Surfacing is the application of an additional layer of metal to the surface of various products and parts by welding.

This procedure not only restores the original properties of the part, but also gives it additional valuable characteristics. It is one of the simplest and most effective ways to return elements to functionality. Fusing can be done for various purposes :

- restoration of product geometry;

- giving the structure a new shape;

- formation of a layer with specific physical and mechanical properties;

- increasing wear resistance, anti-corrosion, strength, hardness and other properties of the base material.

The essence of the process is the interpenetration of hot materials into each other, occurring at the molecular level. To do this, the surface layer of the main product is heated until it melts to a small depth, and the additive is heated to a liquid state. The resulting connection has a high level of reliability. The main advantage of the technology is the ability to regulate the thickness of this layer within significant limits and apply the additive to elements of various shapes.

Below you will find a detailed overview of all types of surfacing, and then a detailed discussion of surfacing with electrodes.

Types of metal surfacing

Currently, a large number of surfacing methods are used in the industrial and manufacturing fields. Next we will look at the different types of surfacing depending on the type of surfacing material used.

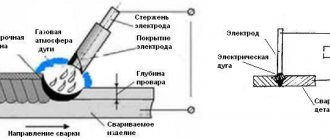

Manual arc surfacing with coated electrodes

Surfacing with coated electrodes is the most universal method; it can be carried out in all spatial positions. It is used both in the industrial sector and in the domestic sphere.

- The popularity of this method is due to several reasons : simplicity, convenience, flexibility, and no need for special equipment.

- Main disadvantages : low productivity, difficult conditions for the performer, instability of the quality of the resulting layer, large penetration of the base material.

Fusing requires the performer to have certain skills.

It is necessary to melt both components at a minimum current. By determining the composition of the metal, the type of electrode is selected, and the thickness and shape of the workpieces affects the diameter of the welding rod. If the thickness of the deposited material is less than 1.5 mm. – then the diameter of the rod should be 3 mm. With a thickness of more than 1.5 mm. – 4-6 mm.

The surface of the part must be cleaned of various types of contaminants.

The need for preheating and subsequent heat treatment also depends on the brand of electrodes used.

Surfacing of steel products is carried out using direct current of reverse polarity.

This method involves the use of various patterns of surfacing welds.

When working with flat products, there are two main types:

- using narrow rollers (in the picture), each subsequent roller should overlap the other by 0.3-0.4 of its width;

- the use of wide rollers, which are obtained with increased transverse movements of the electrode.

Another type is the laying of narrow rollers at some distance from each other. The slag crust is removed after applying several rollers. Then the gaps are also filled with rollers.

Surfacing of cylindrical products is carried out in three ways:

- rollers along the generatrix of the cylinder;

- rollers in closed circles;

- along a helical line.

Cylinder surfacing will be analyzed in more detail below.

Manufacturers and retailers offer a wide range of coated surfacing electrodes. The most popular brands are:

OZN-6 are used for surfacing parts of equipment for various purposes, operating under conditions of significant shock loads and intense wear. Metal deposited using electrodes of this brand has increased resistance to cracking.

OZI-5 electrodes are used for welding of metal-cutting tools and dies. The deposited metal is highly resistant to crushing and abrasion under significant impact loads.

Manual arc surfacing can also be carried out with carbon, graphite or tungsten electrodes. Deposition with these welding materials has limited application and is therefore rarely used.

Vibro-arc surfacing is performed by vibrating the electrode, the amplitude of which is 0.75-1.0 times the diameter of the rod. The procedure is carried out using a reverse polarity current of 80-300 A. At the moment of contact between the main product and the electrode wire, a short circuit occurs, which heats both surfaces to the melting temperature.

This method allows you to obtain a durable and thin layer. At the same time, slight heating eliminates the deformation of the part.

The vibro-arc method is used for fusing external and internal cylindrical, external conical and flat surfaces. This method is also used to restore the following structures: shaft journals, mud pump rods, drill pipe joints and others.

