An unequal angle is a popular type of rolled metal, which has an L-shaped cross-section. A special feature of the product is its high lateral rigidity, which ensures the integrity of structures even under high loads. Another important characteristic of the corner is strength.

A large selection of sizes of unequal steel angles allows you to choose the right model for any task. The corners are marked by numbers. For example, a corner with the number 10/6.3 has dimensions of 63x100. We supply angles of measured, multiple measured and unmeasured lengths from 4 to 12 meters.

Unequal steel angles are used to create engineering and building structures of an increased level of complexity. One of the areas of application is strengthening metal structures in which equal-flange angles cannot be used. The products are used for installing lattice structures and compressed elements, creating structures that play a decorative role. The material is used in carriage and mechanical engineering, the manufacture of road and special equipment, sea and river vessels.

| Table of main characteristics of unequal angles | |||

| Drawing | Shelf width, mm | Weight, kg | Standard |

| from 25 to 200 | 0.91 to 39.07 | GOST 8510-86 | |

Main content of the state standard

In total, the specified state standard has three tables, two of which are in the notes section. The main table is the first one, which shows all the required dimensions of the corners, including:

- Assortment number;

- Main dimensions of products;

- Cross-sectional area in square centimeters;

- Reference values for axes;

- Moments of inertia;

- Angle of inclination on the axis;

- Weight of a 1 meter long assortment in kilograms.

The numbering goes in a certain way, for example, 2.5/1.6 and up to 20/12.5. At the same time, it is worth carefully selecting assortments in accordance with the client’s requirements, since they may have the same internal and external radius. Product masses vary from 0.91 to 39 kilograms. Also, each assortment can have several values of the same value, be it cross-sectional area or reference values for axes. The table is very detailed and quite easy to work with. With proper preparation, finding the necessary assortments will not be difficult.

Steel for making unequal angles

Let's consider the grades of carbon steel that are most often used for the manufacture of steel unequal angles of standard accuracy:

- St0 - in such steel the amount of carbon is up to 0.23%, there are no restrictions in weldability, it is used for non-critical parts and secondary structures;

- St3kp - amount of carbon from 0.14 to 0.22%, with no restrictions on weldability, used for the production of elements of parts and structures under low load, the decoding of the letters “kp” shows its degree of deoxidation - boiling;

- St3sp - characteristics correspond to St3kp steel, the only difference is the degree of deoxidation - calm;

- St5ps - amount of carbon from 0.28% to 0.37%, used for the manufacture of rods, handles, nuts, bolts, all kinds of riveted structures, etc. Limited weldability. The degree of deoxidation is semi-calm.

In the manufacture of high-precision unequal angle angles from low-alloy steel, grade 09G2S steel is used.

Notes on the table

After the main table there are notes. First, it is indicated that the main parameters regarding the cross-section and main dimensions are calculated from the nominal dimensions. The radii of curvature, shapes and dimensions of the area, together with some other data, are given to construct the caliber without checking on the assortment itself. Information has also been added that products marked with asterisks are manufactured according to consumer requirements.

The accuracy of rolling angles is indicated by the symbols A and B, which correspond to high and normal accuracy. Tables 2 and 3 contain assortments indicating the maximum deviations for the width and thickness of the shelf. The range of deviations in width is from 1 to 3 millimeters, in thickness up to 1 millimeter.

The deviation from the right angle at the top cannot be more than 35 minutes. The blunting of the outer corners of the shelves is not controlled, but the approximate indicators are as follows:

- 0.3 shelf thickness for thicknesses up to 10 millimeters;

- 3 millimeters for corners with a thickness from 10 to 15 millimeters inclusive;

- If the corners are over 16 millimeters thick, then blunting up to 5 millimeters is allowed.

With lengths from 4 to 12 meters, we produce such types of angles as measured length, multiple measured length and unmeasured length, as well as limited unmeasured length. Twisting around the longitudinal axis is not allowed, and the cross-sectional values must be checked at a distance of at least 500 millimeters from the end of the rod. The curvature of the corners should not be more than 0.4 percent of the length of the product.

Documentation for the production of steel unequal angles

Basic documents for the production of steel angles:

- Regarding the material - GOST 535-88, GOST 380-94, GOST 19281-89.

