Performance Diagnostics

There are several ways to test a generator. The surest way is to carry out diagnostics using a multimeter. This device is sold in almost every auto store.

The simplest check algorithm that you can do yourself looks like this:

- Start the car.

- Make sure that all external and internal electrical equipment is turned off.

- Select the DC voltmeter scale on the device.

- Connect to the battery terminals and take readings on a multimeter.

The voltage should be around 14 volts. Then you should add the electrical load one by one: headlights, seat heater, audio system. If at any time when new consumers are connected the voltage drops below 12 volts, then there is a problem in the vehicle’s on-board network. Next, you should make sure that the same voltage is present at the terminals of the electric generator

If this is not the case, you need to look at the battery, not the alternator.

There is a dangerous way to check if your car's alternator needs repair. This method is practiced by owners of old car brands. It involves disconnecting one of the battery terminals while the engine is running. If the car stalls instantly or within 30 seconds, then most likely the alternator is unusable.

Overload

Sometimes it happens that a power plant can be overloaded with consumers and devices, the sum of their powers exceeds the rated power of the generator. Try running the generator completely without load or simply disconnecting several devices from it.

Carburetor clogged

Check the gas generator carburetor for blockages.

Gasoline injection needle clogged.

If the needle is clogged, it must be cleaned. Blow it out using a car compressor. Apply the nozzle.

Video instructions for cleaning the carburetor needle

Clogged or stuck float mechanism for supplying fuel to the gasoline unit.

Purchase a carburetor cleaner and treat the entire structure. Wait a few minutes, and then move the float mechanism with your own hands and blow out the valve.

Valve repair

The valves of a gasoline engine are controlled by a timing belt. To check its operation, remove the unit cover by unscrewing several bolts. You will see several valves and a pushrod. You need to push the shaft in the right direction. If you see that everything is moving, but the valves are not moving, then they are stuck. To repair them, take carburetor cleaner and a hammer. Rotate the rocker arm and carefully hammer in the valves. Next, turning the shaft, push the valves back, pouring plenty of liquid on them. Repeat this step until the valves come off.

The generator works, but does not provide energy.

If the gas generator starts but does not produce energy, then most likely the engine is damaged or the internal settings of the generator are lost. Take a voltmeter and an ammeter and compare the readings at the power plant with the readings given in the instructions. If the readings differ, then this is certainly an internal failure and your unit needs professional examination and repair. So call the experts.

Purpose and device

Contrary to popular belief, the role of the battery in the on-board network is small. In addition to the fact that the battery powers the electronics in a switched off car, it performs only one function - it starts the engine, that is, it is used for a limited time. After starting the engine, the generator takes on the task of providing current to all vehicle components, including charging the battery.

A typical automobile uses AC electrical machines as on-board power plants. The phenomenon that underlies the conversion of mechanical energy into electrical energy in them is called electromagnetic induction. It lies in the ability of a magnetic field to generate an electric current in a turn of a moving conductor and vice versa. The autogenerator has two windings:

- Stator - external stationary.

- Rotor - rotating internal.

Voltage is applied through the collector to the rotor and turns it into a magnet. Using a belt and pulleys, torque is transmitted to the rotor from the engine. The magnetic field created by the rotating rotor induces an electric current in the stator windings. Next, the resulting alternating current is converted into direct current using diodes, stabilized and then used in the on-board network. As a rule, the stabilizer and voltage regulator are built into the device body.

DIY generator repair

11/30/1999 00:005887 Alexander

Reasons that can lead to failure of a car generator. And how you can deal with them yourself, at home.

It will be unpleasant for any car owner when the generator fails. It qualifies as a complex electrical appliance. If it breaks down, the battery will not be able to charge, causing the engine to stop starting. And traveling by car will not be possible. It follows that a broken generator must either be repaired or replaced with a new one. Any of the chosen options will cost a lot of money.

They will get your generator back up and running in no time, and at a reasonable cost. To make the best decision, you need to find out the market prices for new and used generators. And the obtained figures must be compared with the cost of repairs. But if the owner of an iron horse is comfortable with an electric soldering iron and has at least a little knowledge of electrical engineering, then expensive repairs can be avoided by doing it yourself.

