has 20 years of experience working with equipment and technologies based on the use of plastics in the food, cosmetics, pharmaceutical, electrical, automotive, construction and other industries. In 2022, we built our own production complex in Minsk with divisions: - design, engineering, operational and technological, for the development of designs and design documentation, prompt feedback from customers and organization of the technical process; — tooling for the production of technological equipment (precision metalworking), supporting the full cycle for molds, dies and fixtures: from metal blanks to testing, obtaining prototype castings (or trial series) and delivery to customers; — for the production of serial products: plastic products; — logistics: picking, packaging and warehousing.

Main areas of our activity

Design and production of molds for casting and blowing

We produce molds of any complexity for injection molding of polymers, for extrusion blow molding, for blowing PET containers. Along with the production of molds/equipment for any purpose, we have a number of specializations

, which have accumulated many years of experience and extensive interaction with our regular customers. Among them:

Injection molds

— PET preforms

in a wide range of types, weights and purposes;

— disposable cutlery

(forks, spoons, knives, stirrers);

— closure elements

(stoppers, lids, caps, handles, valves, auxiliary and decorative elements for them);

- stationery

(vertical and horizontal trays, pencil holders, jars and boxes for gouache and watercolor paints; -

components for building finishing and decoration

(corners and connectors for PVC skirting boards, plugs, overlays, etc.); -

body parts of arbitrary designs

, including transformable ones, to obtain an assortment range on one form using form-building replaceable parts.

Blow molds

— from PET preforms

(bottles, including those with a side handle, cans, kegs, etc.) for bottling and packaging: water, carbonated drinks, beer, alcohol, juices, dairy products, vinegar, vegetable oils, sauces, syrups, honey, bulk: tea, spices, salt, household and automotive chemicals, technical.

liquids, detergents (except alkaline solutions), cosmetics, varnishes, paints, medications, etc.; - made of polyethylene, polypropylene, etc.

(bottles, jars, flasks, canisters of all types) for bottling and packaging: milk, kefir, ketchup, mayonnaise, detergents and cosmetics, household and auto chemicals (including alkali-containing solutions), creams , machine oils, paints and varnishes, medicines, bulk products, etc.

Equipment supplies

We supply special equipment and peripherals for casting, extrusion, blow molding, recycling, its technical support and service, and provision of spare parts from a hot warehouse.

Manufacturing Services

We offer our plastic molding services at our site in Minsk for mold customers who do not have their own polymer processing cycle. In this case, clients, on a contractual basis, transfer the manufactured technological equipment to us for safe storage and operation, do not bear any costs or risks for routine (including post-warranty) maintenance, pay only for the finished product at a pre-agreed price, agree on a schedule for the production and delivery of goods parties.

Development of the serial production direction

We have launched a new project to produce plastic products developed under the PTL brand.

About Plastic Technologies

Types of fastenings

The clamps are made of durable plastic that is resistant to aggressive influences. This ensures the required performance indicators and an acceptable price for the material. Less commonly used are elements that are parts of the formwork, after removing which the resulting cavities must be filled with concrete. There are different types of clamps based on the location of the reinforcement they hold:

- Supporting – for fixing the reinforcement frame horizontally, for example, a cube, a chair;

- Wall - designed for fastening vertical conductors, for example, an asterisk;

- Universal – combines the characteristics of horizontal and vertical options;

- Special - used in cases to create cavities in a concrete monolith, for example, tubes and plugs.

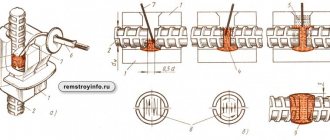

"High Chair"

This is the most popular type of clamps for horizontal fittings. It is used when pouring floors, slabs, and other elements with large loaded surfaces. The universal shape of the fastener for “chair” type fittings is a cylinder with four cut grooves and upper crossbars. The standard design has four legs, the reinforced design has five. This type reliably holds metal elements with a diameter of 4-16 mm, allowing a layer of mortar of 15-40 mm above them.

To use clamps on loose soils, they are supplemented with a base element that prevents them from sinking. It is also used in cases where waterproofing material is laid under a metal frame so that the legs do not break through it when pouring. There is a modernized version of this element, called “herringbone” with 4 inclined jumpers, with the possibility of laying protection with a thickness of 20 to 35 mm.

"Cube"

“Cube” fastenings are designed for fastening reinforcing elements of foundations, horizontal floors and bridges. Its body can be installed so as to obtain the required distance between the frame elements and the required protective layer. According to SNiP standards, depending on the diameter of the metal rod, 6-10 attachment points are installed per square meter.

