Every year modern mechanical engineering places new demands on the manufacture of parts from metal alloys, their performance properties, geometric parameters, and surface quality. The invention of a centrifugal casting machine is attributed to foundry production, one of the main directions of which is the creation of parts based on cast rolls.

As you know, in manufacturing, casting is the technological process of manufacturing a blank or finished part. There are several varieties of special types of casting, however, for the manufacture of pipes for various purposes (water supply, sewer, etc.), bushings, sleeves, worm wheel rims, drums for paper machines, electric motor rotors and many other cast pieces, the centrifugal method is most often used casting In addition, thanks to modern technological schemes and innovative developments, it has become possible to produce workpieces of various shaped profiles (sprockets, gears, turbine disks with blades, fittings parts) using the centrifugal casting method.

Unlike all other casting methods, where the melt is poured into a stationary mold, centrifugal casting is a process in which liquid metal is poured into a rotating mold. Under the influence of centrifugal force, the molten metal is pushed towards the walls of the mold, evenly distributed there and solidifying. This results in a strong casting with good density, which always has the shape of a body of rotation.

Classification of centrifugal casting machines

Being the main technological equipment in foundry production, the centrifugal casting machine has two types - vertical and horizontal. The production of bushings, sprockets, wheels, fittings and much more is based on rotation, which is created by connecting to an electrical network. The casting method was borrowed from dental and jewelry technology as it is very productive - for example, in the production of jewelry, 50 rings can be made in one such casting.

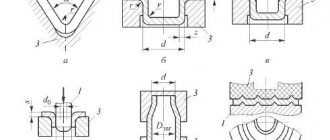

In order to produce a casting whose diameter is less than its length (such parts include pipes, sleeves or bushings), a machine with a horizontal or inclined axis of rotation is used. A vertical centrifugal machine is used for casting more complex workpieces that have internal cavities. Also, machines with a vertical axis of rotation are used for casting parts whose diameter significantly exceeds their height (wheels, gears, etc.).

At the same time, a vertical centrifugal casting machine can have a central or offset rotation axis. In the first case, the axis of rotation of the mold and the axis of rotation of the casting coincide. In the second case, the mold rotates about an axis located at a certain distance from the working mold.

The horizontal centrifugal machine is produced in several versions: double-support, cantilever, roller. For a two-support horizontal machine, the mold is secured on both sides. In a cantilever mold, the mold is attached cantileverly, that is, on one side. In a roller horizontal centrifugal casting machine, the mold rotates, supported by rollers.

The design of a centrifugal casting machine involves the presence of a water cooling system, as well as a frequency converter, which allows you to change and regulate the rotation speed of the mold, which is measured by the number of revolutions per minute. In addition, injection molding machines have a control system consisting of several elements. Thanks to this, the technological process is simplified as much as possible, and losses from defects are reduced.

According to their complexity, all these devices can be divided into: 1) single-position (carousel) machines; 2) two-position; 3) multi-position (so-called carousel machines).

There are automatic and semi-automatic casting machines, with a variety of sizes for castings, designed for different alloys - cast iron, bronze, copper and other metals, power from 7.5 to 250 kW, overall dimensions from 2565x1700x1200 to 10500x10300x6080 mm, weight from 3300 to 60000 kg. Each type of such machines can be filled with from 5 to 165 fills per hour.

Advantages and disadvantages of centrifugal casting

Using centrifugal casting, it is possible to obtain a casting with a geometrically correct free surface only if the rotation speed is strictly defined (it is determined by such an indicator as the gravitational coefficient). If the rotational speed of the casting is insufficient, then due to shrinkage, both in the vertical and horizontal position of the axis, distortions inevitably occur.

Thus, it can be stated that one of the advantages of centrifugal casting is that it can significantly improve the fillability of the mold with the melt, since it is subject to increased pressure arising under the influence of centrifugal forces. In addition, fewer shells, pores, and various inclusions are formed in castings, and their density increases significantly.

It should also be noted that the advantage of this casting method is also a reduction in metal consumption and an increase in such an indicator as the yield, due to the absence of a gating system. In addition, when centrifugally casting parts and workpieces in the form of pipes and bushings, there is no need to incur costs for technological rods.

As for the disadvantages, centrifugal casting also has them. These include the difficulty of making castings from those alloys that are prone to segregation; inaccuracy in the dimensions of the cavity of castings having free surfaces; increased contamination of casting surfaces with liquids and non-metallic inclusions (because of this, it is necessary to significantly increase the allowances for their mechanical processing).

