The steel cable was invented in 1834. It has many advantages, such as high tensile strength , stable and reliable performance, and high ability to withstand dynamic loads and overloads. It is widely used in lifting, conveying and traction systems. During the operation of steel ropes, defects and damage will occur: wire breakage, wear, rust, fatigue, strand breakage and even sudden breakage for various reasons. Therefore, academia and industry are trying to explore various damage detection methods to ensure their reliability and safety.

However, due to the complexity of the structure, the diversity of the operating environment and the limitations of detection methods, it has become a difficult problem. The development of relevant technologies is slow. It is difficult to achieve efficient and reliable industrial applications.

Nowadays, manual inspection and installation with manual touch is still the main method in most cases.

Take for example: On March 9, 2022, while lifting, the steel rope of a mining company's multi-rope friction mine hoist suddenly broke. The fire in the cabin was aggravated by a broken cable. As a result of the incident, 17 people were killed, trapped in cages. Therefore, it is very important to learn reliable and effective methods for securing metal cable.

The end of the wire rope wears out and cannot be easily connected to the plant or equipment, but there are various ways to secure the ends of the wire rope to prevent it from fraying.

Cable

A wire rope is a complex mechanical device that has many moving parts that work in tandem to support and move an object or load. In the lifting and rigging industries, a wire rope is attached to a crane or hoist and equipped with swivels, shackles, or hooks to secure it to a load. It is also used to raise and lower elevators and support suspension bridges or towers.

The cable is metal and has a unique design consisting of steel wires that form individual strands laid in a spiral around a central core.

Steel rope is the preferred lifting device for many reasons. Its unique design consists of multiple steel wires that form individual strands that are laid in a spiral around a core. This structure provides strength, flexibility and the ability to cope with bending stresses. Different material, wire, and strand structure configurations will provide different benefits for a specific lifting application, including:

- force;

- flexibility;

- abrasion resistance;

- crush resistance;

- fatigue resistance;

- corrosion resistance;

- rotation resistance.

However, how you attach ropes to your lift requires careful consideration. Our goal is to help you understand what devices are available for securing the ends of wire rope to load handling devices, methods for attaching a load rope to a drum, as well as other methods of fastening and securing steel ropes. This will allow you to choose the most efficient installation method and long-lasting performance of the metal cable.

Specific types of clamps

Since fastening units in construction experience dynamic loads, and loads often rise to a height, spring mechanisms are used here.

Thanks to them, not only the usual fastening of cables is carried out, but also the fixation of objects. Structurally, they have levers with moving brackets. As a result, the object can be fixed on the cable, regardless of its thickness.

Wedge connections are indispensable for working with copper and aluminum wires with a cross-section of 35-100 square meters. mm. They are a body made of cast iron steel with a wear-resistant wedge made of bronze or aluminum alloys.

For greater reliability when clamping large cross-section aluminum wires, special gaskets made of the same material are used. The fastening will be strong, but the bolts should be tightened every 7-10 days.

Crimp sleeves

Crimping sleeves for steel cable assemblies are one of the frequently performed functions of equipment for lighter operating conditions.

The question often arises , which is better, crimp ends or wire rope clamps?

Steel Cable Clamps and Crimping Sleeves

Crimp sleeves, stronger and more efficient. Requires no future maintenance or re-tightening of nuts. It has a streamlined shape than metal rope clamps.

Crimping refers to the process of using a tool or machine to apply force to a bushing or ferrule. As a result of this process, the sleeve is sealed on and around the cable portion.

Sleeve crimp

Aluminum crimp fittings

Most often, an aluminum cable clamp is used with galvanized steel cable to form cable assemblies.

Aluminum sleeve placed on a galvanized cable

Aluminum is soft. When compressed, using a crimping tool, it will be pressed into the grooves of the rope , locking the aluminum sleeve in place.

Aluminum sleeve in cable

Installation

Passing the steel rope through the sleeve.

