Most often, the question of how to make a spring yourself, using improvised means, does not arise. However, there are situations when a spring of the required diameter is not at hand. It is in such cases that the need arises to make this element with your own hands.

Making a small spring is quite possible

Of course, springs for critical mechanisms operating under intensive conditions are best manufactured in production conditions, where it is possible not only to select correctly, but also to comply with all the parameters of the technological process. If you need a non-standard spring for use in a mechanism that will be operated in a gentle mode, then you can make it at home.

Cold coiling technology with quenching and tempering

The first stages of the technology coincide with the previous process. Changes begin at the heat treatment stage. It is carried out in several stages:

- Hardening. The workpiece is heated to a given temperature and held for 2 to 3 hours. Next, it is subjected to rapid cooling by immersing it in a container with mineral oil or saline solution. During the hardening stage, the workpieces must be in a horizontal position. This will avoid deformation

- Vacation. The workpiece is heated to 200-300° and kept for several hours to relieve internal stresses and improve elastic properties.

Further measuring and control operations are also carried out. The workpieces that have passed the inspection are sent for sandblasting to remove scale. If necessary, shot blasting should also be done to increase the strength of the surface layer of the metal.

The process is completed by applying a protective coating.

How to make and harden a spring at home

Almost every home craftsman knows that it is possible to make a spring from almost any wire and successfully use it in everyday life. Basically, there are no problems with making the part yourself. However, sometimes situations arise in which it is necessary to either make a spring of non-standard dimensions, or give it increased strength and elasticity. To do this, you should resort to heat treatment operations. It is quite possible to harden a spring at home. It goes without saying that a homemade part should not be used in particularly critical devices operating under increased load. For such purposes, it is recommended to use factory-made springs. But for home use in a device operating in a lightweight mode, the technology in question is quite suitable.

Required tools and materials

In order to make and harden a wire spring with your own hands, you need:

- Steel wire. The diameter is selected based on the necessary characteristics of the future product.

- Ordinary gas burner.

- Metalworking tools: pliers, hammer, etc.

- Vise.

- Stove. This may be, if available, a special one or an ordinary household one.

Additional devices that are selected individually in accordance with the size and stiffness of the spring can facilitate the process of winding the spiral.

If the use and hardening is intended to be made from wire with a diameter of less than 2 millimeters, then it may not be preheated. It will bend without any problems without this operation. However, before starting winding, it is recommended to straighten it along its entire length and completely level it.

When using wire with a diameter of more than 2 millimeters, it should be burned before starting work. Without this operation, aligning and winding it will be problematic.

Features of the operation

- The right foundation is the key to success. In factory conditions, an alloy of non-ferrous metals (65G, 60HFA, 60S2A, 70SZA, Br. B2), alloy or carbon steel is used for production. During home production, the optimal base will be an old spring of the required diameter.

- A special furnace is best suited for annealing. If this is not available, brick or metal will do.

- For cooling after heating, it is recommended to use transformer oil. If it is not available, a spindle will do.

Sequencing

1. Before tempering the spring wire, you should check the base material and make sure that the wire used is carbon steel.

2. The annealing procedure, as mentioned earlier, can add plasticity. This will make the process of alignment and winding onto the mandrel easier. You can use a special oven or any suitable oven for this. In everyday life, it is possible to harden in the most suitable structure (metal or brick). To do this, a regular fire is lit and then the future spring is placed in the coal. After heating the workpiece red-hot, the wire must be removed and allowed to cool naturally. The cooled wire will be much softer and you can work with it comfortably.

3. The softened wire should be completely aligned and begin winding onto a mandrel of a suitable diameter. During the procedure, you need to control the tight arrangement of the turns to each other. To make it easier, you can use a screwdriver.

4. To impart the required elasticity, hardening will be required. Thanks to this heat treatment, the part is harder and more durable. Hardening springs involves heating them to a temperature of 830 to 870 degrees. To do this, you can use a gas burner. Earlier we talked about hardening metal at home.

It is unlikely that you will find a suitable thermometer at home that can accurately determine the temperature of a part. Therefore, you can navigate by the color of the metal. When the required temperature is reached, the workpiece will turn light red. We recommend watching a video with a detailed description of the heating temperature. After this, the spring is placed in a cooling medium (oil).

5. Afterwards, the hardened spring must be kept in a compressed state. This requires from 20 to 40 hours.

6. Finally, process and adjust to the required dimensions.

Correct implementation of such hardening will allow you to successfully use the spring in home mechanisms.

Hardening of the product

For those who are interested in how to make a spring themselves, experienced craftsmen also advise paying attention to its hardening. This procedure consists of heat treatment of the product in order to give it the required elasticity.

A spring that has undergone hardening becomes much harder and more durable compared to its original state. Heat treatment is performed in special furnaces at temperatures from 830 to 870 degrees. You can also cope with this work at home using a regular gas burner. Since there are usually no temperature sensors in such devices, the home craftsman will have to control the process visually. The color of the item being heated can be used as a guide. When heated to 800 degrees, the metal turns cherry red. This means that it is too early to remove the product from the oven. If the spring is hot enough (870 degrees), it will turn light red. Now it should be cooled. Transformer or spindle oil is suitable for this purpose. In special factory thermal furnaces, metals are heated to 1050 degrees. Products at this temperature regime acquire orange shades.

Production

According to the established GOST rules, wire is created by pulling or drawing initial blanks through holes arranged in order of decreasing section diameter. To increase the tensile strength, thermal hardening is carried out at the end. When drawing, a special form for calibration is installed at the last outlet hole of the machine - a die. It is installed in the case when the material must be manufactured already calibrated and not have defects on the surface.

