The performance of many types of power equipment, both industrial and domestic, is ensured by a device such as a hydraulic cylinder. Acting as a reciprocating drive motor, such a mechanism, with minimal energy consumption, ensures a full cycle of operation of power equipment used in construction, in various industries, in agricultural enterprises and in everyday life. Hydraulic cylinders are most widely used as the main element of equipment for pressing equipment, which is actively used to solve various problems.

A hydraulic cylinder is a volumetric hydraulic motor that converts the energy of fluid flow into mechanical energy

How does a hydraulic cylinder work?

Hydraulic cylinders are essentially volumetric hydraulic motors designed to convert fluid energy into mechanical energy that provides translational motion. The output (moving link) can be either the rod or the cylinder body (liner).

Depending on the working cycle, speeds and forces that the working parts of road-building, municipal, and forestry equipment must develop, different types of hydraulic cylinders are used with different methods of their inclusion in the hydraulic circuit of the volumetric drive.

Telescopic HCs

Unilateral

Consist of more than one sliding section. The number of sections is limited by the diameter of the cylinder chamber. The plungers are separate hydraulic chambers in which, following the “matryoshka” principle, there are smaller chambers.

The return movement is realized under the influence of external forces - the mass of the connected equipment.

The telescopic GC in the unfolded state is sensitive to lateral vibrations.

Therefore, hydraulic cylinders of this design are used mainly for lifting equipment with insignificant dynamic loads.

The second factor of choice is compactness when folded.

The best application of single-sided telescopic hydraulic cylinders is found in dump trucks.

Double sided

Each chamber has a system for supplying liquid under pressure into the rod cavity. In this way, the force for the return movement is realized.

Multi-chamber design is more complex and more expensive than single-chamber ones. A system of several sections nested in series is not as stable as a mono system. Therefore, double-sided telescopic hydraulic cylinders are mainly used to control suspended equipment.

Types (classification) of hydraulic cylinders

Hydraulic cylinders can be divided into two types according to their design: single-sided and double-sided.

In the first case, the movement of the output shaft under the action of the working fluid is possible only in one direction, and in the second, the movement of the rod under the action of the working fluid is carried out in two opposite directions.

Double-acting cylinders are manufactured with a single-sided, double-sided or telescopic rod; they can also be equipped with a damping device that reduces the speed of movement of the output link at the end of the stroke.

To drive the working parts of excavators, cranes, loaders and other mobile machines, double-acting cylinders with a single-sided rod are most widely used. The force on the rod and its movement can be directed in both directions, depending on which of the cavities the working fluid is injected into.

The main parameters of hydraulic cylinders are nominal pressure, piston diameter and stroke. The last two determine the force developed by the hydraulic cylinder at a given pressure.

Domestic-produced earth-moving, leveling, land reclamation, municipal, peat-extraction, fire-fighting, load-lifting and hoisting-and-transport machines usually operate at nominal pressures of 10, 16, 25, 32 MPa, and the peak values of this series are 20, 32, 40, 50 MPa with speeds rod, not exceeding 0.5 meters per second.

One of the main parameters when choosing a hydraulic cylinder is the level of nominal pressure. However, when assessing the technical life, the operating modes of the cylinders at maximum and peak pressures are decisive.

Hydraulic cylinders - manufacturing and repair in Nizhny Novgorod

Even if you know the structure of a hydraulic cylinder very well, repairing it at home or assembling your own cylinder is quite a difficult task. This requires special equipment and skills. Therefore, it is better to turn to experienced professionals with such questions. specializes in the repair of hydraulic cylinders, as well as the manufacture of hydraulic cylinders according to your orders.

Our company deals with the full range of work related to hydraulic cylinders. Our workers repair hydraulic cylinder rods, repair hydraulic cylinders for special equipment, such as loaders, asphalt pavers, excavators, concrete pumps, truck cranes, manipulator cranes, other construction and municipal equipment and production machines. We can also manufacture a hydraulic cylinder according to the drawings or samples you provide. We guarantee high quality and short terms of work.

Buy hydraulic cylinders : single-acting, double-acting, plunger, telescopic, double-rod and tandem, outriggers, hydraulic cylinders with stroke damping. Low prices.

Buy spare parts and components for hydraulic cylinders : axle boxes, pistons, seals, eyes, bonnets, rods.

Hydraulic cylinder repair : professional, fast, quality guaranteed.