Pass the cable through the sleeve

Before crimping, make sure that the “cut end” of the steel rope sticks out to a length of at least 2 cable diameters. This ensures full contact with the cable as the sleeve expands during crimping.

Two cable diameters

Place the sleeve into the jaws of the tool.

Sleeve correctly in the tool Sleeve incorrectly in the tool

Pay attention to the correct orientation of the crimping tool cavity with the aluminum bushing.

The sleeve should always be aligned vertically, not horizontally.

Keeping the case in the correct position, make your first crimp by squeezing the crimping tool handles together until the jaws are completely closed.

Forging

Sleeve crimp

For each sleeve size there is a prescribed number of crimps that must be completed.

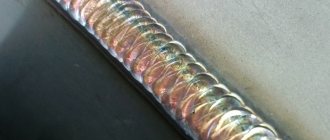

Leave a little space between each crimp. Your finished assembly should look like the image shown.

Crimping Distance For 1/16" and 3/32" hoses, 2 crimps will be required. For 1/8" and 5/32" hoses, 3 crimps will be required.

For 3/16" and 1/4" sleeves, 4 crimps will be required.

For 5/16" and 3/8" sleeves, 5 crimps will be required.

Pressure gauge

To ensure that the crimps are done correctly, use a calibrator.

Pressure gauge

Using the appropriate measuring cavity, slide the sensor onto the sleeve.

If the pressure gauge rotates freely around the crimp zone, then everything is done correctly.

The pressure gauge rotates freely around the crimp area

If the sensor does not slip in the crimp area, use a re-crimp tool to ensure that the coupling has been fully compressed.

Steel rope with polymer coating

It is recommended to trim the vinyl far enough to ensure that the sleeve makes direct contact with the cable.

Vinyl coated cable

Using the same crimping method, elbow joints can be made to connect two pieces of cable.

Knee connection

Remember to leave a small area between the sleeves.

Small area between sleeves

Extend the end of the metal cable beyond the outer edge of the coupling at least 2 cable diameters.

Cable end

Zinc Copper Sleeves

Zinc, copper and glass sleeves are recommended for stainless steel wire ropes.

Zinc and copper hoses

Aluminum sleeves are not recommended for use with stainless steel cables due to the possibility of corrosion of aluminum upon contact with stainless steel. Over time, this can lead to weakening of the contact between the coupling and the cable.

Fire on a rope or cable

Speaking about how to braid a cable - steel or from another material, it should be mentioned that you can make a fire. It's a little more complicated. At some distance from the end of the cable, a durable temporary mark is made, and the ends of its strands are secured with the same marks. After this, you should unravel the end of the rope.

In the form of a loop, the cable is laid on a surface (preferably hard), and all its strands are broken through. Several punches are made, but special attention is paid to the first one, since it is the most important of them. The reliability and strength of the fire is ensured mainly by the first punching. This is also an acceptable way to braid a cable. The scheme will not cause any difficulties.

Koush

Eyelet for steel ropes is a special mandrel for a cable loop, made of steel or soft materials. When the wire rope anchorage is limited to a loop, there is a risk that it will bend when the loop is connected to a device that concentrates the load over a relatively small area. A thimble is installed inside the loop to maintain its natural shape and protect the steel rope from pinching and abrasion inside the loop. Using thimble in loops is industry best practice. The thimble prevents direct contact of the load with the steel rope.

Conventional steel rope ending in a loop

Protective function

The outer side of the tip is made in the form of a groove (groove) into which the cable fits tightly. This frame, in itself, is close to the contour of the drop.

Thanks to this design, the cable tip located in the groove does not come into contact with the part (element) that is attached to the loop. The sides of the thimble groove prevent the loop from slipping off it, and also protect the cable from lateral damage, although there it is least susceptible to wear and other mechanical stress.

