What are clinker tiles

It is a ceramic material produced by firing clay, limestone and slag at very high temperatures (1000–1300°C). Clinker is used to create bricks and tiles for wall cladding.

These products are characterized by very high strength, frost resistance and fire resistance, as well as low water absorption, so they are excellent for building facades.

However, it is worth knowing that clinker bricks can only be installed in a three-layer wall, so its use must be taken into account at the building design stage.

Clinker tiles produced by extrusion, that is, squeezing clay through a press, are much thinner, therefore they do not load the walls as much and are a universal alternative to plaster.

Equipment for clinker production

The production of high-quality clinker tiles is impossible without the use of special equipment. To provide

quality production line should include:

- Extruder (with appropriate technology).

- Equipment for molding and pressing. Various designs of pressing equipment are used, most often these are vacuum, belt, lever and rotary models.

- Pre-drying chambers are now mostly electric; they vary in power and volume of loaded material.

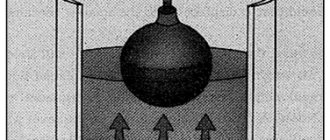

- The main equipment for the production of clinker tiles is, of course, a kiln. Serious enterprises use so-called tunnel kilns; the time when clinker was produced in small kilns using coal has already passed. Although such devices can be found in small private factories for the production of clinker products, this is mostly an exception.

Advantages and disadvantages of clinker tiles

Clinker tiles have many advantages and are excellent as external cladding of building walls. The most frequently cited benefits of its use include:

- High resistance to weather conditions and temperature changes;

- Durability of the facade, which does not fade or change color;

- Elegant appearance;

- Easy to clean;

- Fire resistance;

- Resistance to mechanical damage.

Clinker tiles are not covered with moss, mold and mildew. Ideal for outdoor use and in areas subject to heavy use.

Laying a tile facade is not difficult - you can do this work yourself (if you have the necessary skills) or entrust it to professionals.

Do clinker tiles have any disadvantages? As mentioned above, this is its carcinogenicity in the crushed state. Also among the disadvantages is the high price.

Decorative qualities of the material

Manufacturers produce different types of products, they differ in texture:

- smooth: easy to clean, because dirt does not get clogged into the pores; just wipe the surface;

- rough: non-slip, often used in the bedroom, living room;

- with a glossy finish: looks attractive, used in interiors decorated in modern styles (high-tech, etc.);

- with a rustic surface: this imitates the texture of natural materials.

Clinker tiles and bricks - differences

Some manufacturers' catalogs have additional offers - bricks and tiles of the same color and texture. They are made from the same material and fired the same way. Thus, their properties are also similar.

- Clinker brick is primarily thicker than tiles, and therefore heavier. The decision to use clinker bricks on the facade must be made at the design stage of the house - its foundation must be wide enough to distribute the weight of the additional wall in the form of a facade.

- Three-layer walls use brick as the outer layer. Theoretically, in the case of such walls, clinker tiles can be used, which are glued to non-facade bricks.

- However, such a solution is very rare and experts do not recommend it - it is uneconomical and has no technological justification.

Clinker tiles, unlike bricks, are universal and can be used on almost any surface. It is used in the case of two-layer walls and is attached directly to the insulation layer.

Attention! If you are replacing brick with tiles, you should make sure that the thermal conductivity coefficient of the wall is the same. It may be necessary to increase the thermal insulation layer or make it from a material with better thermal conductivity.

Cement production

The granules obtained after heating the starting materials are used to produce cement. To do this, they are mixed with a certain amount of gypsum (about 5%), and then the resulting mass is ground into powder. The exact ratio of the components depends on the percentage of SO3 in the granules.

Adding gypsum allows you to control the speed of setting of the mixture. Sometimes this material is replaced with other types of calcium sulfate.

When grinding the original components, other substances are added to the powder. They are selected depending on the required technical characteristics of the final product. What cement clinker is can be understood if we consider its typical composition.

The granules contain the following chemical compounds:

- calcium oxide - 66-67%;

- silicon dioxide - 21-22%;

- aluminum oxide - 4-5%;

- ferric oxide - up to 3%.

The amount of other additives ranges from 3-6%.

Clinker tiles on the facade

Clinker for facades is most often chosen for three reasons: it is very durable, beautiful and goes well with other materials. Clinker tiles will work well in places that are exposed to various external factors.

Creating a plinth from clinker will provide strong protection for the wall from dampness, and tiled corners will protect the facade from damage.

- Combining clinker with other materials allows you to achieve a unique effect.

- Separate parts of the facade can be covered with wood or plastered.

- In turn, clinker frames of windows and doors or stepped tiles on the facade will successfully break the monotony of the wall.

