A typical example of final metal processing is steel tempering. It involves heating a part for a certain time with slow cooling. This helps eliminate internal defects of the alloy, which negatively affect stability, strength, and ductility. But what defects does this heat treatment method help eliminate? Is it possible to temper steel at home? Is it true that improper heating can degrade the physical properties of the metal?

Process description

Steel tempering (STE) is a type of heat treatment in which the metal is gradually heated and then cooled.

In most cases, the tempering procedure is performed at the final stage immediately after hardening. OS can be performed both before and after the formation of a part from a semi-finished steel product. Allows you to eliminate internal stresses inside the metal, which negatively affect its physical structure and properties. Internal stresses at the chemical level are violations of the crystalline structure of the metal. Because of them, there is an uneven distribution of carbon and alloying additives throughout the metal alloy. Vacation allows you to redistribute these elements more evenly. This improves the physical and chemical properties of the material (ductility, strength, shape retention, chemical inertness). Heating is carried out using special furnaces in a protective environment (oil, saltpeter or alkaline baths). The method of cooling parts after heating is air (usually) or liquid (rarely).

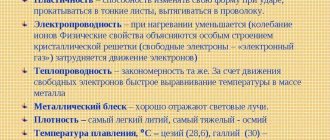

The quality of steel tempering depends on the following physical parameters of the thermal procedure:

- Heating temperature. OS can be performed at temperatures from 100 to 700 degrees, and the higher the heating temperature, the higher the quality of processing. This dependence is explained by the fact that at higher temperatures a deeper change in the structure of the crystal lattice occurs. Mainly due to the processes of polygonization and recrystallization.

- Heating duration. OSes typically last between 1 and 3 hours, although longer formats exist. All main processes in the material take place in the first 20-40 minutes. Additional exposure is needed for uniform distribution of carbon atoms, iron, and alloying additives throughout the entire thickness of the material.

- Cooling speed. The rule here is extremely simple - the slower the cooling, the higher the quality of the material. To slow down cooling, metallurgists use various tricks and tricks. The main trick is to place the material in an oil, saltpeter or alkaline environment, which slows down the cooling of the material. Theoretically, cooling can be performed without the use of liquid media, but the cooling rate will be high, which will negatively affect the quality of the OS.

Coolants

The main coolant for steel is water. If you add a small amount of salts or soap to the water, the cooling rate will change. Therefore, under no circumstances should the quenching tank be used for other purposes (for example, washing hands). To achieve the same hardness on the hardened surface, it is necessary to maintain the coolant temperature at 20 - 30 degrees. You should not change the water in the tank frequently. It is absolutely unacceptable to cool the product in running water.

The disadvantage of water hardening is the formation of cracks and warping. Therefore, only products of simple shapes or cemented ones are hardened using this method.

- When hardening products of complex configurations made of structural steel, a fifty percent solution of caustic soda is used (cold or heated to 50 - 60 degrees). Parts heated in a salt bath and hardened in this solution turn out light. The solution temperature should not be allowed to exceed 60 degrees.

Modes

Vapors formed during quenching in a caustic solution are harmful to humans, so the quenching bath must be equipped with exhaust ventilation.

- Alloy steel is hardened in mineral oils. By the way, thin carbon steel products are also carried out in oil. The main advantage of oil baths is that the cooling rate does not depend on the oil temperature: at a temperature of 20 degrees and 150 degrees, the product will cool at the same rate.

Be careful not to let water get into the oil bath, as this may cause the product to crack. What is interesting: in oil heated to a temperature above 100 degrees, the ingress of water does not lead to the appearance of cracks in the metal.

The disadvantage of an oil bath is:

- release of harmful gases during hardening;

- formation of plaque on the product;

- oil's tendency to flammability;

- gradual deterioration of hardening ability.

- Steels with stable austenite (for example, X12M) can be cooled with air supplied by a compressor or fan. At the same time, it is important to prevent water from entering the air duct: this can lead to the formation of cracks in the product.

- Step hardening is performed in hot oil, molten alkalis, and low-melting salts.

- Intermittent hardening of steels in two cooling environments is used for processing complex parts made of carbon steels. First they are cooled in water to a temperature of 250 - 200 degrees, and then in oil. The product is kept in water for no more than 1 - 2 seconds for every 5 - 6 mm of thickness. If the exposure time in water is increased, cracks will inevitably appear on the product. Transferring the part from water to oil must be done very quickly.

Welding a car yourself is not an easy task, but it can be done. Do you need to cut metal quickly and efficiently? Use a plasma cutter! How to do it correctly, read this article.

If you are interested in how to turn metal products, read the article at https://elsvarkin.ru/obrabotka-metalla/tokarnaya-obrabotka-metalla-obshhie-svedeniya/ link.

Types of steel tempering

The main technical parameter of the OS is the heating temperature. There are 3 types of OS - high, medium and low. Of course, high-temperature tempering is the optimal means of processing, since the higher the heating temperature, the more actively recrystallization of the metal will occur. However, low- and medium-temperature processing methods also have practical benefits that should not be underestimated. Below we will look at each type of OS separately.

