The electrode holder is included with the welding machine. Its function is to hold the electrode in the desired position during the welding process and provide current supply to the work area. The quality of the accessory will determine the reliability of the welded joint, the formation of defects, productivity and safety of work.

The designs were gradually improved, the appearance and the principle of fixation changed, but the convenience and reliability of fastening was always valued. Welders use both old and new clamp models. They can be selected at your discretion and used with any welding machine. In addition, they periodically fail because they come into contact with a melting rod. The welding holder is easy to replace and rearrange due to its versatility.

Types of ground clamps

Ground clamps for welding machines, depending on the nature of the fixation, can be of several types. Next, we will look at the main types of clamps, as well as their advantages and disadvantages.

Welding earth clamp “crocodile”

Most often, performers use an alligator clip (“clothespin”) for grounding, which is attached directly to the part.

Advantages:

- reliability of connection with the surface of the part;

- convenience and speed of use;

- minimum connection resistance;

- the ability to fix parts of various geometric shapes, including those with complex configurations;

- high degree of disclosure.

The main disadvantages should also be highlighted:

- low, compared to other types, level of strength of some components - spring;

- This type of clamp is used only in cases where it is possible to attach directly to the product.

The alligator clip should be selected based on general recommendations. Terminals of this type are available in three main modifications: ground clamp 300A, 200A and 500A. Depending on the model of the welding machine and the current it produces, you need to determine the optimal modification. To carry out work at a professional level, it is recommended to purchase a 400-500A clamp.

Important! It should be noted that the use of a “clothespin” clamp when welding large diameter pipes is impossible.

Useful video

We recommend looking at tips on how to extend the life of the clothespin that came with the device and what to consider when buying a new one.

Magnetic mass for welding

Welders quite often use magnetic ground clamps. This type has a whole range of advantages:

- the ability to attach the contact to any surface or structure, including pipes;

- simplicity of design ensures durability and trouble-free operation;

- the absence of springs and other mechanisms also contributes to long service life;

- a ground magnet for welding is able to withstand voltage surges and not burn out;

- successfully used in hard-to-reach places;

- The large contact area guarantees secure fastening.

Flaws:

- unreliable fastening of the contact to small parts, for example, fittings;

- impossibility of securing the clamp to products made of non-ferrous metals;

- the magnet must be periodically cleaned of contaminants, in particular metal shavings;

- overheating of the magnet should be avoided, otherwise it may demagnetize; Overheating occurs if the terminal is attached to a dirty surface.

3. Clamp

Clamp-type welding clamps are used less frequently than the two types listed above. This type of terminals also has several advantages:

- high degree of fastening reliability, since fixation is carried out using a hex head screw;

- good contact with the workpiece ensures a smooth transition of current.

The disadvantages include the rather complex structure of the mechanism and the relatively large dimensions of the terminal.

Centralizer

In rare cases, experts select a centralizer-type clamp, designed for centering and tacking pipes previously located in the desired position. Can also be used to connect welding parts.

Advantages of this type:

- ensuring tight contact;

- guarantees welding accuracy;

- Suitable for pipes of various diameters.

Flaws:

- limited scope;

- high cost compared to other types of clamps.

Useful video

We recommend watching the video, which contains recommendations on how to extend the life of the complete mass of the crocodile and which one is better to choose for purchase.

And another review from an experienced welder, which has some tricks.

How to Make an Alligator Clip Last Longer

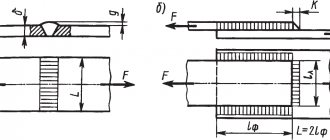

The alligator clip has several weak points. It has a spring that has a service life. But even when the compression force is not so important and the issue with the spring disappears, the tendency of the “crocodile” remains to burn out at the junction of two moving parts in the hinge area. This is because contact with the cable through the bolted connection is made only with one part of the crocodile.

During the welding process, you can observe a process where that part of the “crocodile” where the mass is connected may have poor mechanical and, therefore, electrical contact with the part, while the opposite part, on the contrary, has good contact. Then all the current will flow through this element. But here a weak link appears - the hinge; in the area around it there will be unstable conductivity, overheating and melting of the metal.

Information to note. Experts recommend throwing an additional soft bus from one crocodile sponge to another, then in any case the current will flow from the metal directly to the ground, bypassing the weak link!

Anyone who has real experience in solving the problem of how to improve the contact of the welding compound clamp, or questions on this topic, write in the comments!

