Replacing the muffler on a VAZ 2110

VAZ 2110 owners are quite lucky, since replacing the muffler is quite simple and does not require special skills or extensive experience. But you definitely need an inspection hole.

The replacement procedure sequence is as follows:

- The muffler is connected to the resonator through an O-ring on the pipe flare. Plus, the connection is compressed with a clamp, which consists of two parts.

- The clamp must be dismantled, so remove the ring. Since the O-rings used here are graphite, they should not stick to the metal.

- Now the old muffler can be dismantled quite easily.

- Be sure to check the condition of the suspension rubber bands located on different sides of the muffler body. They often end up stretched or covered with cracks. Rubber bands are quite cheap, so buy new ones and replace the old ones with them.

- The new muffler is first mounted on rubber bands, after which it is inserted into the same new graphite sealing ring between the flares. Use a clamp to compress the connection. Ready!

Reasons for muffler failure

The car muffler is made of strong materials, since it is practically not protected from external influences. Despite this, a bad road, an unsuccessful move over an obstacle or a stone rebounding into the muffler can lead to its breakdown under unfortunate circumstances. But due to mechanical stress, the muffler rarely fails; chemical corrosion often leads to its malfunction.

When the car is moving, the muffler, which is located on the bottom, operates in an aggressive environment. Water constantly gets on it if the road is wet, snow sticks in winter, and in large cities salt and other reagents that are sprinkled on the road to prevent ice formation can get on the muffler. All these factors lead to corrosion on the muffler. Simply put, the metal begins to rust and the strength characteristics of the muffler deteriorate. Over time, rust itself will make a hole in the muffler, or a breakdown will form due to mechanical impact on the weakened metal.

If the muffler is seriously rotten, it is customary to replace it, but in case of local damage, the unit can be repaired to maintain its functionality for some time.

Exhaust system repair

Any work related to repairing this car system will require you to install the car on an overpass, since the entire network of pipes runs along the bottom. If it is necessary to remove the entire system or part of it, a number of measures should be taken:

- Unscrew the bolts that tighten the clamp. They are usually covered with rust, making them very difficult to unscrew. Usually they are simply cut off with a grinder, replacing them with completely new ones during each repair.

- Next, remove the graphite O-ring. If it shows signs of damage, then it should also be replaced; below we will describe how to do this.

- After this, the muffler is carefully removed from the hangers; they are special rubber bands, which it is also advisable to replace with new ones during repairs.

- Next, a new muffler is mounted and secured with rubber bands.

- A graphite O-ring must be installed at the joints of the pipes.

- Next, the clamp is returned to its place, which must be tightened tightly with bolts.

Using a similar scheme, you can also repair the resonator or replace it together with the muffler

It is important to remember that it is also advisable to replace small fastening devices that have been subject to wear, they are inexpensive and will protect your car from troubles for such minor reasons

VAZ 2115 and VAZ 2114: removal of catalyst

The main difference between the first and the second is that the service life of the second equipment is slightly longer.

Be that as it may, the first time you will have to replace the catalyst already at 50,000 km.

Alas, our products cannot be released anymore.

The main reason is the poor quality of the fuel used to fill the car. The systematic formation of soot and deposits leads to premature wear of the part and its replacement.

Directly for the VAZ 2115 and VAZ 2114, catalyst removal and cutting are conventionally divided into two stages. These are two slightly different concepts, although they imply similar operations.

- So, after completing the repair task sheet, the car is handed over to the master;

- Depending on where the catalyst is located, a decision is made on the need for lifting on a hydraulic lift for ease of work. In our case with VAZ 2114 and 2115, it is installed directly on the exhaust manifold. There is no need to lift the car initially;

- To ensure the accuracy of the “diagnosis” we carry out a complete diagnosis on computer equipment. To do this, the master connects a number of digital sensors-scanners to the main components of the technical device and starts the motor. The operation of the power unit at different speeds is recorded and sent to the monitor;

- Based on the data received, the mechanic makes a decision on the degree of criticality of the breakdown, its location, and the number of parts to repair;

- In parallel, during the scanning process, other units and components are examined for operability;

- At the end of the diagnosis, the final result is displayed, with which the car owner is informed;

- Start dismantling the catalyst. To do this, use spanners and open-end wrenches set to “17”;

- In the engine compartment, unscrew the mounting bolts that hold the entire exhaust manifold body. First, you need to remove the air filter for ease of unscrewing;

- After the body is lowered from above, we raise the machine on a hydraulic lift to feed the lower mounting bolts. A total of seven such fastening nuts need to be supplied;

- We do not remove the manifold from the studs, but move to the junction of the resonator pipe and the rear part of the manifold. There is a fastening connection there, unscrew it;

- Now we completely remove the equipment assembly, having first disconnected the two oxygen sensors with plugs.

