Metal rod bending

Metal rods are classified as high-quality products and are usually supplied to customers in large quantities.

These large batches will have to be processed by bending specialists. Of course, on a serial, and even on a smaller scale, there can be no question of any manual bending of a rod along the radius. Firstly, this is technically impossible, and secondly, the performer will not meet the deadline. And finally, in a hurry and with the use of manual tools, defects in work are inevitable. Modern bending equipment is precise and accurate. Moreover, with any type of product: processing “traditional” rolled products with a round cross-section is as simple for it as bending a square, rectangular, hexagonal bar, as well as any non-standard-shaped profiles.

Sheet metal bending

For comparison, we can consider the features of a typical welded joint:

- This method requires careful preparation of the surfaces to be joined to prevent contaminants from entering the melt zone.

- Similar functions are performed by inert gases that prevent foreign impurities from entering the work area.

- Exposure to high temperature significantly disrupts the original structure of the material.

- Working with refractory metals requires large energy costs.

- Upon completion of the operation, it is necessary to clean the seam, check for the absence of cavities and other hidden defects using non-destructive testing tools.

- The surface in the seam area must be leveled and well protected from corrosion.

The disadvantages and additional difficulties listed in this list can be eliminated if bending is used. This technology has the following advantages:

- There is no need for careful preliminary preparation of workpieces.

- The required action is performed quickly, in one working cycle.

- No inert gases or other consumables are required.

- This technology does not destroy the structure of the product.

- Bending is accompanied by relatively low energy costs.

It should be noted separately that bending is easy to automate. The production uses the latest specialized machines with numerical control. Such equipment increases labor productivity and eliminates handmade defects.

Features of professional metal bending

Modern machines from a huge fleet of equipment are capable of processing workpieces with a maximum length of up to 2500 mm. Built-in presses develop forces of 85-130 tons. All equipment ensures the accuracy of the final forms with a tolerance of no more than 0.05 mm. Wide production capabilities allow you to select equipment suitable for completing a specific order. This optimization reduces overall costs.

During production practice, the Ephesto team monitors the compliance of the drawings with ESKD standards if customer materials are used. If necessary, the design department quickly creates a complete package of design documentation, and all necessary changes are made at the stage of its preparation.

A metal bending machine performs technological operations according to a given program with high accuracy. Its actions do not need to be closely monitored: unnecessary verification and work operations are excluded from the algorithm, so the final cost of the products is quite affordable.

To correctly formulate technical specifications, you must remember the following nuances:

- Bending can be performed at 1, 2, 3 or more angles. It is also possible to create curved surfaces.

- Using this technology, workpieces made of aluminum, steel and other metals are processed.

- Bending of rolled metal is suitable for creating housings, brackets, cable ducts, pallets, other products and components of complex structures.

It should not be forgotten that the Ephesto team also performs drilling, milling, and other processing operations. Using modern technologies, protective and decorative surfaces of various types are created. All work is carried out by our own departments, which helps control the production process and offer reliable comprehensive guarantees.

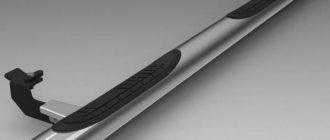

Bending of solid bars

In this article, by bar we mean a solid product without internal voids, that is, solid.

Although production also produces hollow rods that have internal voids and, thanks to them, are often classified as small-diameter pipes - round or profile. When passing through a profile bending machine, they exhibit different properties, and their deformation can cause serious difficulties. Unlike rolled pipes, solid rods, that is, rods, can withstand any load. Although their ability to withstand deforming forces will largely be determined by the type of material. It is known that bending a metal rod made from medium-carbon steel is easier and safer than bending from unalloyed structural steel.

Characteristics of metal bar bending

During the impact of bending equipment on metal, a phenomenon called deformation occurs.

But its character throughout the process is heterogeneous: first, elastic deformation appears, and then plastic. This change helps the rod maintain its cross-sectional shape at the bend and avoid defects. When bending a rod, it is subjected to deformation processes not as a whole, but in specific areas: so-called deformation centers appear on the workpiece. The metal fibers on the inner side of the bend experience compression and have a smaller radius of curvature than the outer ones, which experience tension. In the boundary area between the tensile and compression fibers, a so-called neutral zone is formed, which practically does not change during bending.

Machines and devices for bending reinforcement

In the process of development of construction technologies and metal processing methods, more than one machine for bending reinforcement was created. All such equipment works on the same principle; the difference between the models consists only in certain design features and the maximum diameter of the bending rod.

Any bending machine, including a homemade machine for bending reinforcement, works on the following principle: the rod is fixed between two rollers (central and thrust), and with the help of a third roller (bending), the reinforcement is bent at the required angle. Conveniently, the machine for bending metal reinforcement can bend a rod both to the left and to the right. The required bending radius is ensured by the thrust shaft, thanks to which the reinforcement does not deform along its entire length.

One of the options for a homemade machine, consisting of two parts - movable (lever) and fixed (base)

Drawing of the moving part

Fixed part drawing

An example of how ordinary nails can be used to quickly measure the distance between the bends of rods.

