Structure and capabilities of the grinder

An electric angle grinder is used for grinding, polishing and cleaning surfaces, welds and edges. The technique is effective in cutting various materials and making products from metals, stones, bricks and concrete. The development of artificial diamond technology has made it possible to turn the grinder into a universal cutting machine. Now the quality of their execution is regulated by GOST R IEC60745-2-3-2011 and is tested in laboratories.

Grinder grip

In general, the device in an angle grinder is as follows:

- The rotation of the motor rotor is ensured by an electric motor with a control unit and a current supply cable.

- A gear and a fan are installed on the shaft. The mechanism is engaged with a driven gear mounted on the drive spindle. The latter rotates the working tool - a disk or stone.

According to their design, there are one- and two-handed grinders:

- One-handed tools. There is no main handle, they weigh up to 2.5 kg, the diameter of the circle is 100, 115 and 125 mm.

- Two-handed instruments. There are main and additional handles, the diameter of the circle ranges from 125 to 230 mm, the weight of the machines is 2.5-6 kg.

Preparing to work with an angle grinder

The rules for working with power tools and their accessories always provide for preparatory work. Bulgarian is no exception. First of all, you should prepare the required protective equipment.

Safety precautions when working on a lathe

Note! The minimum program is glasses and a casing. Failure to comply with these requirements may result in sparks entering the eyes and injury.

You should also have protective gloves. During the labor process, the hands are close to the disk. This causes particles, scale and sparks to land on your fingers and palms. Thick gloves are used to protect hands and preserve their skin. This is a minimal set for home use. If we are talking about production, then in the work area you need full protective clothing that covers all parts of the body.

Pipe cutting methods

To cut a profile pipe, including at a certain angle, you can use the following tool:

- angle grinder - grinder (picture above). This method is most often used for domestic purposes, as it is characterized by the simplicity and availability of equipment;

- hacksaw for metal. Using a hacksaw is not difficult, but the process of doing the work is quite labor-intensive;

Using a hacksaw for cutting corrugated pipes

- electric jigsaw. To cut metal, you will need to purchase a special diamond-coated saw. The work is done quite quickly;

Cutting corrugated pipes with a jigsaw

The use of a jigsaw and a hacksaw is not possible for cutting thick-walled profile pipes or pipes with a large diameter.

- special machine for cutting pipes. The equipment is most often used by professionals due to its high cost. Currently, specialists use two types of machines:

- equipment with mechanical cutting, which is performed with a cutting wheel or a special file;

- laser equipment. Laser cutting is more accurate compared to mechanical analogues.

Using a special laser cutting machine

When choosing any method, it is important to pay special attention to safety precautions. When cutting corrugated pipes, metal shavings are formed, which can damage the hands and eyes of the master, so it is important to wear gloves and safety glasses before performing the work.

Features of working with an angle grinder

Safety precautions when working on a drilling machine

A modern angle grinder allows you to replace the emery when working on metal. To avoid problems, it is useful to remember a few guidelines when using the tool:

- The angle grinder should be held with both hands during operation. In the event of a kickback, a strong fixation will minimize displacement. Otherwise, the risk of injury increases.

- Work should be carried out on a flat surface, confidently maintaining balance.

- Place the power cord on the opposite side of the disk. The operating instructions for the angle grinder make these requirements in order to avoid short circuits and shock waves from the unit.

- When completing work, the tool should be held firmly in your hands until the disk comes to a complete stop.

- If there is a power outage, you must unplug the tool from the outlet. Otherwise, the angle grinder may start working without operator control.

- The work process is accompanied by heating of the disks. After turning off the tool, they should not be touched until they cool down.

Fixing the material

Correct use of the tool

When you start sawing any part using an angle grinder, you should adhere to these rules.

- When cutting metal, you need to hold the grinder firmly, with both hands.

- The wheels can be changed only after they have completely stopped rotating and cooled down to an acceptable temperature, disconnecting the power tool from the power supply.