High tempering of steel is a variant of tempering treatment at temperatures from 500 to 700 degrees. This method is the most effective, since with such heating, polygonization and recrystallization of the material occurs, which eliminates all stress inside the metal. Usually lasts from 2 to 3 hours. In the case of processing complex structures, the recommended time can increase to 6 hours.

During high annealing, a process of recrystallization occurs (bringing the substance to a state of greater thermodynamic stability) in combination with spheroidization of cementite. Cementite particles acquire a round shape with a size of 0.5 to 2 microns, and the structure of tempered sorbitol with a granular shape is acquired. Tempering sorbitol gives steel increased toughness. Alloy steels acquire a granular pearlite structure. Structural stability is ensured and internal stress is relieved.

Technological processes at our plant are carried out in modern computerized equipment under the control of qualified personnel. This helps to achieve the highest performance in the field of chemical-thermal processing of metals. We practice an individual approach to each client and each order.

The main disadvantage of high-temperature tempering is a slight decrease in the strength of the material. Therefore, the technique is not suitable for processing parts that will experience extremely high loads during operation. The high temperature technique applies to all types of steel, but note that in the case of some alloy alloys, so-called reversible high temperature embrittlement may occur during processing.

The main feature of medium tempering is the active diffusion of carbon without polygonization and recrystallization of the alloy. In the case of medium-temperature treatment, the elasticity of the material improves and its relaxation resistance increases. The steel tempering temperature in this case ranges from 350 to 500 degrees. The average processing time is 2-4 hours. The optimal environment is oily or alkaline. Medium processing is well suited for durable parts of complex shapes - springs, springs, impact structures. However, in practice this technology is rarely used due to a number of limitations:

- In the temperature range from 250 to 300 degrees there is a so-called island of brittleness of the first kind, which should be avoided. At the same time, at temperatures above 500 degrees, there is another island of fragility of the second type (it is also recommended to avoid it). We will discuss the features of these islands below. A slight deviation in temperature up or down during the holidays can lead to fatal consequences.

- The technique has no advantages in comparison with alternative technologies (low and high). At the same time, weak processing furnaces usually cannot heat the working environment to such temperatures, and stronger furnaces can reach higher temperatures, which is inconvenient from a practical point of view.

Low tempering of steel is a method of processing a steel alloy or product in which heating is carried out to a temperature of 100 to 250 degrees. The processing time is usually 1-3 hours depending on the type of part and its dimensions. During low-temperature processing, diffusion of particles of carbon components occurs without polygonization and recrystallization of the atomic lattice. This allows you to increase some of the physical characteristics of the material - strength, ductility, hardness, chemical inertness.

Low tempering is a universal technology, but in fact it is used mainly for tempering products made from low-alloy and high-carbon steels (knives, utensils, simple parts). You also need to avoid heating the material above a temperature of 250 degrees (otherwise it will fall into a type I island of fragility, which can lead to irreversible damage to the metal).

Temperature table for quenching and tempering steels

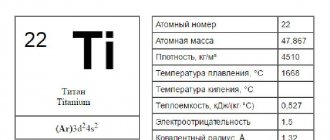

| No. | steel grade | Hardness (HRCe) | Temperature hardening, degrees C | Temperature holidays, degrees C | Temperature zak. HDTV, deg.C | Temperature cement., deg. C | Temperature annealing, degrees C | Temper. Wednesday | Note |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 1 | Steel 20 | 57…63 | 790…820 | 160…200 | 920…950 | Water | |||

| 2 | Steel 35 | 30…34 | 830…840 | 490…510 | Water | ||||

| 33…35 | 450…500 | ||||||||

| 42…48 | 180…200 | 860…880 | |||||||

| 3 | Steel 45 | 20…25 | 820…840 | 550…600 | Water | ||||

| 20…28 | 550…580 | ||||||||

| 24…28 | 500…550 | ||||||||

| 30…34 | 490…520 | ||||||||

| 42…51 | 180…220 | Sech. up to 40 mm | |||||||

| 49…57 | 200…220 | 840…880 | |||||||

| <= 22 | 780…820 | With oven | |||||||

| 4 | Steel 65G | 28…33 | 790…810 | 550…580 | Oil | Sech. up to 60 mm | |||

| 43…49 | 340…380 | Sech. up to 10 mm (springs) | |||||||

| 55…61 | 160…220 | Sech. up to 30 mm | |||||||

| 5 | Steel 20Х | 57…63 | 800…820 | 160…200 | 900…950 | Oil | |||

| 59…63 | 180…220 | 850…870 | 900…950 | Water solution | 0.2…0.7% poly-acrylanide | ||||

