Short description

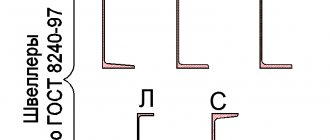

The regulatory documents indicate that bent channels can be produced with different profiling accuracy. The most common types are regular, high, or increased degree of rolling. Thanks to this, experts began to distinguish between several types of steel profiles, which differ from each other not only in rolling accuracy and shape, but also in other parameters.

Large enterprises are engaged in the production of channels from various types of steel, the main of which are:

- Carbon.

- Rolled hot rolled. This technology involves changing the crystal lattice of steel.

- Low alloy. This steel contains special alloying additives that significantly increase the performance characteristics of rolled metal products.

- Rolled cold rolled. This metal has increased resistance to deformation.

- Structural steel.

According to GOST regulatory documents, all products that are distinguished by equal shelves can have a length from 3 to 12 meters. As for unequal products, their length always varies from 4 to 11 meters. Despite this, experts distinguish several types of bent steel channels:

- Measured. In this case, all indicators comply with the requirements specified in the contract or order.

- Unmeasured. A length that was regulated by a certain range of standards, but not less than what was specified in the order.

- Multiple of measured. Must be agreed upon with the manufacturer.

- Measured length with unmeasured channel bars. Its amount does not exceed 7% of the mass of the entire batch.

- Multiple of measured with unmeasured channel bars (all within 7%).

It is worth considering that for unequal bent products, it is customary to classify as unmeasured sections those channels whose length exceeds 3 meters.

Bending metal along a radius

Bending is one of the key metalworking methods. The technological process makes it possible to obtain a curved product from a flat straight blank. One type of metal bending is radius bending.

It involves the use of press brakes that are capable of giving the sheet or pipe the desired angle.

Bending allows you to avoid stamping and welding and obtain products of the required shape at a lower cost.

Figure 1 - Bending along the radius

Demand for the technology of “metal bending along a radius”

By bending metal at angles and different radii, the following is obtained:

- elements of curtain facades;

- metal furniture;

- cornices;

- interior details;

- advertising signs, etc.

Figure 2 - Radial bending of a channel

The need for radius bending of metal is often encountered in everyday life, during construction and repair. For example, when you need to bend a profile pipe at a certain angle without unnecessary deformations and kinks. It is unlikely that you will be able to do this on your own.

High-quality work can only be done with the help of a professional machine. The task of the machines is to perform plastic deformation without damaging the metal.

The technology allows you to take into account the characteristics of the workpiece and produce products with different technical data.

How to prepare sheet metal for radius bending

Before using machines for radius bending of sheet metal, it is important to properly prepare for the process:

- analyze the characteristics of the future product;

- calculate the force required;

- select the standard size of the equipment;

- make workpiece drawings;

- calculate deformation parameters;

- design tooling.

An important stage is selecting the material and testing it for suitability. Once the bending parameters have been determined, you need to understand whether the existing workpieces are suitable for the job. To do this you need:

- determine the plastic characteristics of the product, compare the results with the real stresses that arise during bending;

- determine the minimum bending radius of sheet metal at which the risk of cracks is not high;

- identify the possibility of workpiece deformation after pressure treatment, especially if the final configuration is complex.

The results of such a study may vary. After checking everything, experts make the appropriate decisions:

- replace the workpiece with a more plastic one;

- heat the metal before deformation;

- carry out softening heat treatment.

Important: before bending, you need to determine the smallest angle, minimum radius, and spring angle of the selected sheet of metal.

How to bend sheet metal along a radius

Bending operations are the main methods of processing sheet metal. First, the sheets are prepared in bending machines in the procurement areas. Often, workpieces are cut into strips - strips of a certain width, which are then deformed according to plan.

Figure 3 - Sheet bending

When performing radius bending of sheet metal, a number of features should be taken into account:

- As a result of pressure treatment, the metal becomes fibrous. To prevent cracks from appearing, bending is carried out across the fibers. The sheet can also be bent so that the bend line is at an angle of 45° to the direction of the fibers.