Technical characteristics, operating principle of centrifugal casting machines

By purpose, the centrifugal casting machine has the following varieties:

1. The machine is single-rotor. Designed for casting grinding cast iron balls and rings for bearings. It has a horizontal axis of rotation of the chill mold. The operating principle is as follows:

1) the chill mold is heated using gas burners; 2) the die halves are coated with heat-insulating paint and dried; 3) the halves of the mold are closed; 4) the tray with the casting material is placed in the mold, then a strictly dosed portion of metal is poured in; 5) remove the tray from the chill mold, and the chill mold continues to rotate until the mass hardens completely; 6) when the movement of the centrifuge stops, the casting cluster must be removed from the front mold; 7) the die halves are wiped and painted, then the whole cycle is repeated.

2. Double-rotor centrifugal machine, model 4986. The centrifugal casting machine operates in semi-automatic mode, pouring liquid metal is placed manually into a mold - a metal mold.

The machine has:

1) a pneumatic system for pushing the casting out of the mold into a receiving tray for processed material; 2) rotation of the mold is based on a three-stage V-belt drive transmission method; 3) automatic supply and removal of the receiving tray; 4) water cooling of the case; 5) removable liners for low tide.

3. Special mold turning machine. Designed for casting large-sized, extended parts using self-filling. Aluminum alloy is used for casting. The centrifugal casting machine is controlled using electricity, operating modes are adjustment and semi-automatic. Such equipment is recommended for supply to foundries for small-scale and large-scale mass production of castings.

SpetsTehSnab

SpetsTehSnab LLC is a modern, dynamically developing enterprise. During our work, we have come a long way in establishing contacts with leading Russian and foreign partners and establishing a production base.

The company's development strategy is based on the principles of mutually beneficial cooperation with each of our partners. Compliance with these principles allows us to reduce the lead time of orders, improve quality, and also reduce the cost of supplied products, which has a positive effect on business relationships.

Today SpetsTehSnab LLC is a leading supplier of modern technological and laboratory equipment, materials and tools for foundry production.

Our company is the official dealer of the following Tiraspol; Republican Unitary Enterprise "Volkovysk Foundry Equipment Plant" Volkovysk, Republic of Belarus; JSC "LITMASHPRIBOR" Usman, Lipetsk region; representative in Russia of the Unitary Enterprise “INSTITUTE BELNIILIT”, Minsk, Republic of Belarus. The products of these enterprises are widely used in the foundries of most factories in Russia, the CIS and non-CIS countries.

The company's technological capabilities allow us to develop and manufacture non-standard equipment for various industries, which helps solve the problems of our partners.

FOUNDRY EQUIPMENT

HIGH AND LOW PRESSURE CASTING EQUIPMENT

Die casting machine mod. 711E08

Die casting machine mod. 711E08 with a mold locking force of 2500 kN is made on the basis of components from leading companies and corresponds to the modern world technical level.

The machine implements the technological process of injection molding parts made of aluminum, zinc and magnesium alloys with increased requirements for mechanical properties, tightness, dimensional accuracy and surface quality.

High quality of castings is achieved due to a shockless double-circuit pressing mechanism, a control system based on a programmable controller, a high degree of visualization of all technological parameters and the reliability of hydraulic, pneumatic, and electrical equipment from leading countries.

Instead of oil, compressed nitrogen gas is used as a drive for the multiplier in the pressing mechanism, so the compressibility of the gas makes it possible to absorb hydraulic shock and reduce the peak pressure in the working cavity of the mold and, as a result, minimize the locking force.

A separate multiplier drive circuit allows, regardless of the speed of movement of the press plunger, to adjust and maintain the pressing force during operation, which increases the stability of the technological parameters of the pressing mechanism.

Particular attention is paid to the safety of the foundry operator, for which electrical, hydraulic, and pneumatic interlocks are installed to prevent unauthorized closure of the mold, which is the most dangerous thing in an injection molding machine.

To protect the mold from damage, an electro-hydraulic device is provided, which is activated if there are casting residues, flash, etc. in the mold connector.

The main technological parameters (pressing force, press plunger paths in phases 1 and 2, moment of switching on the 3rd pressing phase) are programmed and controlled.

If necessary, graphs of the path, pressure in the piston cavity of the pressing cylinder and the speed of the press plunger in each pressing phase can be seen on the computer display.

The search for faults that arose during operation is reduced to zero, since the necessary information is displayed on the operator panel located on the door of the control station, and an emergency alarm is displayed on the control panel in the form of a flashing red lamp.

The main parameters that determine the quality of the casting are stored in the memory of an industrial computer for a long time and, if necessary, can be printed or transferred to any storage medium.

Cold chamber injection molding machines

Die casting machines are designed to produce a wide range of castings from aluminum, zinc and copper alloys.

