Application and Description of Electromagnetic Rectangular Plate:

use in industrial production for fastening metal workpieces, parts made of ferromagnetic materials Fe, Co and Ni. Plates are often installed on metalworking machines, such as surface grinders, cylindrical grinders, and milling machines. The supply of lubricants during grinding does not affect the quality of fixation of the part to the surface of the plate. Our electromagnetic plates are manufactured in accordance with GOST, divided into standard and small-pole with different pole arrangements. Metal workpieces are fixed by the action of a magnetic field; the moisture resistance of the plate coating allows the use of lubricating fluid, for example, when operating an electromagnetic plate on a surface grinding machine.

Metalwork, page No. 43

Tools for grinding flat surfaces

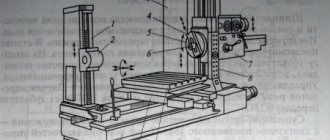

When grinding, parts can be secured directly to the machine table using clamping bars. However, such fastening is used in cases where the parts cannot be fixed to a magnetic plate or other devices.

Pattern vices (Fig. 10.9a) differ from conventional machine ones in manufacturing precision and the ability to turn. The fixed jaw of the vice is integral with the base 1. The body has grooves for the passage of the movable jaw 2, which is moved by a screw 3. The base of the body has threaded holes for attaching the vice to various devices. All vise planes are machined at an angle of 90°. The pressed-in cylindrical measuring pin 4 is used to measure inclined planes.

Rice. 10.9. Pattern vice (a) and electromagnetic plate (b)

Electromagnetic plates . The design of the electromagnetic plate (Fig. 10.9b) is based on the following principle. If a wire is wound around an iron core (Fig. 10.10a) and a direct current is passed through it, the core will be magnetized. If you now bring a steel object to one of the ends of the core, it will be strongly attracted to the core. After the current in the winding stops, the magnetic action of the core will also stop.

You can bend such a core in the form of a horseshoe (Fig. 10.10b) and also pass current through its winding. In this case, the magnet will be even stronger. By combining horseshoe-shaped magnets into a group, we get an electromagnetic plate.

Rice. 10.10. Diagram of the magnetic action of current (a) and a horseshoe magnet (b)

The magnet poles located on the top of the plate are carefully insulated from its body with non-magnetic alloys (babbitt, zinc), due to which the magnetic forces are not dissipated in the body of the plate, but are directed directly into the body of the part. Only magnetic metals (for example, steel, iron, cast iron) can be attracted to the electromagnetic plate.

Electromagnetic plates are used in various sizes, round and rectangular. Only direct current is suitable for powering them, so machines are installed with devices that convert alternating current into direct current.

Electromagnetic plates provide reliable and quick fastening of the parts to be ground. To maintain the functionality of the plate, it is necessary to protect it from shocks and shocks, and also to ensure that no coolant gets on the windings. Upon completion of work, you should immediately wipe the working surface of the stove dry.

Magnetic plates

In addition to electromagnetic plates, magnetic plates with permanent magnets are used on grinding machines. This type of stove does not require special generators and rectifiers with wiring and distribution devices. However, as a rule, the force of their attraction is weaker than the force of attraction of electromagnetic plates.

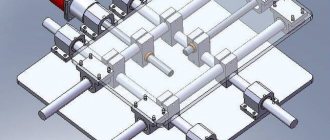

The design of a rectangular magnetic plate and its operating principle are shown in Fig. 10.11. Its upper part is made of steel plates 1 with non-magnetic layers 2 between them (Fig. 10.11a). Strong permanent magnets 4 can be moved, closing them either to the iron plates or to the part being fixed. In Fig. 10.11b shows the position of the magnets when fastening parts 5, and in Fig. 10.11c – during their removal or installation. The magnets are switched using handle 3. The lower part of the plate 6 is fixed on the machine table.

Rice. 10.11. Magnetic plate:

a – general view; b – position of the magnets when securing the part; c - the same when installing and removing the part

Segmented grinding wheels for grinding flat surfaces

Surface grinding with solid grinding wheels of large diameter is economically unprofitable due to large waste, increased heat generation and the possibility of breakage during transportation. In addition, if a crack appears or partial destruction of the wheel, it is necessary to replace it entirely and lose a significant amount of usable abrasive material. These inconveniences are eliminated when using wheels made from inserted abrasive segments (Fig. 10.12). If one or more of them breaks, such segments can be easily replaced with new ones.