Electroslag surfacing is based on the use of heat generated when current passes through molten slag. The main feature of this method is high productivity. In an hour of work, a performer can obtain hundreds of kilograms of deposited metal. Other characteristic features of ESP: lack of spattering, economical consumption of filler materials and electricity, low heating and cooling rates have a negative effect on the structure of the deposited layer, and a slight tendency of the metal to form pores . [ads-pc-2][ads-mob-2]

For your information! To obtain a stable process, it is necessary that the depth of the slag bath be at least 30 mm. Failure to comply with this rule leads to instability of the process.

Electrodes of various cross-sections can be used as filler material: rods, plates, etc.

Main advantages: the process remains stable in a wide range of current densities: 0.2-300 A/mm2, the ability to deposit layers of large thickness in one pass, this method can be used to work with materials prone to cracking, the ability to give the deposited metal the desired shape .

The main disadvantages: overheating of the main product in the heat-affected zone due to the high heat input of the process, the need for complex and unique equipment, the impossibility of obtaining thin layers, significant preparation time.

Automatic plasma surfacing complex SBI (Austria)

Currently, the plasma cladding method . The heat source is a high-temperature compressed arc produced in special burners. The filler material can be surfacing powder, tape, wire, electrode, etc.

Plasma surfacing with the supply of two consumable electrodes into the bath provides high productivity.

A universal subtype of plasma surfacing is surfacing with powder injection into an arc. When performing such work, a combined type burner is used, which produces two types of arc: direct and indirect. Surfacing powders are fed from the feeder to the burner using a transport gas and are blown into the arc there. During its stay in the arc, most of the powder melts, and it falls on the surface of the main product in the form of droplets.

Before starting welding, the working surface should be cleaned of various contaminants: rust, moisture, scale and oil.

When applying the first surfacing layer, each previous bead must be overlapped by 20-30% of its width.

- Main advantages : high quality of the deposited layer, small depth of penetration of the base metal, high adhesion strength, the ability to obtain layers of small thickness.

- Disadvantages : relatively low level of productivity, presence of complex equipment.

Submerged arc surfacing has several characteristic features: high productivity, great versatility and wide possibilities for alloying the base metal.

There are four types of submerged arc surfacing:

Electric arc surfacing with tape is widely used . The arc that occurs at the end of the electrode strip moves from one edge to the other. These cyclic movements result in a dissipated heat input into the main product.

2. Multielectrode electric arc surfacing . The essence of the process is that the arc automatically occurs at the end of either one or the second electrode, which are located at some distance from each other and have a common current conductor. The arc moves from one rod to another, causing the rods to alternately melt.

3. Multi-arc electric surfacing . This type is in many ways similar to the multielectrode method. Only here the number of electric arcs corresponds to the number of electrodes.

4. Vibrating submerged arc surfacing involves performing the process using oscillatory movements of the electrode.

In addition to the advantages already listed, submerged arc cladding has the following advantages: low losses of electrode metal, absence of radiation.

Disadvantages : large penetration of the base metal, the need to use flux-forming devices, surfacing can only be carried out in the lower spatial position, when working with small-diameter parts and deep internal surfaces, there are difficulties in removing the slag crust.

Surfacing in shielding gases

The most popular method is surfacing with a consumable electrode in a carbon dioxide environment, which is characterized by availability and low cost. This method allows you to work with parts of small diameters and apply layers with a thickness of 0.5 to 3.5 mm on them.

- Main advantages : excellent quality of deposited metal, high productivity.

- Disadvantages : increased level of spattering; to obtain a high-quality additional layer, the use of special wire is necessary.

Surfacing in an inert gas environment is carried out with a consumable and non-consumable electrode.

In the first case, the arc occurs between the electrode and the base metal. Deposition is carried out under automatic electrode wire feeding conditions. The protective medium is a mixture of argon with oxygen or carbon dioxide.