The hose for steel ropes is made of carbon steel and also of plastic. Steel is produced by casting, stamping or forging and then galvanizing or painting to protect against corrosion. Structurally, the thimble is one-piece or composite, consisting of several parts. One of the types of such mandrels is shown in the photographs below. This is a teardrop-shaped thimble.

How to choose a thimble for a steel rope

After repeated use, under loads, wear and kinks, it reduces the strength of the rope and leads to premature failure.

Thimbles are produced in two classes:

- lungs;

- heavy.

Lightweight thimbles are used in static applications such as permanent installations, controlled environments of ISO 14644 cleanroom standards or in situations where heavy loads are not experienced.

For light loads For light loads

Light-duty thimbles work best on traditional fiber ropes because they can handle the load of a rougher setup. Here you will see that this lightweight thimble is suitable for this application, while the heavy thimble is greatly oversized.

Heavy-duty thimble

High-strength thimbles have expanded protective material around the edges to resist deformation. They are used for devices that are subject to dynamic loading or conditions close to the operating load limit. Heavy duty thimbles are suitable for lifting or towing applications where the user will need to frequently attach and detach the thimble to other rigging components.

Which experience dynamic load

When choosing a thimble for a metal cable, it is important to consider the environment in which it will be used.

Manufacturing materials:

- Cink Steel;

- hot-dip galvanized steel;

- stainless steel.

Stainless steel thimbles are better suited for outdoor and are rust resistant. Also suitable for use in or near salt water where corrosion often occurs, and is a better choice when using rope or chain of the same material.

Galvanized ferrules are less expensive than stainless steel and are also suitable for outdoor use. Galvanized components may show signs of surface rust. If the galvanized coating wears on the load-bearing or contact areas of a component, this type of surface rust will usually wear off under stress and should not affect the performance of the component.

Types of thimbles

It is important to remember that the zinc coating is thinner than hot-dip galvanized steel, so a thimble may show signs of rust sooner than a spray-galvanized thimble.

Fixing the cable in the braid

Steel cable in PVC braid and thimble can be used to form rigging units. In this case, make sure that the fasteners are of the correct size and securely fastened to the eye of the cable being used. If the fastening is loose in the groove, the cable may fall out , and if it is too small or too large, connections to other devices of the correct size will become difficult.

Braided steel cable

When choosing PVC sheathed steel cable, it is important to match the size to the actual diameter of the cable you are using with it. The diameter of polymer coated wire rope is confusing because some manufacturers measure braided steel wire rope differently.

Vinyl Covered Cable Measurement

Actual rope diameter

The diameter of the vinyl cover adds thickness.

With other rigging components

Often a thimble for steel ropes is used with other rigging components , such as an eye-bolt, and a minimum of effort is required to straighten the eye of the thimble. Use a set of pliers to hold each side and twist it open so the component can be inserted into the thimble and then return it to its normal shape.

Unbend the eye

Open and insert with eyebolt

The same process can be done by hand if the thimble is small enough.

Return him to normal form

Some thimbles cannot be bent using pliers or your hands, so for larger mounts, it is preferable to use a vice and pipe.

Use a vice Open with a pipe

Driver node

A truly legendary knot that has many different names and even more practical applications. This knot is used in construction work, during transportation, in tourism and other cases when you need to secure something tightly and tightly.

For those readers who find it difficult to navigate the animated drawings, there are additional instructions containing static photos of each step. You can find it at this link.

What other nodes do you consider practically useful and necessary to master?

Asymmetric wedge clamp

The use of asymmetrical wedge couplings is popular with mobile cranes. They are easy to install on site and also easy to remove, which is a big advantage.

Clamp with a short piece of cable

The end wedge sockets are reused after the cable has been discarded. They withstand fatigue tests until the steel rope fails and without damage.