- All standards for this type of rolled metal are shown for hot-rolled angles - GOST 8510-86, and for unequal bent angles - GOST 19772-93, or the standard valid within Ukraine - DSTU 2255-93.

The main and important characteristic of a steel unequal angle is strength. Its readings may change during cold hardening. This is a procedure for strengthening metal, which occurs due to plastic deformation.

When straightening rolled steel, where the flange thickness is 3-5 mm, as well as during other power work, it is necessary to take into account certain properties. If you produce a corner whose assortment does not meet GOST standards, cracking of the metal is often observed in the areas where the cold-hardening procedure was carried out. Thus, these structures do not have the proper safety margin, and therefore their service life is significantly reduced.

Description of document completion

At the end of the standard, information data is provided for unequal angles. They indicate information about who developed and introduced the document (Ministry of Ferrous Metallurgy of the USSR and the State Committee for Construction of the USSR), when the document was introduced and approved (by a commission of certain people related to the government), instead of which previous standard, validity period and reissue . It is also indicated that this guest is not protected from copyright and can be distributed in the public domain without claims regarding copyright.

The range of unequal angles is important in construction and in ferrous metallurgy. And for a competent and correct choice of the required assortment, it is necessary to have a regulatory document, which is this standard. Thanks to the detailed table and the presence of the necessary notes, this document is very convenient for applying and finding any specific corner with the appropriate dimensions and technical characteristics.

Application

An unequal-flange profile has a narrower, specialized scope of application (unlike an equal-flange profile). At the same time, the cross-sectional features of an unequal angle allow the construction of engineering and construction structures of an increased level of complexity. Hot rolled unequal steel angles are used:

- for strengthening metal structures where equal angles are not suitable due to geometric characteristics, for installation of lattice structures, compressed elements from single angles;

- for creating decorative building structures with large design load-bearing loads: arched openings, creating openings of non-standard configuration, etc.

- in car and mechanical engineering, production of road and special equipment, sea and river vessels.

You can also:

- Find out prices and buy an equal angle corner

.

Specific Gravity Calculation

Today, many methods and algorithms have been developed for measuring and calculating not only density, but also specific gravity, which make it possible to determine this important parameter even without the help of tables. Knowing the specific gravity, which differs between different alloys of copper and pure metal, as well as the density value, you can effectively select materials for the production of parts with given parameters

It is very important to carry out such measures at the design stage of devices in which it is planned to use parts made of copper and its alloys

Specific gravity, the value of which (as well as density) can be seen in the table, is the ratio of the weight of a product made either from metal or from any other homogeneous material to its volume. This relationship is expressed by the formula γ = P/V, where the letter γ denotes specific gravity.

Specific gravity and density, which are inherently different characteristics of a metal, should not be confused, although they have the same meaning for copper.

Knowing the specific gravity of copper and using the formula for calculating this value γ = P/V, you can determine the mass of a copper billet having a different cross-section. To do this, it is necessary to multiply the specific gravity value for copper and the volume of the workpiece in question, which is not particularly difficult to determine by calculation.

Description and materials of production in accordance with the standard

Hot rolled unequal flange is an L-shaped profile made of various grades of steel. Its distinctive characteristic is the side shelves of different sizes - one larger than the other. According to standard 8510-86, solid rolled metal products are made from:

- Carbon steel (grades 09g2s, st3kp, St0-St6, st4kp, st4ps and 3sp5);

- Low alloy steel (grades 15HSND, 08G2S, 15G2AFDps, 16GS, 10HSND, 12GS, 14KhGS).

Other grades of steel are also used. Different sizes of product shelves are effectively used in the construction of arched structures, roof trusses, etc. Hot-rolled metal products are produced by hot rolling a steel billet. It is passed between the rolls of a rolling mill. The production technology allows us to obtain a corner with an external pointed angle equal to 90'.

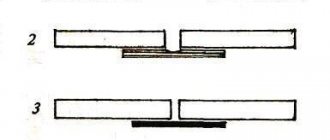

Fig.2. The main quantities described by GOST 8510-86

The dimensions of the corners, reference values for the axes, cross-sectional area, weight must correspond to those indicated in Table 1.