- Do not place the working tool on the ground or table (do not let it out of your hands).

- It is required to periodically stop for about 5 minutes to rest and allow the disk to cool.

- It is necessary to constantly monitor the condition of the cutting wheel, preventing it from being pinched by the edges of the workpiece being cut.

- Do not leave the tool plugged in unattended.

- Use only discs of the correct size as specified in the operating instructions for the device you are using.

- It is better to do the work on a flat surface so that the body position is stable.

- Make sure that the power cord is kept away from the rotating circle, sharp edges, and objects heated above 100 degrees.

- Movements not directly related to cutting must be performed only with the power tool turned off.

- You need to position yourself on the side or behind the tool, doing the work with your own hands so that parts of the body are not in the cutting plane.

When cutting metal with a grinder is finished, you should wait until the disk stops completely and disconnect the power cord of the tool from the mains. Afterwards, it is recommended to ensure that there are no signs of fire. When cutting materials, a right-handed person should correctly hold the handle of the device in the area of the on/off button with his right hand. The left hand is placed on the handle screwed into the body of the power tool from above.

It is unacceptable to perform work using an angle grinder in a very tired state, or while under the influence of alcohol, psychotropic or narcotic drugs.

As for the question of which direction—toward or away from you—the disk of a switched-on angle grinder should rotate, there is no definite answer. The operating instructions indicate that the first option is correct. This is due to the fact that the resulting sparks fly away in the direction opposite to the operator, without causing harm. Also, fragments of the circle will fly in that direction if it breaks into pieces.

But if the rotating disk jams towards itself, the tool will fly off towards the worker. For this reason, many specialists prefer to cut metal so that the circle rotates “from itself”. A power tool torn out of your hands will fly in the opposite direction. This reduces the likelihood of injury, and clothing, shoes and gloves will protect the user from flying sparks.

How to hold an angle grinder correctly

Many people have an angle grinder, but most people do not know how to use it correctly and how to hold it. This leads not only to work failure, but also to serious injuries. An angle grinder is a rather dangerous power tool.

The circle should be installed with the pattern facing up and clamped with a special nut.

The person with the leading right hand holds the grinder by the handle with his right hand. In this case, the circle should be located on the left side of the machine, and the protective cover should cover it on top. The rotation occurs in such a way that during cutting, sparks fly towards the worker. If the grinder's circle jams and the grinder breaks out of your hands, then it will not go towards the carver, but in the opposite direction.

The left hand holds the machine by the handle, which is screwed into a threaded hole on the body. There are several of them for special cases of use, but the correct position of the handle is only the upper one.

This position of the machine requires the use of protective equipment. To protect the eyes and the exposed part of the face, use safety glasses, or even better, a protective mask. To protect exposed parts of the body from sparks and small fragments during the cutting process, it is necessary to wear a suit made of thick material.

Instructions and recommendations for cutting with a grinder

Working with materials is characterized by one sentence: the directions of tool movement and disk rotation must coincide.

Safety precautions when working with disinfectants

Note! It is necessary to come into contact with the surface being cut at maximum spindle speed - otherwise jamming may occur.

Wherein:

- The cutting line should pass by the working person, and not rest against him. If the disc jams, the reactive movement of the tool will pass by the operator.

- Start cutting profiles from the place with the smallest cross-section.

- The protective cover provides safety only if it is between the person and the circle.

- When cutting walls, a cable, fittings or pipe may get caught, which will lead to a kickback. Be away from the possible displacement line.

Cutting sheet metal with a grinder

To cut metal of different types and thicknesses, use appropriate cutting wheels of various thicknesses and diameters. The algorithm for sawing sheets is as follows.

- To cut using a grinder, sheet metal is first laid on a flat surface.

- Mark with chalk (marker) the exact dimensions of the cut out fragments on the surface of the sheet.

- Sawing is carried out along the marked lines, without changing the angle of the initial inclination of the disk to the working surface, so that it does not jam and break the power tool.

