Handles for gates or gates can be purchased ready-made or made independently. Such fittings act as a mandatory component and may be accompanied by a latch or lock. Regardless of which handle or bracket is installed on the gate, it must meet the requirements of practicality, ease of use and safety.

Various design options for gate handles

Return to contents

The role of the handle and lock for the gate

The gate is equipped with a lock and a handle, which, it would seem, have different purposes: a lock for blocking the door, preventing unauthorized persons from entering, and a handle for opening and closing the gate with physical force outward or inward.

But the element can also be part of the design of the lock, if the movement of the latch tongue is performed by moving the handle down. In this way, locks and handles are assembled into a single mechanism for opening (closing) and locking the gate.

Installing an overhead option for closing the gate

One of the best and optimal options is a rim lock with a beautiful handle. It is placed on the sash, thereby solving several important problems:

- limiting entry into the perimeter of the property;

- ease of maintenance;

- quick replacement in case of breakdown.

Rim locks are mounted using fasteners for which holes are made in advance. The latch is placed on the reverse side of the gate. It is convenient to use due to its ease of operation and reliability.

Simplify installation easily. A transverse beam is fixed to the door frame by welding at a distance of about 90 cm from the ground. The lock is applied to the frame from the inside so that the hole for the fastening coincides with the beam, the handle with the core is located slightly higher or even lower, depending on the convenience of the owners. Now make the markings, remembering the crossbar and fastenings.

Overhead

When the door supports are made from a round pipe, first a plate is attached to it, where the counter part is fixed. Then you need to drill holes for fasteners, a handle, and a key with a drill. They are made along the contours and passed with a file to remove the husks. A groove for the crossbar is also formed. Only then is the lock with the core, handle, and linings on both sides mounted.

How to choose and install the handle on the gate correctly

Let's figure out how to choose a handle and install it correctly for your gate. There are certain nuances and differences in selection and installation methods.

For the gate

For lightweight swing gates, elements are selected that are assembled into a single mechanism with a lock. This allows you to ergonomically and effectively use the gate design, cutting into a compact lock and moving the functional handle out.

If a separate lock with a rotating mechanism or a folding latch is embedded, then the handle can be a simple U-shaped structure that can be mounted arbitrarily in any place convenient for the owner.

Options for locks for wickets and gates

The risk of unauthorized entry through a wicket or gate leaf is reduced by installing a reliable locking device. In specialized departments of stores, industrial locking systems are sold, varying in design, installation method and price.

Overhead locks are one of the easiest to install on gates

The classification is made depending on the type of installation and the type of locking mechanism.

Depending on the type of installation, locks are of the following types:

- Padded - installation is limited to attaching two “eyes” for the padlock shackle. The holes in them are slightly larger than the working part of the device.

- The rim lock is installed on the sash leaf from the inside. On the outside there is only a handle and a keyhole.

- Mortise locks. The safest, but most labor-intensive way to install a locking device. In this case, it is placed inside the door structure. Access to the lock actuator is limited. For example, the Doorhan brand represents a version of the system where there are handles and keyholes on both sides. Some locks are equipped with latches.

Model of a mortise lock for a gate

The preferred method of installing a lock with a handle is determined by the design of the door leaf.

When determining the method of fastening, and therefore the category of the lock, the feasibility of installing a particular device for a previously installed gate is taken into account.

Types of locks by type of mechanism

According to the type of actuator and its control, locks are classified into:

- Mechanical – structurally simple, but reliable. Maintenance is limited to periodic lubrication and checking the fastenings. The purchase cost is small. There are cylinder and lever locking systems. The reliability of both is high, but exposure to high humidity or low temperatures has an adverse effect on them.

- Rack and pinion. One of the oldest types of locking devices. It is represented by a movable bar. To perform its main function - reliable protection against penetration - it must be massive. Today such systems are not popular, but you can buy a lock in any store.

- Electromagnetic. A modern device that allows you to control the locking of the sash remotely or using a classic key. Additional installation of a video system or intercom allows you to see the guest and clarify the purpose of his arrival from any room of the house. The electromechanical lock has a drawback, which is compensated for if you buy an additional lock - automatic opening of the gate when the electrical power is turned off.

