| For stamping brass, universal stamping presses with high productivity are used. Brass is a fairly ductile metal, which makes it possible to manufacture parts with high structural complexity from it. The production of some of them requires the sequential performance of several operations on presses of different forces. |

| Brass stamping is carried out at the Bogorodsky plant using a number of special presses, which are formed into production lines. The latter are connected by conveyors, which makes it possible to minimize the time spent on the production of a particular batch of products. Quality control of products is carried out at all stages of their production, which determines the low level of defects in our products. |

| Brass stamping is done using hot and cold methods. For hot stamping, blanks with square and round cross-sections are used, for cold stamping, sheets cut to the required size are used. Further processing of brass is minimal, which means that products made from this metal can be delivered to the customer in a short time. |

details

Alloyed, heat-resistant steels and aluminum alloys

Submit your application

- 1

Casting from aluminum and heat-resistant alloys - 2

Hot stamping of parts

Our production specializes in the manufacture of parts from aluminum, nickel and heat-resistant alloys

We will make model and casting equipment ourselves and carry out heat treatment. We guarantee high quality products. All products have certificates issued based on testing in the company’s laboratory.

Advantages

01

COMPLIANCE WITH DEADLINES AND QUALITY CONTROL

Software and automatic tool changing reduce time and waste

02

QUICK COST CALCULATION

We usually need only 1-2 days to make a preliminary calculation of the cost of the part according to the drawing

03

WE PROVIDE A FULL COMPLEX OF SERVICES

Our specialists will work with you at all stages of production - from the development of drawings and foundry equipment to quality control of finished parts

Stamped brass parts: wide choice

The versatility of our machines lies in the fact that they can produce completely different products.

We are ready to solve any of your production problems: stamping brass fittings, fasteners, gears, flanges and many other parts. Brass stamping offers no less possibilities in the production of original souvenir and commemorative products:

- icons and signs,

- medals,

- Schild,

- magnets,

- cufflinks,

- clamps,

- badges,

- keychains and much more.

As a rule, these are unique items that are developed according to an individual design. Often they are promotional in nature.

Services for manufacturing custom brass products

Our company will perform for you high-precision stamping of brass products according to standard and non-standard projects.

The workshop is equipped with equipment for various purposes. Thanks to this, we can offer you not only all stamping operations, but also metal post-processing - laser engraving on products, application of enamels, gilding, silvering, creating an antique effect, etc. To apply for stamping of brass products, fill out the online form and briefly describe the conditions of the project:

- what needs to be done

- number of details,

- urgency of work.

It will be great if you attach documents (photos, drawings, sketches) to your application. We are waiting for your orders!

We can

Stamping production

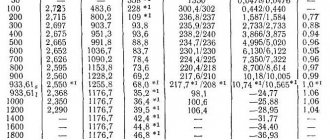

We produce high-quality parts that meet Russian and international standards with heat treatment of workpieces weighing from 0.1 to 15 kg. Forging dimensions with a diameter of up to f280 mm deviation tolerance +-0.3 +- 1.9 mm (depending on the stamping dimensions) Materials: carbon, alloy, heat-resistant, aluminum steels and alloys.

Find out more

Forging production

Wide range of workpieces weighing from 0.1 to 150 kg. Heat treatment. Weight of forgings up to 150 kg Dimensions-diameter up to f 500 mm. Deviation tolerance +- 2.0 +-6.0 mm. (depending on the dimensions of the forging) Materials: carbon, alloy, heat-resistant, aluminum steels and alloys.

Find out more

Foundry

The minimum permissible wall thickness of aluminum castings is 3 mm; The weight of produced aluminum castings is from 20 g to 50 kg; Surface roughness of castings according to GOST 2789-73 Ra = 4 - 20 microns; Accuracy class of the resulting aluminum castings according to GOST R 53464-2009: 6-10.

Materials: alloyed, heat-resistant steels and aluminum alloys.

Find out more

DO YOU HAVE A TASK? WE WILL IMPLEMENT IT INTO LIFE!

Our specialists will calculate and prepare all technical information. Just an IDEA from you!