Standardization

There are many options on the market, with minimal requirements for asymmetrical wedge mounts. The length of the clamp between the coupling and the wedge must be at least 4.3 times the nominal diameter of the wire rope. The asymmetrical wedge coupling can withstand 75,000 tension-extension cycles from 15% to 30% of the minimum tensile strength of the wire rope without permanent damage.

Working mechanism

Using a wedge, the end of the cable is wedged into the cone mount. As the load increases, the wedge is drawn deeper and deeper into the socket and exerts a clamping force on the steel rope.

The traction force in the cable is transmitted due to friction between the metal rope and the wedge and friction between the cable and the coupling. The figure shows a cross-sectional view of an asymmetrical wedge socket.

Sectional view of an asymmetrical wedge socket

Installation

Depending on the design and type of rope, their efficiency varies from 75% to 80%. Please contact your wedge mount manufacturer for details.

When installing a wedge socket , the end of the metal rope is first fed through the tapered socket, then bent into a loop and returned from the socket. After this, the wedge with the cable is placed inside the loop, and the protruding ends are pulled further out of the socket, so that the wedge is well retracted into it.

Then the “dead” end of the cable should protrude from the fastener by at least a few centimeters. Directly at the outlet, the tail end should be protected with a cable clamp . This will prevent the wedge from weakening and falling out.

Here's a quick rundown of the dos and don'ts:

- Always check the socket, wedge and pin before installation;

- Align the end of the metal cable with the center line;

- Use a hammer to seat the wedge and cable as far into the mount as possible;

- First apply a load to completely seat the wedge and cable in the socket;

- Make sure the end is properly secured before inserting the wire rope.

Failure to comply with this requirement will result in core slipping or weakening of the strands, which will lead to serious damage to the steel cable.

Secure the dead end of the cable.

Incorrect connection between the live and dead part of the cable

Incorrect cable installation

At the scene, it was discovered that the end of the steel cable on the crane was not installed correctly. Before work began on the ground site, the 30-tonne mobile crane was inspected and it was discovered that the rope clamp (bulldog) attached to the "dead end" of the hoist ropes was incorrectly installed , which caused the destruction and damage to the "live end" of the rope (part of the rope , which takes the load).

Incorrect installation of cable grips

Incorrect selection or installation of wire rope grips will dramatically reduce the effectiveness of wire rope leads and cause the metal cable to slip through the grips. This may result in personal injury and equipment damage.

The clamp bridge is installed on the working part (current end) of the rope, and the U-shaped bolt is installed on the tail cable (dead end) of the steel rope.

Methods for fastening the ends of a steel rope

The following lessons were learned:

- Make sure that when tying a metal cable, the correct type of clamp is selected;

- Make sure the cable grips are installed correctly.

Beware of signs that indicate a cliff; for example, reduction in rope diameter, corrosion or deformation of the steel rope.

How to use clamps correctly

Some rules require that the dead line be clamped together with another short piece of rope.

Clamp with a short piece of cable

However, the best solution is to let the stub stick out further and bend it back into a loop. The “dead” line can be cut off, along with its own end at the exit from the fastening.

Bend back into a loop

This procedure has the advantage:

- bending the line around a small radius of the wedge creates permanent deformation inside the wire rope;

- Bend-like plastic deformation makes it difficult to push the end of the rope through the hook block.

If the asymmetrical wedge socket is installed correctly , the cable line is in the straight direction (Fig. 1). The tensile tension line runs straight through the mounting pin. Therefore, when the connection is loaded, it will not bend and bend the live line at its output.

If installed incorrectly , the traction line will be misaligned; therefore, whenever the joint is loaded, it tilts to equalize tension with the clamping pin, thereby strongly bending the "stress" line at the clamp exit (Fig. 2).

Installation

Special designs

The number of special designs, wedge clamps for cables, is extensive. Types vary depending on material, manufacturing processes (cast and welded construction), geometry (wedge angles ranging from 14 to 30), and method of securing the dead rope line.

The asymmetrical wedge fastening design secures the dead rope line to the rope socket body.