The weight of 1 m of the product depends on the cross-section of the profile - from 1.16 cm2 to 49.77 cm2. When calculating the mass, it is based on the fact that the density of the steel must be at least 7.85 g/cm3. When manufacturing standard products, the weight of 1 m of corner will vary from 0.91 kg to 39.07 kg. Calculation of mass based on metal density is used in the production of rolled metal at the request of the consumer.

Application of steel unequal angles

Products of this type of rolled metal are often used in a wide variety of industries, as well as in households.

In construction, unequal angle angles are used for the construction of various rigid reinforcement structures, for raising lintels, in monolithic concreting, for reinforcing concrete, as well as for connecting various types of handrails. The corner is used both in private construction, for the construction of small objects, and for more serious objects. Products of such rolled metal products have gained popularity in the automotive industry, shipbuilding, carriage building, aircraft construction and even in interior design.

The unequal corner has also been used in the production of furniture and in interior decoration.

The only thing you should know when choosing a corner is that an unequal hot-rolled corner has higher strength characteristics than a cold-formed corner. Therefore, when using a corner in places where there will be a lot of physical activity, you should opt for a cold-formed unequal corner.

, offers a wide range of steel angles at reasonable prices, which can be found in the price list.

Production Features

Angle bars are produced on automated production lines. The raw material for hot-rolled angles is steel ingots. The cube-shaped bloom is heated to the temperature of metal recrystallization and fed to rolling rolls. Under the influence of high pressure, soft metal is transformed into a product of the desired shape with specified parameters.

The advantages of this hot rolling technology include the following factors:

- production of rolled products without size restrictions;

- large thickness of processed workpieces;

- high speed of production of products.

Products made using this technology are distinguished by the accuracy of linear parameters and have high quality characteristics. Metal products have a smooth surface without visible or hidden defects and are characterized by increased bending strength. Steel that has undergone heat treatment has a uniform structure and has the necessary ductility. The area of use of hot-rolled angles depends on the type and size of the product.

Angle angle GOST 8510

| A GROUP, LLC | DIPOS, GC | TK STEEL-INTEX TRADE, LLC | EVRAZ METAL INPROM, OJSC | ARIEL METAL, JSC | METAL-SERVIS, JSC | METALLO-TORG, JSC | METAGOR, LLC | AMG, LLC |

| 40x40x4.0 mm | 46 990 | 46 990 | ||||||

| 45x45x5.0 mm | 41 790 | |||||||

| 50x50x4.0 mm | 46 490 | 46 800 | 43 990 | |||||

| 50x50x5.0 mm | 44 500 | 46 500 | 44 990 | 45 490 | 46 800 | 46 500 | 43 990 | |

| 63x63x5.0 mm | 4 6000 | 44 990 | 45 490 | 46 800 | 45 490 | |||

| 63x63x6.0 mm | 46 000 | 45 490 | 46 800 | 46 000 | 45 990 | |||

| 70x70x6.0 mm | 48 490 | 45 490 | ||||||

| 75x75x5.0 mm | 50 000 | 47 990 | 48 700 | 50 000 | 46 490 | |||

| 75x75x6.0 mm | 47 000 | 47 250 | 46 490 | 46 990 | 48 700 | 47 250 | 46 490 | |

| 75x75x8.0 mm | 47 250 | 46 990 | 47 250 | 46 990 | ||||

| 80x80x6.0 mm | 48 990 | 46 490 | ||||||

| 80x80x8.0 mm | 48 990 | 46 490 | ||||||

| 90x90x6.0 mm | 45 000 | 49 490 | 48 700 | 43 990 | ||||

| 90x90x7.0 mm | 45 000 | 48 490 | 48 700 | 44 990 | ||||

| 90x90x8.0 mm | 49 490 | 48 700 | 46 490 | |||||

| 100x100x7.0 mm | 49 000 | 51 500 | 49 990 | 50 700 | 48 000 | 46 990 | ||

| 100x100x8.0 mm | 46 500 | 51 500 | 49 490 | 49 990 | 50 700 | 48 000 | 45 990 | |

| 100x100x10.0 mm | 47 000 | 51 500 | 50 990 | 50 700 | 49 900 | 46 490 | ||

| 110x110x7.0 mm | 51 500 | 51 500 | ||||||

| 110x110x8.0 mm | 48 000 | |||||||

| 125x125x8.0 mm | 47000 | 51500 | 50500 | 46490 | 51490 | 53700 | 51500 | 46490 |