If you don’t have the skills to saw sheet metal with a grinder, it is recommended to first practice on soft material - this will give you the opportunity to get a feel for how the tool works.

It is necessary to take into account that the lower proximal segment of the disc cuts metal more effectively.

When cutting a sheet of metal, the following recommendations should be taken into account to obtain a high-quality result.

- To improve cooling, it is necessary to water the sawing area with water, which will also increase the life of the wheel.

- You should start cutting metal only when the disk is rotating: you cannot turn on the tool if the stationary circle is in contact with the surface of the workpiece.

- To saw tin (thin sheet metal) or cut out various geometric shapes, it is more convenient to use small, machined circles (“bits”).

- You should not press the angle grinder with significant force: cutting should take place almost exclusively under the angle grinder’s own weight.

- If the cutting wheel stops in the slot (when the power tool is turned off), then work can be resumed only after it is removed.

If sawing the sheet occurs slowly, you should change the working attachment. Excessive load on the angle grinder when cutting metal will lead to overheating or jamming of the rotating wheel.

What is a kickback?

This is the name of one of the most dangerous cases that can happen during work. The effect occurs when the wheel is strongly jammed into the workpiece, as a result of which the power tool is sharply thrown back. It is necessary to carefully monitor the process and hold the grinder tightly.

The points weren't enough

How to avoid kickback

To do this you need:

- Always hold the tool by the standard handles.

- Take a stable position on the ground.

- Use both hands.

- Be slightly away from where the tool will hit.

- When the angle grinder moves away from itself during a reverse impact, it bounces onto the person.

- Be especially careful when working around corners and edges.

How to cut smoothly

To cut something evenly with a grinder, you need to make the correct markings. For example, before cutting a piece of pipe, you need to mark the size with a marker or thin chalk. Then we take a sheet of paper with a straight edge and wrap the pipe around the mark. We will get a paper pipe on top of a metal one. The border of the paper will be the exact trajectory along which part of the pipe will be cut off.

For these purposes, you can also use construction tape, which makes it easier to wrap the pipe and secure it. Draw a cutting line along the edge of the paper or tape. We remove the paper, heal the pipe in a vice and cut it with a grinder.

You can cut a corner, profile or sheet in a similar way. Just don’t forget that you can’t change the position of the machine while cutting. Misalignment of the circle will lead to jamming or breakage. Do not press too hard on the circle, especially thin ones. The deformation will immediately be reflected by curvature. The machine should eat into the material itself, you just need to hold it.

The evenness of the cut also depends on the correct selection of the wheel. It is difficult to achieve an even trajectory when cutting off part of a thick-walled pipe with a thin circle.

Miter cutting

In this case, we will tell you how to cut a pipe at an angle of 45º. Marking will be needed in this case too (more details: “How to cut a pipe at an angle - marking options for round and profile pipes”).

To apply it you will need a square sheet of paper that needs to be folded diagonally. The resulting triangle is wrapped around the pipe and fixed. This will create an angle of 45º.

You can, of course, try to lower the pipes at the desired slope into the water, then the boundary of the wet surface will serve as a marking. However, it is best to use a special device for corner cutting - a miter box.

The shape of the miter box looks like an inverted letter “P”. Ready-made holes with different angles have already been made in its opposite walls. It is enough just to place the pipe inside the device and cut it by running a hacksaw along the selected grooves.

Results

Thus, making an even cut of a pipe from any material yourself is quite simple. There are only a few tricks in this matter that will allow you to quickly and efficiently carry out all the work and build yourself the necessary object for your household or dacha. We also note that it is better to check the measurements several times before starting cutting, because you can accidentally make a mistake and ruin the material, incurring additional financial losses.