Machines designed for bending reinforcement, including those made by yourself, can be of two types:

- manual;

- with mechanical drive.

The main working element of mechanically driven machines is a rotating disk on which the bending and central fingers are fixed. There is a gap between these fingers, into which the rod to be bent is placed. The reinforcement placed in this gap rests at one end against a roller rigidly fixed to the device body. As the disc rotates, the bending pin acts on the reinforcement and bends it around the central shaft.

Manual bending machine AFACAN 16PT (price approximately 5,500 rubles). One of the models of this particular Turkish manufacturer was mentioned in the video at the beginning of this article

A specific machine for bending reinforcement, depending on its purpose, may belong to one of the following groups:

- light (for bending rods with a diameter of 3 to 20 mm);

- heavy (diameter of processed rods - from 20 to 40 mm);

- extra heavy (for fittings with a diameter of 40 to 90 mm).

Power driven equipment can be used to bend multiple rebar bars at the same time. Modern industry produces machines that can be used for bending rods whose diameter ranges from 3 to 90 mm. For those cases where it is necessary to bend reinforcement at different angles, it is best to use hydraulically driven equipment. Such a universal machine for bending reinforcement allows you to obtain a bending surface without cracks and folds, which can lead to the formation of internal stresses. This equipment also makes it possible to adjust the bending angle to 180 degrees.

On the modern market, you can optimally select a machine for bending various types of reinforcement, including portable ones, which are easy to use and affordable. Bending of reinforcement can be done either using special equipment or using a pipe bender, which is installed on ordinary workbenches.

You can make such bending devices yourself. However, they are used for bars with a diameter of no more than 14 mm and are not intended for cases where high productivity is required. Most often, such devices are used in private construction.

Another variation of the bending machine: a channel as a base, two angles, an axis of rotation and a handle

When choosing equipment for quick bending of reinforcement, two main factors should be taken into account: the maximum diameter of the rod that needs to be bent and the volume of work to be done. When bending a rod, its parts are subjected to different loads: the outer surface is subjected to tension, and the inner surface is subjected to compression.

If you choose the wrong equipment, then folds and cracks may form on the processed bar (or it will collapse under the influence of significant loads). To prevent this from happening, it is necessary to correctly select and configure bending equipment, as well as ensure reliable fixation of the reinforcement being processed.

Bending a metal bar - features

However, this is not all the nuances of bending a rod along a radius. The accuracy of the operation and the quality of the final product can be affected by:

- metal strength;

- bending method - cold or with preheating of the workpiece;

- complexity of the form that the product must acquire.

When constructing monolithic objects “for centuries”, rolled products made from more durable steel grades are used. They are characterized by increased strength, but are extremely inconvenient to bend. If the material is not plastic, the only way to change its shape to the required shape is to heat it from 600 to 700 degrees. Thermal bending is performed on special equipment - horizontal bending machines.

Material influence

All construction reinforcement, in accordance with GOST 5781 (for hot-rolled steel), is divided into the following strength classes:

- A-I, or A240 - round or square bars made from steel type St. 3 (GOST 380);

- A-II or A300 - round or square bars made from steel St. 5, or Art. 5 Gps (GOST 380);

- A-III or A400 - bars of a periodic cross-section with longitudinal, transverse or diamond-shaped notches, which are made from low-alloy construction steels of type 10G or 12GS in accordance with GOST 27772;

- A-IV or A600 - round, square or periodic profile bars made of medium-alloy building steel grades 25G2S, 30 GS, etc.

When constructing buildings with a higher number of storeys, reinforcement is also made from more durable steel grades, for example, 30ХС2, 40Г, etc.

Reference values for some of the specified grades of materials, necessary for the correct development of bending technology, are summarized in the table:

Note. a is the minimum diameter of the mandrel at which the bent workpiece does not form cracks; d is the diameter of the reinforcing bar.

Thus, bending workpieces made of construction medium-carbon steels imposes noticeable restrictions on the final configuration of the product, determined primarily by the bending radius of the reinforcement.

Bar bending - driven machines

On the Internet you can find many recommendations for making a device for bending a metal rod with your own hands. But, we repeat, such a mechanism, even if assembled correctly, will not be able to solve serial problems. For industrial purposes - for processing batches of workpieces - powerful drive machines are used. They:

- quite mobile;

- productive;

- do not take up much space;

- easy to set up and reconfigure;

- work carefully, creating the smoothest possible curves.

The service life of such equipment is practically unlimited. And if a breakdown occurs during operation, it can be easily corrected by replacing failed components and parts.

Bending a rod on a custom machine

Bending of square rods and rolled products with other cross-sectional shapes is one of the leading areas of work in our workshop. An entire area is dedicated to it, where several serial orders can be carried out simultaneously. If you contact us, then:

- Receive high-quality rolled products of any complexity on time;

- save as much time and effort as possible, as we guarantee that your order will be completed on a turnkey basis, with shipping and delivery;

- You can order the service at a good discount if you entrust us with processing a large batch of rods.

With us you can bring to life any construction projects, even the most complex ideas. Contact us!