In the second case, graphite electrodes serve as non-consumable electrodes.

tungsten carbon electrodes (in the picture). The filler material is introduced into the arc zone in the form of wire or powder. When surfacing with a carbon rod, surfacing powders are poured onto the main surface and then melted. The deposited layer is of low quality due to the presence of pores, non-metallic inclusions and other defects. When using tungsten rods, an arc occurs between the base metal and the tungsten electrode.

Arc surfacing with flux-cored strips and wires

This method does not require the use of flux or shielding gases. Therefore, the main characteristics of this method are simplicity and maneuverability.

It also creates the opportunity for the performer to work with parts of complex shapes, deep internal surfaces, small-diameter elements, etc.

Arc stability and protection of the molten metal from nitrogen and oxygen from the air are guaranteed by the presence of the necessary core components of the electrode material.

Gas surfacing

This method uses a gas flame produced by special burners as a heat source. Surfacing materials can be wires, rods and rods. The deposition process involving these materials is practically no different from electric arc surfacing.

Recently, gas-powder surfacing has become widespread. This method allows you to strengthen parts with a complex configuration with a thin layer of metal from 0.1 to 0.3 mm. This does not dilute the base metal. The powder is fed into the work area through an oxygen gas flame. As a result of heating, the powder in a plastic and molten state reaches the surface of the part. It then hardens and forms a deposited layer of metal.

- Advantages : low penetration of the base metal, versatility of the technology, the ability to obtain thin layers of deposited metal.

- Disadvantages : low productivity, instability of the quality of the deposited layer, low coefficient of use of filler materials.

Laser surfacing is performed using a highly concentrated energy source - a laser beam. This method does not require the use of vacuum chambers. Rods, tapes, and coatings can be used as filler material.

- Pros : high adhesion strength, low and controlled penetration of the base metal, the ability to obtain thin layers - up to 0.3 mm, slight deformation of parts; ability to work with hard-to-reach surfaces; the laser beam can affect several places at once.

- Disadvantages : low productivity, low efficiency of the entire process, it is necessary to have complex and expensive equipment.

[ads-pc-3][ads-mob-3] Electron beam surfacing is performed in a vacuum and is the melting of base and filler materials with an electron beam. The electron beam allows you to regulate the heating of both the base and filler materials. Moreover, this happens separately, which allows mixing of the two materials to a minimum. Flux-cored or solid wire can be used as filler material.

- Advantages : slight penetration of the base metal, the possibility of obtaining layers of small thickness.

- Disadvantages : the complexity of the equipment and its high cost, the need for biological protection of the performer.

Electrical contact surfacing is carried out with wire or powder using a special apparatus.

- Advantages : high productivity, low energy consumption, no need for a protective environment, minimal thermal impact zone due to short pulse duration.

- Disadvantages : limited range of processed products. This method is used to restore the following parts: shafts, axles, rods, drums and other elements, the wear of which does not exceed 1-1.5 mm in diameter.

For friction surfacing, a filler rod is used, which is pressed with its end against the surface to be deposited and rotated relative to the longitudinal axis.

This method has not found active use due to the low relief of the deposited layer.

Explosion surfacing. Cladding using explosion energy is carried out using explosion welding technology.

- Advantages : the ability to work with metals that are difficult or impossible to join using other methods, no penetration of the base metal, minimal level of product deformation.

- Disadvantages : the need for special testing grounds, significant preparation time, limited range of parts that are processed by this method.

- home

- Engine repair knowledge base

- Repair of bell shafts, camshafts and any other shafts by welding and surfacing!

Repair of bell shafts, camshafts and any other shafts by welding and surfacing!

The Russian Internet is replete with requests for manual and mechanized welding and surfacing for the repair of internal combustion engines and their parts. This may indicate that the supply of such services lags significantly behind demand. Restoring wear of engine parts using welding and surfacing may be of interest to technical directors of fleets and owners of personal cars, owners of boats with outboard gasoline engines and technical personnel involved in the repair and maintenance of diesel or gasoline generators, etc. Let's try to highlight some aspects of repair using various types of welding and surfacing.