The design of the machines provides for the possibility of connecting (according to the contract) means of mechanization:

- automatic manipulator for pouring metal manipulator for lubrication of the mold

- casting puller manipulator device for controlling the removal of castings

- press plunger lubrication device

It is also possible to control the rods installed on the movable and fixed half-forms according to a given program. The control system ensures the machine operates in the following modes:

- commissioning

- semi-automatic

- automatic - when the machine is working with mechanization in full.

The control system, as agreed with the customer, can be made on a relay element base or on the basis of a programmable controller.

Low Pressure Casting Machines

The machines are designed for casting castings from aluminum alloys under low, controlled pressure.

The machines are equipped with:

- mechanism for moving the top plate with an ejector;

- mechanism for moving the side plate with an ejector;

- a pouring unit, with the possibility of vertical lifting to press the metal wire to the injection mold sleeve;

- casting removal manipulator;

- hydraulically driven movement of additional rods or parts of the mold.

The low-pressure casting method is recommended for producing special thick-walled castings that have increased requirements for the internal structure in terms of density, tightness, etc. To successfully implement this task, the machine’s automation provides multi-stage regulation of the mold filling speed and regulation of pressing and refill pressure.

MIXING PREPARATION EQUIPMENT

Vortex mixers

Vortex mixers are designed for preparing sand-clay molding mixtures.

Vortex mixing is characterized by high linear and rotational speeds of movement of filler particles. The distribution of the binder in the volume of the mixture and over the surface of the filler grains occurs under the influence of high dynamic energies.

Intensive multidirectional translational and rotational movement of the entire mixture, its microvolumes and each individual particle ensures the production of a high-quality mixture, characterized by a high degree of homogeneity and impeccable coverage of each grain. High speeds of grain movement and continuous collision of particles lead to the so-called mechanical activation of the binder complex, thereby increasing the strength characteristics of the mixture.

Continuous aeration of the mixture during mixing improves its formability and compactability, making it possible to prepare high-strength mixtures up to 2 MPa while practically maintaining the mixer's performance.

Foundry cup roller mixers (runners) of periodic action

The mixers are designed for the preparation of sand-clay single, filler, facing and core mixtures on sand bases with dusty, liquid and viscous additives.

At the customer's request, the mixers can be equipped with loading and dosing devices and a system for automatically controlling the formability of the mixture (SARF).

Intermittent paddle mixers

Batch mixers are small-sized paddle mixers with an S-shaped mixing element. The mixers are designed for the production of foundry sand cores and provide fast and high-quality mixing of the components of the core mixture with all kinds of technological additives.

Mixers can be equipped with gear motors with different rotation speeds of the mixing elements. Thus, for the preparation of sand-resin mixtures of hot curing and cold curing by blowing with gaseous hardeners, a low mixing speed is allowed, and for the preparation of short-lived mixtures cured with liquid hardeners, a higher mixing speed is required.

Mixers can be operated as independent technological equipment. In this case, all components of the mixture are dosed and loaded manually.

It is possible to equip the mixers with two or three dosing pumps for supplying liquid binders and catalyst directly into the mixer bowl. In this case, the dosing of liquid components is ensured by the operation of dosing pumps on a time basis through a time relay, which are installed in the mixer operation control panel.

In addition, all batch mixers of the C1C model range can be supplied and operated with installations for supplying and dosing dry sand and liquid components of mixtures into the mixer.

Continuous mixers for preparing cold-hardening mixtures

The mixers are designed for preparing a wide range of cold-hardening mixtures, including synthetic resins and liquid glass, including quick-hardening mixtures, followed by filling flasks and core boxes.

MOLDING EQUIPMENT

Molding machines for pair molding

Molding machines for the production of one-time casting half-molds from sand-clay mixtures using various compaction methods, including combined molding methods.

Pneumatic pulse molding machine mod. 4841

The molding machine is a two-position carousel with a pulse-press method of compacting the mold.

At the first position of the machine, the molding sand is filled in and the model is drawn out; at the second position, the molding sand is compacted using a pneumatic flow (dynamic impact on the molding sand with air at a network pressure of up to 0.6 MPa), followed by upper pressing with a flat plate. The machine alternately produces complete half-molds for the top and bottom.

Casting molds produced by the pneumatic pulse compaction method have a number of advantages over molds made by traditional molding methods, the main of which are high density and shape accuracy, significant cost savings in their production, and improved quality of castings.

Machines for making stack molds

The technology of manufacturing castings in vertical stack molds is currently the most advanced method for producing small castings (piston rings, valve seats, household electric stove burners, grinding balls, fittings, brake pads, body parts and other products).

