Sawing

They are used to cut workpieces and give them a certain shape. Divided into the following categories:

- sawmills for cross-cutting and longitudinal sawing with linear saws. Movements are reciprocating. Bulky units that require complex maintenance are now not as popular as the next two options;

- circular saws. Needed for performing transverse and longitudinal cutting with circular saws vertically and obliquely. They are used to shape primary lumber;

- belt based on a tape that rotates and moves along a linear path. Suitable for harvesting at the initial stages and sawing material later.

What to look for when choosing

A universal woodworking machine is not a cheap purchase. Such equipment, even produced by a well-known manufacturer, can be quite expensive. Therefore, the choice must be taken very seriously.

First of all, pay attention to the number of functions the machine has. Of course, the more there are, the more varied carpentry work you will perform. But you shouldn’t “overdo it” here. Do not forget that the more multifunctional the machine, the more money you will have to pay for it.

When choosing a set of functions, you need to proceed from your needs. Of course, if carpentry is your main source of income, then you shouldn’t waste money on equipment and tools. But if you only need the machine for your hobby, or to perform periodic operations, then spending a lot of money is not rational. In most cases, the minimum set of functions that were listed in the previous chapter will be sufficient.

Another decisive parameter when choosing can be dimensions. If you decide to equip your small home workshop, then take measurements before going to the store. A universal woodworking machine is a small-sized equipment, but still it has its own dimensions. If there is very little space in the workshop, then you can purchase a desktop device. Of course, such a woodworking machine will have a reduced set of functions. But you can carry out basic types of carpentry work.

Video - review of the universal machine "Master - Practitioner HD"

In addition, when choosing, experts recommend paying attention to the following parameters:

- what power source is needed. Of course, almost any such equipment operates from the electrical network. But when purchasing, you should make sure that the machine requires a voltage of 220 V. If the manufacturer expects to connect to a three-phase network, then you will have to spend additional money on its organization;

- characteristics of the electric motor. This unit is the driving force of the entire machine, so its reliability and parameters are very important. As a rule, electric motors with a power of 2.5 kW and 3600 rpm are quite suitable for equipping a home workshop. For more professional use, it is necessary to purchase more powerful equipment;

- Another important parameter is the size of the saw blade. The size of the initial wooden blank that you can saw on the machine, and the performance of the equipment itself will depend on it;

- desktop dimensions. Here, too, everything will depend on the size of the workpiece. The larger the dimensions of the working surface, the larger the parts you can process;

- Drilling is one of the most frequently performed operations. Therefore, when purchasing a woodworking machine, pay attention to the maximum and minimum size of holes that can be made on the equipment;

- planing strip width. This operation is also performed quite often, so it is desirable to have a fairly large range of its implementation. As a rule, planing width ranges from 50 to 250 millimeters.

Another important factor is warranty obligations. A universal woodworking machine is not cheap, so its breakdown and further repairs will cost you a pretty penny. When purchasing such equipment, be sure to inquire about the warranty period and the location of the nearest service center. This will determine how quickly your machine will start functioning again after a breakdown.

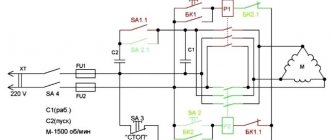

And of course, don’t forget about safety. Such a woodworking machine has many cutting elements, which means the protection must be at a high level. In addition, it is desirable that the equipment be equipped with an automatic power switch that turns off the power in case of overload. If your electric motor overheats and burns out during intensive work, its repair will be expensive.

When working on a woodworking machine, do not forget about basic safety rules.

Planing

Remove the top layer. The cutting tool goes deep and helps control the thickness of the workpiece, correctly creating the shape of the surface.

What types of thickness planing machines are there:

- one-sided - for processing the upper plane of massive workpieces;

- double-sided - for simultaneous work from above and below the workpiece;

- special - they immediately process the material from all sides, which simplifies the creation of the form.

There is also a jointer type for planing in one plane and chamfering at the desired angle.

Milling

Needed for processing wood using a milling cutter. You can work with flat surfaces with patterns, shaped variations, produce cylindrical and spherical parts, make grooves, splines, grooves, etc. Woodworking machines of this type are ideal for carrying out fine carpentry work.