- Radio wave. Electromechanical lock, where control is carried out from a miniature remote control. Manufacturers of these systems declare a hundred-meter control distance. This type of control of locking devices has earned recognition when installed on sliding and swing gates. You can buy a lock of this system in specialized stores. As a rule, the seller offers to order installation on site immediately.

Remote lock opening

When choosing a locking device and the type of control for it, you should focus on the validity of use. If you install an expensive modern electromechanical lock on a flimsy gate, the security against intrusion in the yard will not increase. Another thing is Doorhan entrance products.

Optimal ratio between the types of gate and locking mechanism

DIY pen

Making a handle with your own hands is very simple; the design can be: forged, made of rolled metal, or made on a lathe.

Forged . It is made by forging from a metal billet - a rod; various artistic designs are allowed. The handle can be twisted, with petals, or have a different geometric, streamlined shape.

From rolled metal . Rolled metal with a round or square cross-section is bent into a U-shaped structure, lined with polymer or wood, and mounting ears for self-tapping screws are made at the ends.

Important!

The handle can be welded to the surface of the metal gate, and then painted together with them in the same color.

Turning method . In this case, the element is made from a round metal “solid piece”, which is loaded into a lathe and then processed into a shape. The handle takes on a mushroom-like appearance - a wide place for grasping with the palm of your hand and a thin leg for fixing on the gate.

At the end of the leg, an extension can be made for self-tapping screws or welding.

Types of locking fittings

When selecting a specific model, attention is paid to its type. This characteristic is one of the most important; it depends on the material, device and other qualities.

Depending on the type of locking hardware, the products are as follows:

- Overhead – include a bracket, a cone, and are supplemented with several holes at the base for fastening. For a gate made of corrugated sheets, it is better to take door handles of the C or G shape, which do not have holes and will need to be secured by welding. Craftsmen confirm the fact that welded parts last better and longer.

- Through - this type of different forms is available for sale. To secure it, holes are drilled in the door, and a threaded pin is inserted into the door and threaded into the handle. A second handle is attached to the reverse side. As a result, the same ones are located on both sides.

End-to-end model

- Rotary, push - it is recommended to use a handle-lock when installing the general structure. These types implement 2 tasks at once - reliable grip when opening, fixation thanks to the locking mechanism.

- Forged ones are the most popular of all due to their reliability and large selection of models. Products are often mounted on gates, even garage doors. They look as aesthetically pleasing as possible, blend harmoniously with the existing style, adding richness. Forged products become a real decoration.

The choice of suitable options is simply huge, everyone will choose what they like. In addition to the handle, a lock is also purchased.

Installing a handle on a wicket or gate made of corrugated sheets

Corrugated sheeting reveals some nuances in installing the handle, since it is lightweight and requires reinforcement to install additional structures.

How to install a handle on a gate made of corrugated sheets?

The following actions should be taken:

- The design of the gate is made - it can be a profiled sheet, adjusted to the dimensions of the entrance portal.

- The internal part is reinforced with a lining made of plywood, thin boards or a frame made of metal profiles.

Important!

In the case of reinforcement with a metal frame, the handle should be mounted exactly in the place of the corrugated sheet where the frame is laid on the inside. In addition, the outer edges of the gate are also framed with a metal corner, even if the inner surface is lined with plywood or wooden boards.

Choosing a pen

Handles for gates and gates are presented in two types on the country's construction market. The former are fixed statically, while the latter are rotary with a locking mechanism.

The photo shows a forged handle.

Overhead handles are easier to install

According to the installation method they are classified into:

- Invoices. Such handles are rigidly attached to the sash leaf with self-tapping screws or welding. On the reverse side, install a similar handle in the same way.

- Through. The design provides for a prefabricated double-sided handle. For installation, a hole of the required diameter is drilled in the canvas and fixing rings are installed. The locking mechanism is represented by the second end of the movable part of the handle with a hook on the outer support column.

- Mortise, where the handle is a structural element of a factory locking device. Mounted in hollow doors. Narrow frame profiles limit installation.