Preventing peeling

If a baby's eyebrows peel and crusts form, it is not enough to simply remove them, as they can form again. To prevent peeling, it is necessary to take preventive measures:

- Monitor the humidity in the room where the child is. It must be at least 70%;

Air humidification for babies

It is important not to overheat the child and not to put a hat on him when it is not necessary. In infants, thermoregulation mechanisms are not fully developed, and the body reacts to any overheating by overly active sebaceous glands; Nursing mothers need to exclude fatty foods and foods that provoke allergic reactions from their diet; Even if there are no visible crusts and no noticeable peeling, it is necessary to regularly care for the child’s skin, lubricating it with baby oil and cream after bathing.

You can also sprinkle baby powder, which absorbs sebum well and softens the skin.

Important! If the appearance of scales and peeling is associated with the use of children's cosmetics, you need to lubricate problem areas with natural olive or almond oil and stop using cosmetics. Although seborrheic dermatitis is not a dangerous condition or the result of improper care, it should be remembered that failure to prevent and treat it can lead to serious problems.

Bacteria and fungus love to settle on thick crusts. They can cause fungal infections and weaken hair roots.

Although seborrheic dermatitis is not a dangerous condition or the result of improper care, it should be remembered that failure to prevent and treat it can lead to serious problems. Bacteria and fungus love to settle on thick crusts. They can cause fungal infections and weaken hair roots.

Is it possible to drive a car with a faulty muffler?

It is sometimes difficult to determine defects in car components by external signs. Experts advise looking under the car at least once a month. A visit to the inspection pit and checking the underbody components will help identify various faults, including problems with the exhaust system.

Owners often wonder whether it is possible to drive a car with a faulty muffler. In practice this is possible, but it entails a number of unpleasant consequences:

- exhaust gases, leaking through the floor into the car interior, can cause various diseases of the driver and passengers;

- faulty exhaust increases the release of harmful toxic gases into the atmosphere;

- If the system is not repaired on time, it will cost even more: delaying the work will lead to damage to other components of the car.

For driving a car with a faulty exhaust there is a fine under Art. 8.23 of the Code of Administrative Offenses of the Russian Federation, since increased noise disturbs the peace of others.

Kinds

Hammerite paint comes in several forms.

With hammer effect

A coating designed for processing ferrous metals. When dried, an imitation of hammer chasing is formed on the surface of the product. This was achieved by adding aluminum flakes to the composition. The product perfectly hides unevenness in the metal; when touching up areas, the transition is almost invisible. Suitable for application to rust without pre-cleaning. Also, during the production of paint, wax is added to the composition, which additionally protects surfaces treated with this composition from moisture. This product is heat resistant, withstanding temperatures up to 80 degrees. Suitable for painting fences, gates, and various garden tools. The cost of the product is about 2,500 rubles per 2.5 liters.

Smooth glossy base for tinting

This coating is suitable for indoor and outdoor use. In addition to wax, the composition also includes silicones, which provide additional protection against corrosion. A large assortment of colors makes it possible to create the desired shade of paint. The paint gives the surface a glossy shine. The cost of the product is about 850 rubles per 0.7 liter.

Smooth glossy

The product already contains a color pigment. Suitable for both previously painted surfaces and rusty, unpainted ones. It has high resistance to such natural factors as negative temperatures, rain, snow. Does not fade when exposed to ultraviolet rays. Has a wide selection of shades. Here you will find 17 color options: from white to black. The cost of the product is about 2,000 rubles for 2.5 liters.

Gas exhaust system repair

The above-mentioned mechanical deformations often cause suspension ruptures. These elements are designed to hold detachable tubes under the bottom of the car. But for a burnout to form, it is enough not to notice the development of corrosion on the device. The protective system installed at the factory is not a panacea, and is rather of a formal nature. The accumulation of condensate and exposure to temperature changes can quickly damage the muffler.

Muffler repair

Other reasons include problems with ignition and unstable operation of the catalyst. The latter leads to the fact that the remains of unspent fuel enter the device, where they are exposed to high temperatures. As a result, explosive situations arise that lead to burnouts. Malfunctioning resonators can also lead to the need for exhaust system repairs.

Replacing the exhaust system gasket (muffler o-ring) on a Toyota Corolla 120

There was a time and place to replace the muffler gasket; most likely this was done as a preventive measure, rather than due to any external signs or manifestations of abnormal operation of the exhaust system.

The exhaust system gasket Bosal 256-305 was purchased for 117 rubles 88 kopecks, this was back in May 2014, now the cost is 276 rubles, but for some reason the name of the spare part was changed, now it is called “exhaust system sealing ring”. As usual, I bought it online on existential. The cost of the original gasket is prohibitive for such a spare part, something like 1000 rubles and kopecks.

Bosal 256-305 exhaust system gasket

The first time I changed it, I couldn’t unscrew the nuts, only as it turned out there were no nuts there, I wanted to saw it off with a grinder and order new bolts (I would have created even more problems with drilling out the remaining bolts), and it was inconvenient without a hole. As it turned out, the muffler mounting bolts need to be unscrewed and not the nuts; they are screwed into the pipe of the rear part of the muffler, where the threaded nuts are welded. So, when performing any work, you must first study the design so as not to create unnecessary problems for yourself.