According to the conditions of use, hydraulic cylinders are divided into three main groups:

- for driving lever mechanisms of working equipment, performing repetitive cyclically useful work (single-bucket excavators, front-end loaders, timber loaders);

- for moving working parts, performing useful work while moving (scrapers, motor graders, bulldozers);

- for installing working bodies in a certain position or installing outriggers to ensure a stable position of the machine.

Hydraulic cylinders can be manufactured for moderate (U1), cold (HL1), dry (TC1) and humid (TV1) tropical climates.

Below is the structure of the symbol for piston hydraulic cylinders of a unified design according to OST 22-1417-79:

Excavator hydraulic diagram

The hydraulic diagram of a single-bucket mounted excavator is shown in the figure.

Such excavators are installed on tractors.

The liquid from the unregulated pump H1 flows to the multi-spool distributor P1, which controls the hydraulic cylinders for raising and lowering the boom, rotating the bucket, and rotating the handle.

Hydraulic distributor P2 controls the hydraulic cylinders for raising and lowering the boom and turning the working equipment.

As can be seen from the hydraulic diagram of the excavator, distributor P3 is located in series, after hydraulic distributor P2. Spools P3.1 and P3.3 allow you to control the hydraulic cylinders of remote platforms; spool P3.2 is necessary to control the hydraulic cylinder for raising and lowering the bulldozer blade; to adjust the speed of lowering the blade, a throttle DR1 is installed in the hydraulic system.

The distributors are equipped with safety valves that limit the maximum pressure in the system.

According to the method of fastening the rod and sleeve, hydraulic cylinders can be divided into the following groups:

- 1. On lugs with articulated bearings

- 2. On the eye with a spherical bearing and a journal on the body

- 3. On the eye with a hinged bearing and with the preparation of the rear cylinder cover for welding with the mating structural element

- 4. With the outer end of the rod prepared for welding with a mating part and on the eye with a hinged bearing

- 5. With the preparation of the outer end of the rod for welding with the required part and with fastening

- 6. With preparation for welding of the outer end of the rod and the rear cover of the hydraulic cylinder with the required parts

Depending on the manufacturer, the layout of the elements of this circuit may vary.

Here are examples of hydraulic cylinder designations:

TsG-125×80×1000.11 manufactured by JSC "ELETSGIDROAGREGAT" where 125 piston diameter, 80 rod diameter, 1000 working stroke, 11 design: lugs with articulated bearing on the body and rod

G-150.125.56.400G manufactured by JSC "SDM" Orel where piston diameter is 125, rod diameter is 56, stroke is 400

Moreover, the plant that produces the machine often uses its own separate product markings, for example: the G-150.125.400G engine also has the designation TO-30.44.10.000, which is used directly by the plant that produces the TO-30 loader.

All features of markings and symbols must be reflected in the corresponding accompanying documentation of a particular hydraulic cylinder manufacturer.

Why can the lifting of the excavator boom be controlled from two distributors?

Raising and lowering the boom can be controlled using both distributor P1 and distributor P2, the liquid to which is supplied from different pumps. This allows you, if necessary, to increase the speed of raising or lowering the boom by switching both distributors.

In addition, when switching spool P1.1, it will not be possible to use spools P1.2 or P1.3, but what if you need to simultaneously lower the boom and turn the bucket or use the handle. For this purpose, a P2.1 spool is installed in the system; it allows you to control the boom and at the same time, using spools P1.2 or P1.3, move the bucket or handle.

Now we can outline an approximate algorithm for selecting a hydraulic cylinder:

- 1. Based on the layout conditions, find the connecting and overall dimensions

- 2. From the external load conditions, determine the calculated value of the force of the hydraulic cylinder driven to the rod

- 3. Select the diameter of the hydraulic cylinder with the force required to overcome the external load

- 4. Determine the design of the hydraulic cylinder and the method of its fastening

- 5. Determine the stroke of the hydraulic cylinder rod

- 6. To ensure the required force, select the nominal pressure

- 7. Select a cylinder with the required piston and rod diameter taking into account the speed value

- 8. Based on the specified speed of movement of the rod, the flow rate of the working fluid is determined

Looking for a hydraulic cylinder? Our specialists will always help you with your choice.

Select a hydraulic cylinder

Main characteristics

- Nominal pressure of working fluid

- Piston diameter size

- Rod diameter size

- Stroke value

The main characteristic of any hydraulic cylinder can be called the nominal pressure, since the number of hours that a given cylinder will work directly depends on the load placed on the cylinder.

