Home / Electrodes

Back

Reading time: 2 min

0

628

The products of one of the largest players in the electrical market of the post-Soviet space, Losinoostrovsky Electrical Plant (LEZ), are widely represented in the retail chain.

A wide range of products, reasonable prices - store shelves are never empty.

It is difficult to find a welder, both a beginner and a holder of the highest sixth category, who would not work with electrodes from Losinoostrovsky. What did they do to deserve such fame?

Let's figure out how worthy they are of national fame. Decide: to take or not to take Losinoostrovsky electrodes?

- reference Information

- For every taste

- Pros and cons

- Summary

reference Information

The Losinoostrovsky plant took its place in the history of welding back in the 40s of the last century. Welding wire and electrodes have been tested in their work by more than one generation of welding masters.

Over the past years, products have collected many characteristics. There is both praise and criticism. This is normal for such a diverse list. Without electrodes, you can’t imagine welding, surfacing, cutting, or gouging of metals.

The volume of products that comes out of the LEZ workshops may surprise many. Often buyers make their choice once and for all.

Rating of the eight best electrode manufacturers in 2022.

Part 3

6. LEZ (Losinoostrovsky Electrode Plant), Moscow

“Losinoostrovsky Electrode Plant” has been producing electrodes for various purposes for welding and surfacing work, for cutting and gouging metal for more than 60 years. Over many years of use and sales practice, LEZ electrodes have had a wide range of reviews from extremely positive to extremely negative (terrible!).

Electrode packaging: LEZ MR electrodes and LEZ Uoni electrodes are the most popular brands of this manufacturer.

Packages of 1 kg and 5 kg, boxes are covered with film, placed on euro pallets and additionally wrapped with stretch film.

Current state of affairs: the LEZ plant stopped production in 2016. due to problems at the enterprise (bankruptcy). Lost experienced staff.

Before the bankruptcy of LEZ, the quality control departments of many factories did not pass LEZ electrodes due to a sharp deterioration in the quality of the electrodes.

In September 2022 The company began production again. 4 brands were launched (MR-3S, MR-3, ANO-21 and UONI 13/55). However, at the end of 2018, the plant stopped again due to a conflict between owners, poor quality, poor management of the enterprise, and huge financial debts.

To reduce production costs, rutile was almost completely replaced by ilmenite and sphene, which further impacted the quality of the products.

7. Plazmatek Ukraine, Vinnitsa.

Plazmatek is a large manufacturer of welding electrodes in Ukraine. Created on the basis of Agricultural machinery in the early 2000s.

They are trying to supply Plasmatek electrodes to the export markets of Russia, Belarus, Moldova, and Latvia.

Plazmatek pays special attention to protecting its products from counterfeiting. Plasmatek electrodes are individually marked. Additional protective markings are applied both to the packs and to the electrodes themselves.

The products of the Plazmatek enterprise under the trademarks “Arsenal”, “Monolit”, “Continent”, “Standard” are produced mainly in Ukraine and Belarus at the Svetlogorsk Welding Materials Plant.

The packaging of Plazmatek electrodes, like that of “Electrode” Tolyatti, is 3-layer: inner sealed plastic packaging, cardboard box and outer shrink film. Pallet in film. Packages of 0.5kg, 1kg, 2.5kg and 5kg, depending on the diameter. Plazmatek electrodes 2.0 - 0.5, 1 kg, diameter 2.5 - 0.5, 1, 2.5 kg. Diameter 3.0 - 0.5., 1., 2.5 kg. Plazmatek electrodes with a diameter of 4.0 - 1., 2.5 and 5 kg. Diameter 5.0 - 5kg. Pallets with packs of 1kg and 5kg - 1t, and diameters in packs of 2.5kg - 1.005t

Pros: ease of use at the “everyday level”, easy to cook from a weak network, giving good results even for a novice welder, reinforced packaging to protect against moisture.

Cons: very high, exorbitant price, deteriorating quality in 2019. In addition, the mechanical properties of a seam made with Plasmatek electrodes are much worse than stated, and the same is true for the chemistry of the seam - high content of sulfur, phosphorus and low manganese.

Plazmatek reviews: usually good ignition and stable arc burning, but sometimes they stick.