Methods for cutting metal pipes at an angle

There are several ways to saw off a pipe or cut it into pieces. Of the available tools, a grinder is the best for this task. But the biggest problem remains the need to correctly mark the cutting lines. They can be different, most often you have to maintain either a right angle relative to the axis of the pipe, or 45 degrees. The techniques vary somewhat depending on what products need to be cut:

pipes for laying water supply, gas and for heating distribution;

profile products for assembling gates, canopies, and other metal structures;

large-diameter pipes - as a rule, this is rarely needed at home, where the widest clearance is only in the sewer system;

pipes made of steel, cast iron, thin-walled of non-ferrous metals and soft alloys.

Both problems can be solved quite simply even without the use of a special pipe angle pattern.

45 degree cutting

One particular example of such a situation is the need to cut a metal pipe at an angle of 45 degrees. Such cutting of material is often required when laying water pipes or heating systems. In this case, you have to deal with steel pipes. For these purposes, conventional cylindrical pipes are usually used. If we are talking about the installation of some kind of metal structures, then profile pipes of rectangular or square cross-section are more often used. The main problem here is that in order for the elements to be connected to coincide, the cut must be as smooth as possible, which means that especially close attention should be paid to marking the material.

In cases where cutting at an angle is required, a simple square sheet of paper can be used as a marking template. It must be folded strictly diagonally, and then wrapped around the pipe with the template. In this case, it is necessary to carefully ensure that the side of the sheet, which is located closer to the end of the pipe, is perpendicular to its central axis. Next, using marking material, a series of dotted lines is applied and after the marking is completed along the entire circumference, the template can be removed.

Photo of the template for cutting pipes - side view

Larger pipe blank

Marking a 45 cut using a template

If you have to cut a profile pipe, then it is advisable to make a special template from the same pipe, but with a larger cross-section. In this case, you will only have to use the measuring devices once. To apply markings you will need to use a protractor or a construction square. After sawing off the template, the pipes to be cut can simply be inserted into it and marked. This approach will significantly save work time and cutting a profile pipe at 45 degrees will be convenient.

As for what to use when carrying out work, you should choose the most suitable and familiar one. This can be a simple hacksaw for metal, or a grinder with an installed cutting disc.

90 degree cutting

When the need arises to cut at 90 degrees, the situation is even simpler. In the case of cylindrical elements, you can use the same sheet of paper that is used to wrap the pipe as a template. It is important to ensure that the edge of the sheet is smooth and matches the entire circumference. After marking is applied, the element to be cut is fixed and the cut is made.

The video shows the process of cutting a pipe at 90 degrees.

How to cut a profile pipe evenly

You can cut a profile pipe in much the same way, but here it will be easier to use a square. The device is applied to each side in turn, for which the element to be cut will need to be rotated, and markings are applied. Next, the pipe must be secured firmly and work can begin.

Any suitable tool can be used for sawing. If you have to cut a lot of pipes, then it is advisable to make full-fledged templates from scraps. In this case, measuring and marking work will have to be done only once.

Large diameter pipe cutting

When it is necessary to cut a large diameter pipe, a number of special devices and tools can be used. This may be necessary if, for example, a pipeline needs to be repaired.

- Bulgarian. The use of an angle grinder is justified from the point of view of the availability of tools and the comparative cheapness of the work. However, you should not count on greater productivity in this case; in addition, carrying out work in this way is associated with considerable risk.

- Roller machine. Such devices are also often called pipe cutters. In essence, such a device is the same grinder, but more suitable for this type of work. The machine includes a special frame where the element to be cut is fixed, as well as a holder with installed cutting rollers, which do the actual work. It is important to understand that each machine must be purchased for specific tasks, that is, for the size of the pipes.

- Gas cutting. This option is most often used when working with large diameters. Cutting is carried out due to the action of a high-intensity flame, and the waste produced is blown away by gas pressure. The method can be considered the most practical and effective.

Gas cutting is the fastest option in this case.

There are other options for carrying out the task, such as the use of plasma, waterjet or laser cutting, but in private use they are practically not used.

How to cut a cast iron pipe

If the pipe is made of cast iron, then in order to cut it smoothly you will have to apply certain knowledge. The fact is that this material is characterized by high fragility, which means that before cutting such a pipe, you need to determine an algorithm of actions.

