If your work depends on working on a milling machine, then increasing the number of products should be a priority for you. A magnetic plate will be a good tool for increasing productivity.

A magnetic plate for a milling machine will allow you to process more than one part at once, unlike standard jaws. And processing will be carried out with utmost precision and efficiency. Let's take a closer look at all the features of this device.

Application and Description of Sine Magnetic Plate:

for installation of metal workpieces with subsequent fixation, for grinding, milling work, and other metalworking operations. Due to the inclination of the working surface, workpieces can be processed at different angles; we produce sine magnetic plates with an inclination in the longitudinal and transverse directions. The double-rotary magnetic plate is also used for fastening workpieces, but with the possibility of processing in several planes. Fixation of workpieces is activated by turning the handle, installed on the work table of a milling machine, on the mirror surface of a surface grinder and other grinding machines.

Design Features

The main structural elements of a magnetic plate for a milling machine are:

- The body of the device is made from soft steel. Its base has special oppositely charged protrusions.

- A special lid that covers the work surface. The cover is one pole, and the remaining surface is the opposite pole.

- Coils - designed to pass direct current.

- A magnetic block is a movable element that moves due to the work of an eccentric top.

Main types of work of a magnetic rotary plate:

— Rotary plates are mainly used in metalworking, these are surface grinders, cylindrical grinders, and milling machines.

— can be installed on workbenches, work tables, for attaching metalwork tools and sharpening tools.

— sine single-turn magnetic plate. For sharpening guillotine knives. To do this, the slab must have an inclination in the longitudinal direction.

— sine magnetic two-turn plate. To rotate a fixed part in two directions, longitudinal and transverse.

Making a surface grinding machine with your own hands

A surface grinding machine, which you can make yourself, is a very popular piece of equipment not only in manufacturing enterprises, but also in the home workshop.

Such a device is practically indispensable in situations where it is necessary to grind and adjust metal parts.

Of course, such work can be done manually, but this will take a lot of effort and time and will not allow achieving high precision processing.

Processing a workpiece on an industrial surface grinding machine

It makes sense to think about equipping your home workshop with a surface grinding machine if you often have to work on metal.

In this case, you can choose one of two options: buy serial equipment or make such a machine yourself.

The purchase of a serial machine is associated with serious financial costs, which is not always advisable for its use in a home workshop.

A homemade surface grinding machine will cost much less. Of course, the functionality of such equipment will be somewhat lower than that of serial equipment, but its capabilities will be quite sufficient to perform metal work at home.

How do surface grinding machines work?

The vast majority of parts made of metal undergo a technological operation such as grinding. To perform this with high efficiency and accuracy, surface grinding machines are used.

A rather difficult to manufacture banding machine with excellent functionality

General view of the machine Design of the work table drive

Surface grinding machines of serial models can process both flat and profile parts. The surface processing accuracy that can be achieved using such devices is 0.16 microns.

Of course, it is almost impossible to achieve such a result when processing on machines made by yourself.

However, even the accuracy that homemade machines allow to obtain is quite sufficient for many metal products.

The load-bearing structural element of the machines of this group (as well as any other equipment) is the bed. Its dimensions directly determine what size parts can be processed on the machine.

The most common material for manufacturing beds of surface grinding equipment is cast iron, since this metal, due to its characteristics, perfectly dampens vibrations, which is especially important for devices of this type.

Work table and controls of the 3G71M grinding machine

The structural element of surface grinding machines on which the workpiece is fixed is a work table having a round or rectangular shape.

Its dimensions can vary significantly depending on the specific model of surface grinding equipment. The workpieces can be fixed on such a work table due to its magnetized surface or using special clamping elements.

During processing, the work table makes reciprocating and circular movements.

In mass-produced surface grinding machines, the work tables are driven by a hydraulic system. In self-assembled equipment, mechanical transmissions are used for this.