This makes it possible for novice welders to weld.” In general, Plasmatek electrodes receive good combustion reviews, but the seams are very short-lived. Reviews based on the price allow us to conclude that Plazmatek is for those who do not save at all on welding consumables.

Additional features: NAKS - available on Monolit and UONI 13/55 Plasma

8. Stasva (Novooskol Electrode Plant LLC), Novy Oskol, Belgorod region.

Novooskol Electrode Plant (Stasva) is an enterprise for the production of welding electrodes for general use. Electrodes have been produced under the Stasva brand since 2003.

Packaging of electrodes from the Novooskol Electrode Plant: grades ANO-21 and MR-3S in packs: 1kg, 3kg, 4kg and 5kg. Packs in film.

Pallet - 1t/1,002t, additionally in shrink film.

Brands UONI 13/55, UONI 13/45, OZS-12, MR-3, ANO-4 Novooskol Electrode Plant packages only 3kg, 4kg or 5kg.

Pallet - 1t/1,002t, additionally wrapped in film.

Pros: Welding electrodes are produced using imported second-hand equipment from OERLIKON and are very cheap.

Cons: Small production volume (tens of times less than other leading factories), conflicting reviews from welders about the quality of the electrodes.

NEZ electrodes reviews: “they ignite well, but there is a large percentage of defects, in one pack both excellent and unimportant”, “good for this price”. In general, mixed reviews from welders regarding quality do not allow the plant to increase production volume.

What other complaints do leading factories have about the quality of their welding electrodes?

The largest number of such “complaints” are associated with welders’ compliance or non-compliance with the recommendations that the manufacturer gives for welding with their electrodes.

An important nuance is that the most experienced welders can weld with electrodes of any manufacturer without wasting time.

In this case, choosing the lowest price is more than justified. If the welder is “used to” and “prefers” a certain manufacturer, there is a possibility that if you save on the purchase price and choose an unsuccessful alternative, the result will be a waste of additional time on work, that is, the savings will be imaginary and the cost part will be transferred from the price to welding electrodes cost extra time and wages for the welder.

It becomes extremely important to choose the right alternative in order to meet both the supply objectives - minimizing the cost of purchasing electrodes, and the goals of efficient and high-quality work of the welder.

Video: The best electrode manufacturers from Akti

Meet the Chistoozerny Electrode Plant

Rating of the 25 best electrode manufacturers in Russia

Classification of electrodes for welding.

Losinoostrovsky Electrode Plant (LEZ) is bankrupt again

Electric welding is a great Russian invention

Electrodes MR-3S, OZS-12, OK-46, UONI-13/55, SELB-52, TsU-5, TsL-39

(part1 - part2 - part3)

For every taste

The assortment produced by LEZ can be listed for a long time. The plant's electrodes are included in the rating of the most universal; they are suitable for all types of known steels. There may not be enough space in the article to list them.

Let's name just a part: corrosion-resistant, heat-resistant, high-strength, etc. Cast iron, non-ferrous metals - LEZ products can handle them like two or two.

And there is no need to ask about the brands TsL, UONI, MP 3, etc. LEZ has everything for everything!

Technical characteristics of electrodes MR-3 and MR-3S

MP-3 electrodes type E46 are used for welding low-carbon steels.

Technical characteristics of MP-3

- consumable electrode with rutile coating;

- the rods are made from Sv-08 wire;

- welding in all spatial positions except vertical (top to bottom);

- no-load voltage - 60-80 volts;

- arc - short, medium;

- current - alternating, constant, reverse polarity;

- deposition coefficient - 8.5 g/Ah;

- spray coefficient - 9-13%;

- consumption of electrodes per 1 kg of deposited material is 1.7 kg;

- calcination of electrodes at a temperature of 150-180 degrees.

Mechanical properties of metal:

- temporary tensile strength of at least 46 kgf/m2;

- relative elongation of at least 18%;

- impact strength of at least 8 kgf/cm2.

Mass fraction of chemical composition elements (table):

Weight of one MP 3 electrode based on diameter:

- 30 g (3 mm);

- 60 g (4 mm);

- 92 g (5 mm).

Number of rods in a pack and its weight:

- 83 pcs, 2.5 kg (3 mm);

- 41 pcs, 2.5 kg (4 mm);

- 54 pcs, 5 kg (5 mm).