When an internal combustion engine starts knocking, most owners immediately turn off the engine or immediately take it to a service center so it can be checked by a qualified mechanic. Knocking is often a sign of bearing problems, and if these problems are ignored, there is a good chance that the crankshaft journals will end up being seriously damaged. In some cases, when the journals are so badly damaged that they cannot be repaired by grinding, it is necessary to weld the crankshaft journals.

Crankshaft welding is a process by which new material is welded onto the crankshaft journal or thrust surface. Surfacing of this new material is necessary because only a certain number of bearings are available for a crankshaft whose journals have been ground to their original size. Standard oversize bearings are available in metric sizes 0.25mm, 0.50mm and 0.75mm. For older vehicle engines from North America, Australia and some other countries that may still use inch sizes, bearing sizes may be available in 0.010, 0.020 and 0.030 inches. One millimeter is equal to 0.0393700787 inches, and knowing some simple math rules can easily convert inches to millimeters. Anyway, even at 0.75mm, 0.02952 inches of material can be removed from the journal before having the correct size bearings becomes an issue.

As with any welding process, the crankshaft must be properly cleaned to ensure maximum adhesion and filling of cracks and cavities with the weld material. After this, if necessary, magnetic flaw detection is carried out to determine surface cracks.

During engine operation, bearing material is often transferred and “embedded” into the journal being repaired, so this embedded bearing material must be completely removed from the crankshaft journal by first grinding the journal on a grinding machine. It should also be noted that high performance engine crankshaft journals may have a hardened surface, and these surfaces should also be ground to eliminate potential problems. With proper preparation of the journals or thrust surfaces before surfacing, the deposited areas become stronger and free of defects. Because crankshafts have oil passages that supply oil to the bearings during engine operation, these passages must be properly protected before welding material is applied. Otherwise, they will end up overcooked. To do this, some welding machine operators use carbon or ceramic plugs that are inserted into the oil passage openings. Other operators prefer to briefly stop the welding process as the weld material approaches the hole while the crankshaft continues to rotate slowly in the welding chuck. Regardless of the method used, the operator must ensure that the oil holes remain free of obstructions.

For surfacing the crankshaft journals, special automatic welding machines for submerged arc welding are used. Just like a grinder, a crankshaft welder has one or two chucks and allows you to weld crankshaft journals and crankpins in one pass without having to readjust the welder. During surfacing, the flux acts as a protection for the wire that comes into contact with the neck. The flux does not allow oxygen and nitrogen from the air, as well as other undesirable chemical elements, to pass to the welding site so that they cannot adversely affect the quality of the weld being made. Crankshaft welders and laypersons alike often refer to this process as "arc welding."

Because crankshafts are made from a variety of materials, including cast iron and forged 4340 steel, the correct welding flux and wire must be used. Although you can always find generic welding wire in spools on the market that will produce acceptable quality welds, using wire that is made specifically for a specific crankshaft material and that is free from cracks and pitting can produce higher quality weld deposits. Changing welding wire on a crankshaft journal welder is relatively easy because it comes in spools. Flux, on the other hand, must be removed from the machine, making the process of resetting the welder more difficult. Once the required flux and welding wire have been selected and the cleaned crankshaft has been correctly positioned in the welding machine, you can begin surfacing the crankshaft journals. The world's leading American manufacturer of welding equipment offers wire and flux, which have different characteristics and properties and, accordingly, are suitable for various types of repairs. Some welders use a special softer, more flexible wire for the radials and a harder wire for the journals of the crankshaft. This rule also applies to fluxes: softer types of flux are better suited for surfacing material on radial sections, and harder ones are better for surfacing necks. Some experts believe that submerged arc welding has advantages over open arc welding, since the crankshaft is less deformed during submerged arc welding. Before surfacing, the shaft undergoes preliminary preparation and, after completion of the operation, is cooled with strict adherence to the temperature regime. How does this happen?