Next comes the tempering of the wire at a temperature of 400-480 C. The hardness of the web is 35-45 units (from 1300 to 1600 kilograms per 1 square millimeter of plane). To improve technical properties such as load suppression, carbon or high-alloy steel is used. Typically, manufacturers make it from alloy grades - 50KhFA, 50KhGFA, 55KhGR, 55S2, 60S2, 60S2A, 60S2N2A, 65G, 70SZA, U12A, 70G.

Features and Requirements

The most popular diameter is 6-8 millimeters. To make spring wire, steel wire rod is used. Technical requirements are established in accordance with GOST 14963-78 or GOST 9389-75. Sometimes deviations from the norms to the requirements of spring wire are allowed. For example, at the request of the customer, the amount of manganese in the composition can be changed, but only if chromium and nickel were not used in manufacturing.

During operation, the load will be created in places that are not resistant to flaws. Therefore, all raw materials are tested before producing springs.

The strength of the spring web directly depends on the size of the diameter; the strength of a small diameter is much higher. For example, a cross-sectional size of 0.2-1 millimeters is almost twice as strong as a wire with a cross-section of 8 millimeters. The form of release of the finished spring wire can be in the form of coils, skeins (permissible weight 80-120 kilograms) and coils (500-800 kilograms).

Is it possible to bend the front spring?

Is it possible to bend the front spring?

Post by taar » 25 Feb 2012, 01:19

Re: Is it possible to bend the front spring?

Message TVK2011 » 25 Feb 2012, 09:04

Re: Is it possible to bend the front spring?

Post by natan » Feb 26, 2012 11:55 am

Re: Is it possible to bend the front spring?

Post by sash_u » 26 Feb 2012, 16:09

maybe if they removed the stand for the first time

a spring that has not sagged has a slight displacement to the side, so in your case I think the rubber band just fell off the strut plate, calmly ride on because everything is fixed and there is no knocking

Re: Is it possible to bend the front spring?

Post by taar » 26 Feb 2012, 21:06

Source

Required tools and materials

In order to make and harden a wire spring with your own hands, you need:

- Steel wire. The diameter is selected based on the necessary characteristics of the future product.

- Ordinary gas burner.

- Metalworking tools: pliers, hammer, etc.

- Vise.

- Stove. This may be, if available, a special one or an ordinary household one.

Additional devices that are selected individually in accordance with the size and stiffness of the spring can facilitate the process of winding the spiral.

If the use and hardening is intended to be made from wire with a diameter of less than 2 millimeters, then it may not be preheated. It will bend without any problems without this operation. However, before starting winding, it is recommended to straighten it along its entire length and completely level it.

When using wire with a diameter of more than 2 millimeters, it should be burned before starting work. Without this operation, aligning and winding it will be problematic.

Our production

Device for leveling steel wire with a diameter of 6-10 mm and strips 20x3 30-4 mm with a manual drive. Serves for straightening galvanized steel wire with a diameter of 6-10 mm, as well as galvanized steel strip measuring 20x3 mm, 30x4 mm. Round and flat conductors are supplied in coils of 40-50 kg.

In order to efficiently install an air-termination “mesh” made of steel wire on a flat roof, it is necessary to place the wire in holders and connect the nodes using terminals. The wire is laid in cells measuring 6x6 m, 10x10, 12x12 m. In order to lay the “mesh” conductor evenly, it must be straightened from its twisted state. Galvanized steel wire 8 and 10 mm is difficult to straighten manually, especially steel with a diameter of 10 mm, and in the straightened state there will be unevenness from uneven straightening.

To lay down conductors from lightning rods on the roof, chimneys and other structures of buildings and structures, and install conductors in holders, it is necessary to lay it as smoothly as possible without bending. The reason for this is the aesthetic appearance, as well as unevenness, as a result of which the wire may come loose from the holders or the holder mount itself may be damaged.

For ease of installation, our company offers this device for straightening conductors from nine rollers, which will allow you to save time on installing lightning rods, as well as install down conductors in the shortest possible time without fear of dismantling uneven sections of wire and strip.

The design of the wire straightening machine allows you to install it at a height of 0.5 m from the roof or floor on any structure made of wood or metal, adjust the pressure of the rollers on the conductor and achieve evenness of the wire or steel strip.

Eg:

— installation on wooden pallets — 5 minutes;

- screwing screws into wood - 2 minutes;

— setting the pressure rollers for the conductor from 5 to 15 minutes;

— unwinding of a standard coil 115 m 5-7 minutes

— cutting to required lengths from 5 to 20 minutes

In total, on average, it takes up to 1 hour to unwind and prepare galvanized steel wire with a diameter of 8 mm for installation. For a building with a flat roof measuring 50x20 and 10 m high, approximately 3 coils of wire may be required, this means that in 3 hours you can prepare the conductor for laying on the roof and down conductors, without spending a working day on it.

Cold manufacturing method

The technology of winding springs on lathes in Russia is considered more preferable. This is due to the fact that the hot method requires serious costs associated with the purchase of expensive additional equipment. The cold method has restrictions on the wire diameter; it does not exceed 16 mm. The equipment for this process consists of mandrels adapted to guide the metal thread on a rotating spool.

The type depends on the shape of the spring (cylindrical, barrel-shaped or conical). The device for tensioning and directing the wire is presented in the form of two rotating rollers. Moreover, the top one has a screw that allows you to adjust the tension and direction. When cold curling springs, metal with the necessary qualities is taken and the required part is made from it. At the end, heat treatment is carried out in order to get rid of internal stresses.

The technology itself looks like this. The steel wire is fed through a bar mounted on the equipment support, and the end is fixed with a clamp on the mandrel. The roller device exerts tension on the metal thread, which is important in the manufacture of the product. After turning on the machine, the winding of the spring begins, and the speed, depending on the diameter and material used, is in the range of 10 - 40 m/min. The number of turns is counted visually or with a counter. Upon completion, the craft is subject to mechanical processing.

