One of the main products of metallurgical production is rolled metal. The products presented on the domestic market comply with GOST and international quality standards. The range of Russian manufacturers is wider than that of foreign ones, so consumers of rolled metal in our country do not have problems choosing the right product. You can see a wide range of metal products, for example, on the website of the manufacturing company BSM-Metal. They offer a wide selection of metal products, such as non-ferrous rolled metal, ferrous and long rolled metal, special steel and much more at affordable prices. Next, let's talk about the classification of rolled metal products, the features of its production and application.

Types of long products and shaped steel

Performance characteristics and classification of materials are approved by GOST 535-2005. According to the standard, the range of long products includes products whose cross-section does not intersect with the straight line tangent to the contour:

circle;

square;

hexagon;

wire;

band.

Shaped products include a profile whose cross section intersects with a straight line tangent to the contour. This is an I-beam, an angle, a channel.

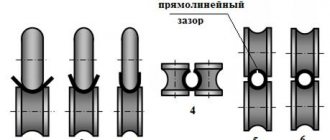

Technology for the production of long products and shaped steel

In the production of materials, carbon steel grades of ordinary quality are used. In the process of producing rolled products, a large number of machines and additional equipment are used:

rail and beam;

wire;

large and small varieties, etc.

Billets of various lengths and cross-sections, as well as crimped ingots, are used as raw materials for rolling in mills. Finished products are produced by the hot rolling method, during which the raw materials are subjected to:

heating;

deformations;

I will cut into pieces of measured length;

branding.

After all the manipulations, the finished assortment is cooled, then subjected to final finishing: cleaning from scale and surface defects, straightening, labeling, packaging.

Classification of rolled metal products

Long-rolled metal products

There are long-rolled, pipe, sheet and shaped rolled metal, but it is long-rolled metal that has the greatest variety of subtypes. Basically, these are not final products, but semi-finished products intended for the manufacture of certain structures and parts.

There are 3 groups of long products:

- Metal products with a simple cross-section: hexagon, circle, square, strip. These elements are most often made of carbon steel and can have any size - from small to very large;

- Shaped (curly) rolled metal products for general and special purposes. Channels and angles are especially in demand due to their wide range of applications. A channel is a beam with a cross-section in the shape of the letter P. The shelves of the channel are on one side of the wall. Channels can be special steel, hot-rolled, bent, perforated, unequal, with edges located at a certain angle and with parallel edges. The corner has a cross-section in the shape of the letter “L”. The edges can have different sizes and thicknesses;

- Reinforcement (corrugated and smooth) used to reinforce reinforced concrete structures and wheels. This category, according to some sources, may belong to the second group, which is not a mistake.

You can distinguish simple rolled products from shaped ones if you know the clear rule prescribed in the technical documentation.

A section of a simple rolled metal product cannot be intersected tangent to any of the points located along the contour of this section. A section of a shaped product can intersect at least one tangent to a contour point. There are several more classification features, knowing which makes it easier to choose the right position.

By surface treatment method

- Matte;

- Mirror;

- Polished;

- Calibrated.

According to GOST

- First grade. Long-rolled metal does not require additional processing, because characterized by maximum physical and technical parameters.

- Second class. For further use it is processed under hot pressure;

- Third class. Processed by cold mechanical means, cutting.

To size

- Large. Round products with a cross-sectional diameter from 80 mm, square with a cross-section from 70 mm, reinforcing profiles, corners with flange sizes from 90 mm, I-beams (regular and lightweight), column profiles, channels, hexagonal and strip steel, rails, etc. . Large-section products are made from carbon steel or low-alloy structural steel.

- Average. Shaped profiles used in a specific industry, narrow-gauge rails, rolled products with a section in the shape of a circle, square, hexagon, I-beams, strips, etc.

- Small. Today you can buy long rolled metal products in the form of precise, neat blanks of very small sizes: round with a diameter of up to 30 mm, square with a cross-section of up to 10 mm, angle steel with a flange size of up to 50 mm, rods, strip steel, channels. Small rolled products are sold in the form of coils and rods.

In addition to steel used to create large rolled metal products, high-alloy and stainless alloys are suitable for the production of medium and small rolled products.

Today, rolled metal products are in great demand. The most popular products are round pipes, angles, beams, sheet metal, circles and more.

Features of the production of long rolled metal products

In addition to physical characteristics and size, the price of long rolled metal depends on the method of its manufacture.

Hot rolled metal

Hot Rolled Round Bar

Heating the billet before placing it in the rolling mill speeds up the manufacturing process. The products obtained in this way are characterized by a uniform structure and reduced internal stress. This makes further machining easier.

Hot rolling is used to create large-sized products, profiles from simple alloys and other parts, the production of which is difficult without heating.

Cold rolled metal

Cold-rolled metal

The main feature of products produced by cold rolling is surface hardening. The method is suitable for the production of small-format profiles; it improves the physical and mechanical parameters of the product.

At the end of the manufacturing process, long rolled metal products must be marked. The marking contains all the geometric data, information about the accuracy of processing, the metal used and the manufacturing method.

The production methods for long products are regularly adjusted and improved to ensure that the products meet the stringent (and constantly growing) requirements for finished products. Maximum precision and the highest performance characteristics are required in mechanical engineering, shipbuilding, and the construction of strategic facilities. The use of new generation technology makes it possible to easily solve problems that seemed impossible one or two decades ago.