There are several reasons why the generator may not work:

1. It does not charge the battery;

2. The resulting voltage is too low to charge the battery;

3. The generator is charging, but the warning light is still on;

4. Extraneous noise is heard during generator operation.

Considering the problems according to the list can give the following answers:

– if the generator does not charge, then the following options are possible1

. Fuse burned out

2. Brush faults

3. Relay malfunction

4. Broken electrical circuit of the rotor

The first three faults can be eliminated very easily - simply replace the faulty part. But you will have to tinker with the rotor winding. There are two development options - buy a new one or repair a burnt one. The most common cause is a break in the winding near the slip rings. A soldering iron will help here. One turn is unwound back from the winding and the end is soldered to the ring. The ring needs to be cleaned to obtain better contact.

If you hear noise when the generator is running, you should look at the rotor bearing. It is either changed or only the lubricant is replaced (Litol-24). If the voltage is low, the regulator relay must be replaced. If the control lamp is on and the generator is working properly, you need to inspect the diode that is responsible for powering the lamp. To remove the diode bridge you will need a key set to “7”; use it to unscrew three nuts. During this operation, you can change the rotor winding. But it’s worth doing independent repairs only in one case – when you understand at least something about it. Otherwise, you can simply break it.

Similar materials

- Common problems with all-wheel drive on the Kia Sportage 3

- Cooling system malfunctions: identifying and eliminating them

- Gas equipment for a car: pros and cons

- Is it possible to check the serviceability of the turbine yourself?

- General information about engine diagnostics

Storage of petrol generators

Any equipment requires professional care. Therefore, it is recommended to adhere to the rules that the manufacturer provides to customers. These are very important aspects that will not only improve equipment startup, but also increase the turnaround time. Basic recommendations:

- During long-term storage, be sure to drain all fuel from the tank. Gasoline oxidizes carburetor parts, which can lead to clogged channels.

- It is recommended to use polyethylene to cover equipment during long-term storage to protect against corrosion and moisture.

- It is best to carry out maintenance before storage.

- Under no circumstances should the generator be left disassembled for a long period of time, as foreign elements may get inside.

- Should be stored in a dry and cool place.

- Do not operate equipment in severe frost unless it is designed for use in such conditions.

This way you can protect not only your money, but also your equipment. Currently, manufacturing companies provide customers with special technical instructions that cover all the details in detail.

In everyday life, we do not notice how important the availability of electricity is. Only when we find ourselves in places where there is no way to connect to power grids do we realize the depth of the problems that arise. Thanks to progress, this problem is being solved with the help of portable gasoline generators.

Unfortunately, gas generators have a “habit” of breaking down, just like any complex tool. Many malfunctions can be resolved independently without contacting a service center. Repairing electric generators will not be difficult if you have already repaired a car or chainsaws.

Disassembling the generator

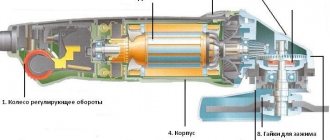

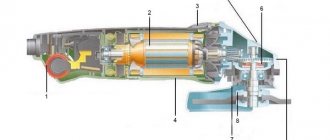

Rice. 117. Generator parts 37.3701:

1 – capacitor; 2 – voltage regulator assembled with brush holder; 3 – terminal block for additional diodes; 4 – insulating bushings; 5 – rectifier block; 6 – contact bolt; 7 – stator; 8 – rotor; 9 – spacer sleeve; 10 – inner bearing mounting washer; 11 – drive side cover; 12 – pulley; 13 – outer bearing mounting washer; 14 – coupling bolt; 15 – front rotor ball bearing; 16 – bushing; 17 – cover from the side of the slip rings; 18 – buffer sleeve; 19 – clamping sleeve

Details about the appointment

Equipment of this kind can perform different functions, each of which is extremely important:

- Providing autonomous backup power supply to the facility;

- Operating on a permanent basis if there are no power lines in the area.