This can be a technology for trimming compression springs with abrasive wheels on special machines or on industrial sharpeners. On products of other profiles, the technological ends must be trimmed or trimmed using a special device and an appropriate tool. The finished product is heat treated in electric ovens.

The technology for heat treatment of parts depends on the material. For some grades of steel, tempering and hardening are used; for others, including bronze, it is low-temperature tempering, after which the items acquire spring properties.

Finished products are checked and tested for compliance with technological parameters (tension, compression, bending, torsion). If necessary or with the consent of the customer, additional processing (galvanic, paint or other coating) is performed.

Welding wire

Welding wire is an alternative to welding electrodes for mechanized and automatic welding. In the first case, it is supplied to the machine manually, in the second, the entire process is fully automated, the welder only controls and corrects it if necessary. Parts are welded under flux or in protective gases, which allows you to obtain the desired weld quality. In this case, neither the wire nor the rods made from it have a coating, like electrodes.

There are three main types of this group of hardware.

Polished (light) welding wire

Polished wire for welding is produced in accordance with GOST 2246-70. As a result of processing, it has a smooth polished surface on which the content of technological lubricants is thousandths of a percent. The optimal option for mechanized gas-shielded welding of low-alloy and carbon steels. Among the advantages:

- fast continuous feeding;

- the best option is if the steel is alloyed with molybdenum;

- minimum amount of aerosol harmful emissions during welding.

Polished wire allows you to obtain a high-quality weld with the correct geometry. Widely used in shipbuilding, bridge building, and mechanical engineering.

Copper-clad wire for welding

For the production of copper-plated welding wire, low-alloy (Sv-08GS-O, Sv-08GA-O, Sv-08G2S-O) and low-carbon (Sv-08A-O, Sv-08-O) steels are used. Manufactured according to GOST 2246-70. Welding work is performed in a protective gas environment - carbon dioxide or its mixture with argon.

Advantages:

- instant ignition, since copper is an excellent electrical conductor;

- stable arc burning;

- economically consumed due to minimal splashing;

- excellent seam quality.

Unlike regular and polished wire, copper-plated wire is more resistant to corrosion, which makes it stand out during long-term storage. Purpose - installation of pipelines, welding of products working under pressure (tanks and the same pipes), mechanical engineering, shipbuilding.

Flux Cored Welding Wire

It does not have a solid cross-section, like other welding wires - the core is filled with a mixture of metal powders, slag and gas-forming components. During welding, they create a protective environment for the weld pool and provide alloying of the weld metal. Used to connect parts made of low-carbon and low-alloy steels.

We talked in more detail about welding wire earlier. Read more ->

In the catalog, metal wire is presented in a wide assortment individually and in finished products:

- chain-link mesh, welded and woven;

- steel ropes and cables;

- nails and dowel-nails.

Tactics for catching crucian carp using a spring feeder

When using a spring for catching crucian carp, both loose and viscous bait is suitable. The feeder is filled with it and several casts are made for the starting feeding. Leashes with hooks are not attached. When feeding is done, you can install a smaller spring with leads.

The bait is compacted in the feeder so that it is washed out no faster than 10 minutes. All that remains is to attach the bait to the hooks and throw the equipment into the feeding area.

The fishing rod is placed on a stand, the fishing line is tensioned, and a bite alarm is mounted. The friction brake is weakened, and if there is a baitrunner, it should be turned on. Now you can sit comfortably and wait for the fish to bite.

To catch crucian carp at shallow depths and short distances, it is better to use small springs made of thin wire 1-2 mm. If you need long casting with a large depth at the fishing point, then it is better to install large models made of 2.5-3.5 mm wire. Having a wide range of feeders, the angler can easily select the optimal spring for fishing in a particular fishing area.

Especially for Homemade FISH – Sergey Viktorovich Shchetko, Belarus, Stolbtsy

do-it-yourself compressive, conical, torsion and tension

When creating various devices, it is very useful to have springs on hand. The question naturally arises: how many, what type and size may you need next time and how to make a spring with your own hands?

However, sometimes a situation arises when it is difficult to find a spring that ideally suits your requirements. So why not make your own?

Making springs may seem intimidating, but with a basic tool and simple instructions, anyone can create one.

In this article I will show you how to make some of them, the simple ones first and then I will move on to some "advanced" tools, but this will not add any complexity to the creation process.

Step 1: Types

Here are a few of the many types of springs we will learn to make. From left to right:

- Tension

- Compressive

- Conical

- Torsion bar

Step 2: Let's get started with basic tools

You can start creating many different types using the tools outlined in the list:

- pin diameter 1.4 cm

- piano string or wire

- pliers with wire cutters

- saw

- clamps

- cordless drill

Step 3: Cut the pin

First, take a wooden dowel and cut it to a length of about 12 cm. Then cut a groove in one of its ends for the string. A pin with a diameter of approximately 1.4 cm is best because it fits well into the drill chuck.

Step 4: Create a Tension Spring

The good thing about cordless drills is that you can adjust their rotation speed. To be safe, always use pliers - if the wire comes off, it could cut your hands.

Secure the drill to the table using clamps. One hand rests on the power button of the drill, and the other holds the pliers. Turn the drill as much as you need until you reach the required number of turns. While winding, keep the cord under tension and the spring will turn better.

Step 5: Bending the String

After winding, I bent the remaining ends with pliers and got a tension spring. By experimenting, you can achieve different loop sizes.

Step 6: Squeezing

It will require a longer pin, in which a groove will also be cut. When winding, measure the distance between the turns by eye. This will take some practice on your part, but it's actually a lot of fun.

Once the spring was ready, I did a test (see last photo). I placed it on the pin, pressed it down on top with a small wooden block and quickly released it - the block shot up to the ceiling.

Step 7: Tapered

The conical shape is made using a drill and a belt sander.