The main criterion for the type division of hydraulic cylinders is their operating principle. There are five main types of hydraulic cylinders:

- Single acting

- Double acting

- Telescopic

Single-acting hydraulic cylinders.

When pressure builds up in the working chamber, the rod extends. The return of the rod in this type of device occurs by means of a spring installed inside, or due to the gravity of the lifted load. It is also possible to return the rod using another hydraulic drive. The operation of the single-acting unit is similar to the operation of a jack.

Diagram (design) of a hydraulic cylinder

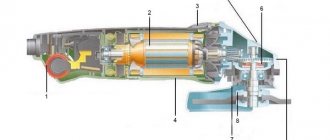

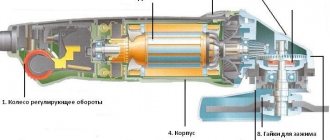

Structurally, a hydraulic cylinder consists of the following main parts: sleeve, piston, rod, guide bushing, cover, eye and support and guide elements (cuffs, rings, wipers, etc.).

It is worth writing a few words about the operation of hydraulic cylinders.

During installation and operation, the rules of safe operation determined by GOST, as well as the operating instructions for the machine, must be observed.

Before installing the hydraulic cylinder on the machine, it must be unpreserved. When installing hydraulic cylinders on articulated bearings, the deviation of its geometric axis should not exceed 2 degrees in one direction. When lubricating bearings through the support pins, the lubrication grooves must align with the lubrication holes in the inner ring of the bearing.

After installing the hydraulic cylinder, the hinge bearings must be lubricated with universal medium-melting grease until it appears in the bearing gaps.

During the first 8 hours of operation, the pressure in the hydraulic cylinders should not exceed 50% of the nominal value.

When the rod of a new cylinder is heated or after adjusting the axial compression of the multi-row seal package, it is necessary to loosen the seals by installing an additional gasket under the front cover.

When hydraulic cylinders operate, the rods must move smoothly, without jolts or jamming; There should be no external leaks of working fluid along the rod and at the junction of the supply pipelines.

Still have questions? Our managers are always ready to help.

To get a consultation

Subscribe to us!

Send the article to yourself by email

Telescopic hydraulic cylinder: device and scope of application

A telescopic hydraulic cylinder is a structure of several hydraulic cylinders inserted into one another like a nesting doll. In this case, the rod of the larger cylinder itself serves as a housing (sleeve) for the smaller one. The number of cylinders can be from 2 to 6.

The peculiarity of the telescopic hydraulic cylinder is that it can extend to a very large length, several times the length of the body. Thanks to this, telescopic cylinders can be used where a folded cylinder should take up as little space as possible: these are a number of industrial machines and mechanisms, oil and gas equipment, some

types of lifts, dump truck bodies, etc.

Types of telescopic hydraulic cylinders

The most common type of telescopic hydraulic cylinders are single-acting cylinders. In this case, the force develops only during forward stroke; return to the original position occurs under the influence of gravity or other external forces. Another, rarer and more complex type is a double-acting telescopic hydraulic cylinder. In it, work is done both during the forward and reverse stroke (it should be noted that the force developed during the reverse stroke is much less). Double-acting telescopic cylinders require the highest quality design and precision execution from the manufacturer: the design includes a complex network of grooves for supplying working fluid and a system of additional seals. Cylinders of this design should only be purchased from trusted manufacturers.

During operation, the telescopic cylinder resembles a retractable antenna, sections of which extend and slide again. There are two ways to supply working fluid (oil or emulsion) to the cylinders:

- Direct-flow - working fluid enters all cylinders simultaneously. When operating under load, the largest cylinder (it has the largest piston area) extends first, then the next largest, and so on.

- Valve is a more complex method in which liquid enters a larger cylinder until it is fully extended. Then the pressure valve opens, allowing fluid to enter the next cylinder, and so on as the pressure in the hydraulic system increases.

Telescopic hydraulic cylinders of the “Gidrolast” brand for any production needs

Gidrolast is a Russian enterprise that produces telescopic hydraulic cylinders of any model, from 2-stage to 6-stage, based on Italian components from Gidrolast Srl. The company's catalog presents a wide range of standard single- and double-acting telescopic hydraulic cylinders with different types of fastenings. Gidrolast also designs and manufactures non-standard models of telescopic hydraulic cylinders (cylinder D up to 500 mm, stroke length up to 30 m).