| «— | 840…860 | ||||||||

| 6 | Steel 40Х | 24…28 | 840…860 | 500…550 | Oil | ||||

| 30…34 | 490…520 | ||||||||

| 47…51 | 180…200 | Sech. up to 30 mm | |||||||

| 47…57 | 860…900 | Water solution | 0.2…0.7% poly-acrylanide | ||||||

| 48…54 | Nitriding | ||||||||

| <= 22 | 840…860 | ||||||||

| 7 | Steel 50Х | 25…32 | 830…850 | 550…620 | Oil | Sech. up to 100 mm | |||

| 49…55 | 180…200 | Sech. up to 45 mm | |||||||

| 53…59 | 180…200 | 880…900 | Water solution | 0.2…0.7% poly-acrylanide | |||||

| < 20 | 860…880 | ||||||||

| 8 | Steel 12ХН3А | 57…63 | 780…800 | 180…200 | 900…920 | Oil | |||

| 50…63 | 180…200 | 850…870 | Water solution | 0.2…0.7% poly-acrylanide | |||||

| <= 22 | 840…870 | With oven up to 550…650 | |||||||

| 9 | Steel 38Х2МУА | 23…29 | 930…950 | 650…670 | Oil | Sech. up to 100 mm | |||

| <= 22 | 650…670 | Normalization 930…970 | |||||||

| HV > 670 | Nitriding | ||||||||

| 10 | Steel 7KhG2VM | <= 25 | 770…790 | With oven up to 550 | |||||

| 28…30 | 860…875 | 560…580 | Air | Sech. up to 200 mm | |||||

| 58…61 | 210…230 | Sech. up to 120 mm | |||||||

| 11 | Steel 60S2A | <= 22 | 840…860 | With oven | |||||

| 44…51 | 850…870 | 420…480 | Oil | Sech. up to 20 mm | |||||

| 12 | Steel 35ХГС | <= 22 | 880…900 | With oven up to 500…650 | |||||

| 50…53 | 870…890 | 180…200 | Oil | ||||||

| 13 | Steel 50HFA | 25…33 | 850…880 | 580…600 | Oil | ||||

| 51…56 | 850…870 | 180…200 | Sech. up to 30 mm | ||||||

| 53…59 | 180…220 | 880…940 | Water solution | 0.2…0.7% poly-acrylanide | |||||

| 14 | Steel ШХ15 | <= 18 | 790…810 | With oven up to 600 | |||||

| 59…63 | 840…850 | 160…180 | Oil | Sech. up to 20 mm | |||||

| 51…57 | 300…400 | ||||||||

| 42…51 | 400…500 | ||||||||

| 15 | Steel U7, U7A | HB <= 187 | 740…760 | With oven up to 600 | |||||

| 44…51 | 800…830 | 300…400 | Water up to 250, oil | Sech. up to 18 mm | |||||

| 55…61 | 200…300 | ||||||||

| 61…64 | 160…200 | ||||||||

| 61…64 | 160…200 | Oil | Sech. up to 5 mm | ||||||

| 16 | Steel U8, U8A | HB <= 187 | 740…760 | With oven up to 600 | |||||

| 37…46 | 790…820 | 400…500 | Water up to 250, oil | Sech. up to 60 mm | |||||

| 61…65 | 160…200 | ||||||||

| 61…65 | 160…200 | Oil | Sech. up to 8 mm | ||||||

| 61…65 | 160…180 | 880…900 | Water solution | 0.2…0.7% poly-acrylanide | |||||

| 17 | Steel U10, U10A | HB <= 197 | 750…770 | ||||||

| 40…48 | 770…800 | 400…500 | Water up to 250, oil | Sech. up to 60 mm | |||||

| 50…63 | 160…200 | ||||||||

| 61…65 | 160…200 | Oil | Sech. up to 8 mm | ||||||

| 59…65 | 160…180 | 880…900 | Water solution | 0.2…0.7% poly-acrylanide | |||||

| 18 | Steel 9ХС | <= 24 | 790…810 | With oven up to 600 | |||||

| 45…55 | 860…880 | 450…500 | Oil | Sech. up to 30 mm | |||||

| 40…48 | 500…600 | ||||||||

| 59…63 | 180…240 | Sech. up to 40 mm | |||||||

| 19 | Steel HVG | <= 25 | 780…800 | With oven up to 650 | |||||

| 59…63 | 820…850 | 180…220 | Oil | Sech. up to 60 mm | |||||

| 36…47 | 500…600 | ||||||||

| 55…57 | 280…340 | Sech. up to 70 mm | |||||||

| 20 | Steel X12M | 61…63 | 1000…1030 | 190…210 | Oil | Sech. up to 140 mm | |||

| 57…58 | 320…350 | ||||||||

| 21 | Steel R6M5 | 18…23 | 800…830 | With oven up to 600 | |||||

| 64…66 | 1210…1230 | 560…570 3 times | Oil, air | In oil up to 300...450 degrees, air up to 20 | |||||

| 26…29 | 780…800 | Exposure 2...3 hours, air | |||||||

| 22 | Steel P18 | 18…26 | 860…880 | With oven up to 600 | |||||

| 62…65 | 1260…1280 | 560…570 3 times | Oil, air | In oil up to 150...200 degrees, air up to 20 | |||||

| 23 | Springs. steel Class. II | 250…320 | After cold coiling of springs 30 minutes | ||||||

| 24 | Steel 5ХНМ, 5ХНВ | >= 57 | 840…860 | 460…520 | Oil | Sech. up to 100 mm | |||