Several sizes of the “cube” clamp are offered for horizontal fittings, depending on the connectors and the thickness of the plastic wall. By installing it on different faces, you can achieve a protective layer thickness of 35-80 mm and fix a rod with a diameter of up to 40 mm.

"Cone"

Clamps for cone-type reinforcement are installed at the ends of the stop tubes through which the tie bolts pass and rest against the formwork, preventing solution from entering the tube. Failure to use these embeds will result in the loss of tie bolts, which will fall into the thickness of the hardened concrete. For each of these bolts you will need two plastic tips, which are removed after dismantling the formwork and can be reused. You can avoid conical clamps by using reinforcement with clamps to hold the formwork, but this will cost more.

"Rack"

The design of the “stand” reinforcement clamp is similar to a “cube”. It has a cylindrical shape that can withstand heavy loads. It is well suited for the lower rows of reinforcement, for loose soil; it is additionally equipped with a “base” element, which reduces the pressure on the surface.

The “stand” reinforcement clamp is designed for horizontal surfaces and is attached to reinforcement with a diameter of up to 16 mm. With its help, you can create reinforced structures with a protective layer of 12-40 mm. Using special fasteners, the rack can support several rows of reinforcement cage, while maintaining the overall level of the structure. Material consumption, as for other horizontal models, is 6-10 elements per square meter.

"Star"

Star reinforcement clamps are of the vertical type, but can also be attached to horizontal reinforcement levels. It snaps onto a metal rod and, in accordance with its own diameter, allows the application of a uniform protective layer 15-75 mm thick.

This type of fastening securely snaps onto reinforcement with a diameter of up to 22 mm, suitable for walls, columns, and other concrete structures with vertical surfaces. Consumption, depending on the type of surface, is from 4 to 8 elements per square meter.

Multi-level

Clamps for multi-level fittings are gaining popularity due to their versatility and low price. Technologically, they are simple clamps connected by special fasteners. This design allows you to strengthen several levels of reinforcement, connecting them to each other, increasing the strength and reliability of the monolith by increasing the protective layer. The consumption of embedded elements remains standard - up to 10 per square meter.

Elements of the “chair” or “cube” type are often used as multi-level clamps. This is possible when they are equipped with fastenings that allow them to be built up into several floors, like a construction set. The clamps fixed in the grooves easily withstand increased loads, do not move or burst when pouring concrete.

Do-it-yourself reinforcement clamps

In private construction, when performing small volumes of work, it is possible to use homemade clamps for the protective layer of reinforcement. Often, available materials such as bricks, wooden supports, stone, and tiles are used for this.

The worst option is wooden elements that are too hygroscopic. They change shape, as a result, the integrity of the reinforcement frame is violated, and over time they collapse, leaving voids unforeseen in the design. After this, cracks appear in the concrete and its strength decreases significantly. Another unsuccessful material is plastic bottles, which deform under load.

Previously, separately cast concrete elements in the form of cubes or parallelepipeds were used to create a protective layer. They adhere well to the monolith, maintaining its strength characteristics, but cannot secure the reinforcement firmly enough, often shifting during pouring, preventing the load from being evenly distributed. Therefore, they are now being abandoned, installed only in extreme cases.

High-quality hand-made reinforcement clamps are almost as good as industrial ones and are made from cheap improvised materials:

- Plastic pipe. It must be strong enough, resistant to corrosion, and easy to handle with tools. This allows you to make the necessary holes and clamps for fittings in it.

- Plastic socket boxes with specially made cuts.

- Metal rod. It is used in private construction with small loads on reinforced concrete mass. Among builders, this species was called “frog”.

- Structures made of metal rods and rings. This is one of the types of “frog” - a rod is inserted into the ring and the solution is poured. After this, the entire concrete monolith is made.

Protective layer of concrete and its functions

The distinctive properties of reinforced concrete are explained by the unique combination of physical and chemical properties of its components. The metal frame works in tension, while the concrete mass has high compressive strength. They have the same coefficient of thermal expansion. The hardened solution turns into an array of artificial stone with an alkaline environment, which becomes an excellent insulator for steel frame elements from corrosion. This insulation is effective when, after concreting, the distance between the reinforcement bars and the surface of the finished product is sufficient to prevent the penetration of water, oxygen, and other aggressive substances through the pores of the concrete to the surface of the metal products. The minimum value of this distance (usually 10-40 mm), called a protective layer, depends on the conditions of further operation of the reinforced concrete product or structure and the influence of various factors.