Grinding a steel workpiece fixed on the working surface of the machine using a magnetic field

Important elements of the design of surface grinding equipment, which ensure the accuracy and smooth movement of the work table, are guides. In addition to high precision manufacturing, the guides must have exceptional strength, since in the process of almost constant movements of the desktop they are subject to active wear.

To achieve high processing accuracy, the guides must ensure accurate, smooth (without jerking) movement of the worktable with minimal friction of the contacting elements. That is why high-strength steel is used for the manufacture of these structural elements, which is hardened after the guides are made from it.

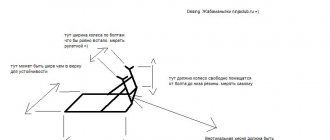

Option for manufacturing guides using angles and bearings

The working tool of a surface grinding machine, which can be a grinding wheel or an abrasive belt, is mounted on the spindle of the headstock. Rotation of the working tool, for which the main electric motor is responsible, can be transmitted through a gearbox or belt drive.

For do-it-yourself surface grinding machines, you can choose a simpler option: select the diameter of the grinding wheel so that it can be mounted directly on the electric motor shaft. This will eliminate the need to use a gear or belt drive.

Recommendations for making a surface grinding machine with your own hands

Serial surface grinding machines, in addition to their high cost, are also distinguished by their large dimensions. Not every workshop can accommodate such a machine, which also limits their use at home. That is why many craftsmen prefer equipment made by themselves.

Many structural elements for making a surface grinding machine can be found in your workshop or garage, but some of them will still have to be purchased additionally. These are materials and devices such as:

- metal corners of two types - 50x50x5 and 25x20x1.5 (their total number will depend on the size of the machine you are going to make);

- pipes with a wall thickness of 2 mm or more, made of stainless steel;

- main electric motor, the shaft rotation speed of which is 1400–1500 rpm;

- a magnetic plate, the dimensions of which will also depend on the dimensions of the parts that you are going to process;

- 4 bearings and a set of ball screws;

- rail type guides;

- grinding wheel;

- end supports in the amount of 2 pcs.

Working surface of the machine with a homemade clamping device

General view of a homemade device Design of lifting the working surface

Do-it-yourself manufacturing of a surface grinding machine begins with a frame, the frame of which is assembled from corners, cut to the required sizes and connected by welding. To increase the ability of the bed to absorb vibrations that occur during operation of the machine, a sheet of chipboard can be mounted into its lower part.

The next structural piece of equipment that will need to be manufactured is the work table, which uses a 4mm sheet of steel welded to the top of the frame.

Rail guides are fixed on the surface of the finished desktop, which must be highly durable and manufactured accurately.

Such guides can be purchased ready-made or ordered from a qualified milling machine operator.

Magnetic plate for grinding machine

A carriage will move along the worktable guides, on which a magnetic plate or a special clamping device is placed. The carriage is also made by hand from corners, which are cut to the required sizes and connected by welding.

Wheels and ball screw elements are fixed to the carriage using screw connections. A screw with a handle, which will be responsible for moving the carriage, is installed in bearing supports, fixed at both edges of the desktop.

Finally, a magnetic plate or clamping device must be fixed to the carriage.

Homemade surface grinding machine with an abrasive wheel as a working part

Homemade belt type grinding machine

The electric motor, on the shaft of which the grinding wheel is fixed, will move in the vertical direction using two guides.

As the latter, you can use stainless steel pipes welded to the frame.

The vertical movement of the metal plate base on which the electric motor will be fixed is communicated using ball screw elements.

One transmission support is fixed at the top of the guide pipes, and the second at the base itself.

To ensure the rotation of the grinding wheels, you can use electric motors from old washing machines or vacuum cleaners.

After the entire structure is assembled, you need to connect power to the motor, lubricate all the guides and perform a test run of your homemade surface grinding equipment.

Such a machine, if desired and necessary, can be modernized without problems by supplementing its design with devices that expand its functionality.