The widespread use of casting technology in vertical stack molds was due to the fact that it has a number of significant advantages over other methods of casting into one-time molds, such as:

- significant savings in molding sand by 1.7-1.9 times;

- high yield of suitable casting due to the compactness of the gating system;

- saving metal and reducing fuel and energy costs for its smelting;

- for the same production volumes, less production space is required.

Description of machines:

The model 4812 molding machine is designed for the production of one-time molds from sand-clay mixtures in flasks with a model imprint on the underside of the mold, followed by their assembly into a vertical stack consisting of 18 molds.

It is used in foundries with serial and mass production to produce castings of piston rings, as well as other small parts.

The machine is a three-position carousel.

At the first position, the molding sand is filled, pressed and drawn, the second position is used for removing the finished mold and inspecting it, installing an empty flask, the third position is free.

The Model 4828 molding machine is designed to produce both single-sided and double-sided molds from sand-clay mixtures in flasks with a model imprint on the bottom or on the top and bottom sides of the mold, which are then assembled into a vertical stack of 7 molds.

The machine is a three-position carousel.

At the first position, the molding sand is filled, pressed and drawn, the second position is used to remove the finished mold and inspect it, the third position is free.

The model 4837 molding machine is designed for the production of one-time molds from sand-clay mixtures in flasks with one-sided and double-sided imprint of mold models, followed by their assembly into a vertical stack consisting of 7 molds.

It is used in foundries with serial and mass production to produce castings weighing no more than 8 kg in one mold.

The machine is a four-position carousel.

At the first position, the molding sand is filled, pressed and drawn, the second position is used for inspection and insertion of the rods, at the third the mold is removed, the fourth position is free.

The molding machine model 4840 with a double-sided model imprint is designed for the production of castings in vertical stack molds in a multi-item production environment.

Distinctive features of this model are mobility, high performance, and compactness.

Shell mold making machines

Equipment for the production of shell molds supplied by SpetsTekhSnab LLC is presented in the table:

ROD EQUIPMENT

Machines for making sand cores in heated tooling

Our company offers a wide range of machines for producing foundry sand cores with curing in heated equipment (Hot-box and Croning processes).

The machines adopt a sand-blowing method for compacting the sand-resin mixture in a core box, which ensures high quality cores and minimal time for filling the core box with the mixture.

The determining parameter of the machines is the volume of the sand-blowing tank, which corresponds to the mass of the produced rod and the dimensions of the core box.

Equipment for the production of rods from CTS with gas purging

SpetsTechSnab LLC supplies equipment for the production of foundry sand cores from sand-resin mixtures, cured by blowing with gaseous catalysts in cold boxes.

The creation of machine designs is based on a unified range of core machines for the production of cores with curing in heated equipment.

In the created designs of core machines, a sand-blowing method is adopted for compacting the sand mixture in a core box, which ensures a sufficiently high quality of cores and minimal time for filling the core box with a sand-resin mixture.

The determining parameter of the machines is the volume of the sand-blowing tank, which corresponds to the mass of the produced rod and the dimensions of the core box.

According to their layout, the machines are single-position shuttle-type machines with a movable sand-blowing tank and a blowing head, moving from the position of loading the core mixture into the sand-blowing tank to the position of inflating the mixture into a box and a stationary or moving core box.

In terms of their technical parameters and design, rod machines are not inferior to foreign analogues and are equipped with:

- systems for localizing harmful gas emissions generated during the curing of the core mixture in a box; shelter in a special casing, partially glazed for

- monitoring the operation of mechanisms and opening for servicing the machine;

- sealing systems for the core box and the purge plate to allow more complete removal of the gaseous catalyst when purging the core mixture in the box;

- systems that ensure quick removal and installation of the inflatable plate and core box on the machine;

- reliable modern control systems for machine operation using programmable controllers (taking into account customer requirements);

- modern licensed pneumatic equipment.

Based on their design solutions, the created rod machines are capable of producing rods using two technologies: the “Ashland-process” and the “Betaset-process”.

KNOCKOUT EQUIPMENT

Inertial knockout gratings

EQUIPMENT FOR PRECISION INVESTMENT CASTING

Our company supplies basic technological equipment for the production of precision investment castings with a capacity of 100, 250, 500, 1000, 2000 tons of castings per year.

Taking into account the various requirements for castings in different industries, equipment has been developed and produced that allows the use of various technologies and materials.

For example, it is possible to coat blocks in a fluidized bed bath in a falling flow - in an elevator or drum sand pour. Drying of ceramic molds can be done by air, air-ammonia or vacuum-ammonia. The model composition can be melted from ceramic molds in water, in the model composition, and also in a steam environment under pressure. Calcination of molds can be done both with filler and without filler.