Using the same winding technique, I placed the string into a groove on the pin. Once the spring was completely wound, I trimmed the ends and the conical spring was ready. I made it twice, and the second version came out better.

Step 8: Torsion Bar

To make a torsion bar, I used a brass rod, since the wooden pin could not withstand the load and broke. To create a spring, make several turns and leave a straight section of string at both ends. By bending the ends of the string you will create a good torsion spring.

Step 9: Conclusion

In the photos you can see a compression spring and a set of different springs that I made at home.

I hope you find crafting easy and will help you make many fun projects. If you use them regularly, it will also save you money.

Material requirements

The strength parameters and fault tolerance of a product are largely determined by the material from which it was decided to be made. Metallurgists distinguish special spring steels in the classification of steels. They have a specific crystal structure, determined both by the chemical composition and the heat treatment of the products. Highly alloyed alloys of increased purity and high metallurgical quality provide high elasticity and ductility, and are able to retain their physical and mechanical properties after repeated deformations.

Spring alloys 60S2A, 50HFA and stainless steel 12Х18Н10Т have gained popularity among mechanism designers.

Where is it used?

The production of springs can be done using cold or hot methods. For cold coiling, special spring-coiling machines and machines are used. The wire must be carbon steel because the final part will not be hardened. In Russia, the cold method is used more often, since it is not so expensive and costly.

Process description.

- The spring wire is prepared for work and checked for defects.

- The wire sheet is threaded through the bracket in the caliper, and the end is secured with a clamp on the frame.

- The upper shaft adjusts the tension.

- The winding roller turns on (its speed depends on the wire diameter).

- The fabric is cut when the required number of turns is reached.

- The last stage is mechanical and thermal treatment of the finished part.

The hot method can produce parts only with a cross-sectional diameter of 1 centimeter. During winding, rapid and uniform heating occurs. The process looks like this.

- A piece of wire, heated red-hot, is pushed through the clamp and the ends are secured with clamps.

- The upper roller sets the tension.

- The rotation speed is adjusted (also everything depends on the diameter), and the machine is turned on.

- Afterwards the workpiece is removed.

- Next comes thermal hardening - cooling in an oil solution.

- Mechanical processing of the finished part and application of an anti-corrosion compound.

During the hot winding method, cutting the spring into pieces is not provided if the desired size has already been achieved, that is, winding occurs over the full length of the web. After this, it is cut into pieces of the required length. In this method, the last heat treatment is needed to relieve internal stress on the part. It is recommended to work with an oil solution rather than water, so that cracks do not appear on the steel during hardening.

See below for what spring wire looks like.

Diameter

If the wire diameter is no more than 2 mm, then a spring can be made without using heat treatment. To do this, you need to bend the wire in such a way that it becomes absolutely even, and then wind it forcefully onto the mandrel.

As for the diameter of the mandrel, it should be slightly smaller than the inner diameter of the spring you want to get. This is necessary to compensate for elastic deformation. Most likely, you will have to unbend and coil the spring several times, try several sizes of mandrels to find the desired diameter. The distance between the coils of the compression spring should be slightly greater than that of the finished spring. The two outer turns should fit well and tightly to each other.

If the diameter of the spring that you want to use as a starting material is more than 2 mm, then before you start working with it, it must be annealed. Because without this procedure it is impossible to straighten and wind such a thick wire.

- First of all, you need to choose the right material for the future spring - this is half the success. Alloys of non-ferrous metals (65G, 60HFA, 60S2A, 70SZA, Br. B2, etc.) or special steels (carbon or alloyed) are used in production. If you decide to make a spring yourself, the most suitable material for this will be another spring of the required size (you need to pay attention to the diameter of the wire from which it is made).

- Annealing is best carried out in a special thermal furnace. If you couldn’t find one, then use brick or metal. Light a fire using birch wood and place a spring in the coals. Wait until it is red hot and let it continue to sit in the oven until it cools completely. After this annealing procedure, the wire will become suitable for winding.

- Straighten it and wind it around the mandrel. Do this as described above. When making a spring, wind the coils close to each other.

- Now so that it does not lose its shape. To do this, it must be heated to a temperature of 830-870 degrees and lowered into transformer oil (spindle oil can also be used). Naturally, you will not be able to monitor the desired temperature using instruments, so determine it visually by the color of the heated metal. At a temperature of 830-900°C the metal has a light red color. If such a shade appears, the spring has reached the desired state.

- After hardening, you need to compress the spring until the coils compress and leave it, without releasing it, for 20-40 hours. Then grind off the ends of the spring on a sharpening unit and the product is ready.

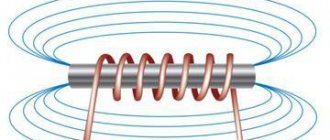

Coil compression springs

Elastic elements can have different spatial forms. Historically, the first springs mastered by man were leaf springs. You can still see them today - these are springs on heavy-duty trucks. With the development of technology, people have learned to make more compact coil springs that work in compression. In addition to them, spatial elastic elements are also used.

Design Features

During operation, such springs take a load along their axis. In the initial position, there are gaps between their turns. The applied external force deforms the spring, its length decreases until the coils touch. From this moment on, the spring is an absolutely rigid body. As the external force decreases, the shape of the product begins to return to its original shape until it is completely restored when the load disappears.

The main characteristics describing the geometry of the part are:

- The diameter of the rod from which the spring is wound.

- Number of turns.

- Winding step.

- External diameter of the part.

The external shape may differ from cylindrical and represent one of the figures of rotation: cone, barrel (ellipsoid) and others

The winding pitch can be constant or variable. The winding direction is clockwise and counterclockwise.

The cross-section of the turns can be round, flat, square, etc.

The ends of the turns are ground down to a flat shape.

Operating area

Cylindrical coil springs of constant outer diameter and constant pitch are used more widely than others. They are used in areas such as

- Mechanical engineering.

- Instrumentation.