| 42…46 | Sech. 100..200 mm | ||||||||

| 39…43 | Sech. 200..300 mm | ||||||||

| 37…42 | Sech. 300..500 mm | ||||||||

| НV >= 450 | Nitriding. Sech. St. 70 mm | ||||||||

| 25 | Steel 30HGSA | 19…27 | 890…910 | 660…680 | Oil | ||||

| 27…34 | 580…600 | ||||||||

| 34…39 | 500…540 | ||||||||

| «— | 770…790 | With oven up to 650 | |||||||

| 26 | Steel 12Х18Н9Т | <= 18 | 1100…1150 | Water | |||||

| 27 | Steel 40ХН2МА, 40ХН2ВА | 30…36 | 840…860 | 600…650 | Oil | ||||

| 34…39 | 550…600 | ||||||||

| 28 | Steel EI961Sh | 27…33 | 1000…1010 | 660…690 | Oil | 13Х11Н2В2НФ | |||

| 34…39 | 560…590 | At t>6 mm water | |||||||

| 29 | Steel 20Х13 | 27…35 | 1050 | 550…600 | Air | ||||

| 43,5…50,5 | 200 | ||||||||

| 30 | Steel 40Х13 | 49,5…56 | 1000…1050 | 200…300 | Oil | ||||

High holiday

High tempering is carried out in a temperature range close to the critical point: from 450 ºC to 650 ºC.

After such heat treatment, the steel becomes ductile, its relative elongation and contraction, as well as impact strength, increase. This is due to the fact that the metal acquires the structure of tempered sorbitol and its internal stresses are reduced by 95%. In this way, products operating under shock loads are released: shafts, axles, connecting rods, parts of presses and forging hammers.

If steel is tempered at 690 ºC, then granular pearlite will prevail in its structure, and it will have maximum ductility and minimum strength. In some vanadium, chrome and tungsten steels, when tempered with heating up to 560 ºC, troostite may form, which leads to an increase in hardness (the so-called secondary hardness).

Tempering brittleness

Temper brittleness is inherent in many steels. Steel in a state of temper brittleness is characterized by low impact strength. The temper brittleness state has virtually no effect on other mechanical properties at room temperature.

The figure schematically shows the effect of tempering temperature on the impact strength of alloy steel, which is highly susceptible to temper brittleness. In many alloy steels, two temperature ranges of temper brittleness are observed. When tempering in the range of 250 - 400 °C, irreversible brittleness occurs, and in the range of 450 - 650 °C - reversible temper embrittlement.

Effect of tempering temperature on the impact strength of steel

The influence of tempering temperature on the impact strength of steel with a high tendency to temper brittleness (diagram):

1 - rapid cooling in water or oil; 2 - slow cooling in air or with a furnace.

The impact strength of hardened steel after tempering in the range of 250 - 400 °C is less than after tempering at temperatures below 250 °C. If brittle steel, tempered at 250 - 400 °C, is heated above 400 °C and transferred to a viscous state, then repeated tempering in the range of 250 - 400 °C does not return the steel to a brittle state. The cooling rate from tempering temperatures in the range of 250 - 400 °C does not affect impact strength.

Steel in a state of irreversible temper brittleness has a shiny intergranular fracture along the boundaries of former austenite grains. This fragility is characteristic to one degree or another of all steels, including carbon ones. Therefore, as a rule, medium tempering of steel is not used, although it provides a high yield strength.

The cause of irreversible temper brittleness is considered to be carbide formation during the decomposition of martensite, in particular the precipitation of carbide in the form of a film along the grain boundaries. This film disappears at higher tempering temperatures, and is not restored when reheated to 250–400 °C. Silicon in low-alloy steels, by delaying the decomposition of martensite, eliminates irreversible temper brittleness.

The impact strength of many types of alloy steel after high tempering at 450 - 650 ° C depends on the cooling rate from the tempering temperature. During rapid cooling from a high tempering temperature (in water or oil), an increase in the tempering temperature in the range of 450 - 650 ° C leads to a normal increase in impact strength (as observed in carbon steel at any cooling rate).

After slow cooling from a tempering temperature in the range of 450 - 650 °C (with a furnace or in air), the impact strength of many types of alloy steel is lower than after rapid cooling. Steel in a state of reversible brittleness has an intergranular fracture along the boundaries of the original austenite grains.

Temper brittleness resulting from slow cooling during high tempering can be eliminated by repeated high tempering, but with rapid cooling. The toughness can be reduced again by applying a new high tempering with slow cooling. Due to the alternation of an increase and decrease in impact strength during repeated heating with different cooling rates, temper brittleness that occurs after tempering in the range of 450 - 650 ° C is called reversible.

Modes of medium (medium temperature) tempering of steel

The temperatures of the medium-temperature tempering process are +350…+500°C. This type of t/o, used mainly for springs, leaf springs, stamps, provides significant limits of endurance and elasticity, and good relaxation resistance. The resulting structures: troostite or trostomartensite, hardness – 45-50 HRC.

Cooling in water after heating to temperatures of +400...+450°C is used for springs in order to create residual compressive stresses on the surface, increasing the strength characteristics of the metal.

Vacation process

All hardened parts are subject to tempering. This is done to relieve internal stress. As a result of tempering, the hardness of the steel is slightly reduced and the ductility of the steel is increased.

Depending on the required temperature, tempering is carried out:

- in oil baths;

- in saltpeter baths;

- in furnaces with forced air circulation;

- in baths with molten alkali.

The tempering temperature depends on the grade of steel and the required hardness of the product, for example, a tool that requires a hardness of HRC 59 - 60 should be tempered at a temperature of 150 - 200 degrees. In this case, internal stresses decrease and hardness decreases slightly.