- We mark in the same way as steel pipes.

- At the cutting site, you need to place a wooden beam as a support.

- Next you need to make a cut of a few millimeters around the entire circumference.

- After this, a chisel is inserted into the groove and a sharp and strong blow must be applied with a hammer.

As a result, it will split along the line, forming a fairly even cut area, which can be further processed if necessary.

Methods for cutting metal products at an angle

Conventional perpendicular cutting at 90°, using a grinder, is carried out quickly and efficiently, if you do not neglect the advice of specialists.

Many people believe that if a large tool with a large powerful disk is used for sawing, then there is no need to apply markings. Experts do not recommend sawing without marking, because after cutting the parts may not align.

Note! Before you understand how to cut a pipe evenly with a large grinder, it is better to make markings several times to make sure the calculations are accurate. After cutting a profile or gas pipe incorrectly, you will have to start working all over again.

Features of cutting a cylindrical pipe at 45

Most often, making a cut at an angle of 45 degrees is required when installing heating or plumbing systems. The main difficulty in carrying out the work is that after combining the cut parts of the pipe, a right angle of 90 degrees should be obtained. A simple way to prepare a homemade pattern will help you achieve the quality of the cutting process:

- Prepare a plain white sheet of paper.

- Fold it diagonally.

- The protruding part of the sheet must be cut off with scissors so that when unfolded you get a square.

- The resulting triangle must be wrapped around the pipe so that the long side runs parallel to the section.

A paper template is great for cutting metal products in the middle.

Paper template

The resulting triangle, folded in half, must be divided into two parts. Then the templates need to be wrapped around the pipe and secured with tape or tape. The templates should be positioned so that one edge of the base coincides with the second.

Use scissors to round the top corners of both templates. The resulting two blanks of the required diameter should be placed on the pipe, and the cut location should be marked with chalk or a pencil. The prepared marked part can be safely sawed off.

For small diameter tubes that need to be cut close to the edge, the marking method using a container of water is suitable. The desired angle of inclination of the cut is marked on a deep container, then the end of the tube is placed in the water and tilted towards the marking. The line of contact with the liquid will become a cutting mark.

How to mark a 45mm cut on a profile pipe

Not everyone knows how to cut a profile pipe at 45 degrees with a grinder correctly and efficiently. Experts advise using an ordinary triangular ruler to mark a profile pipe with a square cross-section.

First, a straight strip should be drawn on one of the faces, located perpendicular to the side of the pipe. Then the workpiece must be rotated and an oblique mark applied to the adjacent face. It should go from the edge of the first strip at an angle of 45 degrees.

After this, the product is turned again and a perpendicular line is drawn. On the fourth side, all that remains is to connect the previously drawn stripes diagonally. Now you can start cutting.

Additional Information! Many experts believe that the best way to mark professional pipes is a tape measure. However, using this tool it is very difficult to do the job perfectly; the cut may turn out uneven. The school ruler will do the job much better.

Straight cut

An even cut at an angle of 90º can be made only after marking has been applied. Use a piece of paper or masking tape. The latter is preferable, because it is attached directly to the surface and does not move.

The sequence of actions looks like this:

- Using a tape measure, measure a piece of the required length, mark this place with a line with a marker.

- Next, stick tape along the resulting mark around the circumference of the pipe. The smoother you apply the adhesive tape, the better - it is optimal that the wide edges meet as accurately as possible. This will allow you to accurately cut the pipe according to the mark.

- The next step is to secure the pipe in a vice or press it to a flat plane so that it does not move during operation and an even seam is obtained. Note that one end of the pipe must be left in a free position so that during the cutting process the disk is not pinched by the walls. Cutting starts from top to bottom.

- The last thing you need to watch out for is how to cut the pipe smoothly with a grinder. To do this, you need to guide the disc as accurately as possible along the edge of the adhesive tape.