| 125x125x9.0 mm | 46500 | 47000 | 45990 | 47490 | 46500 | 45990 | ||

| 125x125x10.0 mm | 46500 | 51500 | 46990 | 49990 | 54000 | 51500 | 45990 | |

| 125x125x12.0 mm | 49990 | 47990 | ||||||

| 140x140x9.0 mm | 57500 | 55880 | 57300 | 57300 | 58100 | 57500 | 57300 | |

| 140x140x10.0 mm | 57300 | 57500 | 57990 | 57300 | 58100 | 57990 | ||

| 140x140x12.0 mm | 58100 | |||||||

| 140x140x14.0 mm | 41490 | |||||||

| 160x160x10.0 mm | 57300 | 57500 | 57300 | 57300 | 58100 | 57500 | 57300 | |

| 160x160x12.0 mm | 57300 | 57500 | 55880 | 57300 | 57300 | 58100 | 57300 | |

| 160x160x14.0 mm | 58100 | |||||||

| 160x160x16.0 mm | 57300 | 57300 | 57300 | 58100 | ||||

| 160x160x20.0 mm | 57300 | |||||||

| 180x180x11.0 mm | 59550 | 59550 | 59550 | 60100 | 59550 | |||

| 180x180x12.0 mm | 59550 | 59550 | 60100 | 59550 | ||||

| 200x200x12.0 mm | 57300 | 57500 | 57300 | 58100 | 57300 | |||

| 200x200x14.0 mm | 57500 | 54380 | 57300 | 57300 | 58100 | 57300 | ||

| 200x200x16.0 mm | 57300 | 57300 | 57300 | 58100 | 50490 | |||

| 200x200x20.0 mm | 57300 | 57300 | 58100 | 57300 |

Angle weight table (equal flange GOST 8509-93)

| Angle dimensions | Shelf size (mm.) | Metal thickness (mm.) | Weight per linear meter (kg.) | Meters per ton |