- Metal has fluidity. If you exceed its limit, the sheet will tear.

- Changes occur at the bending site: the metal becomes thinner, deformed in the cross section, the neutral layer shifts towards a smaller radius (initially it is located either in the middle or in the center of gravity).

Particular difficulties arise when working with small workpieces. It is important to remember the following:

- with a small bending radius, the deformation covers most of the workpiece;

- with a large radius there is no such effect.

How to bend pipes along a radius

The concept of radius exists not only when bending sheet metal, but also when deforming pipes. The use of special equipment allows you to reduce the number of welds and improve the quality of installation.

The technology of bending steel pipes allows the workpiece to be completely or partially deformed. Along the inner radius, the hollow profile experiences a compressive force, and along the outer radius, a tensile force. The process has its own characteristics:

- when bending, some sections of the pipe may be deformed so that the alignment is disrupted;

- radial forces that stretch the outer wall can cause metal rupture;

- compressive tangential forces acting on the inner wall, with uneven bending, can cause folds to appear - corrugation of the metal.

To bend a pipe radius, you can use two main methods:

- cold;

- with preheating of the desired area.

Cold bending is used for small diameter pipes. It involves mandatory determination of the minimum bending radius.

Preheating is used to increase the ductility of the metal and reduce the risk of defects. Most often, this method is used for large diameter pipes. Carrying out work with preheating requires more time and labor.

Both methods require knowledge of technological processes. Only if the relevant norms and standards are observed is it possible to carry out radius bending without the formation of cracks or folds on the walls.

Figure 4 - Radius pipe bending

Sheet metal bending radii

When deforming workpieces, it is important to know the minimum bending radii of sheet metal. For each element or alloy these indicators are different. If you do not take them into account, the workpiece can easily be damaged.

In addition to the material, the bending radius is affected by:

- type of sheets (annealed, riveted);

- position of the bend line (along or across the fibers).

Minimum bending radius of sheet metal

For example, consider the minimum metal bending radii in the table.

| Material | Annealed | Riveted | ||

| Fold line | ||||

| Across the grain | Along the fibers | Across the grain | Along the fibers | |

| Aluminum | 0,2 | 0,3 | 0,8 | |

| Copper | 0,2 | 1 | 2 | |

| Brass L68 | 0,2 | 0,4 | 0,8 | |

| Soft duralumin | 1 | 1,5 | 1,5 | 2,5 |

| Solid duralumin | 2 | 3 | 3 | 4 |

| Steel 05–08 | 0,2 | 0,2 | 0,5 | |

| Steel 8–10, St1 and St2 | 0,4 | 0,4 | 0,8 | |

| Steel 15–20, St3 | 0,1 | 0,5 | 0,5 | 1 |

| Steel 25–30, St4 | 0,2 | 0,6 | 0,6 | 1,2 |

| Steel 35–40, St5 | 0,3 | 0,8 | 0,8 | 1,5 |

| Steel 45–50, St6 | 0,5 | 1 | 1 | 1,7 |

| Stainless steel Х18Н9Т | 1 | 2 | 3 | 4 |

Maximum bending radius of sheet metal

There is no concept of a maximum bending radius. If a specialist knows exactly what the minimum bending radius of sheet metal is, then any larger options are suitable.

Calculation of sheet metal bending radius

From what was written above, it follows that the calculation of the bending radius of sheet metal is based on its parameters. The material of manufacture, the thickness of the product, the method of manufacturing the workpiece, as well as the wishes of the customer are taken into account. The latter directly depend on what product you need to receive.

GOST sheet metal bending radius

It will help you determine the bending radius of sheet metal GOST and other industry standards. For example, OST 1 00286-78 has been developed for steel sheet materials.

This document establishes the calculation formula necessary to determine the minimum bend radius of products up to 3 mm thick.

And in GOST 17040-80 you can find a formula for determining the minimum permissible bend radius for one stamping operation when free bending a material 4 mm thick.

Production principle

Modern production of this universal part is based on the use of hot-rolled, cold-rolled and low-alloy steel. Experts say that hot-rolled technology has managed to prove itself exclusively on the positive side in the field of mass production of channels, beams and other products.

