Manufacturing food products in Russia is one of the most profitable businesses. But the wide range of available products means that not every product finds its buyer. Before choosing a type of business, you should find out how profitable it is. Sunflower oil production is an interesting business that attracts many entrepreneurs. This type of product is in demand and is in great demand among the population. Before you start creating a business, you need to familiarize yourself with some subtleties.

Profitable or not?

It is worth knowing that the production of sunflower oil and its sale is the prerogative of many small and medium-sized enterprises. This is due to the low investment required to start a business. Also, the activity pays off very quickly. There is a high level of competition in this segment, but with competent management, a well-thought-out business plan for the production of sunflower oil and a clear marketing policy, the entrepreneur will not be left without good revenue.

Sales volumes of oil exported annually set new records at 300,000 tons per year. Prices for seeds versus oil on the world market are $300 and $790 per ton. This makes oil production profitable not only for sale abroad, but also for supply to the domestic market.

Documentation

An entrepreneur can organize a business in the form of an individual entrepreneur or a legal entity (LLC). It all depends on the volume of production and sales of goods. It is better to choose an LLC - this form will allow you to cooperate with large wholesale and retail companies and stores.

It is not necessary to obtain a mandatory certificate of conformity for the production of oil. Go through the verification process and issue a voluntary certificate - this will simplify your work with buyers and intermediaries.

Table 3. Regulatory documents.

| Name | Content |

| GOST 22391-77 “Sunflower. Industrial raw materials. Technical conditions". | On the standards governing the quality of sunflower seeds supplied to the plant. |

| GOST 1129-73 “Sunflower oil. Technical conditions". | About the standards governing the quality of the product. |

| GOST 22391-89 “Sunflower. Requirements for procurement and supply." | On the standards governing the storage of oilseed raw materials. |

Sunflower oil production technology

Oil production technology includes several stages, each of which is worth getting acquainted with. First you need to rid the raw materials of husks. Processing of seeds is carried out using the following methods:

- by sifting through a sieve with different holes in shape and size;

- by blowing raw materials with air;

- by separating seeds according to ferrimagnetic properties.

The shell can be removed in several ways:

- by splitting the husk with a blow;

- compression of seeds;

- cutting in half;

- by peeling off the husks on a rough surface.

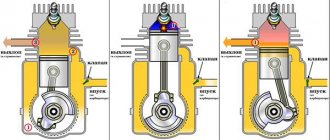

The sequence of actions is as follows - first perform a spin cycle. The seeds are placed in a roasting pan and heated to a temperature of 100º C, gradually pouring in water and stirring constantly. Then the oil is squeezed out through a press. The stronger the unit, the more oil it will squeeze out. But the seeds are of no small importance.

Important! In addition to oil, cake and husks appear at this stage. They are subsequently sold as cattle or pig feed. From 1 ton of raw materials, 422 kg of oil, 356 kg of cake, 172 kg of skins are obtained.

Refining is the second stage. The output is a special type of oil, which is characterized by a pleasant smell and yellowish color. Refining technology is divided into 4 stages:

- Removal of mechanical substances. The product undergoes settling, filtration, and centrifugation procedures. At this stage, the oil is sold as unrefined. It is characterized by a dark color and a pungent odor.

- Treatment takes place in hot water at a temperature of 65-70ºС. The process removes phosphatides. Due to this, the oil becomes lighter.

- Deodorization - getting rid of fatty acids. This will help remove the unpleasant smell and taste. The oil becomes marketable.

- Freezing is necessary to obtain a colorless and viscous oil.

Packaging the products in containers is the last step. Thanks to the complete line, the process of filling oil into bottles is simplified and occurs automatically. If it is a mini-factory, then you can bottle it manually.

Oil mill premises

The main requirements for the workshop are directly related to production volumes. The territory for the oil mill must meet the following conditions:

- have an area of 150 sq. m.;

- divided into several zones - production, warehouse for raw materials, warehouse for finished products;

- be equipped with communications - electricity, water supply, sewerage;

- fully comply with safety conditions - be protected from spontaneous combustion;

- comply with sanitary standards.