Attaching the “dead” part of the cable to the socket body

A wedge socket with an extended wedge to which the “dead” end of the rope is attached.

Attaching the “dead” part of the cable to the wedge

When using rotation-resistant steel ropes , it is recommended to install a swivel between the end connection of the rope and the point of attachment to the crane. However, the lifting height of the device will be reduced by installing a swivel. Here it is recommended to use an asymmetrical wedge socket with an integrated swivel.

This end connection reduces lift height slightly and has the added benefit that the swivel always automatically aligns with the cable.

Wedge socket with integrated hinge

Symmetrical wedge socket, used as an end connection for elevator ropes. It can be easily attached and also easily removed , which is a great advantage when manually adjusting the length of the lifting ropes.

Symmetrical wedge socket

How to tie a tow rope: tow knot and bowline knot

Every motorist, in addition to the standard set, must have a tow rope. He will help you get a stuck car out of the mud, or drag a suddenly broken car to the nearest service station. The cables offered on store shelves are equipped with hooks or carabiners. Thanks to the devices, the driver can quickly attach the twisted product to the car body. What to do if the cable is old or there is no carabiner on it? How to tie a tow rope quickly and securely to get a dead-tight knot? Professionals share with beginners how to tie knots. These skills may be needed at any time, so do not neglect them.

Flemish eye

Eye Splice - Used to splice the free end of a cable to form a loop. The threads of the end of the cable are unwound over a certain distance. The wire is then bent around so that the end of the unfolded length forms a peephole. Next, the unfolded strands are braided back into the wire rope, forming a loop or eye - called a Flemish eye.

Flemish eye connection

The threads of the end of the cable unwind to a certain distance

Consists of a combination of splicing and pressing. Steel rope slings are often used in steel mills where the ropes are exposed to high temperatures and serve as a replacement for thimble splices.

Splicing and pressing

Flemish eye end connections can be used at temperatures from 60 C to + 400 C. At temperatures from + 250 C to + 400 C, the load capacity of the ropes should be reduced to 75%.

Standardization

The types of Flemish eyes are designated as follows:

- Flemish eyes without a thimble.

- Flemish eyes with a thimble.

Various designs of the Flemish eye

Manufacturing and installation

The rope sling, which has not yet been processed, is pulled through the selected steel clamp (Fig. A).

Making a loop of steel rope

The outer threads of the lifting rope are divided into the required lengths (Fig. B).

The core of the rope sling is bent back and formed into a loop. The loose cable halves are then closed around the cable core. For example, the core of an eight-strand rope is closed on the right and left with only four threads until the threads on both sides are joined at the head of the loop (Fig. C).

As the outer strands of the rope have been completely enclosed around the rope core (Figure D), a steel clamp slides over the ends of the strands and is pressed.

Long (accelerating) splash

A long (accelerating) splice is used for splicing the tackle of running block rigging. This mold is convenient because the joint is almost not thickened.

When connecting a broken cable with a long braid, temporary marks are applied at a distance of 1.5-2 m from the ends and the cable is unraveled into strands up to the marks. The running strands are placed among themselves in the same way as with a short braid.

Having removed the temporary mark on one of the cables, one of the running strands is untwisted and a corresponding counter strand of another cable is inserted in its place. Then both strands are wrapped clockwise around each other and tightened with a half-knot. An incorrectly tied half-knot will protrude outward and will not tighten well.

Then, in the same way, a strand of the first cable is inserted into the second one. The remaining two strands are tied together in place. Having carefully tightened all the knots, make one and a half punches with each running end under the nearest root strands. The remaining ends are cut in such a way that the cut strand cannot freely come out from under the root strand.