Compliance with the protective layer is a guarantee of the strength and reliability of the structure being built.

Building codes define the requirements for the thickness of the protective layer. After all, a thick layer increases the load on the frame, increases the weight of the structure and is more expensive, while a thin layer partially loses its functional characteristics. Determining the required concrete thickness is influenced by:

- type of structure being built (wall, column, staircase, foundation, ceiling);

- diameter of the reinforcement used;

- external environment and climatic zone (temperature range, maximums and differences; humidity; contact with the ground and others).

According to the standards, in the most common cases, the following recommendations on its thickness are relevant for regulating the protective layer of concrete:

- rooms with normal or low humidity - at least 20 mm;

- wet rooms without waterproofing – 25 mm or more;

- unprotected external surfaces of buildings - at least 30-40 mm;

- part of the structure buried in the ground that does not have additional protection – 40-76 mm;

- foundation – from 40 mm;

- floors up to 25 cm thick - from 12 mm; more thickened - from 17 mm.

Special magnetic control sensors help to find out the actual depth of reinforcement in finished reinforced concrete structures.

What is important for correct consumption

The installation of clamps dictates their exact consumption. Here, the factor of the total weight of the entire reinforcement frame is taken into account, depending on its different thickness, the use of metal or composite materials. The possible movement of workers during reinforcement installation is also taken into account, which requires strengthening the hardness of the clamps and increasing the number of their use.

According to SNiP standards, the optimal consumption is approximately 6-10 copies of chairs for 1 square meter.

When ordering the rental of floor formwork from the monolithic construction company “Dionysus”, you will definitely be provided with qualified engineering calculations from professionals, completely free of charge, for the entire set of necessary elements.

Why do you need to fix the reinforcement?

As you know, reinforced concrete consists of a metal “skeleton” and concrete. Foundations, floors, complex structures such as bridges and dams - all this is formed from a concrete mixture with an internal steel frame.

The design is durable, withstands significant compression and bending loads, resists the forces of frost heaving, shrinkage, temperature changes and other negative factors.

The weakest point of reinforced concrete is the metal itself. It is subject to severe corrosion when interacting with water and wet soil. To prevent contact with moisture, before pouring the foundation or floor slab into the formwork, embedded elements are first installed.

They are designed to raise the frame and create a concrete layer of at least 5 cm. The height and width of the metal “skeleton” should be 5 cm less than the edges of the structure, so that the same protective “cushion” is formed on top and on the sides.

The trouble is that the elements designed to protect the reinforcement are characterized by uneven edges, instability and can shift at any time, disrupting the spatial arrangement of the frame.

Another problematic issue is the connection of reinforcement frame elements into a single whole. For this, two methods are used - knitting intersections using tying wire with a diameter of 2-4 mm or welding.

The first is considered more reliable; for the second, only certain types of hot-rolled low-carbon metal are used, but it has been proven that the weld weakens the rigidity of the metal at the joint.

In addition, accurately calibrating the distance between reinforcing chords is difficult and time-consuming, so the popular method is used - “by eye”. Of course, it does not guarantee a perfect result.

To avoid such incidents, manufacturers of products made from polyethylene plastics have offered builders the best option - inexpensive reinforcement clamps for different rod diameters. They are available in various shapes and thicknesses. Developers quickly appreciated their convenience, especially for large or extended structures.

Choosing fasteners - advice from an expert

In my 10 years of practice in monolithic construction, I quite often encountered the problem of defective fasteners. After installing them under the reinforcing mesh, and then stepping on it, the stands simply scattered to the sides. They broke in half, and the mesh was lowered onto the formwork. There was also a case with the “star” fasteners; during installation on the reinforcing mesh, they simply flew apart, half the bag was simply thrown into the air. The problem was low-quality plastic; it was fragile.

When purchasing, I advise you to open the bag with plastic stands and check them. If it's a chair, stand on it, it shouldn't break, it might just bend. The fastener is an asterisk, try to put it on something of a suitable diameter, bend it, it should not break. Plastic must be flexible and at the same time strong. If everything is ok, buy it.

Currently, the range of fasteners for fittings is simply huge, and every year it is growing all the time. New companies, new forms appear, but their goal remains the same, which is to provide the necessary protective layer to the reinforcement so that the structure you are building is strong and reliable.