Exhaust pipe fastening

This is what they like to do at service station 76 Express, Chita, st. Lenina, 149, they know nothing about the design of cars, but they happily take money for work that then has to be redone.

Toyota muffler mounting bolts and springs

The bolts came off relatively easily; I sprayed them with WD40 beforehand and everything came off easily. The condition of the muffler mounting bolts 90901-05026 and springs 90501-35035 is good, there is a little rust, so they cannot be replaced.

Old gasket

Next, we clean out the remnants of the old gasket; for convenience, I removed the muffler from one mount; it was simply inconvenient to remove it from the second.

Final exhaust muffler pipe

I cleaned the gasket with a chisel, it seemed to be soldered to the walls of the muffler pipe, apparently the gasket contains tin, under the influence of the temperature of the exhaust gases it melts (I assume so), then I went through it a little with a file.

Cleaned pipe Trying on a new gasket Muffler gasket in place

After I cleaned everything, I put the gasket in place and tightened the fastening bolts, lubricating them with graphite grease so that in the future they could be easily unscrewed if necessary. I started the car, everything works normally, nothing breaks or smokes anywhere, everything is sealed. In terms of time, replacing the gasket took about 30-40 minutes.

Just for fun, I looked at the cost of this procedure at a service station, they charge from 1000 to 4000 rubles, it’s terrible.

Replacing corrugations without a welding machine

If you need to replace the muffler corrugation temporarily, in unsuitable conditions, with your own hands without welding, then you can use two methods.

- The car must be jacked up on the right rear or raised on a lift or placed on a pit. Next, remove the old vibration damper by any means necessary. In its place, install a new corrugation and tighten the seats with clamps with a diameter of 48 mm. This DIY muffler corrugation replacement can last quite a long time.

- Remove the exhaust system completely. Drill 4.2 mm holes at the inlet and outlet simultaneously in the pipes and corrugation. Cut an M5 thread in the pipe, and drill holes up to 5 mm in the corrugation. It is necessary to carefully coat the outer diameter of the pipes and the inner seats of the corrugations with thermosealant. Screw in screws coated with sealant. Mount the system in place. After the thermosealant has hardened, it can be used.

Although these methods of attaching a corrugation to a muffler have shown good results, they cannot compare with a rigid welded mount.

What does the muffler consist of?

The main part of the exhaust system serves to absorb noise. On the Lada Kalina car, this function is performed by a pipe, which includes the muffler itself and its resonator.

The thickening is the resonator, the end is the muffler itself

The pipe has a completely sealed body, which is manufactured using the rolling method, that is, without the use of a welding machine. Thanks to this, the muffler is durable and does not corrode. And the resonator, which is also located in the pipe, consists of several closed chambers. These chambers are connected to each other by small tubes with holes in them. Thanks to this structure, the resonator can quickly smooth out all acoustic vibrations. In the latest modifications of the Lada Kalina, the inside of the resonator is lined with sound-absorbing material.

The three-chamber device allows you to reduce the noise level in the car

Unfortunately, the quality of mufflers for Kalina leaves much to be desired. Often their service life does not exceed 40–50 thousand kilometers. Therefore, the car owner has to think about which “gluker” to choose. Today, mechanisms for the Lada Kalina are presented at a variety of prices - from the cheapest to the most expensive. However, it is better to navigate the world of auto parts using the following parameters:

- muffler material: original spare parts are made of stainless steel or aluminum, they will last as long as possible and ensure high-quality exhaust removal;

- cost: you should not purchase a device below the 1 thousand ruble mark;

- weight: an original and high-quality “glushak” will weigh more than a fake, since the chambers are equipped with thicker walls and sound-proofing materials.

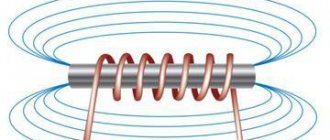

How does a car muffler work?

Car muffler device

Exhaust gases move through the exhaust system under high pressure, and their movement is accompanied by a sound wave that moves faster than the gases. The muffler consists of tubes of various diameters that are not connected to each other, and a steel mesh and sound-absorbing material are installed in the muffler body. Mostly fiberglass is used as such material. When moving, exhaust gases first pass through a resonator, in which their speed and, consequently, the noise level are reduced. Then they move to the main muffler, where they pass through a system of tubes in which the final reduction in speed and noise still occurs. Cars are equipped with a different number of mufflers: from 2 to 5.

How to get rid of the problem

The muffler gasket is usually beyond repair. If the muffler gasket (ring) is damaged, it will have to be replaced with a new one. Replacing the gasket is fairly easy.

- First of all, you need to get rid of the old gasket. You need to unscrew the two bolts that hold the flanges together. The bolts are usually rusty, making them quite difficult to remove. For this purpose, you can use a special tool (“liquid keys” or an angle grinder, if the situation is critical).