In cases where tubular products with large sections are being cut, the work must be done in small sectors. To do this, the pipe will have to be constantly rotated around its axis upon completion of the next cut.

When working with cast iron pipes, the procedure will be slightly different. First, a continuous cut is made along the entire diameter of the product, then, using a chisel and a hammer, the resulting groove is gradually tapped, as a result of which the pipe should split strictly along the cut line.

What tools are used to cut pipes?

At first glance, it may seem that cutting pipes is a fairly simple process that is not worth special mention. However, this is not quite true. It’s one thing when you don’t need precise, even cuts at an angle of 90º or any other, since no further welding or joining of the ends will be performed. And it’s a completely different matter when you need to make an absolutely precise cut. Note that if it is necessary to cut oblique ends with an exact angle, it is worth consulting with experienced craftsmen.

Separately, it is worth mentioning pipes with a large diameter, when joining which a cut of exactly 90º must be ensured. Be that as it may, all these operations are performed using special equipment.

How to properly cut pipes from different metals

Accurate cutting and trimming of pipes depends not only on well-executed markings. The material is also of great importance - metal of different thicknesses and hardness is cut with different forces and side effects. To properly cut a cast iron pipe, it should not be sawed all the way through. Cast iron is a brittle metal, so several cuts are usually made, and then a specialist knocks a piece out of them with one precise blow of a chisel.

To work with thin-walled pipes, you will have to very accurately check the position of the grinder. At the same time, the master must choose the right [discs for cutting metal with a grinder]. In industrial settings, special pipe cutters, gas cutting machines and welding machines can be used to perform the same tasks.

Safety when cutting a gas pipe

When working with gas pipes connected to the mains, it is important to follow safety precautions. First turn off the gas supply valve, then make sure that there is nothing in the pipe. To do this, just open the stove burners and light the gas - when it runs out, the flame goes out.

How to cut with a grinder?

Observe the following:

1. Transportation of disks; 2. External inspection of the disk; 3. The diameter of the circle must correspond to the permissible grinder; 4. Compliance with the maximum permissible speed; 5. Using the disk for its intended purpose; 6. It is not permissible to use a “not fresh” disk; 7. Inspection of the workplace; 8. Hanging parts of workwear; 9. Cutting position; 10. Provide for tool rebound; 11. Direction of disk rotation; 12. Try not to bury the edge deep into the cut; 13. Maintain the specified trajectory of rotation of the disk; 14. Turn off the grinder when changing position; 15. When changing the disk, turn off the power to the angle grinder; 16. Grind only with the disc provided for this purpose; 17. Use a protective cover when working; 18. Always wear glasses when working with an angle grinder.

Let's consider each of the listed points, and remember that each of them is no less important than the other.

Transportation of disks.

Usually the entire tool is in one drawer; be sure to set aside a separate compartment for the discs that prevents impacts on them. Which can lead to damage not visible to the eye.

External inspection of the disk.

Before installation, do a careful visual inspection of the disk to see if it is broken; you can knead it slightly, and if it is broken, it will immediately become apparent; naturally, such a disk is not permissible for use. If there are potholes on the cutting edge, it is better to reject it, the cost of the disc is a pittance, and the consequences can be the most disastrous.

The diameter of the circle must correspond to the permissible grinder.

The grinder indicates the maximum permissible diameter of the circle used. Never set a circle larger than this value.

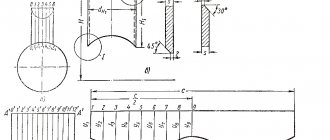

Compliance with the maximum permissible speed.

Both on the grinder and on the cutting wheel itself there are markings indicating the maximum permissible revolutions per minute. On a grinder this is the spindle rotation value, on a wheel - at what maximum speed it can rotate. The first picture shows the result of not following this rule. That is, if the spindle rotation speed is 10,000 rpm, then the value on the circle should be equal to or greater, but in no case less.

Using the disk for its intended purpose.