Creating a Swenson Square

Hydrogen engine: features, advantages and disadvantages

The author of such a useful device did not have time to properly file a patent for his brainchild, and numerous businessmen are actively using it. The only thing they can't use is the special diamond cut hole, but some very resourceful competitors make a slightly different shaped slot.

In the initial version, the Svenson square did not have a comb for special parallel markings and the hole itself. However, the comb is not an option that you cannot do without. It must be said that in almost a hundred years of history the device has not undergone significant changes.

Types of magnetic holders

Types of gas burners: their advantages and disadvantages

Today, the welding equipment market offers various modifications of magnetic holders, which differ not only in shape, but also in their operating principle:

Magnetic square. This is the simplest monolithic special design. welding fixtures, which provide the ability to position the workpieces to be welded at a certain angle.

Magnetic clamp. This device is flexible and allows you to set any desired angle.

Latch. Such devices can be either monolithic or complex configurations, with an adjustable angle. The main feature of this holder is the “fastener release” function. When you press the button, the action of the magnets weakens, as a result of which the device is quite easily rebuilt. The switchable magnetic clamp can be used quite effectively when working with powerful corners.

Holder angles are also distributed according to power. Standard low-power devices are used for light metal samples, and angles with powerful magnets are used for heavier metal structures.

What features of the device should be taken into account

The most significant features of the device that you need to pay attention to are briefly formulated below:

- Ergonomics, weight, linear dimensions.

- Condition of the clamping device: reliability of contact between the jaws and the cathode, quality of surface treatment.

- Handle insulation quality. A hundred volts can not only scare, but also easily kill.

- Maximum operating current and diameter of electrodes compatible with the holder.

- Reliability of welding cable connection. The best connection is soldered, followed by threaded connections in terms of quality. Chinese crimp connections are best left on the shelf.

A correctly selected welding machine holder in a store or a well-made one with your own hands will provide the opportunity to do what you love without being distracted by little things like a dropped rod or a fallen cable.

Manufacturing a welding angle

Welding pencil: principle of operation, advantages and disadvantages

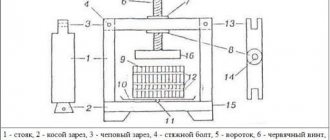

First of all, we shorten the bolts so that they can fit into the enlarged nut (select the sizes individually). I cut off the bolts with a regular grinder.

Next, I sanded the magnet a little to round off the sharp edges a little and so that it would fit in the corner between the nuts.

Then I slightly drilled holes in the corner for the bolts, and also drilled additional ones in the middle of the corner in order to secure it with three nuts in the future.

Now we need to put everything together.

To make the instrument look beautiful and stand out from other instruments, I painted it bright blue.

It all turned out quite beautiful!

Dimensions

Magnetic devices are small in size, which makes them so popular. The length, width and height parameters of equipment with magnets may vary, but regardless of the model and manufacturer, they are all compact and easy to use. The average weight of the product is about 1 kg.

The most important indicator is the force of attraction (holding or pressing) of the magnetic corners. Manufacturers and suppliers may specify this parameter in pounds (LBS or lbs) or kilograms (kgf). The maximum value of this indicator is 34 kgf or 75 lbs. You can also find the following values: 11; 13; 22; 23; 24 kgf and others.

Depending on the tasks, you should choose the necessary model.

How to make a welding holder with your own hands: types of holders

Requirements for holders

The electrode holding device is a very important component, although its design is quite simple. The following are some requirements:

- adequate dielectric and thermal insulation protection must be provided;

- the wire must be fastened securely;

- reliable retention of the rods must be ensured;

- The cinder should be easily replaced with a new rod.

Factory fastener models

Before considering a homemade electrode holder, you should learn about factory models. There are several types of them.

Collet

A very convenient type of clamp, it is light and compact. The electrode here is easily replaced with a new one. The collet handle protects well from electrical and temperature influences. The disadvantages include high cost and limitations on operating current. You should also not leave a short stub, as this can damage the handle.

Pin

The most common type of restraint devices. Depending on the strength of the operating current and the diameter of the electrodes, the holder can be of different sizes. The clothespin can be used when working with almost any current value. The contact with the rod is good, and with the help of the handle you can easily get rid of the cinder. The disadvantages of clothespins include a larger design and a more complex process for replacing the electrode.