- Vehicles.

- Mining industry.

- Appliances.

and in other industries.

Where should I start?

Experts recommend using wire from an old spring whose diameter does not suit the owner. The craftsman will only have to align it and wind it onto a mandrel with a cross-section of the required size. To do this, the wire must be absolutely straight. It will be much more plastic if it is processed in a special oven. If you don’t have one, any other device that can be heated with firewood will do. According to experienced craftsmen, birch provides sufficient heat for firing. After lighting the stove, you need to wait for the wood to burn in it. Only coals should remain. You should put the old spring in them. If the product is hot enough, it will turn red. Now the spring can be moved to the side so that it cools in the air. After this procedure, the metal will become plastic and easy to work with.

How to make a spring?

After waiting until the old product has cooled down sufficiently, they begin to unwind it. Absolutely straight wire should be wound onto the mandrel. For those who do not know how to make a spring, experts recommend placing the coils close together. At this stage, the master will have to make physical effort. The mandrel is clamped in a bench vice.

The work will be much easier if you use pliers. Judging by the reviews of experienced craftsmen, very often beginners have difficulty selecting the size of the mandrel. It is possible that you will have to work not with one mandrel, but with several with different sections. The diameter for a homemade spring in this case is selected experimentally.

Spring manufacturing technology and requirements for them

Spring manufacturing technology plays an important role and is of great importance for their trouble-free long-term operation. Elastic elements are high-tech products that require qualifications and experience from design engineers and technologists, as well as a good fleet of equipment at the manufacturing enterprise.

The operation of the entire unit, where this part will be a component, depends on how correct the calculations of the spring were, the selection of material taking into account the required characteristics and features of its application, as well as the technologies used and manufacturing accuracy.

Twisted compression springs: design and operation features

During operation, this type of spring absorbs loads applied in the longitudinal-axial direction. Compression springs initially have gaps between the coils; the application of external force leads to deformation, characterized by a decrease in the length of the product, and is limited to the moment when the coils touch. When the impact is canceled, the spring must restore its shape and geometric dimensions to what they were before the load was applied.

The main dimensions that determine the type of individual part are:

- — Diameter of wire (rods).

- — Number of turns.

- — Winding pitch.

- — Product diameter.

The most common are cylindrical helical compression springs, in which the diameter of the product is the same along the entire length. These parts are widely used in various industries: instrument and mechanical engineering, mining, gas and oil production, and others.

In general, compression springs can have not only a cylindrical shape, but also a conical, barrel-shaped, or more complex one. The pitch of the turns can be constant or variable, and the winding can be clockwise or counterclockwise.

This introduces features into the generally accepted technology of their manufacture.

Spring requirements

To do their job effectively and correctly, these elements must have good strength, ductility, elasticity, endurance and relaxation resistance.

Achieving these qualities is possible subject to many factors, including:

— Correct choice of material. — Competently carried out calculations. — Compliance with manufacturing technology.

High-quality springs must meet the requirements of GOST and the technical specifications of a specific customer.

According to the standard, there are three accuracy groups for controlled deformations:

- — With permissible deviations up to 5% (+/-).

- - To 10%.

- — Up to 20%.

In accordance with this, three groups of accuracy according to geometric parameters are defined.

An important requirement for these parts is a clean surface; scratches and other defects are not allowed here, as they lead to a decrease in strength and reliability

Wrong type

Among the abundance of designs, you should choose products that best match the original elements in shape, height, and rigidity:

- The number of turns and height may vary. The main thing is the complete coincidence of the seat and outer diameter. The easiest way to choose the right springs is with the help of branded catalogs offering their products for various cars.

- The durability of springs depends on the absence of technological defects. In addition, this parameter is directly affected by violation of recommendations for their selection and the use of unsuitable shock absorbers.

- Color markings may vary from manufacturer to manufacturer. The diameter of the spring rod may also vary. When choosing this suspension element, it is important to focus on the manufacturer, the type of product, which is determined using markings, and rigidity.

Changing the suspension design using artisanal methods has an extremely negative effect on the operation of the springs.

For example, installing elements from station wagons on sedans in case of sagging of the car body is justified. On the other hand, if this is done to increase load capacity, then this is an unjustified step, since reinforced structures can damage the body over time.

An unsuitable type can lead to loss of controllability, deterioration of road stability, damage to the body and shock absorbers.

In addition, the wrong type of products installed on a car often leads to failures of the ABS and ESP electronic systems. This can even lead to ECU failure.

Incorrect springs change ground clearance and wheel alignment angles. As a result, parts, chassis components, and tires wear out much faster.

Cold coiling technology without hardening

First you need to do preparatory operations. Before a workpiece is wound from wire, it is subjected to a patenting procedure. It consists in heating the material to the plasticity temperature. This operation prepares the wire for the upcoming change in shape.

During the winding operation the following parameters must be maintained:

- External diameter of the product (for some parts the internal diameter is standardized).

- Number of turns.

- Winding pitch.

- The total length of the part, taking into account subsequent operations.

- Compliance with the geometry of the end turns.

Cold coiling without tempering

Next, the end turns are ground down to a flat state. This must be done to ensure high-quality support for other structural parts, to prevent their destruction and the spring from slipping out.

The next stage of the technological process is heat treatment. Cold coiling of springs involves only tempering at low temperatures. It allows you to increase elasticity and relieve mechanical stresses that arise during winding.

After heat treatment, it is necessary to carry out test and control operations.

Further, if necessary, protective coatings can be applied to prevent corrosion. If they were applied by galvanic method, the products are reheated to reduce the hydrogen content in the surface layer.

Sunday, August 23, 2022

How to make your own spring

If necessary, you can make a spring yourself. Steel wire for the manufacture of a spring, which will subsequently be hardened, must meet the requirements specified in GOST 14963-78. There are many conditions, but the main thing is that the wire must be grades 51ХВА, 60С2А, 65С2ВА, 70С3А. Although, of course, no one is stopping you from using other steel.