- If the plaster is coated with light-colored paint, for example white, the façade will be perfectly decorated with tile-colored clinker.

- Thanks to this, you will be able to create a solid and original look.

Sometimes clinker is also found in combination with stone. Then the appearance of the facade refers to nature and fits into environmental trends.

Organizational arrangements for opening your own factory

The work begins with the procedure for registering an LLC, which involves collecting and submitting a package of documents to the permitting authorities:

- registration application - form P11001;

- articles of association;

- memorandum of association;

- passport of the company director;

- lease agreement for premises.

Attention! If the lease agreement for production space has not been drawn up at the time of registration of the enterprise, then you can get by with a letter of guarantee from the owner of the property confirming the subsequent drawing up of the document.

You will need to pay a state fee of 4,000 rubles, and the receipt will also have to be sent to the registration authorities.

Product manufacturing technology

The technology for producing clinker tiles is the basis of the entire production process. The main method of manufacturing facing material is extrusion. It is planned to produce a water-based suspension, which is then subjected to compression, which makes it possible to obtain a powder containing about 6% moisture.

The technological process consists of several stages:

- Extruder - molding of a product obtained from a dough-like mass containing several components, such as refractory shale clay, spar, broken earthenware, quartz sand, fireclay;

- Drying chamber - it is exposed to warm air, which helps reduce the humidity level of the product;

- production of glaze - special types of glass are used;

- glazing – coating a product with glaze;

- Kiln firing is carried out at a temperature of 1400°C.

Russian-made clinker tiles are kept in a kiln for 36 hours, which significantly increases its performance characteristics. The appearance of the product is subject to adjustment using technological techniques. For example, side burners operating in mixed mode are installed; they also use the “flickering fire” technique, which makes it possible to achieve resonant temperature changes. This processing makes it possible to obtain a variety of products, diversifying the product range. The production of tiles with different colors is carried out using natural dyes added to the mixture, mainly ocher and henna are used. It is possible to use rollers equipped with spikes in the production, which, by scratching the surface, create artificial irregularities that help give the product an aged appearance.

Equipment for making tiles

To launch a full-fledged technological process, you need to buy equipment for the production of clinker tiles. The following machines will be required:

- extruder;

- molding press – the use of different types of models is encouraged: rotary; tape; vacuum; lever;

- drying chamber - works from the mains;

- tunnel kiln for firing.

The main production equipment is a tunnel-type gas furnace, equipped with a circulation system, as well as a glazing line. The process is controlled using an automated system that allows temperature control and remote monitoring. The production of clinker tiles for facades is impossible without the use of a kiln operating on coal, natural or liquefied gas. The equipment is controlled by screw gears, and the temperature is controlled by a computer. The cooling system operates on the principle of atomization, and there is also an option for processing dissipated heat flows. The leading position in the market is occupied by LINGL, which produces reliable stoves that are in demand all over the world. The price of equipment for the production of clinker tiles is provided by the company that manufactures kilns and dryers upon request. It is not necessary to organize large-scale production; you can purchase the necessary equipment and start making tiles on the basis of your own subsidiary plot. Making clinker tiles with your own hands at home will allow you to assess the prospects for opening a large enterprise in a particular region. If we consider that this niche is mainly occupied by importers, then the production of domestic inexpensive tiles will be in demand.

Other materials:

- Production of PVC film

It is difficult to open the production of PVC film in Russia, since its production is accompanied by harmful emissions.

Cement production

Opening a cement production plant in Russia has always been a good idea for organizing your own.

Production of expanded clay concrete blocks as a business

Expanded clay concrete blocks have proven themselves well in the building materials market, which makes them a product.

Features of a facade made of clinker tiles

Taking into account the fact that clinker tiles are expensive, it is still better to entrust their installation to professionals who thoroughly know how to work with this material.

One of the difficulties of finishing a facade with clinker tiles is the need to eliminate cold bridges. Therefore, all non-standard elements (for example, lintels, window sills, etc.) must be very carefully walled up.

- The quality of workmanship also affects the aesthetic effect. To avoid differences in the color of the wall, it is advisable not to use clinker from different batches.

- The risk of plaque formation will be minimized by constantly protecting the brick from moisture, using solutions specifically designed for clinker, as well as a grouting bath (griding using the slurry method, that is, spreading over the surface, is not allowed).

On the other hand, clinker tiles impose height restrictions - they can be glued directly to the wall (without additional protection) only up to a height of 7 meters.

If the house is insulated, then additional protective measures should be applied, consisting of laying special layers sequentially: glue, corrugated mesh, glue, pins (through the mesh), again glue and mesh of corrugated steel reinforcing bars.