Fork (trident)

Currently, holders of this type are not commercially available; they can only be found on secondary markets. The fork differs from previous types in its simple design. The electrode is almost completely gone, the cinders are very short. But, perhaps, these are all the advantages of the trident. The trident does not comply with safety regulations, which causes a high level of injury risk. In order to remove the rod from the fork, it is necessary to use additional tools, such as a hammer or pliers.

DIY welding holders. How to make a welding holder?

If desired, you can make a homemade holder for welding. Perhaps homemade models are inferior to factory ones in quality and reliability, but they can also be used. Such holders are a fairly cheap analogue to expensive factory models. Here we will look at the designs of homemade holders of various types.

Trident

We talked about this type of retainer above when we described factory models of retaining devices.

This model is easy to make yourself. The trident consists of three pieces of reinforcement welded together in a certain way. In order to protect yourself from electric shock, you can put a piece of rubber hose on the handle. Despite the simplicity of the design, it is necessary to use a homemade electrode holder with extreme caution, as there is a risk of injury during operation. Due to the fact that the reinforcement is constantly covered with scale, it must be cleaned in order to obtain a good weld.

Scale affects the loss of current, thereby impairing contact and making the welding process less efficient.

Fork with spring

Modernized version of the fork. The trident (fork) with a spring must be made of high-quality stainless steel, which will improve the quality of the welding process. A homemade electrode holder of this design has a spring-loaded finger instead of one reinforcement rod, which makes it easier to replace the cinder with a whole electrode.

Threaded and collet fasteners

The thread lock can be made from available material. The manufacturing process is quite difficult. The electrode here is inserted into the provided hole and pressed with a bolt. In the clamping version, the rod is pressed against the holder by a spring-loaded latch. These holders provide good contact, which has a beneficial effect on the welding process, seam formation, and current flow.

Finally

Based on the information provided above, we can say that a DIY welding holder is quite easy to make. Homemade clamps are less reliable than factory ones and require careful handling. But at the same time, it is a cheap and simple analogue of factory models. The homemade holders given above are easy to make at home, because their production does not require expensive and complex parts; everyone can find everything they need at home.

Classification of welding holders

On the equipment market, manufacturers offer a wide range of electrode holders. Despite this, they use several basic methods of fastening and design.

Main types of electrode holders:

- spring (lever);

- clamping (screw);

- universal;

- specialized.

A standard electrode holder consists of a housing, an insulated handle, a clamp and a movable locking mechanism. The design and operating principle of the holder may differ.

Clothespin or pliers

This type is most widespread, which is explained by the optimal fastening for convenient welding. This welding holder also has a drawback - weak clamping force on the electrode with the jaws.

To secure, just press the handle and insert the bare end of the rod into the serrated jaws. Access to the clamps remains open, so the angle of location can be changed. In this case, the current supply is completely inaccessible.

Fork trident

Fork holders for electrodes are considered one of the first. Their production was mastered more than 50 years ago. They were heavy and uncomfortable.

The plug structure often burns contacts, and due to poor insulation of metal surfaces, a short circuit occurs.

Based on the existing diagram, craftsmen made a fork themselves from fittings of a suitable diameter. Three rods were bent to the desired position and welded together. All that remained was to form a handle from the welding wire and weld the edges, and put a rubber hose on top.

The resulting device also turned out to be imperfect. The electrodes are not attached reliably, resulting in poor contact between the reinforcement and the wire. At high currents, the welding holder becomes very hot and makes it difficult to remove cinders.

Screw

The screw-type electrode holder ensures a reliable position of the electrode in the clamping device.

It is a closed structure with an insulated housing. The disadvantage is that you have to spend time unscrewing and tightening the fixing head to change the rod when welding. Gradually the fastening weakens and the rod may fall out. Another minus is only a perpendicular position. To install the electrode, the fixing screw is unscrewed. The exposed edge is tucked into the hole and tightened with a few turns of the handle.

Collet lock

The collet electrode holder appeared relatively recently.

It has become more convenient to change electrodes; now you do not need to waste energy. The design is lightweight, ergonomic and compact. Disadvantages are the limitation on the maximum welding current and the wasteful use of electrodes. You have to leave a long stub so as not to damage the plastic on the body.

The collet holder is mainly used for precision argon arc welding of small parts where the currents are quite low.