To make a spring at home, you need to determine the characteristics:

- steel grade

- wire diameter

- number of wound turns

- turn pitch

When making a spring, you must adhere to the following simple rules:

- The wire must be absolutely straight. If the spring is made from an uneven or old spring, it must be leveled.

- the wire must be free of rust, oils and other contaminants. To do this, use a soda solution or chemicals to dissolve oils and remove rust. It is recommended to wipe the wire with sawdust.

- Before coiling, wire with a diameter of more than 2 mm must be subjected to an annealing procedure by heating red-hot (temperature within 400 °C) and cooling in air.

- When winding, it is necessary to control the position of the turns relative to each other. They should fit tightly one to one. To do this, you can use a suitable bolt or stud as a mandrel. Hold the end of the wire on the bolt with hand pliers or clamp it together with the bolt in a vice.

- During the winding process, you need to try to constantly keep the wire in tension and wind turn to turn.

- Various devices can be used for winding.

- After winding the wire, if the spring must work for compression, you need to use a screwdriver to make the required distance between the turns. If the spring must work in tension, then lugs are made at its ends.

After making the spring, it must be hardened. Hardening of springs at home can be done in several ways: using a gas burner, heating in a stove made of brick or stone, or simply in a fire. Heating should be carried out to a temperature of approximately 870 °C. This is determined by eye by the color of the wire: during the heating process it turns red-orange. Then it must be placed in oil (transformer, spindle or other liquid medium), which will provide slow cooling: rapid cooling can cause cracks that will adversely affect the quality of the spring.

A hardened spring is brittle. In order for it to obtain the optimal balance between hardness and elasticity, tempering is required. To do this, the workpiece is heated to a temperature of 400-500 degrees Celsius. You can determine that it is hot enough by its color. First, the spring will turn light cornflower blue, and then light gray, which signals that the desired temperature has been reached. After heating, it is cooled in air. Many people on the Internet do not mention this point.

It is recommended to keep a spring made by hand in a compressed state for some time. Typically, the holding time ranges from 20 to 40 hours.

Please note that a self-made spring (i.e. made without rigid technology) can burst, compress, stretch, or stretch at any time

Therefore, it is better to try to avoid using such a spring in sensitive places.

Several useful videos

Cold coiling technology without hardening

First you need to do preparatory operations. Before a workpiece is wound from wire, it is subjected to a patenting procedure. It consists in heating the material to the plasticity temperature. This operation prepares the wire for the upcoming change in shape.

During the winding operation the following parameters must be maintained:

- External diameter of the product (for some parts the internal diameter is standardized).

- Number of turns.

- Winding pitch.

- The total length of the part, taking into account subsequent operations.

- Compliance with the geometry of the end turns.

Next, the end turns are ground down to a flat state. This must be done to ensure high-quality support for other structural parts, to prevent their destruction and the spring from slipping out.

The next stage of the technological process is heat treatment. Cold coiling of springs involves only tempering at low temperatures. It allows you to increase elasticity and relieve mechanical stresses that arise during winding.

After heat treatment, it is necessary to carry out test and control operations.

Further, if necessary, protective coatings can be applied to prevent corrosion. If they were applied by galvanic method, the products are reheated to reduce the hydrogen content in the surface layer.

Features of the technology

The technological process for manufacturing elastic elements depends on the technical requirements for the design. Making a spring is not as easy as an ordinary part, which should not have special elastic properties. This requires special equipment and equipment.

Winding of springs with a round coil section is carried out using the following methods:

- Cold. Suitable for small and medium sizes (wire diameter up to 8 mm).

- Hot. For large diameters.

Spring coiling technology

After winding, the elastic elements are subjected to various types of heat treatment. During this process, the product acquires the specified properties.

Hot coiling technology with quenching and tempering

Before winding, the workpiece is heated to plasticity temperature using one of the following methods

- muffle furnace;

- gas-burner;

- high frequency heating.

Heat treatment schedules are constructed based on the properties of the material and the dimensions of the workpiece.

To make an elastic element, specialized equipment is required. These are winding machines. You can make a part on a regular lathe, but it will require additional equipment with special equipment. Medium and large series are produced on semi-automatic machines that operate with minimal operator intervention. You can also make a spring from wire by hand. This will also require special equipment.

At the next stage of machining, the ends are ground on face grinding machines. For single production or small series, this can be done with a grinding wheel.

Heat treatment is carried out using mandrels that prevent product deformation in specialized furnaces for hardening and tempering. Both operations can be done in a universal oven.

For quality control, load installations and measuring systems are used. In case of single production, measurements can be made with a universal tool.

A spring that will serve for a long time and perform its tasks as efficiently as possible can be made not only in production. Yes, there is an opportunity to fully comply with the entire production process, all its parameters, and correctly select the characteristics of all technological processes (for example, hardening temperature). However, you can make a simple spring for a mechanism that operates in a gentle mode with your own hands.

To do this you will need the following materials:

- directly a spring and wire of a size suitable for the intended unit;

- gas-burner;

- metalworking tools;

- vice;

- household or thermal oven.

Final stage

After the hardening procedure, the spring should be compressed and left in this position for two days. Then, using a sharpening machine, its ends are processed. This will give the handicraft the required size. After completing all of the above steps, the spring is considered ready for use. According to experts, homemade products cannot be compared with similar factory-made products.

However, non-standard springs are widely used in various mechanisms. If they are used in a gentle manner, the springs will last quite a long time.

Coil compression springs

Elastic elements can have different spatial forms. Historically, the first springs mastered by man were leaf springs. You can still see them today - these are springs on heavy-duty trucks. With the development of technology, people have learned to make more compact coil springs that work in compression. In addition to them, spatial elastic elements are also used.