Among them are:

- universal - for small and light parts. The rotation angle is adjustable in the horizontal plane;

- widely universal - equipped with a spindle head that rotates at any angle in mutually perpendicular planes;

- horizontal - there is no turning mechanism;

- vertical cantilever - the spindle is located vertically;

- non-cantilever - for working with vertical, horizontal and inclined planes;

- longitudinal - for dimensional workpieces. Massive units are used in large enterprises.

Types of woodworking machines

» Machine » Types of woodworking machines

Woodworking machines can be classified depending on the range of tasks performed, namely:

- universal, combined, which perform a wide range of tasks. They can replace several specialized machines;

- specialized, carrying out a specific type of processing;

- special, processing only the same type of parts (for example, for lining).

Useful: sawmill equipment.

Special ones, in turn, are divided according to the type of operation performed into the following types:

- debarking machines (designed for cleaning bark. They can be rotary, caliper and hydraulic. The former are most often used.);

- sawmill frames (they cut logs in the longitudinal direction with one or several saws. They can be general purpose, intended for stationary workshops, and special - for valuable wood species and plywood production);

- band saws (used for cutting wood materials. They are divided into dividing, carpentry, and log saws. The former can do vertical and horizontal cutting, the material is fed by mechanization. The latter - only horizontal and manual feed);

- circular saws (cut lumber, blanks and sheets of plywood or various types of slabs. They can be for transverse cutting, longitudinal or mixed type);

- longitudinal milling (form the longitudinal surfaces of block and panel parts. They are jointing, thicknessing and four-sided);

- milling (they mill various surfaces along contours, cut tenons and springs, process edges. They can be with a lower spindle or an upper one);

- tenon-cutting (they form tenons and springs on adjacent parts when they are connected at an angle into boxes or frames. They are one-sided and two-sided);

- drilling, drilling-grooving and slotting (they make holes (through and not through), select nests, remove knots that are sealed with plugs. They can be subdivided by the type of cutting tool, the type of specific operation, depending on the location of the spindles and their number) ;

- lathes (used for processing rotating parts. There can be center lathes, lobe lathes and round-rod lathes (centerless);

- grinding (used at the end of processing, smoothing out any irregularities).

Woodworking machines have several ways to feed material. Accordingly, they can be cyclical or incoming. The former work on the principle of intermittent supply of material to the cutting tool or vice versa. In the receiving areas there is a continuous supply of material, that is, processing is in motion.

Also, to determine the type and subtype of a woodworking machine, it is customary to use their letter indexing:

OK - debarking, R, 2R, RG - sawmill frames, LB, LD, LS - band saws, TsD, TsR, TsT, TsK - circular saws, SF - jointer, SR - thickness planer, S - four-sided longitudinal milling, F - milling, Shl - grinding, ShO, ShD - tenoning for frame tenon, ShP, ShlKh, ShK - tenoning for box tenon, SV - drilling, SVP - drilling-grooving, DC - slotting with milling chain, T - turning,

KP – round rod.

At the same time, the first letters are responsible for the type of machine and its purpose, and the subsequent ones are technological features. In addition to letters, there may be numbers. Oki indicates the maximum characteristic parameter. There are a huge number of manufacturers of woodworking machines on the Russian market. The most popular among buyers are Felder (Austria), JET (Switzerland), Belmash (Republic of Belarus), Stark (Germany), Makita (Japan).

kudavlozitdengi.adne.info

It is difficult to imagine a woodworking enterprise or workshop without machines. Without them, it is impossible to do work quickly and efficiently, especially when it comes to serial production of products. For a private craftsman who makes products in a single copy, the use of machines is also beneficial. A positive economic effect for any enterprise, regardless of how many people work at it, is the main reason for which woodworking machines are purchased.

What advantages does the machine provide?

- Allows you to significantly increase productivity. In the same time, 7 or more times more parts are produced on machines than using manual and electric tools. As a result, profits grow!

- The machine guarantees high quality products. Working with it, even an inexperienced master can immediately achieve high precision. The fact is that when processing wood with hand or electric tools, they are moved along the part; when using a machine, on the contrary, the part moves. This allows the operator to better see the cutting area and control the process.