| 20×3 | 20 | 3 | 0.89 | 1123.6 |

| 20×4 | 20 | 4 | 1.15 | 869.57 |

| 25×3 | 25 | 3 | 1.12 | 892.86 |

| 25×4 | 25 | 4 | 1.46 | 684.93 |

| 25×5 | 25 | 5 | 1.78 | 561.8 |

| 28×3 | 28 | 3 | 1.27 | 787.4 |

| 30×3 | 30 | 3 | 1.36 | 735.29 |

| 30×4 | 30 | 4 | 1.78 | 561.8 |

| 30×5 | 30 | 5 | 2.18 | 458.72 |

| 32×3 | 32 | 3 | 1.46 | 684.93 |

| 32×4 | 32 | 4 | 1.91 | 523.56 |

| 35×3 | 35 | 3 | 1.6 | 625 |

| 35×4 | 35 | 4 | 2.1 | 476.19 |

| 35×5 | 35 | 5 | 2.58 | 387.6 |

| 40×3 | 40 | 3 | 1.85 | 540.54 |

| 40×4 | 40 | 4 | 2.42 | 413.22 |

| 40×5 | 40 | 5 | 2.98 | 335.57 |

| 40×6 | 40 | 6 | 3.52 | 284.09 |

| 45×3 | 45 | 3 | 2.08 | 480.77 |

| 45×4 | 45 | 4 | 2.73 | 366.3 |

| 45×5 | 45 | 5 | 3.37 | 296.74 |

| 45×6 | 45 | 6 | 3.99 | 250.63 |

| 50×3 | 50 | 3 | 2.32 | 431.03 |

| 50×4 | 50 | 4 | 3.05 | 327.87 |

| 50×5 | 50 | 5 | 3.77 | 265.25 |

| 50×6 | 50 | 6 | 4.47 | 223.71 |

| 50×7 | 50 | 7 | 5.15 | 194.17 |

| 50×8 | 50 | 8 | 5.82 | 171.82 |

| 56×4 | 56 | 4 | 3.44 | 290.7 |

| 56×5 | 56 | 5 | 4.25 | 235.29 |

| 60×4 | 60 | 4 | 3.71 | 269.54 |

| 60×5 | 60 | 5 | 4.58 | 218.34 |

| 60×6 | 60 | 6 | 5.43 | 184.16 |

| 60×8 | 60 | 8 | 7.1 | 140.85 |

| 60×0 | 60 | 10 | 8.7 | 114.94 |

| 63×4 | 63 | 4 | 3.9 | 256.41 |

| 63×5 | 63 | 5 | 4.81 | 207.9 |

| 63×6 | 63 | 6 | 5.72 | 174.83 |

| 65×6 | 65 | 6 | 5.91 | 169.2 |

| 65×8 | 65 | 8 | 7.73 | 129.37 |

| 70×4 | 70 | 4.5 | 4.87 | 205.34 |

| 70×5 | 70 | 5 | 5.38 | 185.87 |

| 70×6 | 70 | 6 | 6.39 | 156.49 |

| 70×7 | 70 | 7 | 7.39 | 135.32 |

| 70×8 | 70 | 8 | 8.37 | 119.47 |

| 70×0 | 70 | 10 | 10.29 | 97.18 |

| 75×5 | 75 | 5 | 5.8 | 172.41 |

| 75×6 | 75 | 6 | 6.89 | 145.14 |

| 75×7 | 75 | 7 | 7.96 | 125.63 |

| 75×8 | 75 | 8 | 9.02 | 110.86 |

| 75×9 | 75 | 9 | 10.07 | 99.3 |

| 80×5 | 80 | 5.5 | 6.78 | 147.49 |

| 80×6 | 80 | 6 | 7.36 | 135.87 |

| 80×7 | 80 | 7 | 8.51 | 117.51 |

| 80×8 | 80 | 8 | 9.65 | 103.63 |

| 80×10 | 80 | 10 | 11.88 | 84.18 |

| 80×12 | 80 | 12 | 14.05 | 71.17 |

| 90×6 | 90 | 6 | 8.33 | 120.05 |

| 90×7 | 90 | 7 | 9.64 | 103.73 |

| 90×8 | 90 | 8 | 10.93 | 91.49 |

| 90×9 | 90 | 9 | 12.2 | 81.97 |

| 90×10 | 90 | 10 | 13.48 | 74.18 |

| 90×12 | 90 | 12 | 15.96 | 62.66 |

| 100×6.5 | 100 | 6.5 | 10.06 | 99.4 |

| 100×7 | 100 | 7 | 10.79 | 92.68 |

| 100×8 | 100 | 8 | 12.25 | 81.63 |