Coil springs

Design Features

During operation, such springs take a load along their axis. In the initial position, there are gaps between their turns. The applied external force deforms the spring, its length decreases until the coils touch. From this moment on, the spring is an absolutely rigid body. As the external force decreases, the shape of the product begins to return to its original shape until it is completely restored when the load disappears.

The main characteristics describing the geometry of the part are:

- The diameter of the rod from which the spring is wound.

- Number of turns.

- Winding step.

- External diameter of the part.

The external shape may differ from cylindrical and represent one of the figures of rotation: cone, barrel (ellipsoid) and others

The winding pitch can be constant or variable. The winding direction is clockwise and counterclockwise.

Spring device

The cross-section of the turns can be round, flat, square, etc.

The ends of the turns are ground down to a flat shape.

Operating area

Cylindrical coil springs of constant outer diameter and constant pitch are used more widely than others. They are used in areas such as

- Mechanical engineering.

- Instrumentation.

- Vehicles.

- Mining industry.

- Appliances .

and in other industries.

Use of springs in everyday life

How to make a spring with your own hands from wire and in production: we describe it in detail

Steel springs can be of different configurations and it is not always possible to purchase the desired type - the product is quite rare on the market. For this reason, I make them myself for my needs.

Requirements for wire and its diameter

Steel wire for the manufacture of a spring, which will subsequently be hardened, must meet the requirements specified in GOST 14963-78. According to the document, it is classified according to the following criteria:

- winding method (cold and hot);

- method of surface finishing (without finishing and with finishing);

- manufacturing accuracy (normal and increased);

- class of mechanical properties (general and critical use);

- diameter (from 0.5 to 14 mm);

- type of delivery (in rods or coils).

At industrial enterprises, springs are made from wire with a diameter of no more than 16 mm using the cold winding method, and up to 80 mm using the hot method. In production, they are wound using a rotating mandrel, feed rollers and one or two stop pins.

Products are made from wire grades 51ХВА, 70С3А, 65С2ВА, 60С2А, 65Г, 60ХВА with a ground, polished surface or without grinding and polishing. Based on this characteristic and the manufacturing method, the wire is produced in rods or coils of the following groups:

- A, B, C, D, E – with special finishing;

- N - without finishing.

The wire symbol in the technical documentation and on accompanying tags consists of numbers and letters:

ХХХХХ (1) – Х (2) – Х (3) – Х (4) – ХХ (5) – ХХ (6) GOST 14963-78 (7)

Where:

- 1 – steel grade;

- 2 – surface finishing method;

- 3 – manufacturing accuracy;

- 4 — class of mechanical accuracy;

- 5 - winding method;

- 6 - diameter in mm;

- 7 - designation of the standard.

For example, a wire with a polished surface made of high-precision class I steel 60C2A for hot coil springs with a diameter of 2.0 mm will have the following designation:

60S2A – A – P – I – GN – 2.0 GOST 14963-78

The state standard specifies permissible maximum deviations, out-of-roundness and the inadmissibility of certain types of defects, as well as methods of packaging and transportation.

Spring calculation

To do this, you need to use the table in the spring section to correctly select the diameter of the steel wire, the number of turns and pitch. In this case, how the new spring should work - compression or tension - plays a huge role.

The last type of springs can have a rather complex design, but you can also make it yourself.

Having performed preliminary calculations and found out the thickness of the wire for a steel spring, the pitch and number of turns, as well as having determined the design features and created a drawing of the future spring, you can proceed to practical actions.

There is also special software for calculating all parameters:

Common mistakes

We clamp the mandrel in the chuck of the lathe. We insert the end of the steel wire into the hole in the mandrel, start the rotation and wind the steel string tightly.

After checking the thickness of the spring with a caliper, we cut the wire with wire cutters and watch how our spring increases in diameter.

In addition, removing it from the mandrel will be quite problematic - to do this you will have to cut the string at the very beginning of the turn.

Doing it right

We clamp the wire on the mandrel using a screw.

Now we need to create tension on the steel string before winding.

Using a regular piece of thick plastic to clamp the wire into the cutter holder will not be enough. We will need a special device with a guide, in which the tension of the wire can be adjusted by a pressure plate made of soft metal (copper or bronze).

It is also necessary to adjust the rotation speed of the lathe chuck and the movement of the work platform to obtain the desired spring pitch.

Heat treatment of springs

Springs and springs experience repeated alternating loads in operation and, after removing the load, must completely restore their original dimensions. In connection with such operating conditions, the metal used for the manufacture of springs and springs must have, in addition to the necessary strength under conditions of static, dynamic or cyclic loading, sufficiently good ductility, high limits of elasticity and endurance and high relaxation resistance, and when working in aggressive environments (steam atmosphere, sea water, etc.) must also be corrosion-resistant.

Technological properties are also equally important for the metal of springs and springs - low tendency to grain growth and decarburization during heat treatment, deep hardenability, low critical hardening rate, low sensitivity to temper brittleness.

The quality of springs and springs is influenced by the condition of the surface of rods, wires and strips. The presence of external defects (cracks, sunsets, caps, hairs, shells, burrs, depressed scale, etc.), as well as a decarburized layer, reduces the elastic and cyclic properties of the metal. Therefore, external defects on the surface of rods and strips must be removed by cleaning or grinding, and the depth of the decarburized layer should not exceed a certain standard established by GOST for spring steel.

Springs and springs have high properties (maximum limits of elasticity and endurance) with a hardness of HRC 40-45 (troostite structure), which is achieved after hardening (with a uniform and complete martensitic transformation throughout the entire volume of the metal) and average tempering at 400-500 ° C (depending on steel).

For the manufacture of springs, carbon and alloy steels are used, and for devices - alloys of non-ferrous metals, mainly beryllium bronze. Springs are made only from alloy steel.