Filling couplings

Filled coupling for steel rope, used for the manufacture of high-strength, permanent contacts; they are created by inserting a wire rope into the narrow end of a conical cavity that is oriented according to the intended direction of deformation. Individual wires are laid inside the cone, and then the cone is filled with molten solder, tin. In modern conditions, compounds with unsaturated polyester resin are increasingly being used. In this section, we will consider the stages of pouring a steel rope with a resin mixture.

Pouring resin mixture

Principle of operation

As the resin cures, shrinkage occurs, which creates a frictional bond with the wires. Silica is mixed with a resin mixture to impart frictional adhesion properties. Silicon dioxide also serves to absorb heat caused by the chemical reaction that occurs when a hardener is added to the resin.

When a load is applied to the rope, a cone of resin is pulled down into the bell bowl. The cone shape causes compression of the hardened resin against the individual wires and the walls of the socket. The compression creates enormous adhesion, friction between the wire and the resin, resulting in a strength that exceeds the tensile strength of the rope.

Cured resin

Precautionary measures

- Inspect the inside of the bowl to determine if there are any indentations in the socket. If there are grooves, fill them with putty.

- To grip the wire, use only soft annealed iron wire.

- The resin must be thickened and cured before use.

- Do not use oversized rope sockets.

- Do not use resin after the expiration date.

Do not heat the socket before pouring the resin to speed up the curing of the resin, this will cause the resin to gel prematurely before reaching the bottom of the socket bowl. This will cause the build to fail.

Carefully! Exposure to some strong chemicals can affect the cured resin and weaken the assembly.

Contact the distributor or manufacturer if this occurs.

Safety precautions

When working with resin or hardener, it is recommended to use safety glasses and protective clothing , as well as impermeable gloves.

Always work in a ventilated area.

If an aggressive substance comes into contact with your skin, wash with soap and water and remove contaminated clothing. In case of contact with eyes, rinse with clean water for at least 15 minutes. If irritation persists, consult a doctor.

If contents are swallowed, do not induce vomiting. Drink milk or water to dilute and seek medical attention.

If you inhale excess fumes, move to a fresh air area. If breathing stops or becomes difficult, consult a doctor.

Do not point an open flame at the socket lock. Keep away from heat sources. Resin is a flammable liquid.

When using chemicals, always refer to the safety data sheet.

Safety precautions when working with resin

Temperature

The lifting rope, socket and resin should be stored indoors to keep the assembly components at a higher temperature. It is best if all three components are at the same storage temperature. If these three ingredients are stored at room temperature, booster packs should not be used at low temperatures.

It is not recommended to aggressively apply heat (flame) to the socket before pouring, as high temperatures will cause the resin to gel prematurely and prevent the resin from penetrating into the bottom of the socket cone.

Wrapping the rosette in a thermal blanket to facilitate controlled and even heating is a safe and effective method of speeding up the curing process.

Installation instructions

To achieve results, it is important to understand the procedure and the necessary steps for a safe and economical method of fastening, steel rope and socket.

Measure the socket, from the bottom to the top of the bowl, to determine where to apply the clamp cable.

The end of the steel rope must be long so that the wires, after laying, are level or slightly below the top of the socket bowl.

Measure the socket

Place the socket on the steel rope

Socket on a rope

Grip wire at the base of the socket

Place the clamping wire on one (Fig. A). The length of the grip must be at least twice the diameter of the rope (Fig. B).

For plastic-coated wire rope, the braiding is removed from the winding area.

Apply the gripping wire at the base of the socket

To grip the wire, use only soft annealed iron wire.

End of a wire rope

Use a spike and begin to open the strands (Figure D).

Use a short piece of pipe and bend each strand at a 60 degree angle (Figure E).

Open the strands evenly as shown here (Figure F).

If the cable has a vinyl covering, remove it.

End of a broom wire rope

The right broom for the flood nest

Tension is applied to the completed socket assembly. The friction between the cured resin and the wires must exceed the friction between the outside of the resin cone and the inside wall of the socket, preventing the wires from being pulled out and allowing the resin cone to shrink and shrink. The compression that is created between the wires and the polymer cone becomes stronger than the cable itself. For proper friction it is very important that the end of the rope is properly prepared and opened all the way so that the resin reaches the bottom of the socket bowl. See illustration below.