Welding leads to instantaneous strong heating of the neck, which can negatively affect the quality of the surfacing. Preheating the journal or thrust surface is a common method used to prepare the crankshaft for welding. The welding machine is turned on, and the crankshaft, held in the machine’s chucks, begins to rotate slowly, while the torch, set to the required parameters, evenly heats the journal or thrust surface. After heating the neck or thrust surface, the torch is turned off and moved to the side so that the operator can begin the surfacing process. After the crankshaft has been preheated, it continues to rotate. Meanwhile, the welding machine operator puts on personal protective equipment and directs the wire and flux to the place where surfacing needs to be done. In order to start welding, the operator first turns on the flux supply, which, as a rule, flows to the welding site under the influence of gravity, and only after that the electric arc is turned on. The crankshaft continues to rotate slowly while the machine feeds the wire at a constant speed, resulting in a smooth, uniform weld. After the crankshaft has made a full rotation, the machine operator uses a special hammer to remove slag from around the weld. After chipping, the slag falls onto the slag tray of the welding machine. This tray also serves as part of the flux recycling system. The machine is then manually or automatically adjusted to perform surfacing on the rest of the journal.

As with any steel welding, high heat will often cause some bending. When surfacing a crankshaft, it is not uncommon for it to bend 0.020 inch (0.508 mm) or more. Therefore, after welding, the crankshaft must be straightened. This is done after some time has passed and the crankshaft has cooled down. If the shaft is still hot, it is much easier to straighten it than after it has cooled down and become cold to the touch.

The welding seam on the thrust surface is performed in the same way as surfacing the neck, except that such a seam is welded vertically rather than horizontally. In most cases, surfacing is performed on the rear thrust surface, since it is this that is most often damaged.

In most cases, the resulting joint is harder than the surface it was applied to. After the crankshaft has cooled, the weld bead should be ground down to within 0.020 inch (0.508 mm) of its finished size on a grinder. Since grinding will relieve some of the structural stresses of the steel, especially when removing weld radii, it is necessary to check the straightness of the crankshaft again. While the crankshaft is being retested for straightness, most likely with a set of V-blocks, it is wise to check the oil passages. If any obstructions are found in the oil channels, they must be removed. This can be done using a tool grinder, which will remove any burrs that are blocking the flow of oil to the bearings. After all work on straightening the crankshaft is completed, and the surfacing on the journal or thrust surface is successfully completed, you can proceed to final grinding of the crankshaft.

Crankshafts, due to their design, are inevitably subject to stress and vibration, which, in turn, often leads to metal fatigue and cracks. Some crankshafts are more susceptible to cracking than others. The places where cracks typically start are around the oil holes and radial areas. Some small cracks can be removed by grinding the journals down to repair size. Shafts susceptible to cracking should be carefully inspected for cracks before and after grinding. One of the reasons for the appearance of cracks on the crankshaft may be a malfunction of the harmonic torsional vibration damper, which leads to an increase in engine speed to levels exceeding the manufacturer's technical standards. Another reason could be a poorly balanced crankshaft or malfunctions of individual components of the crank mechanism. As a general rule, the crankshaft of any diesel engine should be inspected for cracks before major overhauls begin. Cracks in the radial areas of crankshafts appear as a result of improper grinding. If the correct radius is not maintained (reduced) or if the journal has a stepped edge after grinding, the crankshaft is much more likely to develop cracks and become unusable than a crankshaft that was polished in compliance with all rules. It is necessary to carefully monitor and ensure that there are no scratches or roughness in the radial zones.

If the crankshaft journal is severely worn or, as they say, “burnt out,” the metal in the journal has most likely lost all its strength. The journal can be ground to repair size, but the softness of the metal dooms the crankshaft to work for a few hours after grinding, no more. What are the crankshaft manufacturer's recommendations in this case? Throw it away. In the past, this would probably have been the only correct decision. But today the crankshaft can be saved. And the price of a restored crankshaft will be less than the price of a new one, and the quality will be higher. This result is possible with the help of an American welding machine, which produces the best welding equipment for repairing crankshafts using the submerged arc welding method.