Important! If production will be carried out at home, then one room is enough.

The workshop area should include the following premises:

- the area where the equipment will be located must be 60 m2;

- warehouse for storing raw materials – 50 m2;

- room for storing finished products – from 30 m2;

- waste storage area – 40 m2;

- room for administration and workers - 25 m2.

Depending on the condition of the structure, repairs, distance from the center or city, you need to pay about 150,000 rubles for rent. You also need to pay 80,000 for utilities. It is better to choose a building that has convenient access for cars to make it convenient to load goods and unload raw materials.

The waste storage room must be equipped with a fire protection system, since the cake has the property of spontaneous combustion. The temperature in the warehouse must be constantly monitored and checked. You can do this in the old proven way. A wooden twig is stuck into the cake. When it gets hot, the by-products need to be removed.

The storage for raw materials should be spacious, sunflower seeds will be scattered in it. The thinner the layer of product, the longer it will last. In such a warehouse, 20 to 40 tons of raw materials are scattered.

To store finished products you will need containers with a capacity of 10-15 cubic meters. They are placed in a room with an area of 20-30 square meters. m. 5-7 pieces each. It is recommended to choose barrels made of stainless steel.

If you use containers made of a different material, problems with SES will arise. When storing sunflower oil in rusting steel, the taste and beneficial properties of the product will deteriorate. But in order to save money, it is allowed to use standard aluminum milk cans.

Important! The devices and equipment for producing the product are quite powerful, so it is necessary to have at least 380 W of wiring in the workshop.

For production workshops for the production of food products, the SES imposes certain requirements. Mini-dairy with an area of 40 sq. m. must meet the following conditions:

- The concrete floor has been poured.

- Suspended panels and ceilings are prohibited. The walls must be tiled or plastered to a height of more than 2 meters.

- Purchase lamps and chandeliers only with explosion-proof characteristics.

- Availability of fire alarms and fire extinguishers.

- A ventilation system, hot and cold water, sewerage, and treatment buildings must be present.

A squeezing and regenerative unit can be located in the same area. If the area is large, it is recommended to equip two separate zones.

Our main advantages:

- a wide range of;

- premium products;

- stable availability of assortment in warehouses;

- favorable rates;

- various forms of payment;

- delivery throughout Russia.

For a long time, it has maintained a professional approach to its business and a loyal policy towards its clients. We offer favorable terms of cooperation and payment, and do everything to ensure that everyone who contacts us is completely satisfied.

About profitability and wastelessness

Sunflower oil is waste-free. This means that by-products resulting from the production of a product are used in other areas. Related components are sold to third parties.

The husks are used to make pellets - pet food. They are pre-pressed into briquettes and delivered to customers. The husk is sold to brick factories, and the cake is sold to farms. The sale of waste can be taken into account as additional profit, but most often sales are reflected in the cost price, reducing the price of the output product.

Oil suppliers and market

When creating a business for the production of sunflower oil, it is necessary to resolve the most important issues: where to sell the products and where to purchase raw materials. It is recommended to find a permanent supplier; it will be easier to plan profits there.

If an entrepreneur is engaged in trade, then it will be easier for him - he will connect to his network of customers who constantly purchase goods from him. The oil will be poured into a ready-made sales scheme.

It is recommended to find a supplier in the fall that is located geographically close to the enterprise. If he enters into an agreement for regular supplies of oil in small quantities and with deferred payment, this will be an ideal option. This scheme will help to minimize the cost of seeds, thereby increasing profitability.

The oil can be sold to shops, supermarkets, and private enterprises that order products as the main raw material for creating their goods. The component is used in various fields - soap making, food preservation, paint and varnish production, cosmetics and medical industries.

Important! If you can’t find a customer, the oil can be supplied to Turkey. It is in great demand there.