Considering the magnitude of the load on such a compact device, it is quite logical that gas generators need to be repaired periodically. To ensure that this has to be done as rarely as possible, maintenance of the main components should be carried out on time. The increased load on such a device lies in the fact that several consumers can be powered from it simultaneously, and the duration of operation is often quite long.

Thus, even despite the need to repair gas generators from time to time, a device of this type is sometimes necessary to have in everyday life. Among other things, there is another factor that speaks in its favor - the organization of a stable output voltage for connecting equipment with sensitive automation.

Design and basics of operation

A gasoline generator is a device that runs on liquid fuel. Its task is to convert the mechanical energy of the engine into electrical energy, which is produced by the alternator. These are two main nodes that are interdependent. Repair of gasoline generators is most often associated with the maintenance or replacement of elements that are part of the engine and alternator or are functionally connected to them.

Equipment design

The engine is equipped with a number of systems: starting, shaft speed stabilization, cooling, exhaust and air supply. This unit is driven most often in two ways:

- By hand pull;

- Electric starter.

In more functional models, the engine is started by autostart. If it is quite possible to repair autonomous gas generators of a mechanical starting system yourself, then understanding the automation is much more difficult.

There are single-stroke and four-stroke models of alternators (generators). In gasoline mechanisms, the second of these are most often used.

What breaks

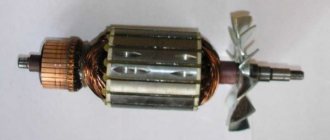

A car generator lasts a long time. Usually, owners of used cars have problems with it due to the time factor. There are few parts in this device, as you can see in the image below.

Statistics of faults associated with car generators allow us to compile a list of parts with the most frequent breakdowns:

| 1. | Brushes |

| 2. | Bearings |

| 3. | Diodes |

| 4. | Voltage regulator |

The car is equipped with an on-board network status alarm. But it is triggered when there are obvious problems with the voltage at the battery terminals. And this is due to diodes, voltage regulator and insulation on the wires. The condition of bearings and brushes can only be determined by external signs and upon inspection.

But while bearing wear can be assessed by grasping the generator shaft and shaking it, you can only see the brushes by removing the voltage regulator. And to do this you will need to remove the generator from the car. You shouldn't do this just to inspect the brushes. But sooner or later one of the above malfunctions occurs. And then you will have to remove the generator for inspection and repair.

The most common breakdowns

Repair of autonomous gas generators may be required for various reasons, but over time, an average list of the main types of common breakdowns has been formed:

- Repair of backup gas generators due to untimely oil changes or even as a result of operating the device without lubrication of the main components is more common.

- Dirty air cooling fins. This leads to overheating of the mechanism and its rapid wear, and as a result, the need to repair autonomous gas generators again arises.

- Problems with the ignition system. You need to unscrew the spark plug, clean it from carbon deposits, and dry it. After this, the spark is checked and you can try to start the engine again. Repairing gasoline generators in this case is not so difficult. You should know that carbon deposits form due to poor quality fuel being poured. In this case, repair of gasoline generators is required due to the fact that gasoline does not burn completely.

- If there is no voltage, then the alternator should be inspected. But in this unit it is not so easy to determine the cause of the breakdown, which means that repairing gasoline generators may take longer.

- Problems in the operation of the fuel system are often caused by low-quality fuel, water getting into the gasoline or air getting into the fuel line. Along with this, there is a possibility of clogging. Before you begin repairing autonomous gasoline generators, you should inspect and check the functionality of the entire system.

- Starting problems due to a faulty starter. The simplest option if repair of a manual type starter of a gas generator is required. In this case, the cause of the breakdown may be poor fastening of the return spring. But still, more often, repair of a manual type starter of a gas generator is required due to its improper operation, when the user makes excessive efforts to start the engine. If, after examining the mechanism, it was determined that these factors were not the cause, then the repair of the manual starter of the backup gas generator is carried out due to an implicit breakdown of one of the mechanism components, which requires an in-depth study of the design to find faults.