The steel version of this metal product involves the use of cold rolled products, thanks to which it is possible to create high-quality products that will well withstand any deformation. As for low-alloy steel, such materials are the most expensive, but also reliable. It is worth noting that this type of material is diluted with peculiar impurities, which several times increase the final performance qualities of the metal itself.

To ensure that all products meet established quality standards, their production must be carried out exclusively by qualified personnel. Before starting the most important process - the manufacture of channels, all parts must be checked for chips and deformations. The edges and ends of the workpieces should not have any nicks or delaminations.

For the production of profiles, only high-quality equipment is used, which is why several important steps are required in order to ultimately obtain high-quality products. The choice of production technology depends on the specific profiling. After forming the segment, universal cutting is carried out by the mill. As for piece profiling, all necessary cutting is carried out in advance.

Due to the fact that this type of profile is produced using a special machine, any changes in calibration can lead to a situation where the final quality of the product will be reduced several times. In this case, you may encounter the following types of damage: helical shape, waviness, distortion of shape, crescent shape.

The range of channels is varied, which is why the use of a particular product may vary depending on the required performance qualities. It is also worth considering that the numbers printed on the product always indicate its height. For example: channel 11 can be used for the installation of structures, and channel 16 is most suitable for reinforcing buildings, as it has high strength values. Of course, depending on the type of channel, its final price also varies.

How to strengthen a channel

In order for the channel to resist deflections, bends and twisting, it is reinforced. The method is selected based on operating conditions.

Reinforcement for bending and deflection

To strengthen a beam for bending/deflection, three methods are used: installing supports, increasing the cross-section, or redistributing the load throughout the structure.

Installing selections is one of the easiest ways. The load on the beam is reduced without significant changes to the metal structure.

Supports and beams are connected based on the type of load on them. For dynamic loads, only connections with rivets and bolts can be used. If the lateral force is constantly applied, then any type of connection of parts is used that ensures high reliability and strength.

You can further strengthen the channel for deflection/bending by increasing the cross section. To do this, you need to weld steel plates or corners in the longitudinal direction. If you weld an additional channel, the structure will become symmetrical.

The third method is as follows: the main load is shifted from the problem point and is evenly distributed over the new shape of the beam.

If none of the above methods can be implemented, then design changes are made to the frame or its elements. To do this, the calculation of the entire object is redone.

Torsional reinforcement

To level out channel torsion, welding or concreting is used. When welding, an additional beam is welded to the main beam, positioned in a parallel direction. The result is an I-beam or “box”. When performing welding work, it should be taken into account that the metal heated during welding can weaken the structure. Therefore, it makes more sense to use special welding methods on both sides.

Concreting improves rigidity, but at the same time increases the longitudinal load on the channel. But in some cases this is the only sure way to strengthen the beam torsionally.

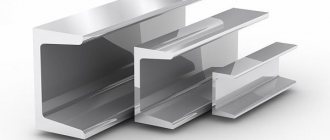

Features of application

Modern channels belong to the category of metal products, the cross-section of which resembles the letter “P”. The material itself consists of a wide wall and two adjacent strips. Most often, a steel channel (bent, equal-flange) is produced in lengths from 3 to 12 meters, while the thickness of its walls varies within 8 millimeters. The main feature of this product is its low specific gravity and high strength. All structures that were made from such rolled metal are distinguished by their lightness and quality, as they are able to withstand heavy loads.

The bent profile is distinguished by the fact that it always has precise dimensions and slightly rounded corners. It is also worth considering that the finished product never has defects, since all errors in the workpieces are eliminated under the influence of a roll forming machine. Thanks to this, the final material does not require additional processing. In repair work, bent profiles are increasingly being used, which can be used together with a chamfer.

Today, bent equal-flange channel is actively used in the reconstruction of buildings, as well as for the construction of various objects. All metal structures in which this material is present are a huge competitor to traditional reinforced concrete buildings.