What does this mean? The fact that a disk intended for cutting metal cannot be used for cutting stone, glass, marble, tiles, porcelain stoneware; for this there are special disks with diamond tips on the teeth. Conversely, it is not permissible to cut a metal pipe with a diamond blade. It is also not permissible to install various cutters and saws on an angle grinder - a clear consequence in this photo: And in the so-called second photo, a man was sawing tiles with a metal cutting disc, moreover, without a casing. I don’t do tile work, so I don’t know what speed of rotation of the cutting disc should be when cutting tiles, but on the forum one of the specialists indicated that no more than 3000 rpm, and of course with a special disc for this. We saw for ourselves what the neglect of this rule led to the unfortunate man.

It is not permissible to use a “not fresh” disk.

Well what does this mean? For example, if you found a disk in the garage or under the bathroom, or somewhere else, break it and throw it away, that’s the whole story, there’s no point in masturbating fate!

Inspection of the workplace.

Also not an unimportant nuance, when cutting out pipes in an apartment there are many jobs, in the toilet, in the bathroom, in the kitchen. First of all, inspect for the absence of hanging wires or ropes. It’s no secret that people like to tie something up on pipes, so you need to get it out of harm’s way and you’ll be safe. If some kind of crap gets caught on the rotating element of the grinder, it will fly out of your hands and you won’t have time to blink.

Hanging parts of workwear.

I don’t even think it’s worth explaining what this could mean. The buttons are fastened, the holes are sewn up, there is no fringe on the legs or sleeves.

Cutting position.

A clear stump, when dismantling, you try to make do with the least number of cuts, but never, you hear, never be on the trajectory of rotation of the disk, no matter what kind of specialist you are, you can’t foresee everything, all sorts of cases happen. The next point is spot on.

Anticipate the rebound of the tool.

Just in case, consider where the tool might fly off if it “bites” the disk. And if you are not sure, do not make the cut all the way (the pipes are often under tension), leave a small jumper, you can always break it with a gas wrench. Don’t relax, hold the grinder tightly at the end of the cut.

Direction of disk rotation.

Who cuts it is a matter of habit, and sometimes there is no other way. In the video you can clearly see what I’m cutting - the sparks are on myself. This is not very convenient, but it is much less likely that the disc will “bite”, and if it does “bite”, then the grinder will fly away from the cutter, and not towards him. So in this case, think about convenience.

Try not to push the edge deep into the cut.

Well, with regards to large-diameter pipes, do not deepen the cutting edge more than necessary, there is less chance that the disc will tear.

Maintain the specified trajectory of disk rotation.

This condition is unambiguous; no changes in the rotation trajectory, that is, as soon as you started cutting, you must finish the cut in the same position. And one more thing, if you don’t have the professional skill, you shouldn’t try to get into an unfinished cut again with a disk, and under no circumstances should you insert a disk and then turn on the “start”, don’t go straight to your grandmother - sadness awaits.

Turn off the grinder when changing position.

I made a cut, I need to change position, turn off the grinder, wait until the disk stops rotating, and only then move. I took a different position, got ready, and turned on the grinder. Only this way, not otherwise. If health is expensive, then as luck would have it, you might stumble.

When changing the disk, turn off the power to the angle grinder.

Be sure to unplug the plug from the socket and install another drive. It's not appropriate to be lazy here.

Grind only with the disc provided for this purpose.

To cut a thread, you need to chamfer along the edge of the pipe, often “breaking” to install the grinding wheel provided for this, but in vain, by sharpening with a cutting wheel, you thin it out, which is not good, and is fraught with the same “scattering” into pieces.

Use a protective cover when working.

Well, no explanation here, the casing will save you even if some of the above points are violated. for beginners to use .

Safety precautions when operating an angle grinder

Note! It is no secret that when interacting with a dangerous tool, there is always an instruction consisting of rules that allow you to avoid unpleasant consequences when working with an angle grinder.

The following points should be emphasized:

- Compliance with requirements and instructions.