- After the bolts are removed, you will have to carefully move the resonator tube to the left side.

- The old muffler gasket is located on the resonator pipe. You will have to use a screwdriver to pry the product and remove it.

- Next, you need to use a metal brush and sandpaper to remove carbon deposits from the flanges.

- After this, the muffler gasket is replaced. The ring is installed on the resonator flange. The main muffler pipes are connected, and the flanges are screwed together using a clamp that has spring-loaded bolts that come in one set with a gasket.

It is necessary to replace it in the event of a breakdown, because otherwise the car interior will be filled with fumes. Also, if a malfunction occurs, carbon deposits will begin to form under the very bottom, which will be very difficult to eliminate.

Muffler Troubleshooting

With some skill, you can independently carry out work to eliminate problems in the muffler quite quickly if you follow a clear sequence of actions. Repair can be divided into several stages:

- Removing the muffler.

- Visual inspection and troubleshooting.

- Direct repair work.

- Reinstalling the muffler.

No complications should arise during operation, and problems can be eliminated using one of the methods described below.

Muffler repair by cold welding

Recently, the cold welding method has become increasingly popular, allowing you to quickly and efficiently patch any hole. Cold welding is a universal composition that hardens very quickly and has excellent resistance to oil, gasoline and other aggressive substances.

Cold welding comes in two forms:

- Liquid. To create a high-quality patch, a liquid mixture is used: it becomes a shell and fastening material for reinforcing elements. The result is a reliable connection to the part.

- Plastic. This composition, in addition to the high quality of the connection, is characterized by excellent adhesion, which allows repairs to be carried out on poorly prepared surfaces.

To ensure high-quality repair of a muffler using cold welding, you must follow the following operating algorithm:

- First, the damaged area is treated with sandpaper to create a flat surface on which it will be easier for the material to adhere.

- Next, the cleaned area must be degreased. Gasoline or alcohol are good for these purposes.

- After preparing the area, you need to take the required amount of adhesive and bring it into working condition according to the attached instructions.

- The finished mixture is applied to the damaged area and leveled. The work must be done as quickly as possible: sealants begin to dry within a few minutes after application.

- The final stage is drying. The finished part must be left for some time to allow the glue to dry completely.

Repairing a muffler by cold welding is a quick and reliable way to get rid of small burns or holes in the part, but in case of serious damage it is better to use more reliable methods.

How to Replace a Graphite O-Ring

The graphite sealing ring of the muffler has become an engine part that allows you to isolate the gas joint in the area of connection between the main (or rear) muffler and its middle part (additional muffler) - the resonator. It is also designed to ensure smooth movement of the mutual movement of two connected pipes.

To carry out this repair you will need:

- new o-ring;

- lift or overpass;

- liquid key product;

- wrench with 13" head;

- lubricant for high-temperature zones - will be used on the brake caliper guides;

- wire brush or emery to remove rust;

- personal protective equipment - gloves and goggles.

There is no provision for replacing this part; if the o-ring is burnt out, it simply needs to be replaced. This process is quite simple and does not require special knowledge:

- It is enough to unscrew the bolts connecting the pipe joints. Often these flanges (spring-loaded bolts) become covered with rust over time, so you need to have a special tool on hand to facilitate the unscrewing process, for example, “liquid wrenches”. If the car is quite old, and you are unable to overcome rust, then you can cut them off with a grinder and then replace them with new ones.

- When the flanges are removed, all you have to do is tilt the resonator pipe and remove the damaged O-ring from its pipe. Sometimes it sticks tightly to the pipe, so pry at it with a screwdriver and it will come off.

- If the flanges have been safely removed, then before putting them in place, clean them with sandpaper or a brush to remove rust and carbon deposits.

- Next, install a new o-ring on the flange of the resonator itself and connect the muffler pipes.

- The last step is to fasten the pipes with a clamp and bolts, which most often come with a new ring.

Be careful when working. Although the process is quite simple, when removing the old o-ring, it may rupture, especially if it has already become fairly stuck to the pipe

The ring, made of metal-ceramic, is therefore fragile and can shoot off splinters, so protect your eyes with special glasses.

If you do not promptly replace the muffler sealing ring, then you will constantly breathe exhaust fumes in the cabin. In addition, due to its breakdown, an incredible amount of soot will accumulate under the hood, which is extremely difficult to clean; this process is long and expensive.

If you are having problems with your car's exhaust system, then it is best to have it examined and repaired as quickly as possible. To do this, it is not at all necessary to involve specialists, since due to its structure, the exhaust system of any car is very easy to use. It is easy to disassemble and change parts, so whether it is replacing an entire section or an O-ring, you can do the job yourself

The main thing is to follow all safety precautions, carry out replacement according to the instructions and work with a car that has already cooled down after driving

Moscow Automobile and Highway State University, Moscow. Level of education: Higher. Faculty: AT. Specialty: Special engineer Cars and automotive industry. Experience in the automotive industry (master consultant...