Springs and spring leaves are strengthened in the following ways:

1) cold plastic deformation followed by low-temperature heating (tempering, aging);

2) quenching followed by tempering (hardening as a result of martensitic transformation);

3) hardening followed by aging (hardening as a result of dispersion hardening).

Hardening by cold plastic deformation.

For the manufacture of medium and small twisted springs, patented wire (up to 8 mm in diameter) is widely used, made from medium-carbon steels with a manganese content of 0.3-0.6% and steels 65G and 70G with a manganese content of 0.7-1.0%, as well as from carbon tool steels. After winding in a cold state, the springs are subjected to low tempering (175-250° C, holding for 15-20 minutes depending on the wire diameter) to relieve stress, increase elasticity and endurance limits, relaxation resistance and ensure dimensional stability of the spring.

Instead of patenting, it is more economically profitable to use the method of strain hardening of normalized steel. This method, developed at the Gorky Automobile Plant, is as follows. Wire, rods, strips of steel 45, 65G, 50KhG are subjected to normalization and then cold plastic deformation by drawing or rolling with a degree of deformation of 40-60%. From the resulting semi-finished product, leaf and coil springs and spring leaves are produced by winding, stamping or cutting, which are heated at 280-300 ° C for 20-40 minutes.

When heated, strain aging processes occur, causing hardening. The endurance limit is higher than after hardening and tempering. For example, the endurance limit of plate springs made of steel 65G after strain aging is b = 96 kgf/mm2 (960 MN/m2), and after quenching and tempering b = 77 kgf/mm2 (770 MN/m2). The advantage of this method is also that the dimensions and shape of the elastic elements are ensured, which is especially important for thin leaf springs that are highly deformed during hardening. To eliminate warping of such springs, it is necessary to use special stamps during release.

Hardening by quenching followed by tempering.

For the manufacture of springs strengthened by heat treatment (quenching and tempering), carbon (65, 75) and alloy (60S2A, 50HFA, 60S2N2A, etc.) steels are used; for springs - only alloy steels; for springs operating in aggressive environments - stainless steels 30X13, 40X13, 12Х18Н10Т, etc.

Carbon steels, due to their low hardenability, are used for the manufacture of springs from wire with a diameter of up to 6 mm. The advantage of silicon steel over carbon steel is its increased hardenability and higher strength and ductility. The disadvantage of this steel is its increased tendency to form surface defects during hot working, decarburization and graphitization. As a result of decarbonization of the outer surface of springs or springs, their resistance to long-term loads sharply decreases. Therefore, heating of springs and springs must be carried out with protection from decarburization or (to eliminate the harmful effects of the decarbonized layer) they must be blasted with shot after heat treatment.

Silicon steels 55C2 (A) and 60C2 (A) are widely used for the manufacture of car springs and railway rolling stock springs. Steel 60S2 (A) is also used for the manufacture of springs operating at temperatures up to 250° C. Steel 70SZA has high mechanical properties, but is prone to graphitization.

Manganese steel (65G) compared to silicon steel has some features, which include a less rough surface during hot working, greater hardenability and a lesser tendency to decarburization. The disadvantages of manganese steel are increased sensitivity to overheating, the formation of hardening cracks, and a tendency to temper brittleness; This steel is used for springs of mechanisms and machines.

Parts made of steel 55GS with a cross-section of up to 25 mm are through-hardened, and therefore it is used for the manufacture of springs with a thickness of up to 10 mm, cylindrical springs with a rod diameter of up to 25 mm and buffer springs; This steel is less prone to decarburization and temper brittleness.

Chromium-manganese steel (50ХГ (А)) has deep hardenability, high strength and relatively low sensitivity to overheating; it is used for the manufacture of springs and springs of large cross-section; steel can be hardened well in oil; The disadvantage of this steel is its tendency to temper brittleness.

A small vanadium additive to chromium steel has a positive effect on the structure and ductility of the steel, and also reduces its tendency to overheat, as a result of which heat treatment is greatly facilitated; Therefore, chrome vanadium (50ХФА) and chrome manganese vanadium (50ХГФА) steels are well quenched in oil and are less prone to grain growth. These steels are used for the manufacture of springs for special purposes, as well as springs for passenger cars.

Steels 60S2HFA, 65S2VA and 60S2N2A are used for large springs for critical purposes. Parts made from these steels are less prone to grain growth and are calcined in sections up to 50 mm. Nickel-silicon steel 60S2N2A has especially high qualities, it is easily annealed to the granular pearlite structure, has high ductility, and does not heat up when cooled in air after hot rolling.

Stainless steels are used for the manufacture of springs operating in corrosive environments and elevated temperatures (up to 400° C). Springs made of high-chromium stainless steels of the martensitic class (30X13, 40X13, etc.) are hardened at a temperature of 1000-1050 ° C in oil (springs made of steel 40X13 can also be cooled in air); the structure after quenching is martensite. Tempering after hardening is carried out depending on the operating conditions of the springs: at 550-500 ° C for springs operating at elevated temperatures, and at 300-350 ° C for springs operating at a temperature of 20 ° C (at a higher tempering temperature, the durability decreases to stress corrosion). The very high hardenability of these steels allows them to be used to produce springs with large sections.

Equipment and fixtures used

To make an elastic element, specialized equipment is required. These are winding machines. You can make a part on a regular lathe, but it will require additional equipment with special equipment. Medium and large series are produced on semi-automatic machines that operate with minimal operator intervention. You can also make a spring from wire by hand. This will also require special equipment.

At the next stage of machining, the ends are ground on face grinding machines. For single production or small series, this can be done with a grinding wheel.

Heat treatment is carried out using mandrels that prevent product deformation in specialized furnaces for hardening and tempering. Both operations can be done in a universal oven.

Equipment and fixtures used

For quality control, load installations and measuring systems are used. In case of single production, measurements can be made with a universal tool.