15 are put on the bar 11, with which the tape is pressed while cutting the teeth. For lateral clamping of the tape, a clamping device is mounted in the hole of the strip 4. It consists of a retainer 16, a clamping bar 17 and a spring 18. The pushing head serves as a guide sleeve into which the spring 19 is inserted. The tape is secured with a nut 13. The nut 20 of the pushing head rests on the metal ring 15 of the rubber ring 14. To release the tape after cutting and moving It is placed on the new section by spring 12, which returns the clamping device to its original position. During operation, the pushing head of the punch slides along a bronze bushing 21, pressed into the bar of posts 2 and 3. Depending on the clamping force of the tape, it protrudes above the bar by one or another amount. The die for setting the teeth does not have a clamping device. Punch 22 is inserted at one end into the pushing head 23, and at the other into the bar 24. Its position is adjusted by a nut 25. A spring 27 is installed between the nut 25 and the guide sleeve 26. The pushing head of the punch slides along the guide sleeve 28, pressed into the bar 29. Combined die installed on the stove and covered with a casing. To thicken the teeth of band saws, the DIXA device (PNR) is used. The distance between the teeth undergoing thickening is 17 mm, the minimum tooth height is 9 mm, the maximum saw thickness is 3 mm. For lateral profiling, leveling and grinding of flattened teeth of band saws, the DHCA-20 machine (PNR) is used.