| 100×10 | 100 | 10 | 15.1 | 66.23 |

| 100×12 | 100 | 12 | 17.9 | 55.87 |

| 100×14 | 100 | 14 | 20.63 | 48.47 |

| 100×15 | 100 | 15 | 21.97 | 45.52 |

| 100×16 | 100 | 16 | 23.3 | 42.92 |

| 110×7 | 110 | 7 | 11.89 | 84.1 |

| 110×8 | 110 | 8 | 13.5 | 74.07 |

| 120×8 | 120 | 8 | 14.76 | 67.75 |

| 120×10 | 120 | 10 | 18.24 | 54.82 |

| 120×12 | 120 | 12 | 21.67 | 46.15 |

| 120×15 | 120 | 15 | 26.68 | 37.48 |

| 125×8 | 125 | 8 | 15.46 | 64.68 |

| 125×9 | 125 | 9 | 17.3 | 57.8 |

| 125×10 | 125 | 10 | 19.1 | 52.36 |

| 125×12 | 125 | 12 | 22.68 | 44.09 |

| 125×14 | 125 | 14 | 26.2 | 38.17 |

| 125×16 | 125 | 16 | 29.65 | 33.73 |

| 140×9 | 140 | 9 | 19.41 | 51.52 |

| 140×10 | 140 | 10 | 21.45 | 46.62 |

| 140×12 | 140 | 12 | 25.5 | 39.22 |

| 150×10 | 150 | 10 | 23.02 | 43.44 |

| 150×12 | 150 | 12 | 27.39 | 36.51 |

| 150×15 | 150 | 15 | 33.82 | 29.57 |

| 150×18 | 150 | 18 | 40.11 | 24.93 |

| 160×10 | 160 | 10 | 24.67 | 40.54 |

| 160×11 | 160 | 11 | 27.02 | 37.01 |

| 160×12 | 160 | 12 | 28.35 | 35.27 |

| 160×14 | 160 | 14 | 33.97 | 29.44 |

| 160×16 | 160 | 16 | 38.52 | 25.96 |

| 160×18 | 160 | 18 | 43.01 | 23.25 |

| 160×20 | 160 | 20 | 47.44 | 42968 |

| 180×11 | 180 | 11 | 30.47 | 32.82 |

| 180×12 | 180 | 12 | 33.12 | 30.19 |

| 180×15 | 180 | 15 | 40.96 | 24.41 |

| 180×18 | 180 | 18 | 48.66 | 20.55 |

| 180×20 | 180 | 20 | 53.72 | 18.62 |

| 200×12 | 200 | 12 | 36.97 | 42882 |

| 200×13 | 200 | 13 | 39.92 | 42880 |

| 200×14 | 200 | 14 | 42.8 | 23.36 |

| 200×16 | 200 | 16 | 48.65 | 20.55 |

| 200×18 | 200 | 18 | 54.4 | 18.38 |

| 200×20 | 200 | 20 | 60.08 | 16.64 |

| 200×24 | 200 | 24 | 71.26 | 42808 |

| 200×25 | 200 | 25 | 74.02 | 13.51 |

| 200×30 | 200 | 30 | 87.56 | 15646 |

| 220×14 | 220 | 14 | 47.4 | 42756 |

| 220×16 | 220 | 16 | 53.83 | 18.58 |

| 250×16 | 250 | 16 | 61.55 | 16.25 |

| 250×18 | 250 | 18 | 68.86 | 14.52 |

| 250×20 | 250 | 20 | 76.11 | 13.14 |

| 250×22 | 250 | 22 | 83.31 | 12 |

| 250×25 | 250 | 25 | 93.97 | 23651 |

| 250×28 | 250 | 28 | 104.5 | 21064 |

| 250×30 | 250 | 30 | 111.44 | 35643 |

| 250×35 | 250 | 35 | 128.51 | 28672 |

Weight of steel unequal angle (GOST 8510-96)

| Angle dimensions | Corner flange size A (mm.) | Corner flange size B (mm.) | Metal thickness (mm.) | Weight per meter | Meters per ton |