The insert segments are used until they are almost completely worn out. By releasing 1 clamp, you can remove 2 segments at once. As they wear, the height of the segments decreases, so spacers are placed under them.

Rice. 10.12. Segment grinding

Machining thin parts

Grinding thin parts on the magnetic table of a surface grinding machine requires preliminary preparation of the base planes (Fig. 10.13). The concavity or convexity of the plane of such parts, formed after planing or milling, cannot be eliminated by conventional installation of them on a magnetic plate. Magnets, attracting the part, straighten it, and after removing it from the table, the part again takes its original shape.

Rice. 10.13. Installing thin plates on a magnetic table:

a – convex down; b – convex upward

Sheet parts are especially susceptible to warping. The direction of their bending is always the same, and the concavity is formed from the side of the grinding wheel. The best way to prevent warping is to remove equal layers of metal from both sides of the record. The plate becomes straight or slightly curved. To maintain parallelism of the planes of such parts, grinding must be carried out as follows. The part is laid with the convex upwards and ground until straight, then the processed plane is turned down and the size is maintained from it. Since the first surface will also receive a slight convexity, you have to make several passes and turn the part over several times.

Quality control of treated surfaces

To control the size of parts and the correctness of their shape during surface grinding, various tools are used. Dimensions are measured mainly with micrometers, staples and minimeters.

Flatness is checked with a sharp edge of a straight edge applied to the controlled plane, and the size of the gap between them is observed. The amount of clearance is measured with a probe. Parallelism between external planes is checked with a micrometer or other measuring instruments. The parallelism of the internal walls is measured depending on the specified accuracy using a template, gauge blocks and an optimeter.

The perpendicularity of the planes forming internal and external right angles is controlled by squares. The angular profile, depending on the accuracy, is measured with angular measures (accuracy 1′), protractors (accuracy 2′), universal and optical protractors (accuracy 5′) and, finally, templates.

Pages:

master4all.com

Modifications and types of electromagnetic plates for machine tools:

— rectangular electromagnetic plate, powered by a DC source, table mirror dimensions from 100mm*250mm to 630mm*2000mm. Can be used when supplying coolant and emulsion.

— electromagnetic small-pole plate with a transverse arrangement of poles, interpolar distance 15 (3+12), 28 (15+2+11), 4 (1+3), 2 (1.5+0.5).

— electromagnetic small-pole plate with a longitudinal arrangement of poles, high accuracy and tightness.

Electromagnetic rectangular plate PE7208-0057 (200x320mm) price – 47,000 rubles.

Electromagnetic rectangular plate PE7208-0060 (200x630mm) price – 50,000 rubles.

The stove is new, all components are made in Russia, 2-year warranty, quality complies with GOST.

Design and operating principle of the electromagnetic plate:

we can make a slab to suit the size of the desktop, the width of the slab varies from 100mm to 630mm, length from 250mm to 2000mm. When connected to a constant power supply, there is an attractive force of at least 60 N per square centimeter. There is a requirement for the minimum dimensions of the installed workpiece; they range from 10-20 mm in the longitudinal and transverse directions. To order, we produce small-pole slabs with a transverse or longitudinal arrangement of poles, the design becomes more complex and more expensive, the client can choose the interpole distance: 4mm, 15mm, 28mm. Due to increased moisture resistance and build quality, the service life of magnetic plates is 10 years. The stove is powered from a constant current source, standard voltage 110V. Basically, rectangular electromagnetic plates are installed on surface grinding machines; when processing a part, the supply of lubricating fluid is turned on; it does not affect the quality of fixation of the workpiece to the plate, nor does it affect the durability of the structure. Connection requires a 110V DC power supply. Plates with transverse poles have increased attractive power compared to conventional ones, and it is also convenient to secure small workpieces.