If the manufactured rolled products are intended for use in industries requiring special properties of the metal (corrosion resistance, other characteristics), this must be taken into account at the production stage. Special components are added to the metal and special surface treatment is performed.

Application of rolled metal products

No matter what industry we are talking about, each of them today cannot do without the use of long rolled metal products. The largest volumes of metal blanks are used in construction, mechanical engineering and shipbuilding.

Civil, commercial, industrial construction

Long lengths are widely used to enhance the strength of critical elements that bear a high proportion of dynamic loads, as well as to create decorative and fencing elements. Rolled metal used for decorative purposes has a lightweight profile. Ventilation, water supply and heating systems, fastenings, etc. are made from metal blanks. In road construction one cannot do without metal rails and fences.

Mechanical engineering, instrument making

Long products are necessary for the manufacture of numerous parts and assemblies. Elements of any technology are made from it. Profiled long products are used to produce parts that increase the strength of load-bearing structures. The main share of long-rolled metal products consumed in the world is accounted for by the mechanical engineering industry.

Shipbuilding

In this area, rolled metal is of utmost importance. Long products perform the function of reinforcing elements, effectively coping with dynamic loads.

Long products. Main profiles of long products. GOST 535-2005.

Long rolled steel is a type of metal product in the production of which carbon steels for ordinary purposes, high-quality structural steels, with alloying additives are used. In accordance with GOST 535-2005, this category of rolled metal includes circle, hexagon, square, and strip.

Production Features

The product manufacturing technology is hot rolling, which occurs at temperatures beyond the recrystallization temperature threshold. Part of the rolled stock goes directly into the production of mechanical engineering parts, fasteners, construction products and structures. And part is subjected to cold deformation - rolling, drawing, stretching. Cold deformation occurs in a temperature range that does not reach the threshold for the onset of recrystallization. As a result of this process, hot-rolled semi-finished products improve the accuracy of geometric parameters, surface quality, and increase strength, but usually their ductility decreases. The structure becomes fibrous, the grains are stretched along the deformation axis. To relieve internal stresses, recrystallization annealing is carried out.

Long products made from unalloyed steels are prone to the appearance of corrosion centers and their subsequent spread. To increase the service life of metal products, they are coated with a protective zinc, aluminum-zinc, galfan layer or paintwork.

Types of rolled metal products

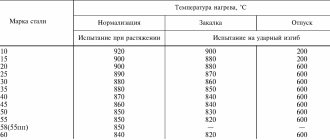

Long products are called hot- and cold-rolled products in which tangents drawn through any point on the contour do not intersect the body of the metal product. This requirement is met by:

- Circle . It goes on sale in skeins (up to 9 mm in diameter) or rods. Depending on the section size, production technology, steel grade, it performs the functions of a semi-finished product for the production of pipes or polygonal profiles, and a rolled product for cold-formed products. The circle is used to make fastening elements, parts for fences and gates, stair railings, and metal structures for various purposes.

- Square . Standardized hot-rolled products, which are produced with side dimensions of 6-200 mm, cold-rolled - 3-100 mm. Products of small sections are sold in coils, medium and large - in rods. The square is in demand in the production of fasteners, for the manufacture of decorative and functional elements of gates, fences, stairs, in interior design, landscape design, and mechanical engineering.

- Hexagon . Hot rolled rods are produced in numbers 8-103. The number is equal to the diameter of the inscribed circle in millimeters. This product is most popular in the production of fasteners. Calibrated hex rods are numbered 3-100. Calibrated rolled products made from corrosion-resistant steel with a polished surface (“satin”, “mirror”, “supermirror”) are in demand in interior design, in the design of facades, and in the production of decorative or decorative-functional elements.

- Strip rolling . The width of the hot-rolled strip is 10-200 mm, thickness is 4-30 mm. Depending on the production method and the steel grade used, the strip is intended for general use, the manufacture of turbine blades, tools, springs, and cladding. Metal products are used as semi-finished products for the manufacture of pipes and bent profiles. Strip products with decorative surface treatment are products that are popular in interior design and architecture. Galvanized strips are in demand in electrical engineering, for the installation of grounding lines and lightning rods.

Types of rental

Factories use different types of rolled products. Technologies differ in the equipment used and the stages of work. To produce steel parts, machines of different designs are used.

Sheet

This is a popular type of metal processing in which the part is first heated and then passed through rotating rolls. The technology can be carried out in two ways:

- Hot rolled - the method involves heating the material to 1700 degrees Fahrenheit. After heating, the metal becomes more ductile and less hard. However, rolling at high temperatures does not allow accurately calculating the size of finished products after cooling. In addition, strong heating promotes the formation of scale, which must be removed.

- Cold-rolled technology involves slightly heating the workpieces before further work. The surfaces of the parts are cleaned of scale. After this, they are subjected to other technological operations.

The first rolling option is more economical. With its help you can work with sheets of large thickness. The second method allows you to create parts that are more accurate in size, but is not suitable for working with metal sheets thicker than 5 mm.

Varietal

This type of technology can be divided into hot and cold methods. With its help it is produced:

- wire, fittings;

- hexagons, squares;

- circles, semicircular details.

Shaped

Small rental group. The technology received its name because of the complex shape of the finished products. The output is large parts. They are made on industrial machines. Shaped products can be divided into two groups:

- For mass use. This includes channels and corner profiles.

- For special purposes. These include rails for railway or tram tracks, floors, beams, industrial stops.

This method of rolling is used in construction.

Shaped products