One of the types of mortise handle for gates

Regardless of the choice of handle type, shape and appearance, the handle must meet the standards for safe use, as well as be practical for everyday use.

For the gate

Entrance gates are complemented with handles of any configuration and design. It is important that it harmoniously combines with the appearance of the entrance to the courtyard, while efficiently performing its direct function. A number of photographs presented in the article demonstrate this.

The entrance handle should match the exterior of the entire fence

Trademarks that are manufacturers of gates and wickets produce high-quality fittings. In the segment of matching price and quality, door handles for Dorhan gates are popular.

The simplest designs of movable gate opening devices are divided into:

- a knob system, where a handle with a latch acts on the lock by turning the knob (knob), while individual handles are equipped with a mini-lock with a pin. Such a system requires periodic maintenance;

- halyard system, activated by pressing the shoulder of the handle. It does not perform a protective role, but simply fixes the closed position of the sash with a rotating mechanism.

Rim lock with visor

The best option is an overhead (built-in) lock with a beautiful handle for the gate. Installed on the sash, it solves several problems simultaneously, including limiting unauthorized entry into the territory. Maintenance of such a lock is simple, and if it fails, it can be quickly replaced with a similar model from Bravo, AGB, Doorhan, ViRO.

Forged handles are the best option for gates

Among all materials, forged metal attracts special attention. Such products often decorate the gates of houses and courtyard gates. They are aesthetically attractive, elegant, and can be used to decorate the doors of hotels, museums, and cafes. A forged handle will fit perfectly into any style, complementing it with luxury and flavor of past centuries.

It is this material that will most appropriately emphasize the taste of the owner of the premises and his respectability. Forged products are also wonderfully suitable for entrance gates made of glass, plastic, wood, and metal.

A forged handle on a gate is prestigious

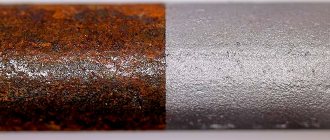

You can do whatever you want with a forged handle. For example, paint it with a new color to match the fence. This will make the product more neat and original, and will give the entire structure made of corrugated sheets the desired thematic mood. By the way, it is forging that allows you to purposefully “age” a product, imitating it as silver or even gold. It is distinguished by excellent heat resistance and wear resistance - not all materials can boast of this.

And the handles are not at all afraid of corrosion, so they are guaranteed to serve you for many years.

Before purchasing, be sure to consider what material the gate is made of. This can be corrugated sheeting, a frame with a mesh, bayonets, etc. Depending on the design, the installation procedure is determined.

A lock is often attached for additional security.

Homemade latches

A simple latch is easy to assemble yourself. For convenience, a simple horizontal spring latch mechanism is used.

Design sketch

Before making a gate latch with your own hands, you should determine the location on the door leaf to install the latch. A tape measure and a marker indicate installation areas.

After this you need to prepare:

- rod with eye;

- steel plates;

- welding;

- pliers;

- spring;

- screwdriver;

- hammer;

- a set of keys;

- hacksaw

The latch for the gate is made with your own hands sequentially. First, the frame is made. Why are ears welded to the plate, which will later hold the rod. The handle is attached to the rod, everything is installed simultaneously with the spring in the prepared frame. Next, the finished latch is installed.

Detailing

If the gate is made of corrugated sheets, the lock is secured by welding to the marked place or the fastening is secured with bolts.

If the model is wooden, self-tapping screws are used for installation. Opposite the locking rod, in the required location of the sash support, a hole is made to secure the shutter when closing.

Simple design drawing

The latch is almost ready. But it can only be opened from the inside, so you can make a torsion bar structure. To do this, take a steel cable of the required size. Holes are made for it at the bottom of the gate.

Handles for gates

Handles for gates or gates can be purchased ready-made or made independently. Such fittings act as a mandatory component and may be accompanied by a latch or lock. Regardless of which handle or bracket is installed on the gate, it must meet the requirements of practicality, ease of use and safety.

Various design options for gate handles

Locking direction

If you manage to make a gate with your own hands, then installing a lock on it will also not be difficult. Devices can be divided into 2 main types based on this criterion.

