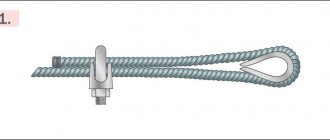

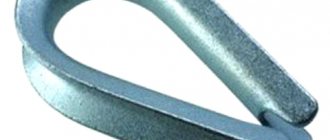

How to properly secure the cable so that it can be used for its intended purpose? To do this, you need to take special clamps that will help fasten strong ropes made of steel or metal. Using a product such as a wedge clamp for a steel cable, you can easily make the necessary loops at the end of the rope.

Types of cable clamps

Disposable clamping elements are short cylinders that splash onto the threaded ends of the rope, clamping it very tightly.

To work with the clamp, a special tool is required, but in industry and construction, fasteners are used quite often.

Products are made from soft types of metals, most often aluminum and copper alloys. Among the “advantages” of disposable clamps, it is worth noting their low cost and ease of installation.

Among the obvious disadvantages: the unreliability and disposability of the design, as well as the inadmissibility of using fasteners on PVC cables.

- U-clips are the most common type of cable fastener. Among the advantages, professionals note the low cost of the clamps, ease of installation and reusability of the product. One of the “cons” is a small contact patch, which causes cutting deformation under heavy loads (cable rupture).

- Cam clamps are a close analogue of the U-clamp with threaded bushings. The cam clamp is more convenient than a traditional clamp, but is rarely used in Russia. Among the “advantages” of the clamp, it is worth noting its low cost, ease of installation and reusable use. The disadvantage is a small fastening spot, which leads to rope breaks at the fastening point.

- Die clamps (busbars) resemble W in cross section. The contact points to the cable have a corrugated texture, which increases the reliability of the connection. Pros: no cutting deformation, reliability and reusability. Among the disadvantages, it is worth noting the high cost of the product.

- Cylindrical clamps are represented by two half-cylinders with tightening screws. The rope lock is made of stainless steel, so its use is approved for stainless, steel and galvanized ropes. The maximum load on the fastener is 80 kg. The clamp easily tensions the rope to the desired limit.

- Crimping clamps (“barrel”) are presented in the form of two relief plates with grooves for laying the cable. The cable is tightened by tightening the screw in. Used in elevator equipment and other lifting mechanical products. The production material may vary depending on the required load: steel, non-ferrous metals. The clamps have proven to be reliable, durable and reusable designs, but the cost of the product remains high.

- SIMPLEX flat clamps are considered reliable elements in which 2 plates with flanges secure the rope with a nut. The clamp prevents the rope from slipping out on the sides, which allows you to increase the load. Single designs are considered reliable, although the cost of the products is quite high.

- Double DUPLEX (flat) rope rigging products look like 2 SIMPLEX spliced clamps. Locks are used when tensioning high-voltage lines or antenna cables.

- Cross clamps are designed to connect cable lines at right angles. The cross clamp is made in the form of a cylinder, inside of which cables are laid out on four sides, clamped with a screw from above. It is simply impossible to imagine fastening intersecting ropes without a cross clamp. However, such a lock is not suitable for other situations. The fasteners are made of stainless steel, which allows them to be used for landscape design and street landscaping.

- Locking clamps do not splice or support the load. The “lock” is simply hung on the rope and prevents the movement of goods along it. The scope of application of the locking clamp is small, which is considered to be the main disadvantage of the clamp.

- Collet clamps neatly join ropes with other structural elements, but professional craftsmen do not recommend relying on the reliability of the structure.

Safety clips are considered one of the best when it comes to hanging loads. The product consists of levers that secure the load on the ropeway. The cable is threaded into a special clamp ring.

Expert advice on choosing cable clamps

Professionals advise carefully selecting cable clamps, carefully inspecting them before purchasing. Ropes carry a lot of load, so clamps should increase the ability of the ropes to carry the load.

First of all, each element must be clearly marked.

The surface of the cable clamp must be smooth, even, without cracks or other deformations. The clamps must fully comply with the type of rope, as well as the external conditions under which the rigging tools are used. Incorrect selection of the clamp reduces the useful load on the rope by 40%.

Installation of rope clamps and fastening

The essence of pairing ropes is simple. When constructing a rope loop, you need to attach the free end of the rope to its body at such a distance that at least three clamps can be installed. There must be a distance of at least six diameters between them. The strength of the connection depends on their correct location. So, the body of the clamp should be located on the side of the rope body, and the clamping bar should press the end against its body.

As mentioned earlier, U-shaped rope clamps can withstand relatively light loads, and the recommended number of clamps per loop is three or more. If the load exceeds the expected one, you should not increase the number of clamps, but use a different type. In some cases, it is necessary to fasten the cable to a plane with a tensioner. In essence, this is fastening to the wall using a special washer and self-tapping screw.

DIN classification of clamps

- Standard clamps are marked DIN 741. This type of product is not recommended for lifting loads. Clamping mechanisms are made of steel and stainless steel. Products with zinc coating are also available on sale.

- Reinforced fasteners DIN 1142 with nuts for reliable fixation have an impressive margin of safety even with fluctuating temperatures. These types of fasteners are used in construction when working with lifting mechanisms. Fasteners are made from galvanized steel.

- DIN 3093 are represented by aluminum bushings that connect ropes to extend them.

Types of materials and coatings

Since working with cables and clamps involves significant loads, very durable materials must be used. The most common types are stainless steel, regular steel, copper and aluminum, but heavy-duty carbon steel clamps are also available. To work in harsh weather conditions, a clamp is used that is galvanized with zinc. The galvanized surface resists corrosion.

Installation of cable clamps

The first clamping element is placed a short distance from the end of the loop. All bolts on the fasteners are tightened. However, it is recommended to place the second clamp closer to the rope loop in order to reduce the rate of cable deformation. The third clamp is placed between the two fasteners.

It is worth considering that the fastening bolts should face up.

- When conducting initial tests, a load equal to the required or slightly more is given to the cable.

- The reliability of the fasteners is checked, and if necessary, the nuts are tightened tighter.

You can install a cable clamp with your own hands, experts say, if all requirements for the selection and operation of the rigging product are met.

Operating rules

Before starting work, you need to check the strength of the connections by applying a load to the cable once. If after several checks the cable and clamps continue to perform their functions, then it can be used. However, it is necessary to regularly check the condition of the clamps, since over time the connections can become loose, the nuts can become loose, and the metal can be destroyed.

The maximum service life of the clamps depends on the operating conditions. If this is a construction site with regular transportation of goods across floors by a construction crane, then replacement should be done every 4-6 months. In a domestic setting, you need to look at the state of wear to determine whether the clamp needs to be replaced or not.

In some cases, proper operation can save lives. This refers to the so-called lifeline. This is a tightly stretched cable with the ends attached to the sides of boats and ships. If a person accidentally falls out of a boat, it will be easier to save his life by grabbing onto it.

Safety requirements for cargo transportation determine the need to adhere to the technique of fastening steel cables and ropes. Before using the fastener, you need to check its load-bearing capacity. And if the connections are actively used, the degree of wear should be monitored.

Did you manage to solve your problem using the recommendations from the article?

Yes!

46.43%

No. More answers required. I'll ask in the comments now.

38.42%

Partially. There are still questions. I'll write in the comments now.

15.14%

Voted: 799