Properly maintained wire rope end

Clean wires

Thoroughly cleaned wires provide greater adhesion ; therefore, providing more friction which helps ensure the resin cone is properly secured and creates compression to ensure the required strength of the assembly.

Align vertically when pouring resin

A socket assembly that has been properly aligned when pouring the socket will allow forces to be evenly distributed across the wire and resin cone; therefore having a strength greater than a rope. If the rope is not aligned properly when pouring resin into the socket, i.e., the rope will be installed at an angle. Tests have shown that when this happens, the rope will break at the lower base of the nest.

Clean end of rope

Place the hardened end of the wire rope in the solvent and make sure the wires are clean from the bottom of the broom to the grip tape. After cleaning the end of the rope, wait until all the solvent has evaporated and the wires are dry.

Clean end of rope

To achieve results, it is recommended to use a pure solvent.

Insert the broom into the nest

Place the socket on the wire broom. Make sure that the rope wires are evenly spaced in the socket bowl, the ends of the wires are slightly below the top edge of the bowl, and the axis of the rope and the socket are aligned.

The top of the grip should be level with the bottom of the socket. Do not allow any wire to extend below the base of the socket.

Insert the broom into the nest

Sealing the bottom of the socket

Wrap the bottom of the socket with spackling putty. Make sure the putty is pressed into the groove between the strands.

To ensure a better seal, wrap the caulk with electrical tape.

Sealing the bottom of the socket

Mix resin

Knead the resin pack for 30 seconds, thoroughly stirring the resin (silicon dioxide).

Cut open the resin bag and squeeze out the contents into the included mixing container.

Cut open the hardener bag and squeeze the contents into the resin.

Using a mixing paddle, thoroughly mix the resin and hardener until the color is uniform.

Proper mixing is necessary to achieve 100% effectiveness.

Mix resin

Pour the resin mixture into the socket

After mixing the resin and hardener, immediately prepare to pour it into the socket.

Position the funnel so that the resin flows out of the funnel into the bowl, along the side of the nest.

This will help the resin reach the bottom of the bowl and reduce the chance of air being trapped.

Fill to the top of the bowl.

Allow the resin to set firmly before moving the assembly. Moving the assembly prematurely may damage the resin before it cures and reduce effectiveness.

When following the resin manufacturer's recommended procedures, completion efficiency reaches 100%

Pour the resin mixture into the socket

Re-lubricating the wire rope

After the resin has cured, re-lubricate the cable to replace any lubricant that may have been removed during the cleaning process.

Wire rope lubrication

It is recommended to check the load on the assembly before using it.

Special designs for steel ropes

Some applications, such as narrow openings in drums or other complex feed systems, may require special end preparation. The end pieces must be removed after the cable has been installed. Brackets are used when another rope is needed to pull the new rope into place. The wire rope must not be shortened, lengthened or interrupted by the knot.

At the ends of a wire rope, staples , or end blanks, are used when another rope is needed to pull the working rope into place.

Four commonly used pockets are shown. Special designs

Double Splash

The double splash is used instead of the short splash.

After completing the preparatory work, the running strands of one cable are pierced under the main strands of the other in the following order: the first running strand is under three main strands, the second is under two and the third is under one strand.

Having finished punching the first three strands, the cable is turned over and the remaining strands are punched. The fourth strand is pierced under two, the fifth and sixth - under one molar.

The last (sixth) strand is punched not against the descent of the cable, like all the others, but in the direction of descent. Subsequent punches are made according to the rule “every other under two” against the descent of the cable or “every other under one” in the direction of descent. At the end of the punching, the running strands are tightened, the ends are cut off, and the splicing area is tied with soft wire.