Non-garden

In a burner-free electrode holder, the electrode is completely consumed. This is possible due to the fact that the rod is not fixed with a clamp, but is welded to a structure with an insulated surface. During the welding process, it completely melts, after which a new one is taken.

How to make magnetic mass for a welding machine at home?

Magnetic mass for welding is a special device that provides reliable fixation on metal surfaces. This allows you to comfortably perform welding work on complex surfaces where the use of classic alligator clips is impossible.

There are many design options that depend on the work conditions. The structure of this device is not particularly complicated. For this reason, some craftsmen prefer to use homemade magnets for welding.

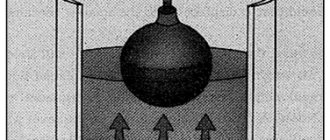

What's happened?

This device is mounted on the working plane of the workpiece. Thanks to the active magnetic field, a strong fastening is achieved, creating a closed electrical circuit - the main condition for the formation of an electric welding arc.

The tool is especially popular among novice welders - it will take a few minutes to familiarize yourself with the principles of the work. Experienced specialists use magnetic mass for welding machines for critical work - welding large-diameter pipes or connecting load-bearing units made of profile materials.

Design of magnetic contact and its characteristics

Consists of two nodes:

- Cable holder. The ground cable of the welding equipment is attached to it using a bolted connection.

- Magnetic node. The size of the magnet depends on the design features. Some models are equipped with a mechanism that regulates the pressure of the magnet on the working plane. Professional devices have switches.

The parts are connected to each other by a rigid fastening. The main characteristics of the devices are:

- Dimensions and weight. Depends on the manufacturer and specific model. The average weight is 1-1.2 kg.

- The force of attraction to the surface. Varies in the range from 2 to 50 kg.

- Welding current strength. The maximum value of the parameter is measured in amperes. For entry-level models, it does not exceed 200 A. An advanced tool is capable of operating at 400-500 A.

- Execution type. They produce special clamps for corners with gap adjustment.

Is it worth buying?

The answer to this question can only be given by the master performing the work. For a novice welder who has just started his professional career, this device can make life significantly easier.

If a specialist works primarily with non-ferrous metals, a magnetic clamp will most likely not be useful.

The cost of the device is quite high. If you have knowledge in the field of electrical engineering, you can try to make it yourself. The technology and manufacturing process will be discussed below.

How to do it yourself?

Experienced craftsmen try to reduce all costs for the purchase of auxiliary and working equipment to a minimum. Due to the simplicity of the design, no special equipment or complex tools are needed for manufacturing.

To assemble a homemade device, you should prepare the following equipment:

- Magnet. The working part of the unit. It must have sufficient power to securely attach to metal. Magnets from old car speakers with a power of 10-15 W are ideal for this purpose.

- Two washers. Their size must correspond to the diameter of the magnet.

- A set of hardware for fixing the welding cable.

Algorithm for performing the work:

- One of the washers will make contact with the working plane. It is necessary to make a hole in it corresponding to the size of the bolt head.

- The cap is cut to the thickness of the washer.

- After preliminary preparation, the structure is connected by welding. The product should resemble a mushroom, in which the threaded part of the bolt plays the role of a leg.

- A magnet is placed on the mushroom. Place a second washer on the reverse side.

- A welding tip is attached to the thread, and the entire structure is secured with nuts.

Functionality testing is performed only in the field. The quality criterion will be the correct functioning of the welding machine.

DIY welding compound is a great way to save money, as well as a way to test your DIY skills.

A properly assembled device will last no less than the factory clamp.

Conclusion

Magnetic mass is a useful invention that can make life easier for both beginners and experienced welders. The device has many advantages that justify the rather high cost.

The need to have this device in the arsenal depends only on the specific master. Having the appropriate skills, you can assemble a magnetic clamp yourself, using available materials.

How to choose a welding holder

The electrode holder is selected according to the type of welding operations most frequently performed. When comparing models, pay attention to the following characteristics:

- technical data. What matters here is the maximum current. It is necessary that it exceeds the welder’s rated capabilities by 10%;

- diameter of installed electrodes;

- dimensions and weight. Given the impressive volume of work performed daily, these parameters are very important;

- welding cable connection type. Threaded is preferable. The Chinese version with a crimp connection is not recommended;

You should not purchase a holder with a power reserve. It won't last much longer anyway.