Modifications of magnetic sine rotary plates:

| Name | Table mirror dimensions, mm |

| magnetic sinus plate single-turn PM1S 7208-0001 | 100*250 |

| double-turn sinus magnetic plate PM1S 7208-0001 | 100*250 |

| double-turn sinus magnetic plate PM1S 7208-0003 | 125*400 |

| single-turn sinus magnetic plate PM1S | 160*400 |

| single-turn sinus magnetic plate PM1S 7208-0011 | 200*630 |

| double-turn sinus magnetic plate PM1S 7208-0011 | 200*630 |

| single-turn sinus magnetic plate PM1S 7208-0109 | 200*400 |

| double-turn sinus magnetic plate PM1S 7208-0109 | 200*400 |

| single-turn sinus magnetic plate PM1S 7208-0010 | 200*450 |

| magnetic sinus plate single-turn PM1S 7208-0117 | 320*630 |

| single-turn sinus magnetic plate PM1S 7208-0019 | 320*1000 |

Double-turn magnetic sinus plate PM2S 7208-0003 price – 52,000 rubles.

The plate is new, 2-year warranty, longitudinal and transverse rotation.

Design and operating principle of sine magnetic plate:

due to the work of magnets, the clamping, fixing force is at least 80N per square centimeter, the tilt of the working plate in one or several surfaces allows you to clamp the part at different angles. To order, we make magnetic sine plates with an inclination in the longitudinal direction, otherwise called a “dump truck,” or with a slab inclined in the transverse direction, called a “book.” Due to the quality of the components, all the accuracy and clamping characteristics of the magnetic rotary plate remain unchanged during its service life. A single-turn magnetic plate consists of a base and an inclined part, a double-turn plate consists of a lower base, a middle rotary plate, and an upper magnetic plate. The basic design of the plate: the housing contains magnetic blocks consisting of pole plates, between which permanent magnets are located. The exact angle of rotation is selected by graduation; there is a special scale on each side. The clamp is turned on by turning the handle 180 degrees, the internal magnets shift and form a magnetic field, the clamping of the workpiece is turned off by moving the handle in reverse.

Expert advice and price

The best-selling models of magnetic plates are:

- MP 400x125 sinus 2S7208-0003. Its advantage is the reliable clamping of workpieces using the magnetic currents of permanent magnets, which guarantees a constant clamping force throughout the entire operation. The price of such a device is from 50 thousand rubles.

- MP 250x100 (7208-0001) – slightly cheaper than the previous model, sold from 19 thousand rubles.

- MP flat X91 300x680 (66120-6) – makes it possible to process parts with a minimum thickness of 8 mm/7 mm. Its cost is from 170 thousand rubles.

It provides reliable fixation of the workpiece, which affects the quality of the work. Another good thing about this device is that the technical parameters and possibilities for using such a design remain the same over time. This quality arouses buyers’ interest in electromagnetic cookers.

Technical characteristics and precision parameters of magnetic sine rotary plate:

| Accuracy class | N, P according to GOST |

| Angle of rotation: | |

| — in the longitudinal direction, gr. | 0 – 60 |

| — in the transverse direction, gr. | 0 – 45 |

| Angular installation accuracy: | |

| — in the longitudinal direction, sec. | ±25 |

| — in the transverse direction, sec. | ±15 |

| Flatness of the slab base, microns | 8,0 |

| Flatness of the working surface of the plate, microns | 10,0 |

| Parallelism of the working surface to the base, µm | 10,0 |

Advantages of use

A permanent magnet, in comparison with an electromagnetic device that performs a similar task, has the following advantages:

- Lack of connection of the table to a power source;

- Low maintenance requirements;

- Electrical safety;

- Long-term use of working properties;

- Simplicity and reliability.

Upon completion of grinding (milling), the resulting products are demagnetized by passing them through a demagnetizer coil right there on the machine.