- Do not work with a damaged disk.

- Use the wheel according to its intended purpose: cutting wheel for cutting, grinding wheel for processing.

- A good master is careful, attentive and calm.

- Monitor the situation both before and after the operation.

- When using an angle grinder, do not stretch

How to cut a pipe with a grinder

To cut pipes with a grinder, it is recommended to use cutting wheels with a thickness of no more than 1 mm, otherwise the cut will be more difficult, and there will also be too many sparks and flying hot particles.

The technology for carrying out the work is as follows:

- The pipe is secured in a vice or secured in another way. In this case, the cut part should hang down. It is not allowed to place the workpiece between two supports and make a cut in the middle, as the cutting blade will jam (due to sagging pipe).

- Markings are applied using a strip of paper and masking tape. The ends of the tape should meet as accurately as possible. Home craftsmen recommend lowering the pipe into the liquid at the required angle, and then marking the cut line along the dry and wet boundary.

- The cut should be made from the top of the pipe, gradually lowering the angle grinder lower. The cutting disc should go along the very edge of the glued strip.

A large diameter pipe is cut a little differently, since the working part of the circle does not allow this to be done in one go. The wall is cut sector by sector, and the pipe is turned to the desired side.

90 degree cutting

To cut a round pipeline or metal profile of rectangular cross-section evenly across, use a sheet of plain paper. They wrap the workpiece so that the edges of the paper sheet coincide, after which it is fixed to the part using tape or glue. Using a grinder, a thin line is drawn near the edge of the paper sheet, after which it is gradually deepened until it is completely cut out.

A metal profile or round pipe can be cut using a template by placing an evenly cut element with a large internal diameter on it.

Collar insert

To obtain branches of metal pipeline lines in the form of tees, a collar insert is used, for which it is necessary to cut the edge of a round pipe adjacent to the walls of another at a right angle. To implement the method proceed as follows:

- cut the edges of the workpiece at right angles using the previously described method.

- On the round end surface, a marker marks four equidistant points located at angles of 90 and 180 degrees to each other.

- The size of the circle is measured, the resulting diameter is divided by 3. The resulting distance is plotted from two diametrically located points, after which these points are connected to two others by a smooth arc, drawing a line with a marker.

Fig.5 Example of a collar section of a pipe

- According to the markings, a cut is made with a grinder and semicircular segments are separated, after which the part is ready for welding. If there are minor inaccuracies in the mating, it can be compacted with a sledgehammer, placing it against the round surface of another element.

Final part

You should not think that a grinder with a cutting disc is a tool used exclusively for dismantling metal structures and does not require careful operation. Quite the contrary. An angle grinder requires extreme concentration and accuracy in work. This is a rather traumatic tool, and therefore, when working with it, you should not forget not only about the correct markings, but also about safety requirements.

Only accurate calculation and cutting will allow the pipes to be perfectly aligned at an angle Sources

- https://instanko.ru/osnastka/kak-pravilno-rezat-bolgarkoj.html

- https://instrument-blog.ru/elektroinstrumenty/kak-rezat-bolgarkoj.html

- https://trubaspec.com/montazh-i-remont/kak-rovno-otrezat-trubu-instrumenty-i-sposoby-otrezaniya.html

- https://rezhemmetall.ru/sposoby-razmetki-i-rezki-metallicheskix-trub.html

- https://WikiMetall.ru/metalloobrabotka/kak-rovno-otrezat-trubu.html

- https://alsver.ru/rezka/metalla-bolgarkoy

- https://HouseChief.ru/kak-rovno-otrezat-trubu-bolgarkoj.html

[collapse]

Similar posts:

- How to work with an angle grinder correctly: step-by-step instructions

- Why is an angle grinder called an angle grinder, and what else is it called?

- FBS GOST blocks: foundation blocks 13579 78

- How to cut a plastic window sill evenly

- Do-it-yourself semi-automatic inverter: reworking algorithm

- How to become a good leader - where to start