- conditions for welding. The housing material must withstand low temperatures and high humidity if you have to work in an open space;

- price. The price range for electrode holders is quite large. For small, periodic work, you can choose a cheap option that meets the previous criteria. It all depends on the task being performed. Professional welders need a more expensive device;

- It is recommended to keep an inexpensive holder in reserve in case the main one breaks during the suture process.

Regular maintenance will help extend the life of the accessory. The clamp should be cleaned of scale and dirt every time. When the electrode comes into contact with clean sponges, the seam is smoother and of higher quality.

It’s good when the holder has a quick electrode change. Then it’s easy to get rid of the cinder and replace it with a new rod.

Main requirements for holders

- The clamping part must be brass.

- The device should be light, compact and comfortable in the hand.

- The quality of the clamping jaws.

- Contact with the electrode must be tight.

- It is better to give preference to the middle price category.

- A good holder has an elongated handle with grooves that prevent slipping in the hand.

- The type and condition of the insulation on the handle, on which the safety of the welder depends.

- The electrodes must be securely attached at different angles.

- Ideally, the holder can withstand 6,000 installation and removal cycles.

How to choose the right electric holder

When selecting a holder, you should pay attention to the following characteristics:

- Size and weight of the device. The weight and dimensions of the holder are very important. When working for many hours, the extra 50 grams of the device will be felt. In this case, it is better to purchase a compact and lightweight design. If you have a choice, give preference to light and small parts, provided they have the same characteristics.

- Specifications. The holder must match the current strength. Failure to comply with this requirement will result in burnout of the contact part. If the contacts burn, further use of the device will be impossible. You can determine whether a device belongs to a category based on current strength by the markings that are applied to the non-replaceable part of the product.

- Quality of insulating material. To ensure safe performance of work, you should select a holder with a high-quality insulated handle. Plastic of sufficient thickness is used as a dielectric in almost all parts to reliably protect the welding machine operator from the effects of electric current.

- Price. You can buy a holder for a welding machine from 100 rubles, but the quality of a cheap model will not differ. Branded copies sell for several hundred dollars, but for everyday work there is no need to purchase holders at that price. It is enough to purchase a product in the middle price category to provide yourself with a high-quality tool for welding metals for a long time.

Video:

The best holder models

To purchase an electrode holder for a welding machine and not be disappointed in its quality, you should choose models that have been used by welders for a long time and do not cause negative emotions in them.

Negative reviews most often occur about Chinese-made products, but low-quality products can enter the domestic market from other countries.

In order not to make a mistake when choosing a holder, it is recommended to purchase the following models:

1. ESAB Handy 200 (200 A) - is in great demand among professional welders.

The part has high performance characteristics that do not decrease throughout the entire period recommended by the manufacturer. The product was made in Sweden, so you can count on European quality.

The Handy 200 weighs 550 grams, but given the good insulating coating and high-quality clamp, the slight increase in the weight of the holder compared to other models is quite justified. Handy 200 is a screw holder, which allows you to perform welding work efficiently and safely.

When using the device, you can weld metal with electrodes with a diameter of 2.0 to 4.0 mm. The cost of the product on the Russian market is about 500 rubles.

Video:

2. Sibrteh 500A - an inexpensive but high-quality domestically produced instrument that can be used up to 500 A.

The Sibrtech 91455 500A holder is a clamp-type device in which the working electrode can be replaced quickly.

The product has reliable plastic insulation, which can protect the operator from the effects of electric current. You can buy it for 300 rubles.

Video:

3. ESAB 500 is a holder from a well-known Swedish company that has been producing high-quality products for more than 100 years. The esab electrode holder can be used for welding work with currents up to 500 A.

The main advantage of ESAB 500 products is their ultra-light weight, which is only 200 grams. The cost of the product on the Russian market is about 3,000 rubles.

4. Germany type 300 A - ideal for welding with currents up to 300 A and electrode diameter 2 - 4 mm. Thanks to the special corrugated design of the device’s handle, it is possible to achieve a reliable hold in the hand. The model is distinguished by high-quality plastic insulation and relatively low weight.

The current-carrying part has a low resistance coefficient and high corrosion resistance due to the use of brass as the main material. The electrode can be fixed in the device in four positions, which makes performing complex work more comfortable and precise. You can purchase Germany 300 A for only 300 rubles.

PS If welding holders for manual arc welding are selected correctly, the connection of metal structures will be comfortable.

Magnetic corners

Magnetic angles are very practical and can be of great help to the welder, especially if he is working without an assistant.