Packing

The production of vegetable oil requires high-quality packaging. Filling of the product into containers is usually carried out automatically on special production lines. Bottling is carried out in polymer bottles. They are marked and sealed. The bottles are hermetically sealed with aluminum caps with a thick cardboard lining and a cellophane surface. Containers made of polymer materials are sealed with polyethylene caps of slight compaction.

Required Equipment

The technological process for producing oil is quite labor-intensive and complex. It will take time to set up and automate. It is important to correctly calculate the indicators.

The main thing is to purchase a unit that will produce oil. The price is very high - about $20,000, but the enterprise cannot manage without it. It is recommended to find trusted, good suppliers who will sell an excellent quality machine at an affordable price.

If the scale of oil production is small, then in order to save money, you can purchase a manually controlled unit. To make a good profit, it is necessary to purchase large volumes of raw materials, and to process them, the plant must have an automatic line.

To produce sunflower oil, you need to purchase a number of machines:

- oil press;

- filter;

- fryer;

- separator

Approximate costs for units:

- a separator for initial seed cleaning costs about 50,000;

- a crusher-winter unit, which will separate the peel from the seeds, will cost about 60,000;

- machine for grinding raw materials – 500,000;

- fryer - 300,000;

- oil press – 600,000;

- refining apparatus – 600,000;

- automatic bottling line – 300,000.

When starting a business, you can get by with a mini-factory. When a sales market is found and the technological side is established, then they expand.

Recruitment

If the workshop has an automated line, the number of employees is reduced to a minimum. But if you hire people, they must be experienced workers who know how to operate machines.

Only specialists should work on the units. If the plant is medium-sized, then it is necessary to hire loaders, drivers and maintenance personnel. Statistics show that finding a professional with experience is not easy. In this case, you can hire young certified people and develop a scheme for them according to which they will work.

Revenue and profit

An important section of a business project is the calculation of projected income. To do this, the upcoming costs and possible profits are summed up. Costs that an entrepreneur will face:

- equipment and machinery – 2,000,000 rubles;

- carrying out preparatory work in the workshop – 300,000;

- obtaining documents for carrying out activities – 50,000.

The total is about 2,350,000 rubles. The entrepreneur will also spend money monthly on the following needs:

- workshop rental from 500 sq. m. – 100,000;

- issuance of salaries to staff for 3 people – 60,000;

- payment of taxes – 70,000;

- marketing activities, payment for utilities, transportation costs - 100,000;

- purchase and delivery of raw materials for oil production – 700,000.

As a result, the cost of the finished product is 1,030,000 rubles. To calculate income, take the work of equipment for 1 shift daily. Oil production per month will be:

- (5 tons per day: 3 shifts) * 30 days = 50 tons;

- oil is sold on average for 40 rubles per 1 liter, therefore, the income will be equal to: 40 * 50,000 = 2,000,000;

- profit will be: 2,000,000 – 1,030,000 = 970,000 rubles.

Capital costs will pay off in 2.5 months: 2,350,000/970,000=2.4

Sunflower kernel price for 2016 harvest per ton

Ours is one of the leading suppliers on the Russian wholesale market of agricultural crops. We accept orders every day, process them in the shortest possible time and ship them the same day anywhere in the country. We only have this year’s fresh harvest at a favorable price, for example, the price of a ton of sunflower kernels harvested in 2016 is one of the most attractive, since we do not work with intermediary organizations, but collect, process and deliver ourselves.

To ensure complete preservation of all beneficial properties, we carry out stable quality control. All our products are stored in warehouses with a certain temperature regime so that the content of all minerals and vitamins in them does not decrease. By choosing us, you get an improved selection and storage system, a multi-stage purification process and delivery of only high-quality products in a short time!

Korepanova Production Possibility Curve Practice 2003

PRODUCTION POSSIBILITY CURVE

TASK 1.

The medieval blacksmith specializes in spears and ploughs. Can its alternative production possibilities be described by the following data?

Spears, pcs. 36 30 24 18 12 6 0

Plows, pcs. 0 2 5 9 12 15 17

TASK 2.