Thanks to this, craftsmen receive many economic and technological advantages, which allows them to reduce the complexity of installation work, thereby reducing construction time. For example, many engineers are accustomed to always paying attention to the types of channel, which, in particular, is a galvanized type of thermal profile, manufactured to individual sizes.

It is also worth considering that the large-scale use of this material can significantly reduce the level of load on the final structure, making it possible to use more affordable types of foundation. The final dimensions of the bent channel made this material universal and multifunctional, due to which it is actively used in both private and industrial construction. Experienced craftsmen use it to produce high-quality partitions in offices and residential buildings.

We should not forget about mechanical engineering, where it is simply impossible to do without bent metal products. Channels are actively used for the manufacture of durable parts and mechanisms for cars, as well as for the construction of universal frame structures. The strength of this material is so great that it is considered mandatory in those factories where reliable frames for massive trucks are manufactured.

Channel bending at home

Construction workers probably wondered how to bend this profile. In garage conditions, only local bending is possible, since there is hardly room for a bulky machine. To work, you will need a welding machine, as well as a grinder with both types of discs.

The sequence of work is as follows:

- Marking lines are applied on the channel flanges in accordance with the required angle of inclination (bending) of the profile;

- a triangular piece of metal is cut out on both sides with a grinder; it is important that the cutting is carried out accurately and symmetrically, otherwise the workpiece cannot be bent;

- the profile is bent at the selected angle at the cutout;

- to restore strength, the joint is welded;

- the weld seam is processed with a grinding disc.

This method is the only correct one that will allow you to bend a metal channel without the use of expensive equipment.

Source

Main advantages

The bent profile has many positive characteristics, due to which it is highly valued in many industrial and domestic areas. This popularity is due to a large number of advantages, the main ones of which are:

- Rational use of channels gives the consumer an excellent opportunity to reduce the final weight of the structure being built. Thanks to this, it is possible to save more than 30% of the material used, which cannot be achieved using an I-beam or hot-rolled channel.

- The products are characterized by low cost and good strength characteristics. Due to this, such rolled metal is widely used in industry and construction.

- The bent profile is distinguished by its quality, due to which it is most often used without preliminary chamfering.

- To carry out installation work, you do not need to use a welding machine.

- The finished structure is light in weight.

- The profile tolerates incoming bending pressure well.

- The material has a very smooth surface.

- High precision and compatibility of all parts.

- With the help of such channels you can create unique designs of arbitrary shapes.

- When workpieces pass through the press of roll forming machines, all existing defects are eliminated, so no additional processing of the material is required.

Due to the presence of all these advantages, bent steel profiles are actively used in many modern industries.

What is the operating principle of channel bending?

During operation, the channel is subject to pressure from an external weight in the bending direction. Therefore, designers calculate upcoming loads in advance. What do experts start from?

The first thing designers calculate is the maximum value of the moment in the channel profile (M). They use a complex formula for this. The distribution load and channel length are taken into account.

In the second step, experts look for the value of the moment of resistance of the channel section. There is a formula for this too. The previously obtained value of M and data on the material’s yield strength are substituted into it. For the last value, data is taken from technical tables; the values differ for different steel grades.

Experts compare the results obtained from the second formula with GOST 8278 in the “moment of resistance” category. Based on this, for each project they select a rolled or bent channel that meets all the criteria.

Execution options

The most popular material in the metal rolling industry is bent channel. The main purpose of this product is to give the structure the necessary level of stability and strength. The specificity of the channel is that it not only tolerates the load applied to it well, but also redistributes it evenly. Depending on the size and shape, several types of channel can be found on sale:

- With parallel edges of all shelves.

- With a slight slope of the edges of the shelves.

- Universal copies.

Depending on the manufacturing method, they are usually divided into unequal-flange and equal-flange channels. As for the last type of product, the main process of its manufacture is not considered difficult, since a pipe machine is used in the work process. Standard quality steel coils and high quality carbon structural steel are used as blanks. Bent steel unequal-flange channel is produced using universal roll forming mills.