For production needs, the company imports honed pipes with a high surface finish and chrome-plated rods. Seals, wipers and protective rings are made from high-quality polymers of various grades. Telescopic hydraulic cylinders can be made from both standard and special materials.

Telescopic hydraulic cylinders of the “Gidrolast” brand have been used for many years at enterprises in the oil industry, heavy industry, and mechanical engineering, including in adverse weather conditions. The company also offers stationary and mobile telescopic lifts that meet all safety requirements. There are 17 service stations operating in Russia, Ukraine, Belarus and Kazakhstan.

Designation on the diagram of the excavator filter and elements for monitoring fluid parameters

To clean the working fluid, a drain filter with a bypass valve is installed in the hydraulic system of the excavator. The pressure at the inlet to the filter is controlled by an MH3 pressure gauge; the pressure value can be used to judge whether the filter element is clogged.

The pressure at the pump outlet is controlled using pressure gauges МН1 and МН2; the pressure gauges are connected to the excavator hydraulic system through valves.

The temperature of the working fluid is controlled by thermometer T1.

Source

Operating principle and types of GCD

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

What is a cylinder? This is a mechanism belonging to a class of devices characterized as reciprocating propulsion units. It is the most important element of any equipment used for construction, submersible or excavation purposes.

Hydraulic cylinders or hydraulic cylinders can be different in their purpose:

- GCD for lifting the body (GCDP), crane boom, bucket, etc.;

- Hydraulic mechanisms for turning the same boom, bucket, etc.;

- GCD compression, for example, doors, hatches.

The main versions of the GCD are shown in the table below.

| According to the method of fixing the rod and sleeve | By design | By operational operating modes |

| Eyelets. | Jacks. | Easy mode. |

| Lugs with articulated or radial bearings. | Plunger | Medium mode. |

| Flange mounting of hydraulic cylinder. | Telescopic. | Hard mode. |

| Hydraulic cylinder with holes in the rod and eye. | Piston | — |

| Fork on rod. | — | — |

| Trunnion on the rod. | — | — |

| Trunnion and eye on the rod. | — | — |

| Double rod hydraulic cylinder. | — | — |

| Hydraulic cylinder on tie rods. | — | — |

GCDP body: its features and differences

The most common are, of course, GCDP bodies, used since the beginning of the production of automobile trucks. Dump trucks, which first saw the world, were initially equipped with chain and rope lifts, but they were too unreliable. Engineers also tried to develop inertial lifts driven by a load.

Because of this imperfection of the above structures, new research was required. The breakthrough was made in the 20s of the last era by the Miller company. It was she who patented a hydraulic device for lifting the body of a truck.

GCDP became standard in the 30s of the last century and was installed on the vast majority of machines with lifts and mechanisms. Since then, there have been no global changes in the design of the GCDP.

The modern GCDP mechanism consists of a subframe, a platform and a tipping element operating hydraulically.

The world's leading truck manufacturers, such as MAZ, BelAZ, Volvo, ZIL, Man and others, produce vehicles with rear unloading. As for the specific design of the GTsDP, it will depend on the type of dump truck.

For example, dump trucks operating primarily in quarries are often equipped with a double-acting hydraulic pump, which is also equipped with a return link. The latter softens the impact when unloading large stones and rock fragments. In addition, the return link facilitates convenient lowering of the platform.

As for conventional dump trucks, so to speak, of the small type, they are equipped with a single-acting hydraulic cylinder, because their bucket lift angle is less than that of mining dump trucks.

Internal links of the GCDP

As mentioned above, GCDP can be different. In other words, the moving link of a hydraulic cylinder can be either a rod or a sleeve. GTsDP piston, translational, plunger, etc. - these are serial-type mechanisms, but today non-standard types of these engines are also known (they are, as a rule, made to order).

The main links of any type of GCDP are the following elements.

- The rod of a custom-made GTsDP, depending on the specific operating conditions, can be chrome-plated.

- As for seals and cuffs, the mechanism uses, as a rule, polyurethane seals with protection, which effectively seal the GCDP operating in difficult conditions with an OP speed of no more than 0.5 m/s (at a pressure of up to 63 MPa).

- There are also guide rings inside the mechanism, made of very durable anti-friction material.

- An equally important link in the GCDP is the working pressure, on which the dynamics and speed of work directly depend.