Do-it-yourself generator repair, maintenance and replacement

Good maintenance, which any car requires, will allow it to serve its owner for many years without serious problems. You just need to monitor the serviceability of the main components and systems. These include a converter of mechanical energy into electrical energy. Replacing and repairing car generators is one of the main operations of service center workers.

After all, without power supply, the comfort of the vehicle disappears, and it turns into a horseless cart made of stamped metal. The generator rarely stops functioning immediately. It usually gives the owner signals for quite a long time by “winking” its sensor in red and making noise from under the hood. You must carefully study the operating manual of the machine.

Weak or overcharging of the battery is also a symptom of its suffering. Checking it will show a number significantly less than 13 Amps on the multimeter. Then you need to seek help from specialists. Although, if a car enthusiast feels sufficiently prepared and experienced to try to find and fix the breakdown on his own, then he can begin to master the profession of a car mechanic.

Of course, technologically repairing generators is not difficult, but it is better to stock up on a sufficient set of tools and enlist the support of a friend experienced in this matter. The soldering skills of at least one of your friends will be very useful. Otherwise, you will have to invite a third one. You can start the event. It should be led by the most experienced member of the team.

Preliminary identification of the cause of the breakdown

- Noise during operation indicates wear of the bearings. If one bearing breaks, it will make a small sound. If two bearings are involved, the generator will rumble.

- The regulator indicator flashes red and charging is normal. Most likely, the relay in the electrical circuit is broken.

- Insufficient battery charge can be explained by worn-out or broken brushes, diodes, relays, or voltage regulator. Or there is a short circuit in the windings of the unit.

How to replace or replace the starter spring?

If everything turns out to be in order with the rope on the starter, suspicion falls on the reel itself. It is driven by a ribbon spring rolled into a roll. To change the spring, certain steps must be taken.

- Remove the starter from the lawnmower.

- Remove the starter coil.

- Unscrew the main bolt holding the pulley to the housing.

- Pull out the gripping tendrils and the spring; the ribbon spring will almost completely straighten or curl into rings of larger diameter.

- Hold it in advance.

- Check whether the spring is intact (there may be rust marks, breaks, etc.). If the hooks at its ends are torn, it will not be possible to bend new ones - high-carbon steel breaks when you try to bend it. Loose hooks are suitable for easy bending.

- Make sure the auxiliary (regular) spring and washers are in place. These parts protect the coil frame from being pierced by the ends of the main spring. If the washers and spring are broken and new ones are not available, do not screw the coil bolt tightly, but keep an eye on it - it may come loose and get lost.

- If the main (flat) spring is damaged, insert a new one of the same type. Place the engaging hook on the end of the spring in its place and bend it, inserting coil by coil into the space where it is supposed to be.

Rewinding the spring is completed in a minute. Skill in this action is acquired quickly.

How to replace or replace the starter spring, see the following video.

Typical problems

The alternator is a maintenance-free component of the vehicle. On average, its service life is 8-12 years without repair.

Over time, some generator components age or wear out naturally. Most likely it will be:

- Brushes. With each revolution of the shaft, they imperceptibly wear out more and more, until the moment comes when the brushes lose their ability to provide electrical contact with the commutator.

- Voltage regulator. Its task is to control the electricity produced. When additional electrical equipment in the car is turned off, the generator supplies a minimum amount of current to the network. As the load increases, it increases power. If the regulator loses its ability to limit output, there is a risk of battery explosion. Or, conversely, underestimating the load can lead to the car not starting.

- Pulley and belt. If the belt becomes loose, the generator's performance will drop. Rarely, there are cases of belt rupture or pulley distortion. This is possible if the car generator is repaired incorrectly or replaced incorrectly.

- Connections. Wiring and terminals are susceptible to corrosion. As a result, contact is lost in connections important for proper operation.