The price for MP-3 electrodes is reasonable. 3 mm rods are purchased for 80 rubles kg.

MP3 electrodes are stored in dry rooms. When moistened, calcinate for 1 hour at 150-180 °C.

Recommended current values

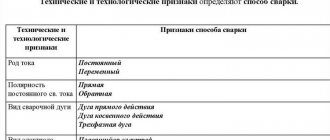

The table will help you determine the welding current depending on the diameter of the electrode and the method of application.

Advantages of using MP-3:

- high arc stability;

- moderate metal spattering;

- beautiful seam formation;

- good separability of the slag crust.

Technical characteristics of MP-3S electrodes

Not much different from MP-3. The product has a rutile coating with special ionizing additives. MP 3C (blue) are a relative of OK 46 and operate on low-power household welding machines of 50 volts.

When burned, 0.6 grams of manganese are released versus 1.25 grams. That's all the differences. Other characteristics are the same as MP-3.

Video: review of MP-3S.

https://www.youtube.com/watch?v=Jpdp2S2SGCY

Reviews

Ivan:

Basil:

Professional welder, Ivan Koreiko:

Video:

https://www.youtube.com/watch?v=xuiPOI-XyZc

PS According to reviews, the conclusion is this: ESAB's MP-3S are good, but the quality of LEZ's is lame (50 to 50).

Summary

The choice: to take or not to take electrodes from LEZ depends only on you. If we take the indicators price: quality, we get a good ratio.

Here habit comes to the fore, as in the saying about taste and color. For family craftsmen or debutants in the field of welding, the purchase of these electrodes will be profitable.

I spoiled it, took another one, without straining the family budget too much or without bankrupting the employer. Do you already have an opinion on this matter? Add it to the comments! And success to all buyers of welding rods from LEZ!

Basics of choosing electrodes for welding

The main feature of any coated electrode is its coating. Each electrode coating has its own chemical composition, which largely determines the purpose of the electrode. Electrodes are available with basic, rutile and acidic coatings.

- Basic coated electrodes are used for DC welding. They have somewhat more difficult ignition than rutile electrodes, and are also more sensitive to moisture.

- Rutile-coated electrodes provide easy arc ignition, which is why they are popular among welding beginners.

- Acid-coated electrodes are used for inverter welding. However, due to the special composition of the electrode coating, it is recommended to cook with acid electrodes in a well-ventilated area.

In manual arc welding, coated piece electrodes are used. Below is the rating of electrodes in 2022, according to users.

Advantages and disadvantages

If you have ever read reviews about LEZ electrodes, you have probably noticed that they are contradictory. Actually, this is not surprising. After all, their products are designed for mass buyers. And since there are incredibly many of these buyers both here and abroad, the reviews are different. We decided to express some of the advantages and disadvantages that we discovered during operation.

Among the advantages, we highlight a huge assortment. From this manufacturer you can find all types of electrodes for all types of metals. At the same time, the cost is not very high, because the products are domestic. Another undeniable advantage is the prevalence of electrodes from LEZ. The batches are large and supplied to many stores. So their products can be found even in a small town. Another advantage that follows from the previous advantage is a large number of reviews and tests on the Internet. Some of them are really objective and help in making a choice.

Disadvantages... in our opinion, there is only one. This is a quality that is incomparable with foreign analogues. Yes, LEZs have many quality certificates from supervisory services in different countries. They are approved in Germany, Russia, Belarus, Ukraine. Their products comply with GOST and NAKS standards. But domestic laws are too easy to circumvent and our quality standards are not as strict and modern as those of Japanese or American manufacturers, for example.

Rules of use and storage

Buying electrodes is not enough; you need to know how to use them. Before you start work, you need to prepare the material. All edges and welded surfaces must be clean and dry. In this case, the connection will be of high quality, and cooking will be convenient.

Electrodes are supplied in packages and moisture-proof film. But this is not always enough. If storage conditions are incorrect, the electrodes may absorb a lot of moisture or be subject to mechanical stress. The first can be “cured”. If it turns out that the rods have become too wet, they need to be calcined in a special oven. This is done for an hour at a temperature of about 160 - 170°C. After this they will be ready to go.

Store electrodes in dry places and in rooms with minimal humidity.