It is also worth considering that the galvanized type of bent channel, due to its strength and specific gravity, has found its application not only on large-scale construction sites, but also in mechanical engineering, machine tool building, automotive industry, carriage building and many other areas. The manufacturing process of this type of rolled metal consists of two main stages:

- A product of the desired shape and size is produced from the blank.

- The finished part is covered with a galvanized coating, which serves as reliable protection against the negative effects of corrosion.

The stainless steel type of channel can be either bent (not coated with zinc) or hot-rolled. During the period of active operation of such products, it is necessary to carefully monitor its strength characteristics, since it participated in the creation of metal structures and the quality and safety of the entire facility depends on it.

How to cut a channel

Here we will not tell you how to cut a channel on high-precision machines. Let's consider the field option, when materials are cut to size directly on site. And there they use a grinder. So let's start with safety precautions. You can never hope for chance. There are many examples when disks were destroyed during operation and scattered everywhere, causing harm to people and property. Such incidents last a fraction of a second, so it is almost impossible to dodge the flying parts of the disk. And if you don’t protect yourself, such exposure can cause irreparable harm to your health.

Basic rules for working with an angle grinder:

- Before work, make sure that the disk is intact, not tilted and is level. Keep an eye on this while working.

- When cutting, place the beam on an object so that it is raised. Due to this, the cut part will fall under its own weight.

- While working, take short breaks to allow the disc to cool down.

- When working, stand slightly to the side and not in the plane of the cut.

- The disc on the grinder must be tightly tightened. It will unwind more easily after work if you place a cardboard washer under it.

- Do not, under any circumstances, work with the angle grinder cover removed. It is extremely dangerous to work without it.

- You need to wear protective clothing when working. In addition to a protective suit and closed shoes, glasses and gloves must be used.

- When working with an angle grinder, make sure that the disc rotates away from you. If for some reason the grinder is torn out of your hands, it will fall away from you.

The manufacturing technology of a bent channel is shown in four figures below.

1.

Place the workpiece by pressing it against the working surface of stop No. 1.

2.

Press the pedal of the sheet bender and make the first bend.

3.

Let's reinstall the semi-finished product by pressing it against the working surface of stop No. 2.

4.

Let's press the pedal of the sheet bender - make the second bend - the channel is ready!

Bent and hot-rolled channel: what to choose?

We have already given different versions of answers to the question about the difference between a cold-rolled channel and a hot-rolled analogue. The most significant difference between these types of rolled products is that products with the same wall height have different strength and, accordingly, load-bearing capacity. This indicator is a determining factor in the selection of rolled products, which are intended for the manufacture of load-bearing structures in construction and industrial production.

Bent and hot-rolled channel in construction

In construction, bent and hot-rolled channels are usually used for building floors, bridge spans, loading and unloading overpasses and other structures where structures must have high load-bearing capacity with relatively low weight. Both types of rental are completely equal in the construction industry. The main condition is that their strength characteristics meet the requirements of the construction project or technical documentation for the production of a particular industrial product.

Which channel to choose - bent or hot rolled?

The main criterion for choosing channels is their strength. If bent and hot-rolled products of suitable size meet the design requirements for the moment of resistance to vertical load, bent products are preferable. It is lighter and cheaper. However, when it comes to extreme loads, hot-rolled channels have no alternative.

For example, the moment of resistance for the walls of hot-rolled channels of the maximum standard size (No. 40P) is 763 units. For bent products with a wall height of 400 mm, it is only 458.99 units.

Choosing a channel from the point of view of economic feasibility

The cost of a channel is calculated based on data on weight and cost per ton:

| Characteristics / Name | Channel 12P | Channel 140x60x5 |

| Weight of 1 meter, kg | 10,7 | 9,77 |

| Weight of a channel 6 meters long, kg | 64,2 | 58,6 |

| Price per ton* | 97790 rub. | 87490 rub. |

| Price for 1 piece of channel | 6278 rub. | 5127 rub. |

* Price as of December 2022, see the current prices on the date of purchase in the online store in the Rolled Metal - Channel section.

It can be noted that from the conditions for calculating the strength of a channel working in bending, a more economical solution would be to use a bent channel in comparison with a hot-rolled one.