High-speed steel is tempered at a temperature of 540 - 580 degrees. This tempering is called secondary hardening, since as a result the hardness of the product increases.

Products can be tarnished by heating them on electric stoves, in ovens, even in hot sand. The oxide film that appears as a result of heating acquires different tarnish colors, depending on the temperature. Before you start tempering one of the tarnish colors, you need to clean the surface of the product from scale, oil deposits, etc.

Usually, after tempering, the metal is cooled in air. But chromium-nickel steels should be cooled in water or oil, since slow cooling of these grades leads to temper brittleness.

What is steel tempering?

Tempering of a metal is one of the types of heat treatment in which its phase state is preserved, but at the same time a number of hardening characteristics are corrected. First of all, during tempering, the stress of the internal structure, which arises as a result of deformations of the crystal lattice during quenching, sharply decreases.

In addition, rigidity and brittleness are reduced, which is a consequence of the saturation of the needle-shaped elements of martensite with ferrite and the formation of pearlite grains (see figure below). This structure retains the properties of hardened metal, but at the same time becomes more ductile and tough.

In alloyed steels, all these processes occur with some differences, which are associated with the fact that alloying elements under certain conditions become centers of crystallization and thus change the physical and chemical characteristics of the metal.

Steel products are tempered by heating them to a given value, followed by slow cooling in the open air or in a special environment. The phase state and structure of the metal formed after tempering, and, consequently, its physical characteristics, directly depend on the heating temperature.

In general, the rule is observed: the higher the temperature, the lower the brittleness and hardness and the higher the flexibility and toughness. Depending on the temperature ranges used, there are three main types of steel tempering: low, medium and high, the heating limits of which are, respectively, 300 ºC, 450 ºC and 650 ºC. The first type is characterized by the highest hardness, and the latter by the highest impact strength.

The heating temperatures during tempering of steels directly depend on their chemical composition, since alloying additives have a significant impact on the process of formation of structural elements. This is usually due to a slowdown in the decomposition of martensite, which requires an increase in temperature conditions.

In addition, when high-alloy steels are tempered, phenomena such as an increase in rigidity associated with the formation of troostite and the occurrence of temper brittleness may be present.

Tempering of high-speed tool steels

The main alloying elements of high-speed steels (P18, P6M5, etc.) are tungsten, molybdenum, cobalt and vanadium - elements that provide heat resistance and wear resistance during operation. High-speed steels belong to the carbide (ledeburite) class. For hardening, these steels are heated to a temperature above 1200°C (P18 to a temperature of 1270°C, P6M5 to a temperature of 1220°C). High quenching temperatures are necessary for more complete dissolution of secondary carbides and obtaining austenite highly alloyed with chromium, molybdenum, tungsten, and vanadium. This ensures that heat-resistant martensite is obtained after quenching. Even at very high heat, only part of the carbides dissolves. These steels are characterized by the preservation of fine grains at high heating temperatures.

Iron and “quick-cut” alloying elements have very different thermal conductivity properties, therefore, when heating, temperature stops should be made to avoid cracks. Typically at 800 and 1050°C. When heating a large instrument, the first exposure is made at 600°C. The holding time is 5-20 minutes. Holding at the quenching temperature should ensure the dissolution of carbides within the limit of their possible solubility. Cooling of the instrument is most often done in oil. To reduce deformation, stepwise hardening is used in molten salts at a temperature of 400-500°C. The structure of “quick cuts” after quenching consists of highly alloyed martensite containing 0.3-0.4% C, undissolved excess carbides and retained austenite. The higher the quenching temperature, the lower the position of points Mn, Mk and the more retained austenite. In R18 steel there is approximately 25-30% retained austenite, in R6M5 steel - 28-34%. To reduce austenite, cold treatment can be done, but as a rule this is not required.

After quenching, tempering follows at 550 - 570°C, causing the transformation of retained austenite into martensite and dispersion hardening due to the partial decomposition of martensite and the release of dispersed carbides of alloying elements. This is accompanied by an increase in hardness (secondary hardness). During the holding process during tempering, carbides are released from the retained austenite, which reduces its alloying, and therefore, upon subsequent cooling, it undergoes a martensitic transformation (Mn ~ 150°C). During a single tempering process, only part of the retained austenite is transformed into martensite. In order for all the austenite to transform into martensite, two and three times tempering is used. The holding time is usually 60 minutes. When assigning a regime, it is necessary to take into account the chemical properties of the elements and the frequency of carbide release depending on temperature. For example, the maximum hardness of R6M5 steel is obtained through 3-stage tempering. The first tempering is at a temperature of 350°C, the next two at a temperature of 560-570°C. At a temperature of 350°C, cementite particles are released, evenly distributed in the steel. This contributes to the uniform release and distribution of special M6C carbides at a temperature of 560-570°C.

Varieties

The most important characteristic of the tempering procedure is the temperature at which it is performed. According to this indicator, this heat treatment is divided into three types. Let's look at them in a little more detail.