Such devices can be of several types in configuration: triangular, pentagonal, reminiscent of a trapezoid. Their application in practice is simple, just take the required magnet, install it on a horizontal plane and attach a metal rod to the edge; it will be fixed in the tilt position of the magnetic edge. So, for example, you can easily, by aligning the prepared sections at right angles, assemble the frame, align it, eliminating any distortions that have arisen by taking diagonal measurements, and fix it by welding. Also, with the help of these corners, you can fix the vertical posts without fear of their deviation from the vertical. Magnets are produced in various configurations and sizes, which are divided into series. The side edge must indicate the slope of the edge in degrees.

Another convenient device is a mass holder.

The principle of operation of a magnetic contact is not difficult to understand. It is a magnet for connecting a second wire to the workpiece to create a looped circuit (the first one will be on the electrode). Such a wire is usually called a “mass”. The ground wire is firmly connected to the magnet, then touch-connected to the workpiece. Connecting the secondary wire in this way has its advantages and disadvantages.

Advantages:

- it is possible to create a circuit as close as possible directly to welding, which reduces the resistance to current as it moves through the metal;

- quick connection and connections with the ground cable blank;

- does not require additional maintenance, as it has a simple design.

Flaws:

- a clean surface is required to establish contact;

- low mechanical strength of fastening;

- dependence of the magnet size on the current strength;

- A large mounting area is required;

- unacceptable when welding narrow-profile or small-sized parts;

- decrease in magnetic properties over time and heating.

- high price. The cost of magnets for a contact of 200 - 300 A will cost approximately 500 - 600 rubles.

Welding machine Resanta – SAI 250

This device is one of the cheapest and most powerful in its line. The head office of Resant is located in Latvia and the device is manufactured in China under license. The inverter is positioned as a professional one, producing electrodes with an arc power of 150 to 250 A (electrode diameter 3-6 mm). Available complete with all accessories: cable, holder and earth clamp.

"Resanta" produces a line of inverters in 160A, 190A. Separately, you can dwell on the electrode holder for the resanta welding machine - this device, made of especially strong and heat-resistant plastic, has good reviews from users.

How to use magnetic mass? And is it worth buying it?

Reading time: 2 minutes

Magnetic terminal, magnet clamp, magnetic contact of welding cable This device has many names. But the essence is always the same: a magnet allows you to quickly and reliably attach it to the ground and start welding.

But what is it? What are the pros and cons of a magnetic ground terminal? How to use it and is it worth buying at all? You will find the answer to these and some other questions in our article.

What it is?

The magnetic contact of a welding cable is a device that is mounted on the surface to be welded (ground) using an active magnetic field. The device is necessary to form a closed electrical circuit. Without this, manual arc welding is impossible.

The magnetic ground clamp is very popular among both beginners and professional welders. Magnetic mass is also often used for DIY welding at home. It quickly and securely attaches to any surface, even curved ones.

Advantages and disadvantages

We have already mentioned several advantages of a magnetic terminal above. But the list does not end there. The magnetic terminal has a simple design, so it is extremely durable and lasts for many years. Simply put, it is a regular magnet with a switchable or permanent magnetic field. There are no springs or other mechanical elements that can fail.

The magnetic terminal tolerates temperature and voltage changes well. It rarely burns out and can work with most types of metals. Also, such a ground clamp is indispensable when welding in hard-to-reach places. Even if the part is bent, the magnet will still provide reliable fastening due to its large contact area.

But it was not without its drawbacks. So the magnetic terminal is not able to provide reliable fastening to small parts. For example, on fittings. To maintain an active magnetic field, the device must be constantly cleaned. Its operation is very badly affected by metal shavings.

Also, to use a magnet, preliminary cleaning of the metal is necessary. If you attach a magnet to uncleaned metal, the device will stop working.

Don't forget that there are metals that are not magnetic. These are most non-ferrous metals. You won't be able to use a magnetic terminal with them.

How to use?

There is nothing complicated about using a magnetic terminal. Most models have a special handle, turning which you turn on the magnetic field. By default, the magnet will not attach to metal.

Popular models

Consider popular welding ground clamps. The market for the sale of welding consumables offers a wide variety of work clamps, both domestic and foreign. Next we will look at the most popular models.

Earth clamp Ergus 300A Pro , manufacturer - Quattro Elementi (Italy). Characteristics : crocodile type; affordable price; high quality; light weight; supports current up to 300A, which is perfect for the home craftsman.