The harder the crankshaft journal material, the less flexible it is. Design engineers take this factor into account to select the appropriate steel so that the crankshaft is strong and wear-resistant without losing flexibility and can resist torsional failure. By resorting to exotic alloys, developers could create a shaft with maximum hardness and flexibility, but the cost of a shaft made from such alloys would be prohibitive. Therefore, in this situation a compromise solution is required. Unique welding materials and technological processes developed for more than four decades have made it possible to achieve that, after surfacing, crankshaft journals have improved hardness (on the Rockwell hardness scale) and, at the same time, improved flexibility. Technologies are truly unique. Many companies tried to copy them but were never successful.

As noted above, the supply of services for repairing crankshafts, camshafts and other engine parts on the Russian market still lags behind demand. One of the companies that stably and very successfully operates in the market for repairing parts of gasoline and diesel engines is the Motor-Rep company. The modern professional equipment that our company has and a team of experienced and like-minded specialists allow us to repair and restore cylinder blocks and liners, beds, crankshaft journals and liners, camshafts and technological holes and threads in engine parts with high quality.

In our work we use the most advanced technologies of high-quality arc welding and submerged arc surfacing, argon surfacing and metal spraying. High quality repairs of engine parts are ensured by the use of equipment from recognized leaders in the production of repair machines. So, to repair and restore worn crankshaft journals, we use a submerged arc welding machine from the American Gleason Corporation.

On our company’s website (https://motor-rep.ru/) you can find prices for repairs of cylinder blocks, crankshafts and other engine parts. We successfully repair crankshafts of engines of imported cars, such as Mercedes, BMW, Toyota, General Motors, Renault and others, as well as Russian ones: KAMAZ, YaMZ (in particular, YaMZ238), MTZ and so on. In addition to restoring crankshafts of land vehicle engines, we are often asked to repair crankshafts of outboard engines, for example, the popular SUZUKI DF 5. If we talk about the geography of requests, they come to us not only from Moscow. Among our regular clients are many private car owners and fleet managers from St. Petersburg, Nizhny Novgorod, Novosibirsk, Omsk, Yekaterinburg, Ufa, Krasnodar, Murmansk, Belgorod, Yaroslavl and other cities. The reason for contacting us for services for the repair and restoration of engines and engine parts by welding and surfacing from other cities in Russia indicates the high quality of the repairs performed by us. Another reason for this may be the small number of companies that can provide adequate welding and surfacing repair services in Russian cities other than Moscow.

In our work, we focus on quality so that you, the customer, are completely satisfied with the results of the repair. We pride ourselves on performing repair work at competitive prices, accurately and quickly. Timely repairs are extremely important to us as we understand all too well that downtime for your vehicle can be very costly. In addition, we do everything we can to ensure that your engine rebuild or repair is done right the first time, so you can get back to using your vehicle.

In addition to numerous requests for manual and mechanized welding and surfacing for the repair of internal combustion engines and their parts, on the Russian Internet you can often find requests for the restoration of crankshaft journals, mating surfaces of the cylinder head, bearings, hubs and other parts of automobile and marine engines using the spraying method. The benefits of thermal spraying for repairing and rebuilding engine parts are many and varied. However, one of the most important advantages of this method is its low cost. Considering that prices for some engine spare parts, in particular new crankshafts, can reach hundreds of thousands of rubles, repairing worn shafts by spraying provides significant cost savings. In addition, sprayed coatings can have properties superior to those of the base material and can therefore be used to provide locally enhanced wear protection for parts.

In addition, repairing parts, assemblies and components of vehicles using spraying can significantly reduce the time for repairing and returning a car or equipment “to operation”, and in the complete absence of necessary spare parts or parts on the market, it can become the only possible way to reanimate worn parts.