A generator can fail prematurely when engine protection is damaged or missing. Sand and dirt from the road will shorten its lifespan. Leaking coolant, detergent or oil can also cause damage. It is advisable to keep the engine compartment clean and dry.

https://youtube.com/watch?v=69W44lBcIuw

Prevention

Of course, the best way to avoid problems with the vehicle's power supply is to undergo technical inspection at service centers on time and do not forget to periodically diagnose the vehicle. After and before long trips, take the time to check the voltage level with a multimeter, as well as inspect and secure the main parts of the generator to its body. Otherwise, you risk escalating the problem to the point where you need to completely replace your car's alternator, which will cost your wallet a much larger sum.

vote

Article rating

Welding unit design

The key components of a welding electric generator are a stator with magnetic poles placed on it, as well as an armature. This armature contains the turns of the transformer winding containing an electromotive force of alternating direction.

Any electric generator includes a magnetizing excitation winding. Its power comes from two sources:

- In this case, the generator is called a unit with independent excitation. The demagnetizing winding is connected in series. The current strength is regulated by a rheostat. As the current in the welding network increases, the magnetic flux generated by the demagnetization winding increases. In this case, the magnetic flux, which is generated by the independent excitation winding, remains unchanged. As a result, the voltage at the generator terminals decreases and a falling external characteristic appears.

Thus, we get a self-excited unit. The armature winding of the electric generator transmits direct current to the magnetizing winding. All generators can operate in both modes. To change the operating mode of the electric unit, it is enough to smoothly change the magnetizing current.

Welding generators differ from each other and in their external characteristics:

- Generators with a falling external characteristic.

- Generators with a rigid external characteristic or a flat-sloping one.

- Universal generators.

Symptoms of a problem

The generator operates under high mechanical and thermal loads. Its bearings can crumble due to excessive wear or contamination, and the diodes inside the voltage regulator lose their properties over time. The heat from the motor, in addition to heating the windings, creates an additional load. In other words, like any part in a car, the generator does not last forever. Its service life is difficult to predict, since so many factors influence the survivability of the component.

Recommendations

Comments 35

Try starting there.

I have the same type of generator. It sat for 10 years. I decided to assemble it. I changed the carb because the old one spat out its insides. It started up perfectly, it runs smoothly, but there is no voltage. If you manually increase the speed almost to the maximum, the voltage floats from 100 to 250V. Also change the avr ?

I can’t say for sure, but with the AVR not working, it doesn’t stall, the voltage is induced at about 3V, which means the windings are intact. If it jumps, there is a large load - a short circuit is possible. — Continue disassembling, ring the winding, if you have the skills, rewind the winding yourself, if you don’t, find out the price of the issue. And what else?

Repair and restoration

Most generators consist of a rotor and two aluminum shells with stator windings sandwiched between them. Both body parts are connected using bolts. The brushes and straightener assembly are located on the back. Restoration involves the following types of work:

- disassembly;

- testing of windings and rectifier;

- replacing the regulator;

- installation of new brushes;

- replacing the front and rear bearings;

- restoration of stator windings;

- rotor replacement and balancing.

- testing.

Do-it-yourself dismantling of the assembly is a fairly simple procedure for most cars. As a replacement, you can purchase a new unit or buy a refurbished one from companies specializing in the repair of auto generators. The worst option is to take the unit from disassembly, since in this case the chances of long-term operation after replacement are low. To remove the generator, the following steps are most often required:

- Turn off the car and disconnect the battery terminals.

- Provide access to the unit and connectors on it.

- Remove the terminal covers and loosen the bolts.

- Disconnect the terminals and remember their original location.

- Loosen the pulley.

- Remove the alternator belt.

- Remove the bolt on the armature shaft.

- Unscrew the mounting bolts and remove the generator.

To install a new or repaired unit, you must perform the steps in reverse order. These instructions are very general, since the design and location of the generator unit can vary greatly among different car models. Often the drive is equipped with automatic tensioners or V-belt drives, and attachments significantly complicate access to the unit and require a unique disassembly algorithm. In any case, during such work it is useful to replace the belt.

The simplicity of the procedure for installing and dismantling the generator, as well as the availability of belts for it, implies a low cost of such work at specialized stations. Therefore, if you have doubts about your own strengths and skills, it makes sense to turn to specialists.