Low Vacation

Heat treatment of this type involves heating the part to a temperature varying within + 100 °C≤T≤ +250 °C. The duration of the technical process usually fits into a time interval of one to three hours. The exact value of this parameter is determined by the dimensions of the workpiece and its type. During low tempering, the phenomenon of diffusion of microparticles of carbon-containing components is observed, which is not accompanied by recrystallization, as well as polygonization of the molecular lattice. This improves a number of material properties:

- degree of chemical inertness;

- hardness index;

- the level of plasticity increases;

- strength characteristics increase.

Low release is classified as a universal technology. However, in most cases it is used for products for which high-carbon steel and containing alloying additives were used as raw materials (for example, cutting tools in the form of knives, kitchen utensils, etc.).

The main requirement for low tempering is formulated as follows: it is necessary to exclude the possibility of heating the metal above +250 °C. Otherwise, it will fall within the range of the type I fragility island, which can cause the part to become irreversibly unusable.

Average holiday

This heat treatment method is performed by heating the metal and holding it while maintaining the temperature in the range + 300 °C≤T≤ +450 °C, usually for at least 2 and no more than 4 hours. Cooling occurs in open space under natural environmental conditions. At the same time, the above-mentioned processes such as

- restructuring of the metal, accompanied by ordering of its dislocation structure - polygonization;

- formation and increase in size of some crystal grains at the expense of others - recrystallization

do not appear during active diffusion of particles of the element carbon (C).

The main goal of heat treatment of the type under consideration is to give parts the required elasticity, relaxation stability, and toughness without sacrificing high strength properties. Alloys obtained by the medium tempering method are characterized by a troostite structure and are characterized by a hardness determined by the Rockwell method at a level from 45HRC to 50HRC.

This heat treatment method is relevant mainly for structural elements and hardware, in the production of which spring-type steels were used. (eg 65C2BA. 70C3A). Such products include: bent steel strips connected together with brackets - springs; forging single- and multi-strand dies; elastic elements in the form of a spiral - springs; saws designed for working with wood, etc. The following basic requirement is put forward to them: resistance to the effects of variable dynamic loads.

High holiday

Heat treatment of this type involves heating parts to a temperature ranging from + 500 °C≤Т≤ +680 °C. The duration of the high holiday is approximately 2-3 hours. Very complex items can take up to 6 hours to process.

As a result:

- internal stress occurring in the metal is reduced by 95 percent;

- the impact strength indicator increases;

- the level of plasticity of the material increases.

But all this happens against the background of a decrease in the strength characteristics of the alloy. Its structure becomes sorbitol-like. That is, the processed metal in this case is a mixture of cementite and ferrite, which have a granular structure. When heated to a temperature fluctuating around +680 °C, the structure of the alloy will be distinguished by the predominance of granular pearlite.

High tempering heat treatment is used for products that are exposed to increased pulse loads during operation. These are, for example, moving parts connecting the piston to the connecting rod journal of the crankshaft of the power unit - connecting rods; forging hammers of all types, from steam-air, including hydraulic and ending with pneumatic; press.

Is it possible to temper steel in a home workshop?

Home use of this technology becomes possible when it is necessary to relieve the internal stress of the metal. In this case, the steel grade does not matter - heating must be done to 200°C (no higher), and maintained in such conditions for up to 1 hour. If you need to reduce hardness and increase viscosity, then it is important to know the grade of steel (to determine tempering temperature conditions). Information of this kind can be found on the Internet or in textbooks on heat treatment, which present tables with steel grades, products and temperature conditions for quenching and tempering steel.

A homemade forge, kitchen stove or gas burner can serve as a heat source for heating the part. In this case, the heating temperature is determined using tarnish color tables - the disadvantage of this ancient method is the subjectivity of color perception and its dependence on external light sources. Beginners are recommended to use stove thermostats or a multimeter with a thermocouple.

Typically, home tempering of steel is used for knives, forks, metal cups, automobile parts, etc. In this case, you may encounter some fairly common problems:

- Most home ovens cannot reach high temperatures. Therefore, at home you can only make a low or medium vacation. Theoretically, you can try to re-equip or “strengthen” your stove to increase the heating temperature, but this will be difficult for a person without experience.

- To carry out heat treatment, it is necessary to use a protective medium (oil, alkali, saltpeter). But each substance has its own temperature characteristics. A simple example: saltpeter-based compounds can explode when heated to high temperatures, which can be dangerous to the life and health of the home metallurgist.

- Tempering without the use of a protective environment can be fatal to the metal itself. The fact is that without the use of a protective environment, the metal will cool quickly, which can affect the quality of the steel (increased brittleness, bending, plastic deformation, rust).

- Also, do not forget about low-temperature brittleness of the first type (from 250 to 300 degrees). If the temperature is incorrect, the quality of the metal can be seriously affected, up to the complete destruction of the alloy.

High temperature tempering of steel - modes, goals

High tempering temperatures are +500…+650°C, the resulting steel structure is tempered sorbitol. The problem solved by this type of T/O is to obtain an optimal ratio between strength and viscosity. Complex heat treatment, including hardening and high tempering, is called improvement. Its advantage over various types of annealing and normalization is an increase in tensile strength, yield strength, impact strength, and relative contraction.

Quenching and tempering of hardened steel is used for medium-carbon steels with a C content of 0.3-0.5%, which are subject to increased requirements for impact strength and endurance limit. With their help, they increase the strength of the material, reduce sensitivity to stress concentrators, the temperature of the cold brittleness threshold, and the tendency to crack formation.