Let's give a specific example. The Caterpillar mining trucks used at Southland Mine in New Zealand have a lifting capacity of approximately 100 tonnes. The service life of the dump truck's rear axle is approximately 13,000 hours, which is equivalent to approximately two and a half years of operation. The cost of replacing axles is very high and they are difficult to obtain, so the mining company's management was faced with the question: Can the life of the rear axles be extended? A thermal spray specialist carried out work on the repair of the rear axle using the spraying method. The features and nature of the process eliminated any risk of deterioration in the quality of the base material of the bridge as a result of spraying. After surface preparation, a nickel-aluminum-molybdenum alloy bond coating was arc sprayed to achieve a tensile strength of over 7,000 psi. After this bonding layer, a coating was applied, which was formulated according to the customer's specifications. Finally, the rear axle was finished to within tight tolerances. The first rear axle repair was completed over 20 years ago, and since then many other dump truck rear axles have been repaired using spraying. As a result, the mining company was able to save tens of thousands of dollars on replacing worn out units and parts and significantly reduce downtime for vehicles and equipment.

In conclusion, a few words about welding and surfacing on cast iron crankshafts. Given the brittle nature of most cast irons, failure of cast iron shafts is not uncommon. However, the experience of companies involved in the repair of cast iron products suggests that, despite the difficulties, cast iron can be welded. If you need to restore a cast iron crankshaft, you can contact Motor-Rep, and we will repair your shaft efficiently and quickly.

Surfacing of gear teeth

The gear is a part of many mechanisms and machines used in various industries. The most common defects of this element are wear of the teeth along the length and thickness, chipping, formation of scoring, cracks and scratches. The most effective restoration method is surfacing of worn parts.

If no more than two teeth in a row break in not particularly critical mechanisms, repairs are allowed, including the following procedures: the defective teeth are cut out, 2-3 holes are drilled along the width of the tooth, threads are cut into them, pins are made and screwed into the prepared holes, the pins are welded to the gear and the metal is deposited by electric welding, the deposited layer is given the shape of a tooth.

Restoration of worn gear teeth can also be carried out with special electrodes for surfacing, for example OZN-300. Before work, the product is cleaned of contaminants.

How it's done. The nominal dimensions of the teeth are maintained using a copper template made from an undamaged tooth.

When restoring gears with several defective teeth, repairs are carried out only on the worn side of the tooth. For this purpose, sormite alloys are used, surfacing is carried out using the gas or electric arc method. Surfacing is carried out using electrodes TsS-1 and TsS-2. The work is performed on direct and alternating current of reverse polarity. Then the teeth are ground.

Schemes for surfacing layers at the gear tooth and cavity

The performer can also use stalinite, a powdered alloy that is melted with a carbon or steel electrode using a direct current of reverse polarity. Then the powder in a plastic state is applied to the part in a layer 3-4 mm thick. Borax should be used as a flux.

For repairing the ends of teeth with wear along the length of 2.2-8.2 mm. It is recommended to use automatic surfacing of each worn tooth separately. The process is carried out using flux cored wire. The weld metal is formed in a cooled copper mold.

Types of manual welding and surfacing

There are several parameters by which they are classified.

For example, there is a common division:

- • by the nature of the arc – compressed (short) and free (long);

- • according to the type of electrode used – with a melting rod (coated) and not;

- • according to the effect on the base metal of the part - direct, three-phase, indirect.

They are also grouped according to the result, that is, according to the restored layer - into:

- M – thin;

- C – average;

- D – thick;

- G – especially thick.

They are classified separately by purpose - options for connection are distinguished:

- • low-alloy and carbon steels;

- • alloyed and heat-resistant;

- • alloys with special properties;

- • layers with non-standard characteristics.