Magnetic plates with permanent magnets

In Fig. 136 shows a general view, and Fig. 137 - plate design with permanent barium oxide magnets. It has a box-shaped cast iron base 1 (see Fig. 137), in which a movable power block 2 is located. The lower support plane of the movable block is separated from the cast iron base by a non-magnetic layer 3, which reduces magnetic flux leakage through the body of the device. On top of the base are installed an upper magnetic block 7, assembled in a frame made of non-magnetic material, and an adapter plate 6. All these units are connected to each other by through screws and are mutually oriented by pins.

In order to reduce magnetic flux leakage, the distance between the poles on the adapter plate is filled with non-magnetic styracrylic, which in this case is also a structural material.

Rice. 136. General view of a plate with permanent magnets

The movement of the movable block 2 is carried out using a gear-eccentric drive, consisting of a lever-handle with a toothed sector 9, a gear 8, a pin 5 and a pillow 4. The latter is located in the groove of the pole of the movable block.

Rice. 137. Design of a magnetic plate with permanent barium oxide magnets

The increase in force transmitted by the handle to the movable block (reduction) is determined by the ratio L:e, where L is the length of the handle, and e is the eccentricity. Despite the significant reduction, the force on the handle still remains quite large (50-70 N) and, with frequent activation, can cause additional fatigue for the worker. In order to completely eliminate the cost of manual labor for switching the handle in some designs of magnetic plates, the movement of the moving block is mechanized and carried out using a pneumatic drive.

Similar materials

www.metalcutting.ru

Technical characteristics and accuracy parameters of electromagnetic rectangular plates:

| Length, mm | from 250 to 2000 |

| Width, mm | from 100 to 630 |

| Nutrition | 110V |

| Height, mm | 100 – 120 |

| Attractive force per 1 cm2, N | 60 – 80 |

| Minimum part dimensions, mm | 10x10*2 |

| Execution according to GOST | 30273-98 |

| Flatness of the slab base, microns | 8,0 |

| Flatness of the working surface of the plate, microns | 10,0 |

| Parallelism of the working surface to the base, µm | 10,0 |

Magnetic plates

In various production areas it is often necessary to use such working elements as magnetic plates. This product is usually used widely in machine tools. The purpose of magnetic plates is usually to secure iron-containing parts to these plates, which are used as holding elements. Magnetic plates perform a function similar in principle to the function of a vice, however, these elements have a number of advantages over a vice, since they do not cause mechanical damage to parts and do not deform them.

Application of magnetic plates

Most often, magnetic plates are used on machines of various types of production, these can include grinding machines, milling machines, lathes and many other types. They are often used as a separate device to assist in such work as welding and assembly of various structures and parts.

Structurally, the magnetic plate is made in the form of a reinforced metal plate, inside of which powerful magnets are installed; about four of them are installed. Depending on the model of the magnetic plate, its length can be of different sizes, and the width of the magnetic plate also varies within different limits. The attractive power of the magnets themselves may vary depending on different versions of the plates, but as a rule, the average value is a value of eighty Ncm2; the thickness of the magnet layer is approximately eighteen millimeters.

Magnetic plate design

The magnetic plate is structurally made of three main elements. These elements are magnetic blocks, which can be either movable or remain immovable in the main body. The magnetic plate blocks are made in the form of metal plates, which are the basis of the entire structure. In these plates, or rather between them, there are magnets, which, as a rule, are made of ceramics. The remaining space is filled with material that does not have magnetic properties.

The magnetic block, which has a movable state, moves inside the plate through the operation of a top, which is eccentric. The movement of this element is carried out by adjusting the handle, and the movement of this element is possible by about one hundred and eighty degrees. The magnetic plate begins to function only when it is turned on; the rest of the time the magnetic plate does not perform any work. This type of plate has many advantages over other types of holding devices. These advantages include the high efficiency of this design, which ensures an accurate and even position of the product, which in turn allows it to be completed with maximum accuracy.

The magnetic plate provides a very strong and reliable fastening of the material, and this is the key to the correct execution of the work on its processing. All operating parameters of a magnetic plate remain unchanged throughout the entire life of this device, so the choice of this type of equipment is the most popular today. Another excellent characteristic of magnetic plates is that this device does not require additional maintenance or repair work throughout its entire operating life.

It should also be noted that, if necessary, the surface of the magnetic plate can be sanded depending on the parts used on the plate.

promplace.ru