4 comments

- Anton says: My exhaust pipe manifold is getting very hot - it’s under my seat, it’s glowing so much that it’s scary to stick your hand in. How can we insulate it inexpensively and effectively?

Miroslav says:You can ask plumbers - they use fire-resistant tape to wrap pipes. In theory it should help. By the way, due to this, the power will increase - I tested it from my own experience, there is a noticeable increase in horses.

Anton says:

I don’t understand why the horses are added - what is the connection with the collector temperature?

- Stanislav Vyacheslavovich says: Good afternoon. The thermal insulation of the manifold retains more energy in it, which increases its efficiency and has a positive effect on the functioning of the turbocharger.

The muffler is broken

The exhaust system of a car is the most unprotected part of the car. It is exposed to external influences and car enthusiasts often have to repair it. A breakdown of the system is not just an unpleasant knocking sound and other “delights” such as a decrease in car power, jerking of the car, but also the danger that toxic fumes coming out of the engine can leak into the cabin and poison people. In order for your exhaust system to function properly, it, in particular, and the car in general, must be systematically checked and taken for maintenance. If you neglect this, you risk getting into an accident at the most inopportune moment. Don't forget that muffler damage is on the list of ten reasons why you have to call a tow truck.

Corrosion protection

The muffler often suffers from fading of paint, which is why corrosion quickly renders it inoperable. One of the effective ways to protect the surface of the exhaust system from corrosion is to paint it. It should always be remembered that the temperature of the gases leaving the exhaust pipe is usually 420–760 °C, and the surface temperature of the exhaust pipe is 200–540 °C. Therefore, only heat-resistant, silicone varnishes and enamels are suitable for painting.

To paint the “glushak”, you need to proceed like this:

- First, remove the muffler and prepare it for painting (to do this, you need to thoroughly clean it of all dirt and oil, degrease it and dry it well).

- Inspect the dried muffler, not missing any areas where the factory coating has peeled off or oil stains.

- If you do find oil stains, take a rag soaked in gasoline and wipe them thoroughly.

With peeling factory paint, proceed as follows:

- Take a strong knife or putty knife and remove the previous coating.

- If you notice rust on the exhaust system, remove it immediately using coarse sandpaper or a special rust remover.

- After these manipulations, apply a layer of primer.

- After the primer has completely dried, paint as stated in the instructions for the paint you purchased.

- Then let the muffler dry a little, install it back under the car body and let the engine run for a few minutes so that the muffler warms up and the paint dries.

There are times when the rust has penetrated too deeply and it is impossible to get rid of it. If this is your option, then you should treat the muffler with a rust converter.

There are alternative ways to protect the exhaust system:

- First you need, as for painting, to clean the muffler and exhaust pipe from dirt, oil and rust, and then apply a thin layer of graphite lubricant. You can do it as follows:

- Let's go to the nearest computer store.

- We ask them to process the powder from the printer.

- Mix it with a small amount of grease.

- Then you need to coat the surface with the mixture, place it on stands and start drying with a hair dryer, blowing from the side of the resonator.

Until the grease completely burns out, the coating will not stop emitting a pungent odor, so carry out all manipulations in a respirator and outside, or at least in a well-ventilated room (garage).

The muffler is leaking

You carried out an inspection and found no signs of corrosion on the muffler, but saw damage. Unfortunately, this happens, because the exhaust system is the most unprotected part of the car; it is affected by both mechanical influences (for example, a bouncing stone or unsuccessful parking of a car) and chemical ones, in the form of aggressive chemical compounds, salts and even the external environment. But there are also obvious reasons for the formation of a hole: perhaps the muffler is made of poor quality material.

Muffler burnout

If you are faced with such a nuisance as a muffler burning out, then do not rush to think that the problem lies inside the car. Novice car enthusiasts believe that mufflers burn out due to too intense exhaust emissions created by the internal combustion engine. But often this is not the case. Today, many car manufacturers, even well-known brands, produce cars with low-quality parts, without normal processing, which are highly susceptible to chemicals and the environment.

Example of a burned out muffler

Obviously, the main reason for system burnout is various types of environmental influences on the part. If you treat your car irresponsibly, it is stored in rain, snow or scorching sun, then you should not be surprised that part of the exhaust system quickly burns out, because this is facilitated by a natural chemical process in this case - metal oxidation.

Another common reason for part damage is idling the car and driving short distances. Do not forget that sudden temperature changes are detrimental to the muffler. At low temperatures, condensation forms in the muffler, which has a destructive effect on all metal except stainless steel.

Exhaust system structure

By design, the exhaust system is multi-tasking; each individual component does its own job. On the way to the exit, the exhaust first enters the converter, which is designed to cool the gases and extinguish the remaining unburnt fuel. Among car enthusiasts, it is popular to replace this part with a flame arrester, which promises to increase engine power and last much longer, but at the same time you need to be prepared for an increase in fuel consumption by an average of 15%.