- The machine operator is significantly less tired. Working with manual machines requires much more physical effort; due to overwork, he does less and loses attention.

Agree, the benefits of using machines are obvious.

And to figure out what equipment is required in your case, it is convenient to use the classification. It is carried out according to several criteria.

Types of machines

Classification according to operations performed and purpose examines production tasks and allows you to select the appropriate equipment for them.

| Operation | Machine tools | Purpose |

| Sawing | Longitudinal, transverse and curved sawing of workpieces, cutting and trimming of parts. | |

| Planing |

| Processing the workpiece along the plane and profile allows you to obtain a smooth surface of the board, shield, or bar. Thickness planers perform planing to size according to the thickness of the part. |

| Milling |

| Profiling of parts, processing of panels and frames along the contour, artistic work on wood. |

| Drilling |

| Making holes. Drilling and filler machines prepare dowel connections. Slotting - used for selecting nests. |

| Turning | Processing of cylindrical parts. | |

| Grinding |

| They remove waves and burrs, smooth out sharp edges, remove sag, and calibrate parts. Used to give the surface the desired roughness. |

| Pressing | Production of plywood, chipboards, MDF. Manual – for clamping parts to be glued (mainly used in workshops). |

The features of the technology are discussed in detail in the article “6 basic operations for processing wood on machines.”

Auxiliary equipment performs the work without changing the shape and dimensions of the part.

A typical example is chip ejectors. They remove waste from the work area. The effect of their use is not only better visibility of the cut line. They collect wood dust, which is harmful to humans. Chip suckers keep the shop and workshop tidy, as all the garbage is collected in bags. Glue application machines are used in production to produce laminated wood materials. When making furniture, the edges of the parts are edged. This task can be quickly accomplished using edge banding machines.

Turning

For the manufacture of elements in the form of bodies of revolution. They are created from straight blanks, from which a layer of material is removed in several stages.

The processed product is widely used in the construction industry and furniture production. These elements are used to make fasteners, body parts and decor.

Types of lathes:

- manual. The turner re-tunes the tool every time and constantly participates in the process;

- automated with a copying mechanism for carrying out template work. Managed;

- automatic. They work independently based on installed software and adjust the workflow based on logical algorithms.

Drilling

Needed to create holes of the required depth in wood. Suitable for working with high hardness rocks where precision is required. There are:

- vertical;

- horizontal;

- horizontal for recessed drilling. You can control runout and axis stabilization to make the process more precise;

- radial. You can quickly and accurately change the direction of drilling.

SAWMILL FRAMES

Sawmill frames are designed for longitudinal sawing of logs and beams into lumber.

Sawing is carried out with one or more strip saws, tensioned in a saw frame and forming a composition of saws. Depending on the specialization, sawmill frames are divided into two groups: general

and

special

purpose. General purpose frames are designed for sawing logs and beams into lumber with installation in stationary sawmills.

According to their design characteristics, they can be one-story

(P63, P80) and

two-story

(2P50, 2P63, 2P80, 2P100).

Depending on the production technology, frames may be first

(2Р63-1) and

second

(2Р63-2) rows. General purpose frames are always equipped with a four-roll feed mechanism.

Special purpose sawmill frames include: horizontal

(RG),

short

(RK),

container

(RT) and

mobile

(RPM).

Feature of horizontal

sawmill frame is that the saw frame, carrying one saw blade, moves in the horizontal direction. The longitudinal supply of logs is carried out by a trolley. The feed to the thickness of the sawn board is carried out by the saw frame support. They are intended for cutting ridges of valuable species, as well as for sawing vanches in plywood production.

Shorty

Sawmill frames are designed for sawing logs up to

3 m

. Their special feature is the presence of an eight-roller feed mechanism for reliable positioning of short logs during the sawing process.

Containers

Sawmill frames are used for sawing logs into container boards up to

6 mm

with insignificant waste of wood into sawdust due to the thin (up to 1 mm) saw blade.

Mobile

sawmill frames are used in temporary sawmills and forest plots. They are installed on movable platforms and transported to their destination without dismantling by tractors and vehicles.