The terms of cooperation with us are simple:

1

Application

Send drawings with technical specifications to [email protected]

or a sample of the product;

2

Calculation

Our specialists will analyze your drawings and also calculate the cost of materials and work for your task;

3

Coordination

Concluding an agreement, issuing an invoice, paying an invoice;

4

Manufacturing

Production of equipment;

5

Production

Manufacturing of parts, post-operative and final quality control of each product;

6

Delivery

We ship and deliver finished products;

Technical nuances of brass stamping

Factories also do not need to purchase any “special” furnaces for hot stamping of brass: ordinary forging furnaces are suitable for this purpose, providing uniform and gentle heating. Specific features of specifically stamping include:

- maintaining the required temperature range. Which, it should be noted, is very narrow: the minimum limit is +720-730 degrees, the maximum is +750. This is why die stamping of brass cannot be a lengthy operation: it is very important to carry it out in one blow or effort;

- if burrs form on the surface of the part, it is better to cut them off either at forging temperature (the same 720-730 degrees), or after cooling, when it has completely “accustomed” to room temperature.

However, in professional production it is possible to reduce the formation of burrs to a minimum. This is due to the design features of the stamps. When stamping brass products, the workpiece fills the mold without “climbing” beyond the established barriers in the form of internal forms and protrusions. In essence, it fills a closed cavity and immediately takes on the dimensions and shape of the finished product. As a result, finishing processing of the resulting part is not required.

Cold stamping of aluminum

Aluminum workpieces are cold stamped without heating. And the thin-sheet metal “excellently” withstands the flexibility test, which is prepared for it by two main participants in the process - a stationary matrix and a movable punch.

This type of processing is understood not as one operation, but as a whole complex of actions that can be conditionally defined as separating and form-changing. Under separating influences, the workpiece changes shape due to cutting, cutting, punching and other methods of separating a part from the whole.

Cutting is performed on various equipment: from mechanical scissors to a laser machine. The cutting line of the workpiece can be either straight or figured. The tool for punching is a punching press. After its passage, holes appear on the future part. Punching is used to produce blanks with a formed closed contour.

The form-building operations of cold stamping of aluminum are much more diverse. These include:

- flexible,

- twisting,

- hood,

- relief molding,

- crimping, etc.

Application area

Liquid stamping is applicable at any enterprise, regardless of the direction of the main activity. This technology is suitable for creating monolithic and variable configurations.

Liquid and semi-liquid stamping is suitable for creating:

- Round and rectangular flanges;

- Gear;

- Guide blocks and rollers;

- Gear and worm wheels;

- Valov;

- Components of various mechanisms;

- Lids and boxes.

Equipment

Sheet metal stamping is done using a press and a stamp. The press is used to create pressure, that is, the stamping process itself, and the stamp gives the product the desired shape. The stamp is made of tool steel and consists of a punch and a matrix.

The deformation process occurs with the help of a punch and a matrix at the moment of their approach. The movable part is the upper half of the stamp, fixed on the press, namely on its slider.

The lower half remains motionless and is located on the working surface of the equipment. If it is not steel that is being stamped, but the material is soft, then the working parts of the stamp can be made of polymer alloys or wood.

When producing a single, particularly large-sized product by stamping, it is usually not a press that is used, but a special device made of a cast iron or concrete matrix and a container with liquid (usually water). A sheet of metal is placed on the matrix, and above it is a liquid punch.

Concrete matrix fixture

To create the pressure in the liquid necessary to deform the metal into the desired shape, a gunpowder-based charge is detonated in the container or an electric discharge of sufficient power is provided to the water.

For cutting sheet metal, scissors, rather than a press, are used. They come in several types:

- with parallel knives;

- disk;

- guillotine;

- vibration.

Vibrating type scissors are most often used.

For high-quality manufacturing of products, you need to carefully select a press for each type of operation and material being processed. There are several types of presses:

- Hammer (maximum speed up to 20 m/s).

- Hydraulic press (maximum speed up to 0.3 m/s);

- Crank machine (maximum speed up to 0.5 m/s);

- Rotary type machine (maximum speed 8 m/s);

- Pulse stamping machine (maximum speed up to 300 m/s).

Crank machines are suitable for most types of operations. They can have from one to four crank mechanisms. The operating principle of the crank mechanism can be described according to the following diagram:

- The drive electric motor transmits motion to the crank shaft through a kinematic chain, which consists of a friction clutch and a V-belt drive.

- An adjustable length connecting rod drives the crank slider.

- The foot pedal through the clutch starts the working stroke of the press.

Equipment for stamping products with complex configurations may have several sliders.

Sheet stamping of aluminum and other metals

Professional machine stamping of sheet blanks is a fairly young technology: its first successful experiments date back to the 90s of the 19th century. However, it developed very quickly: after just 20 years, single operations on disparate equipment began to give way to work on assembly lines. And in the 20s of the twentieth century, methods of anti-corrosion protection of stamped products were tested and successfully introduced into production.

Modern stamping of sheet aluminum is carried out on high-tech stamping presses. The choice of sheet processing technology depends on their thickness.