All parts inside the system are bolted together and behind which a graphite O-ring is attached, they help prevent dirt from getting inside and gases from escaping outside the pipes.

Graphite O-ring

- An exhaust manifold. The suspension part consists of separate pipes that fasten each individual combustion chamber across all cylinders to the converter. Usually the part is made of cast iron, sometimes stainless steel, but there are also ceramic models. Cast iron is more resistant to high temperatures, but when condensation occurs, it undergoes corrosion, which is not a problem for stainless steel. Ceramic is much lighter, but it cracks due to prolonged use at high temperatures, so it needs to be changed much more often.

- A connection converter or popularly known as a “neutralizer”. It consists of specific elements made of ceramics - honeycombs, on the top of which there is a thin layer of a special platinum-iridium composition. It allows the reaction of chemicals with exhaust to form nitrogen oxide and pure oxygen, which will be used to burn out the remaining fuel in the gas. As a result, a nitrogen compound and an admixture of carbon dioxide enter the exhaust pipe.

- Muffler. A device that is designed to reduce noticeable noise during the removal of exhaust gas. This part consists of the following structural elements:

- connection pipes;

- the muffler itself;

- long exhaust pipe and one or more tips.

Exhaust system The muffler consists of separate chambers, so the mixture of gases passes through each of them in turn, thereby being cleaned. The gases are muffled and the sound becomes quieter. The gases then pass into the exhaust pipe. There can be from 1 to 4 such pipes, depending on the modification of the car. The tip acts as the outermost section, its task is to remove gases to the outside.

The muffler body can also be made from several steel options:

- ordinary steel will last up to 2 years;

- an aluminized muffler will last longer, 3-6 years;

- Stainless steel will withstand 10 to 15 years of use.

Various modifications of exhaust systems and their individual elements are installed on different car models. Thus, on cars equipped with turbocharged engines, smaller mufflers are installed. On cars with naturally aspirated engines - larger ones. This is due to the fact that the turbine itself effectively uses exhaust gases during operation, so the amount of them that enters the exhaust network is much less.

Homologated exhaust system

Replacing the cabin filter and oil

For dismantling you will need a set of screwdrivers and a TORX wrench. First, pry off the plug, then unscrew the bolts. The hood is opened and the grille is removed. The cabin filter is located under the grille. The lid slides to the right and the filter is removed.

If necessary, clean the seat with a vacuum cleaner. Install the new filter by performing the steps in reverse order. It will take no more than 20 minutes to dismantle and replace this part. Upon completion of the repair work, turn on the heating unit. Foreign odors should disappear.

An equally important process is changing the oil in the Lada Kalina engine yourself. This process is carried out using a 17 key. For engines of 1.6 and 1.4 volume, about 3.5 liters of new oil will be required. First, open the hood of the vehicle. Then unscrew the filler cap. This is necessary to depressurize the corresponding system. Under the car body there is a drain plug, which must be unscrewed using a 17 key. A container is installed under the car into which the waste substance will drain.

Oil level control

The next step involves removing the oil filter. It must be removed carefully, placing some container under it. Then enough oil is poured into the new unit to keep it full. If the waste liquid leaves the system, you can tighten the drain plug. Install a new filter. After pouring oil into the system, check the fluid level. A probe is used for this. If necessary, add liquid. The process of changing the oil and the corresponding filter on Kalina takes 30 minutes. Upon completion, you need to start the engine and wait until the oil sensor lamp goes out.

Do-it-yourself repair of a Lada Kalina car is also required due to the uncomfortable interior. In this case, the trim is replaced and the vehicle is tuned. To eliminate creaking and engine noise in the cabin, you will need to lubricate the doors and check the engine's performance. It is a rigid structure, so to improve or replace it, you will need a car repair manual.

Main reasons

It is worth understanding that a change in the color of exhaust gases, their causticity and density can occur for several reasons:

- Malfunctions in the cylinder-piston group and gas distribution mechanism, read more detailed information on this topic -;

- car, for example VAZ 2109, but how to regulate the ignition;

- Injection control systems;

- Malfunctions, for example, a VAZ 2114 car;

- A number of other reasons.

The color of smoke from the exhaust pipe may also change depending on whether oil or coolant has entered the engine cylinders, engine overheating, fit of piston rings, etc.

All faults that arise are interconnected. For example, if the cooling system fails, then as a result the engine overheats, and this entails a number of other malfunctions, usually this is stuck rings, etc.

Replacing a return flow muffler with a direct flow one with your own hands

When manufacturing a direct flow, it is advisable to use the positive properties of several types of structures.

Reasons for replacing a standard muffler with a direct-flow muffler

Car owners change the factory muffler to a direct flow one for several reasons:

- obtaining an increase in engine power;

- subjective improvement of acoustic parameters of the exhaust;

- increasing the aesthetic parameters of the car;

- complete modernization of the exhaust channel;

- The installed muffler has failed.