In one field, a farmer can produce 500 tons of potatoes or 100 tons of wheat, and in another field, the opportunity cost of growing 2 tons of wheat is equal to 5 tons of potatoes, with a maximum potato production of 1000 tons.

Draw a farmer's production possibility curve.

TASK 3.

120

100

Here is the production possibility curve for a farmer who grows wheat and potatoes in two fields.

- What is the opportunity cost of producing one ton of potatoes if 75 tons are grown? 150? What is the opportunity cost of one ton of wheat?

- Determine the opportunity cost of growing the first 50 tons of wheat.

- Calculate the average yield of wheat and potatoes using the best use of resources, if the area of each field is 100 hectares and 70 tons of potatoes are grown.

- 50 tons of potatoes were grown, and 100 tons of wheat. How much can the wheat harvest be increased next year? What about potatoes?

TASK 4.

Draw a production possibilities curve using the following information. The maximum oil production is 135 tons.

How to organize a mini strike

To open a small workshop for producing sunflower oil, you will need minimal investment. The price for a churn that will produce 10-17 liters per hour ranges from $200 to $450. Other units required for operation:

- a filter to clean the product will cost $100-200;

- the cost of additional tools, products, and kits will be about $100.

Capital investments are small, so agricultural producers often open private mini-dairies.

The modern design for producing oil is a press extruder. It is visually similar to a meat grinder. Equipment for the production of sunflower oil

consists of three parts:

- bunker for supplying seeds;

- auger compartment where raw materials are crushed;

- nozzle for squeezing oil.

After receiving the product, it will need to be filtered. For small production volumes, canvas bags are used for filtration. After the process, the oil must be kept in a cool room for some time. Then it is poured into barrels.

If sediment forms at the bottom, the oil is filtered again. For larger oil mills, it is better to purchase special filters that will quickly clean the product.

It is better to open a small production when the owner plans to grow sunflowers on his own. Due to this, he will save a significant amount on the purchase of seeds and their delivery.

As the practice of entrepreneurs shows, the profitability of a mini-enterprise can reach 25%. The first investment pays off within six months. Here it is important to find consumers and establish the technological process.

To open your own creamery, you do not need to obtain permits or licenses. The business owner must register as a sole proprietor. Since the activity is related to food, sanitary and epidemiological stations will regularly visit the owner to check the quality. It is also impossible to do without control of the fire service.

Important! When opening a small plant for the production of sunflower oil, it is recommended during registration to ensure that the owner is recognized as a manufacturer of agricultural products. In this case, he will pay taxes at reduced rates.

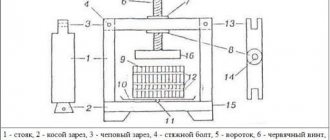

Homemade makukha press complete with butter churner

Circles of flour from roasted seeds can be pressed using equipment of our own production. To do this you will need a homemade crown press. A little imagination and desire and I assure you that everything will work out and you will save a lot of money.

And so, in order to press the top circles, you must build a homemade press. This equipment is very simple to manufacture and lasts a very long time. You need a small metal ring, maybe from a large piece of pipe or part of some kind of cylinder with a diameter of 50 cm, a car jack, a circle plate of durable metal with a diameter of 49.5 cm (this is the most difficult part that can be ordered from a turner). Next, assemble everything into a kit, as shown in the figure. I think it’s clear from the picture how a homemade crown press works. Such a homemade press does not have high productivity, but it will cost much less than an industrial press for mahogany, and it does not consume electricity. It’s just important to note that when you roasted a sunflower seed during production and want to press circles of flour from sunflower meal, this must be done while the meal is still warm, that is, immediately from under the churn. 1 circle of flour is obtained from approximately 1 bucket of meal.

conclusions

From the point of view of investing money, the business idea of creating your own creamery has not lost its relevance. The business is still characterized by fast payback periods, profitability and demand. In addition to the oil, the owner will receive by-products that can easily be sold and receive additional profit. Sunflower oil production breaks even. When creating a small workshop, the owner may not need to obtain licenses; it is enough to register with the tax service as an individual entrepreneur and remit taxes on time.