Latch in warehouse

Vertical latches

An effective gate latch that provides the most reliable locking of the system. Basically, this type of locking mechanism is installed on swing structures. To secure the door leaf in the closed state, a handle with a steel rod is used, which fits into a recess made in the ground.

Vertical lock for wickets and gates

These latches are also used in mortise sashes, but in a miniature size. To secure the top and bottom of the gate opening, steel mating fasteners with a hole for the bolt rod are installed.

Homemade wooden yard gates, as well as gates made of corrugated sheets, can be closed in a similar way.

But when installing a lock from below, fixation is carried out by a hole in the ground filled with cement screed. If desired, you can install a double-sided latch on the gate.

Scheme for making a lock for a gate

Horizontal overhead valves

These are the most common locking mechanisms used in all types of gates and wickets. The principle of operation is approximately the same as that of the vertical closing method. The latch itself is made from a metal rod or plate, a locking eye and a holder. Popular factory models include the gate lock NOEZ ZK-230-S (black, matte).

Installation features

When installing doors or gates made of corrugated sheets, the frame cross member is most often located at a height of 950 mm. If this lower threshold is missing, then a special plate will need to be welded for the lock. The structure itself should be installed so that there is one of the fasteners on the crossbar. This will help make the gate strong.

Wicket installation diagram

At the next stage of the work, you need to make holes for the handle to open the door. Once the holes are made, they should be filed. The lock is secured with self-tapping screws.

Installation of the mortise mechanism

The steps for attaching the handle to a mortise lock are as follows:

- A place for the handle is marked on the sash.

- At the marked points, holes are formed for screwing in self-tapping screws; the notches must be ground.

- The handle is attached to the gate with self-tapping screws.

- A rectangular groove is formed for the lock, and the lock body is mounted there. The loose product is outlined to identify points for fastening.

- If a handle is included in the package, a hole is drilled for it, then during installation the handle is attached to the rod.

- When the holes for the fasteners are finally ready, the lock is securely fixed using self-tapping screws.

Mortise

Tips for use

To ensure that the installed gate locks last as long as possible, you need to adhere to the following recommendations:

- periodically check the device for serviceability: if problems are identified, repairs should not be delayed and it is better to immediately find out what the reason is;

- It is recommended to make a protective canopy over the locking mechanism, which will prevent direct ingress of precipitation;

- check the mechanism annually before winter and after frosts; if necessary, lubricate.

Correct installation and operation of the device in question is the key to a long service life without problems.

Door handle with leaf holders, hot forging, bending and stripping

The master takes a round rod, the diameter of which is 16 mm, with pointed ends, heats it, and processes it on an anvil with a hammer.

The rod is placed at the corner of the anvil and some part of the workpiece is removed by hammer blows. Thus, in one place the thickness becomes smaller and at the end a voluminous sheet is obtained, which is then tapped with a hammer and takes on a flat shape.

A second leaf is forged in a similar way, at the other tip.

Using a homemade device, the middle of the workpiece is marked to easily achieve symmetry of the product.

The part is being bent.

The product is cleaned using a file and a drill with an attachment.

Installation

Installation is quick and requires a welding machine or drill. This element can be made from an ordinary metal rod or thin tube, which can be bent and welded to the fence, although this is not always convenient.

For example, it is irrational to attach it to a metal profile in this way, since welding marks will remain, which will give the canvas an unaesthetic appearance even after painting.

Before installing it yourself, do not forget to mark the location of the future handle and decide which side is best to place it on. Sometimes handles are attached to outdoor gates using a drill. To do this, you need to smooth out the sharp edges and remove the resulting jagged edges - construction skills will come in very handy in this case.

To simplify the process, just go to the market or a construction hypermarket and purchase a ready-made design that suits your taste - it can be a shaped handle made by using artistic metal forging or any other.

In this case, you will only need to correctly attach it to the gate leaf with your own hands. Moreover, in this way you benefit financially by spending a minimum of money on purchasing modern locks.

The standard procedure for installing a handle consists of several steps:

- site marking;

- preparation for fastening;

- fastening.

Welding the handle is much more reliable than attaching it with screws, so if you want to make a structure for a long time, it is better to borrow welding from friends if you don’t have it in your home arsenal.