Tools and materials for work

A direct-flow muffler is often purchased, but for lovers of tools and an insatiable thirst for creativity, we recommend making it yourself. It is preferable to make parts from stainless steel with a thickness of 0.8–2.0 mm. Select ferrous metal blanks with a thickness of 1.0–1.5 mm for the case, the rest 2.0–4.0 mm to avoid premature burnout of parts, and also use standard blanks. For the body, use a suitable size: a fire extinguisher, a thermos, an empty gas or scuba cylinder.

To fill the muffler chamber, non-flammable porous material or a combination of them is used:

- basalt or other mineral wool;

- fine mesh metal mesh;

- metal mesh for the kitchen;

- metal shavings.

- angle grinder (grinder);

- drill or drilling machine;

- welding machine;

- consumables: metal discs for grinders, drills, electrodes, etc.

Reworking an old muffler

- We dismantle the old muffler, disassemble it using a grinder, leaving the body parts and the inlet pipe. While preserving the partitions, we drill holes in them for the passage of exhaust gases. The cameras further reduce exhaust volume.

We cut out everything that is not needed from the old muffler

We perforate the inner pipe in an accessible way. The diameter of the perforated pipe is equal to the diameter of the inlet pipe or more up to 30%.

a small number of small holes will help preserve the rich bass rumble from the engine when exhausting

Keep in mind that mineral wool fibers will be “blown out” of the chamber faster through large holes and grooves.

Stainless steel helps to increase the service life of parts and mechanisms several times

In the future, the diameter of the inner pipe can be reduced by simple manipulations, but increasing it is disproportionately more difficult.

cut the length of the pipe to the required size

We put metal mesh for the kitchen in place of the perforation of the pipe.

cover the internal perforation with fine-porous non-flammable material

Wrap the kitchen mesh tightly with metal mesh in 1-3 layers. We fix the mesh with annealed steel wire with multiple twists or crimp it with several clamps.

We enhance perforation, reducing its permeability to mineral wool

We coordinate and clean the welding points, weld the perforated pipe into its regular place.

We carry out welding in compliance with all safety rules

We fill all free space inside the muffler tightly with the selected filler.

the presence of several chambers contributes to greater functionality of the muffler

Working with mineral wool requires personal protective equipment.

the absence of a metal mesh between the holes and the wool will lead to a faster “blowing” of the wool out of the muffler

We grab the edge of the “lid” of the body with two or three tacks to avoid displacement and weld the body.

To protect against corrosion and give it an aesthetic appearance, we paint it with heat-resistant paint in your favorite color.

To make the muffler last longer, we drill one or more holes with a diameter of 1.5–2.0 mm in the housing to drain condensate. To determine the lowest point, the car must be horizontal.

Changing the resonator

It is also advisable to replace the resonator on a VAZ 2110. This is done after changing the muffler.

New resonator for VAZ 2110

The work of replacing the resonator is performed in the following sequence:

- The resonator is secured to the muffler with a crimp clamp with an O-ring.

- It is attached to the neutralizer using a floating flange consisting of two bolts and a flare.

- On the opposite side of the element there is a so-called fist.

- Removing bolts is often quite difficult. So that you don't have to suffer, just cut them off with a grinder and buy new bolts. This is the simplest solution to the problem.

- If you couldn’t get a grinder, use a liquid key. This is a popular product among motorists - WD40 or its analogues. Treat the bolt attachment points with this compound, wait a while, after which the bolts should come off.

- After removing the bolts, remove the muffler clamp.

- Remove the resonator from the suspension rubber bands. Check the condition of the rubber bands. If they are worn out, replace them with new ones.

- Take a new resonator, secure them to rubber and connect them to the muffler so that the pipe leading to the muffler from the resonator is parallel to the ground.

- If you notice wear, burrs, or traces of rust on the neutralizer fist, be sure to coat the connection with sealant. Moreover, it must be a high-temperature sealant.

- Armed with new bolts and nuts, tighten the catalytic converter and resonator flanges.

- The neutralizer is fixed to the resonator with two bolts using a flange connection. The fastening occurs to the states, but there is a receiving pipe, using a spring-loaded connection and two flares. The space between them contains a sealing ring made of graphite or metal asbestos.

Read more: Block for VAZ 2108

Making the exhaust quieter

If you want to forget about noise and make your exhaust system even quieter, you will need some tools:

- welding machine;

- angle grinder with a set of discs;

- a workbench equipped with a vice.

There are two ways to improve the exhaust system: insert a factory resonator between the muffler and the resonator, or make one yourself. And also do not forget that the thicker the walls of the part, the less noise there will be.

To weld an additional resonator you will need to perform the following manipulations:

- Make two halves of a barrel from a steel pipe with thin walls or from sheet metal.

- Weld and make holes in the pipe of the future resonator.

- Connect the body parts, place the perforated pipe inside the future barrel and weld it.

- Place sound insulation (glass wool or mineral wool) into the cavity between the pipe and the housing.