Ground clamp Skrab 27621 300A (in the picture), made in Italy. It is one of the best options for doing work at home.

Popular grounding terminals are Russian models. The Moscow company offers clamps with various types of mechanisms.

For welding work in industrial or production environments, it is recommended to select a mass clamp of 500A or more.

Elitech 500A mass clamp, made in China.

Choosing or making a holder: tips and tricks

A more reliable and durable welding element, which allows you to hold the electrodes during the soldering process, is a holder with a threaded fixation. It allows you to select the level of inclination of the electric cathode at any angle.

Electrode holder designed by V. Anikin.

Select a holder that allows you to fix the electrodes taking into account the welding current required for the operation of the equipment. When planning a job that involves traveling, you should carefully consider a backup version of the welding fixture. You should not skimp on this device if you need to perform professional welding under prolonged loads. This will increase the service life of the holder.

If the choice is made on a device holder designed for 200 amperes, then when welding using such an inverter operating at a current strength of 300 amperes, this device will only be enough for two days. During the welding process, a characteristic smell of plastic will appear, burnt when the electrode holder is heated and there is weak contact between the device and the welding electrode. This will lead to burning of the holder clamp, which will then fail, becoming unsuitable for further use.

When choosing a holder, you should take into account its amperage, which increases as the weight and size of the device increases. Convenience of work can be ensured by selecting a holder if a current strength close to the working current of the welding inverter is required. Holders corresponding to 200-500 A are often available for sale.

What is important when choosing a holder

An electric welder holds this device in his hands for a significant part of his working time, so his choice should be approached with maximum responsibility. An experienced master will definitely pay attention to the following points:

- weight, dimensions, ergonomic qualities of the handle;

- compliance of the product labeling with the range of current used in the upcoming work;

- possibility of reliable fixation of electrodes of the required diameter;

- ease of fastening the rod at different angles;

- quality of manufacture of live parts and clamping devices;

- the degree of outer coating of the holder with insulating materials;

- model cost.

choosing a magnet for a welding machine

When working with complex structures, any welder will appreciate all the advantages of magnetic mass. This is a fairly convenient device that allows you to attach it to parts to be welded without any problems.

As a result of using this alternative to standard “crocodiles,” it becomes significantly more comfortable.

Contact Features

Magnetic mass for welding work.

As a rule, it is equipped with a clamping cable. At first glance, it may seem that the use of such devices is very convenient. After all, they are securely attached to most products, especially when it comes to sheet metal.

However, there are often situations where installing this type of clamp is not possible. Magnetic contact is an excellent replacement for the usual “crocodiles”. In addition, such a device can be easily mounted on any surface.

This device has a number of advantages:

- the ability to easily attach to the surface of the product being welded;

- a simple, almost eternal design, the probability of failure of which is minimal;

- this device does not burn out, as it can withstand power surges;

- high reliability ensured by a large contact area.

The only disadvantages include the inconvenience of connecting to small products, rods and fittings.

Bottom line

Magnetic mass is a useful and simple device that makes welding work more comfortable.

This contact is more reliable. It can withstand voltage surges and is more durable due to its simple design.

What is a welding holder and how to work with it

Before you include a welding machine holder in your work, you need to be well aware of all its functions, advantages and disadvantages. Let's say the voltage in your welding inverter is about 300A, moreover, it is running at full power, and the holder you are using is only rated for 200A. Then using the latter in your work will not be the best idea: the holder will simply burn. Therefore, to prevent this from happening, read the characteristics of the device more carefully before purchasing it.

Note that the conditions in which you have to work with the electrode holder are not the best. Constant heating and sudden cooling, however, the voltage even at 200A is quite high, external environmental influences: rain, dirt, snow, etc.

Therefore, a good welding electrode holder is made of durable and reliable materials: the jaws that clamp the electrode are made of copper, since this metal conducts electricity better than aluminum or steel, the outer casing is protected by a thick layer of plastic, the clamp should be large and, if possible, , cast Don't waste money on a good grip.

Let us note here that many welders buy a holder for a welding machine with a “reserve”, that is, they work at a voltage of up to 200A, and the device is designed for 300A. Of course, this option is the safest, you don’t have to worry about overvoltage, but the higher the stability threshold of the holder, the larger, more massive it is, and therefore heavier. Remember that when working in inconvenient conditions, it is better to buy a holder with a suitable amperage for the work.