| 25×16×3 | 25 | 16 | 3 | 0.91 | 1098.9 |

| 30×20×3 | 30 | 20 | 3 | 1.12 | 892.86 |

| 30×20×4 | 30 | 20 | 4 | 1.45 | 689.66 |

| 32×20×3 | 32 | 20 | 3 | 1.17 | 854.7 |

| 32×20×4 | 32 | 20 | 4 | 1.52 | 657.89 |

| 40×25×3 | 40 | 25 | 3 | 1.48 | 675.68 |

| 40×25×4 | 40 | 25 | 4 | 1.94 | 515.46 |

| 40×25×5 | 40 | 25 | 5 | 2.37 | 421.94 |

| 40×30×4 | 40 | 30 | 4 | 2.26 | 442.48 |

| 40×30×5 | 40 | 30 | 5 | 2.46 | 406.5 |

| 45×28×3 | 45 | 28 | 3 | 1.68 | 595.24 |

| 45×28×4 | 45 | 28 | 4 | 2.2 | 454.55 |

| 50×32×3 | 50 | 32 | 3 | 1.9 | 526.32 |

| 50×32×4 | 50 | 32 | 4 | 2.4 | 416.67 |

| 56×36×4 | 56 | 36 | 4 | 2.81 | 355.87 |

| 56×36×5 | 56 | 36 | 5 | 3.46 | 289.02 |

| 63×40×4 | 63 | 40 | 4 | 3.17 | 315.46 |

| 63×40×5 | 63 | 40 | 5 | 3.91 | 255.75 |

| 63×40×6 | 63 | 40 | 6 | 4.63 | 215.98 |

| 63×40×8 | 63 | 40 | 8 | 6.03 | 165.84 |

| 65×50×5 | 65 | 50 | 5 | 4.36 | 229.36 |

| 65×50×6 | 65 | 50 | 6 | 5.18 | 193.05 |

| 65×50×7 | 65 | 50 | 7 | 5.93 | 168.63 |

| 65×50×8 | 65 | 50 | 8 | 6.77 | 147.71 |

| 70×45×5 | 70 | 45 | 5 | 4.3 | 232.56 |

| 75×60×5 | 75 | 60 | 5 | 4.79 | 208.77 |

| 75×60×6 | 75 | 60 | 6 | 5.69 | 175.75 |

| 75×60×7 | 75 | 60 | 7 | 6.57 | 152.21 |

| 75×60×8 | 75 | 60 | 8 | 7.43 | 134.59 |

| 80×50×5 | 80 | 50 | 5 | 4.49 | 222.72 |

| 80×50×6 | 80 | 50 | 6 | 5.92 | 168.92 |

| 80×60×6 | 80 | 60 | 6 | 6.39 | 156.49 |

| 80×60×7 | 80 | 60 | 7 | 7.39 | 135.32 |

| 80×60×8 | 80 | 60 | 8 | 8.37 | 119.47 |

| 90×56×5 | 90 | 56 | 5.5 | 6.17 | 162.07 |

| 90×56×6 | 90 | 56 | 6 | 6.7 | 149.25 |

| 90×56×8 | 90 | 56 | 8 | 8.77 | 114.03 |

| 100×63×6 | 100 | 63 | 6 | 7.53 | 132.8 |

| 100×63×7 | 100 | 63 | 7 | 8.7 | 114.94 |

| 100×63×8 | 100 | 63 | 8 | 9.87 | 101.32 |

| 100×63×10 | 100 | 63 | 10 | 12.14 | 82.37 |

| 100×65×7 | 100 | 65 | 7 | 8.81 | 113.51 |

| 100×65×8 | 100 | 65 | 8 | 9.99 | 100.1 |

| 100×65×10 | 100 | 65 | 10 | 12.3 | 81.3 |

| 110×70×6 | 110 | 70 | 6.5 | 8.98 | 111.36 |

| 110×70×8 | 110 | 70 | 8 | 10.93 | 91.49 |

| 125×80×7 | 125 | 80 | 7 | 11.04 | 90.58 |

| 125×80×8 | 125 | 80 | 8 | 12.58 | 79.49 |

| 125×80×10 | 125 | 80 | 10 | 15.47 | 64.64 |

| 125×80×12 | 125 | 80 | 12 | 18.34 | 54.53 |

| 140×90×8 | 140 | 90 | 8 | 14.13 | 70.77 |

| 140×90×10 | 140 | 90 | 10 | 17.46 | 57.27 |

| 160×100×9 | 160 | 100 | 9 | 17.96 | 55.68 |

| 160×100×10 | 160 | 100 | 10 | 19.85 | 50.38 |

| 160×100×12 | 160 | 100 | 12 | 23.58 | 42.41 |

| 160×100×14 | 160 | 100 | 14 | 27.26 | 36.68 |

| 180×110×10 | 180 | 110 | 10 | 22.2 | 45.05 |

| 180×110×12 | 180 | 110 | 12 | 26.4 | 37.88 |

| 200×125×11 | 200 | 125 | 11 | 27.37 | 36.54 |

| 200×125×12 | 200 | 125 | 12 | 29.74 | 33.62 |

| 200×125×14 | 200 | 125 | 14 | 34.43 | 42854 |

| 200×125×16 | 200 | 125 | 16 | 39.07 | 42911 |

We calculate the weight of rolled sheets

Calculating the weight of rolled metal is a fairly simple task of this class. Simplicity is determined by the shape of the sample being studied. To begin calculations, you need to know the following characteristics:

- geometric dimensions of the test sample;

- metal density (for steel you can use the average indicator, which is equal to 7850 kg/m 3);

The first stage involves calculating the weight of a sheet of metal with an area of one square meter and a thickness of one millimeter. The volume of this sample is calculated and multiplied by the density of the steel. It is obtained by standard multiplication of three geometric parameters: length, width, height. Multiplying the result by the density, we get a value equal to 7.8 kg/m3. It will allow you to calculate the weight of a sheet of any geometric size and shape. Convenient because it does not depend on length, width, thickness. You can get the final value without resorting to preliminary recalculation. Therefore, the main task will be to calculate the volume of the selected sheet.

For example, the weight of a sheet whose size is one meter long, two meters wide, 0.35 mm thick will weigh 5.5 kg. A sheet 5 mm thick, measuring 1.5 m wide and 6 meters long will weigh 353.25 kg.

Before using a metal sheet as a ceiling or building structure, you should evaluate its weight.

Sheet weight