The range of manufactured equipment for investment casting is distributed in the following areas and machine models:

For the preparation of model composition and production of models and model links

To prepare a fire-resistant coating

For applying refractory coating, making model ceramic blocks and melting model composition

For firing and pouring ceramic molds

For separating castings from risers and ceramics from castings

CENTRIFUGAL CASTING MACHINES

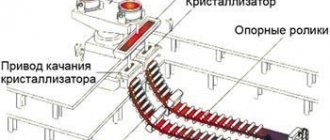

Centrifugal casting machines Models 552-2, 553-2

Centrifugal machines with a horizontal axis of rotation are designed for centrifugal casting of hollow cylindrical blanks (bushings) from copper alloys and cast iron.

The design of the machines provides for the mechanization of such operations as pushing the casting out of the mold, installing and removing the mold cover, opening and closing the casing door, supplying and removing the tray for receiving castings, turning on and off water cooling.

The machines are equipped with a MICROMASTER frequency converter from SIEMENS to control the main motor.

Centrifugal two-rotor machine model 4986.

The machine operates in semi-automatic mode with manual pouring of liquid metal into a rotating metal mold (mold).

The machine is equipped with:

- pneumatic system for pushing the casting (bushing) from the mold into the receiving tray;

- three-stage V-belt transmission of the mold rotation drive;

- mechanism for supplying and discharging the receiving tray;

- water cooling of the mold body.

The design of the mold provides for the possibility of producing castings with different outer diameters by using removable liners that form the outer surface of the castings.

CLEANING EQUIPMENT

Shot blasting machine 44124

Cleaning shot blasting device mod. 44124 is intended for shot cleaning of castings, rolled forgings, seams of welded joints, parts after heat treatment, glass, stone and other materials. Used as a component of treatment plants.

The device is mounted on the foundation by means of three supports screwed to the lower chamber. In this example, the lower chamber with supports is the base of the apparatus, on which it is mounted: from below - a mixing chamber, from above - a sequential bypass valve, a loading device. The valve block is mounted to the upper chamber using flange connections. The electrical cabinet is hung on the wall or a special rack in a place convenient for servicing the device. The device has a flange in the upper part for connection to the shot storage hopper.

The device performs the following operations:

- selection of shot from the storage hopper,

- transportation of shot to the lower chamber,

- formation of a mixture of shot and compressed air,

- feeding the mixture into the nozzle for ejection from the latter onto the surface to be treated.

The selection of shot from the storage hopper is carried out using a loading device, which is a sector gate. The gate is opened by a single-acting pneumatic cylinder, closed by an extension spring and a counterweight.

Operating mode – automatic.

The device is controlled remotely from the electrical cabinet.

SpetsTehSnab LLC also supplies:

- Chilling machines

- Melting equipment

- Pouring equipment

- Thermal equipment

- Laboratory equipment

- Equipment for analysis of molding and core mixtures

- Thermoelectric converters

- Casting

- Spare parts for portal cranes

The company's technological capabilities allow us to develop and manufacture non-standard equipment for various industries, which helps solve the problems of our partners.

Contacts:

LLC "SpetsTechSnab"

Address: 195248, St. Petersburg, st. Degtyareva, 4

Director Igor Valentinovich Sirotin tel./fax (multi-channel): +7 e-mail

Manager Minin Ivan Mikhailovich tel./fax; tel.; e-mail

Website:

www.spectechsnab.ru

Operation of centrifugal casting machines

The use of centrifugal casting machines has a number of serious advantages over other casting methods. Thanks to special technology, finished castings are dense, high-quality and wear-resistant, without the inclusion of slag and non-metallic elements. Because of this, the output of quality products is maximized.

In addition, the use of this particular casting technology allows you to significantly save metal and energy, optimally adjust the duration of the production cycle, and increase labor productivity several times. Centrifugal casting eliminates the need for molding space and drying equipment for molds and cores.

The cost of a centrifugal casting machine, if you look at it, is not that high, given the excellent functionality, high productivity, excellent quality, and ease of operation.

Centrifugal casting with horizontal axis of rotation

This method is the most widely used centrifugal casting method. It consists in the fact that the formation of a casting with a free surface occurs in a field of centrifugal forces. In this case, the inner surface of the mold plays the role of a forming surface. The melt is poured into the mold from the ladle through a special pouring chute. During the production process, the melt spreads over the inner surface of the mold, and under the influence of centrifugal forces it forms a hollow cylinder. After the metal or alloy has hardened, the mold stops and the finished product is removed from it.