As already described above, the function of the holder is extremely simple: a cable with a certain voltage (calculated in amperes) is connected to the back, the base is unscrewed using a screwdriver, to which the cable is attached, and the electrode is clamped in the pliers. Next, the current is conducted through the cable, through the holder and to the electrode.

Note that for many holders, the insulation (plastic covering) is held on by screws, that is, if possible, you can replace the old plastic with a new one, thereby avoiding unnecessary worry and, at worst, damage. It’s better to monitor the condition of your devices constantly if you don’t want to harm yourself.

Is it worth buying?

The answer to this question can only be given by the master performing the work. For a novice welder who has just started his professional career, this device can make life significantly easier.

If a specialist works primarily with non-ferrous metals, a magnetic clamp will most likely not be useful.

Experienced workers have a set of various clamps for all occasions, including this device.

The cost of the device is quite high. If you have knowledge in the field of electrical engineering, you can try to make it yourself. The technology and manufacturing process will be discussed below.

How to improve the ground terminal?

This problem is usually encountered by novice welders. Purchase a budget manual arc welding inverter for welding at home: for a fence, gate, canopy, etc. Such an inverter, costing 6-10 thousand rubles and more, is equipped with a “Crocodile” clothespin. In addition to other negative aspects of such a clothespin, which were already mentioned above, it most likely has steel jaws coated with a thin layer of galvanic copper (to give the impression that they are copper). It’s very easy to check whether it’s copper or steel; you just need to hold a magnet. If it is magnetic, it means it is steel. Usually, food-grade stainless steel in an unhardened state is not yet magnetic, but that’s a completely different story (read the article “How to determine what kind of metal”).

What are the dangers of steel jaws? They will get hot - steel is a much worse conductor than copper or brass. To prevent this from happening, you can remake a cheap clothespin that costs 40-50 rubles. (if, of course, you have some copper or brass in your household, for example, a plate or tube, a busbar).

Magnetic mass for welding. Advantages and disadvantages

Like everything else in the world, this device has both positive and negative sides. Let's look at the pros and cons of magnetic mass for welding. Some of the points below will only make sense in comparison to the clothespin.

Just a second, attention! Have you ever wondered why a semi-automatic welding machine fires? We answered this question to one of our colleagues...

Pros:

- Easy to use

- Can be used in places where there is nothing to attach a clothespin to

- Reliability of the hook - no need to be distracted, the mass is firmly fixed on the surface

- Unlimited use

- When securely fixed, the mass does not heat up

Minuses:

- Constant contamination of the magnetic surface with metal shavings and scale. Requires regular cleaning with a wire brush.

- The need for preliminary cleaning of the junction of the mass with the metal for tight fastening and to eliminate the possibility of heating the mass.

- A magnetic field. It is impossible to perform high-quality welding in close proximity to the magnetic mass. It's all about the magnetic fields that every now and then set the welding arc in motion...

- A serious drawback is that it is impossible to fully use the magnetic mass when working with non-ferrous metals. You understand why. Of course it can be used, but if you just put the mass on the welding surface.

As you can see, there are both pros and cons. But it normal! Many will find significant positive aspects for themselves that will cover the negative ones.

Varieties

There are three main types of electrode holders.

"Fork"

The most primitive type of holder. Easy to make with your own hands at home. Simple, durable and cheap. But it is not entirely convenient, since the “fork” in some cases does not fix the electrode tightly enough.

"Collet"

The collet type holder is the most convenient and, therefore, the most expensive. It easily adjusts to any electrode diameter, holds the rod securely and allows you to arc with a high degree of accuracy.

"Clamp"

The clamp type holder is the golden mean. It is not as expensive as a collet, but it holds the electrode securely. The clamp can have different degrees of “corrugation”, so you can choose it for the type of electrodes that you use most often.

They all differ in how they work, but the essence remains the same. These devices are designed to hold the welding electrode. In this case, the type of electrodes used is not at all important. It is possible to use graphite or tungsten, steel or copper, as well as ESAB or UONI, Kobelco or LEZ electrodes. In short, neither the manufacturer nor the type of electrode is important. Therefore, when choosing a holder, electrodes can be ignored.

But something still needs to be taken into account. The welding electrode holder should be convenient for you personally. The plastic handle should be made of thick, durable plastic, preferably rubberized. However, we will talk about choosing a holder later.