The duration of the high holiday is 1-6 hours. The specific time depends on the dimensions of the metal product.

How to release steel yourself

In order to temper steel at home in order to relieve internal stress, it is not necessary to know its grade - it is enough to heat it to a temperature no higher than 200 ºC and hold it in these conditions for at least an hour. If you plan to temper a steel product to reduce hardness and increase toughness, then knowledge of the steel grade is necessary to determine the tempering temperature conditions. This is actually not as difficult a task as it might seem. In textbooks on heat treatment and on Internet sites there are enough tables with lists of products and the grades of steel from which they are made, and often even with the temperature conditions for their quenching and tempering (see table above).

To heat your part, you can use almost any heat source: from the oven to a gas burner or a homemade forge. An important point is the heating temperature. In principle, it can be determined by color tables of tarnish appearing on hot metal, which are also easy to find on the Internet.

This is an old proven method, known since ancient times, but it requires some experience, since its main disadvantages are the subjectivity of color perception and its dependence on external lighting. For a beginner, the best solution would be to use a stove thermostat or a regular multimeter with a thermocouple.

Has anyone ever used a multimeter with a thermocouple to measure the tempering temperature? How accurate is this device and how do its readings correspond to the color of the tarnish? If anyone has such experience, please write your opinion in the comments.

Low Vacation

Low tempering is carried out in the temperature range of 120÷300 ºC.

The choice of a specific temperature regime depends on the grade of metal and the desired result. Most often, this method reduces internal stresses and slightly increases the toughness of tool steels, which require increased hardness and wear resistance. At 120÷150 ºC there is no change in hardness, but only residual stresses decrease. To reduce it, the product must be heated to at least 200 ºC and kept under these conditions for at least one hour. In the range from 200 ºC to 300 ºC, the formation of tempered martensite begins and the hardness decreases with a simultaneous increase in the toughness of the steel.

In some cases, a significant decrease in viscosity is observed in this temperature range, which is called temper embrittlement. The consequences of this phenomenon are eliminated by additional heat treatment. In addition to tool steel, low tempering with heating up to 250 ºC is also used for structural steels, the surface of which has been subjected to thermochemical treatment.

Heat treatment of tool alloys

The following statement is true for almost all metals: with increasing tempering temperature, strength decreases and ductility increases. The only exceptions are high-speed steels used in the production of tools. To ensure better heat resistance and wear resistance characteristics, they are alloyed with carbide-forming elements: molybdenum, cobalt, tungsten and vanadium. And for hardening, heating to temperatures above 1200 °C is used, which allows the formed carbides to be most completely dissolved.

The thermal conductivity of iron itself and its alloying elements varies significantly, therefore, to prevent deformation and cracking during heating, temperature pauses should be performed. This occurs when temperatures reach 800 °C and 1050 °C, and for large objects the first interval is assigned at a temperature of 600 °C. The duration of the stop ranges from 5 to 20 minutes, which allows for the best conditions for dissolving carbides. Cooling is most often carried out in oil.

Deformation can be significantly reduced by stepwise heat treatment of steel in molten salts, where hardening is performed at a temperature of about 500 °C. To increase the hardness of the products, this is followed by double tempering at 570 °C. The duration of the process is 1 hour, and its mode is influenced by the chemical properties of alloying elements and temperature, which determines the rate of carbide release.

Average holiday

Medium tempering is intended for heat treatment of steel products, which must combine increased strength and elasticity with specified toughness parameters. As a rule, spring and spring steels operating under variable dynamic loads are tempered in this way.

The temperature range in this case is from 300 ºC to 450 ºC, and the hardness is reduced to 45÷50 HRC versus 60÷63 with low-temperature tempering. After such heat treatment, the steel acquires a troostite structure. The heating time during an average tempering can be up to several hours, and cooling is carried out naturally in calm air.

Islands of fragility

The heat treatment in question requires careful adherence to temperature requirements throughout the entire cycle. The reason is the possibility of the appearance of the so-called. tempering fragility.

This phenomenon occurs when the temperature of the workpiece begins to take values out of certain ranges of numerical values. It is these ranges that are called “islands of fragility.” This phenomenon is accompanied by structural changes (can be either reversible or irreversible) in structural alloys and steels with alloying additives, causing a deterioration in their characteristics. This appears in:

- uneven course of the process of diffusion of particles of carbon-containing components;

- violation of the crystalline structure of the metal;

- an increase in the fragility of the alloy to a critical level.

Tempering brittleness is usually divided into two types. Whether this characteristic belongs to one of them determines the temperature range, as well as factors associated with disturbances that have occurred in the structure of the material.

Fragility of the first kind

Such fragility is most often observed when the temperature of the part is within the range of + 250°C≤T≤ +400°C. It appears in almost all carbon structural alloys and is irreversible. If the metal passes into this state, it loses its usability and is usually sent for remelting. It is possible to prevent the appearance of type I fragility. To do this, you need to heat the part so that its temperature is outside the range in which the “island of temper brittleness” is located.