- Carefully weld the transverse edge of the muffler.

At the end of the work, treat the seams, clean and degrease the new device and cover it with heat-resistant paint.

After changing the design, its weight will increase, therefore, the pressure on the motor will increase. After all the work, be sure to carry out additional tests of the car to avoid trouble.

Video: how to replace the resonator

How to replace the Lada-Kalina muffler with your own hands

You can replace the “glushak” in two ways: contact a service center or do everything yourself. In the first case, you will have to do practically nothing: you will only need to take the car to a service station and pay a certain amount for repairs. If we consider the second option, then we will need to take care of preparing the tools that will be needed during work.

Tools and materials

To carry out repairs you will need:

- WD-40 type lubricant;

- wrenches 13 (socket, socket);

- hammer or flat screwdriver;

- new muffler.

Choosing a muffler and its cost

Finding a new part is not so easy. Despite all the variety of elements that the modern automotive market offers, it is quite difficult to buy a truly high-quality product. There is a high probability of purchasing a part that was made in an unknown location or manner. The only advantage of such a muffler is its low cost, but the service life compared to the factory product will be much shorter. Therefore, in order to buy a good quality element, you need to know what parameters to rely on when choosing.

First, attention is paid to the material of manufacture. Factory muffler made of stainless steel or aluminum

The first option is quite difficult to find, but it is quite possible to make it to order. Any other material in this case will last less. An important parameter is cost. A high-quality part cannot cost less than 1 thousand rubles. Although you can find a price of 5 thousand rubles, which is clearly overpriced. The price of an outright fake will fluctuate around 500 rubles.

To ensure that the muffler lasts as long as possible, when purchasing, you should choose a part made of stainless steel or aluminum

In addition to cost and material, attention should be paid to the weight of the muffler. A worthy part must be massive, which is due to the presence of compacted walls and noise-absorbing material inside

If your goal is to purchase a good quality muffler, then it will be difficult to find one in the car market. It is better to contact a service center or a store with original spare parts to purchase.

Do-it-yourself muffler corrugation repair without welding

The muffler corrugation is designed to reduce vibration loads on welds and elements of the suspension system. However, such an element is exposed to high temperatures and mechanical damage. The corrugation is a small elastic element, which is covered with a metal protective mesh and installed in the exhaust pipeline. The corrugation is not repaired, but replaced entirely, especially since the price of the muffler corrugation is low. But if you don’t have a welding machine at hand or it’s impossible to get to a car service center, then it can still be repaired. The most common occurrence in which a muffler corrugation is repaired is a violation of the integrity of the weld. If you repair the corrugation yourself, you will need to purchase an exhaust system repair kit or cold welding, fiberglass and epoxy resin. You can apply a “tourniquet” in the seam area, but it is worth remembering that this operation is temporary, so the best option would be to buy a new corrugation and weld it into place. The procedure for applying the tourniquet is as follows:

- It is necessary to clean the desired place on the weld with coarse sandpaper;

- Degrease the repair area;

- Prepare the repair composition according to the instructions on the package;

- Apply the mixture liberally to the weld and allow it to dry.

- Impregnate fiberglass with epoxy resin and screw it tightly to the diameter of the weld;

- Apply another layer of cold welding on top of the fiberglass in a circle and allow to cool.

In this way, a broken weld can be temporarily repaired. Often, when repairing a muffler, the corrugation is also replaced.

Replacing the exhaust manifold gasket

The process of replacing a sealing element when it fails (the gasket has burned out) is relatively simple. The scheme for dismantling the old and installing a new seal is as follows:

- open the hood of the car;

- remove the air intake and carburetor, under which the exhaust manifold is located;

- dismantle the thermal screen covering the manifold (in old carburetor cars it may not be there);

- unscrew the bolts that secure the manifold to the exhaust distribution pipe, and then the bolts connecting it to the engine block.

Replacing the exhaust manifold gasket on a VAZ-2114 is a very complex procedure and requires certain knowledge and experience. So, not all experienced car enthusiasts are able to do this correctly. In addition to the fact that exhaust gases exit through the exhaust manifold, it is also responsible for the normal operation of the engine, since a lambda probe is installed on it.

Video about replacing the exhaust manifold gasket on a VAZ-2114

Replacing corrugations with a welding machine

Nissan X-Trail RedBull Logbook Changing the oil and filter in the automatic transmission

Replacing a vibration compensator by welding the pipe and the seat is the most reliable and durable way of fastening metal parts. The connection does not depend on the reliability of clamps, screws and sealants - only on the quality of welding.

Replacement algorithm using the Opel Zafira as an example:

- unscrew the nuts from the manifold studs;

- remove the clamp from the side of the exhaust pipe;

- cut off the corrugation stream with a grinder;

- clean the cut area;

- weld the corrugation;

- install the structure in place.

Before installing the updated exhaust system element in place, it is necessary to purchase and install new muffler rubber bands and additional gaskets installed under the resonator and exhaust manifold.