Fragility of the second type (reversible)

Brittleness of the second type appears, as a rule, when the product is heated to a temperature in the range + 500°C≤T≤ +550°C. The reason for its occurrence lies in the excessively slow cooling of the processed part. But type II fragility can be corrected. To do this, additional heat treatment is carried out, including the following steps:

- the product is reheated to at least 500°C;

- the part is placed in an environment that changes its state of aggregation - oil, where it is provided with accelerated cooling.

There is another solution to the problem: elements such as tungsten or molybdenum are added to the alloy. The amount of the first should be somewhere around 1% of the total weight of the alloy, and the second should be no less than 0.3% and no more than 0.4%.

Well, the most reliable way to avoid the need to solve this problem is to heat the product so that its temperature does not reach a value in the range of the “island of tempering brittleness of the second type.”

How to do hardening and tempering

After the blade blank has been given the required shape, it is hardened. Of course, everything is very individual for different grades of steel, for specific products, but on average, craftsmen call the heating temperature for hardening about 700–800 degrees Celsius. The optimal color of the product in this case will be scarlet or cherry. If the redness goes away, giving way to orange and yellow hues, the temperature has most likely exceeded 1,100 degrees - this is already too much for most steels. The white color indicates that the temperature has reached at least 1,300 degrees, and it is not suitable for hardening - it will cause overheating; in this case, it will be impossible to restore the strength of the steel.

It is these colors that are called the colors of incandescence. We will meet with them again when we consider a vacation.

The heat colors show us the temperature the workpiece has reached. They should not be confused with tarnished colors - shades of oxides

When a blade is hardened, it gains high hardness, but at the same time loses strength. Now the strength must be restored: vacation serves this purpose. Vacation, as we remember, is reheating to lower temperatures followed by cooling; Let's add to this that between repeated heatings the blade must cool completely - naturally or by cooling it in a saline solution or oil. We select the heating temperature for tempering as follows.

- Most likely, we do not need high-temperature tempering - it is done for parts that are subjected not so much to deformation as to shock loads, and this clearly does not apply to knives. However, let’s say about it that its temperature limits are 500–680 degrees.

- Medium-temperature tempering is heating to 350–500 degrees; This is also a lot, only suitable for throwing knives.

- Low temperature holiday is what you need. Warming up here goes up to 250 degrees. Of course, the knife will not be so resistant to lateral impact loads, but we don’t need this: we have already achieved the required hardness during hardening, and now we are interested in strength. At this temperature it will turn out just right.

The desired temperature will again be shown by the heat colors: the optimal color in this case (for the knife) will be light yellow.

After each stage at which oxide products (tarnish) appear, the product should be cooled in salt water or oil. In clean water, the workpiece should not be cooled either after hardening or during tempering - due to too high a cooling rate, the product may crack. Neither water nor oil fully meets the necessary requirements for hardening carbon steel: rapid cooling to 550 °C and slower cooling from 300 °C to 200 °C. Therefore, water is used in combination with oil: first into water, and then into oil. This method is used on tool steels and is called “into oil through water.” But alloy steels can only be hardened in oil.

The colors of tarnish on the blade of the “Zombie” collection knife are oxides that were not removed after tempering

Selection of steel for hardening

To begin with, let’s conditionally divide all steels into high-carbon and alloyed. All steels are alloys of iron with carbon and various alloying elements; The name of the steel will depend on whether one carbon predominates in it or whether alloying elements are present in significant quantities. It cannot be said that this or that group is worse or better at hardening; They initially have very different characteristics and different tasks, so we will simply talk about the hardening of both steels.

Hardening of carbon steels

We have accumulated vast experience working with this steel, as well as with products made from it. By itself, it requires lower quenching temperatures than those alloyed with various elements - it already has fairly high hardness and strength indicators, which are so valued on the market.

- Low-carbon steels are hardened at temperatures from 727 to 950 °C.

- Medium and high carbon steels are hardened at temperatures from 680 to 850 °C.

It must be remembered that steels with very low carbon content cannot be hardened at all.

If we want to make and harden a blade from carbon steel at home, the following brands are suitable for us.

Russian:

- U7 – U10;

- 65 G.

American:

- O1;

- 1095.

These grades, when properly heat treated, are characterized by great strength and hardness, although low resistance to corrosion.

Hardening of alloy steels

In addition to iron and carbon, such steels contain a significant amount of various alloying elements, which give the alloy special properties needed in a particular area.

- Chromium makes steel corrosion-resistant if its content exceeds 12–16%.

- Molybdenum and nickel increase the strength of steel and its ability to withstand high loads.

- Vanadium improves the wear resistance of the alloy and gives its blades the ability to hold an unusually sharp edge.

Due to the presence of these elements in the alloy, steel has worse thermal conductivity than pure carbon steel, therefore: 1) it will take more time to heat and cool - if the process is artificially accelerated, then cracks may appear in the alloy; 2) for hardening it needs a high temperature - from 850 to 1,100 ° C.

Unfortunately, correct heat treatment of complex alloy steels is quite difficult, since to give the blade high performance properties, both precise temperature and special equipment for deep cooling are needed. Therefore, it will not be possible to harden them qualitatively “by eye”.

The most common brands include the following:

- 420;

- 440A;

- D2;

- ATS34;

- CPM S320V.

We can say about the last sample that it is extremely wear-resistant.