Now we will schematically consider the main methods of manual arc welding and surfacing:

They use:

A – carbon electrode (1) and bulk alloy (2);

B – coated (1) and alloying layer (2);

B – tungsten conductor (1) and filler rod (2) in inert gas;

G – rod (1) in a protective environment;

D – wire (1) and flux (2);

E – tape (1);

G – plasmatron jet (1) and powder (2), already sintered or applied;

Z – conductor (1), copper slider (2), workpiece (3), restoring coating (4).

The choice of a specific option depends on the specific conditions in which the work is carried out, on the planned result and on the required productivity. But each of them can be implemented quite simply and quickly.

Surfacing of rail ends

Photo source: specserver.com

The operation of high-speed trains requires good condition of the rails. Wheel impacts lead to deformation, crushing and bending of the ends of the rails. Restoration by surfacing is a standard technique.

Before starting work, all flattened and peeled metal is removed from the rail. To do this, it is recommended to use a chisel, emery wheel or other tool. To increase the deposition rate, it is necessary to preheat the ends of the rails.

The following surfacing technologies are used on Russian railways to restore rail ends:

1. Manual arc surfacing is performed with a piece electrode of the K-2-55, OZN-300, OZN-350 brands. The rollers are applied in three ways: along, across the rail and diagonally. The best results are obtained when working with the second method. The average width of the roller is 24-30 mm. This value may vary depending on the diameter of the rod, current strength and other factors.

There is also the possibility of fusing a bunch of electrodes: 2-3 rods arranged in a comb. This method improves productivity. Surfacing should begin at the end of the rail by applying a bead. The arc is excited on the inside, making a small indent from the end. The deposition of the first bead is also completed by moving slightly away from the end of the rail. The ends of each of these rollers are brought to the end of the previous roller and the crater is sealed there. The overlap of adjacent rollers should be 1/5-1/6 of the width of the previous roller. The work ends with grinding the ends of the rails along the rail.

2.

as a filler material when performing semi-automatic electric arc surfacing . This method has several advantages compared to the manual arc method: high quality of work, significant labor productivity.

The work is carried out in stages:

- defect measurement;

- preparation of equipment for surfacing;

- removal of defects by grinding;

- installation of surfacing apparatus on rails and setting work boundaries;

- heating the working area;

- performing the main process - deposition;

- mechanical processing with an abrasive tool after natural cooling.

Surfacing is carried out in one or several words, depending on the depth of the defect.

Features of surfacing technology using manual arc welding

The basic conditions for its implementation are the same as in the standard case.

- • Before performing the procedure, the surface of the part must be thoroughly cleaned so that there is not the slightest trace of rust or a single greasy stain left on it.

- • The selection of electrodes is carried out depending on the conditions under which the element being restored is operated; the most common options are for alloy steels, or special flux-cored wires for wear-resistant coatings.

- • Power sources are transformers and serial rectifiers.

The work process is accompanied by the application of rollers. They should be used alternately - so that the previous one overlaps the next one by a third of the width; you can apply them using the so-called transverse vibration method - exactly the same as when enlarging a welding seam. It is also acceptable to create gaps and then fill them (after removing slag and cleaning). The main thing is that in the end the entire worn surface is evenly covered with a layer that restores its original geometry.

If we compare the technology with classical connection welding, manual metal surfacing has one important difference: in its case, the applied material can seriously differ from the base one in its chemical composition. Therefore, it is so important to choose the right electrodes so that they help provide a suitable structure (uniform and durable). When this cannot be achieved, it is worth giving preference to other solutions, for example, applying alloying powders, pastes, briquettes or immersion in a protective gas environment.

In this case, various techniques can be used, including automatic ones. But in all situations it is necessary to minimize residual stresses, deformations and tolerances.

Surfacing of cylinders and planes

To restore the surface of cylinders, the following fusing methods are used:

1. Surfacing with coated electrodes is carried out in three ways: a) with rollers along the generatrix of the cylinder (longitudinal surfacing); b) rollers in closed circles (circular surfacing) and c) along a helical line.

Products of small diameter and considerable length should be processed using the first method . A bead is fused onto the cleaned surface. Then the part is rotated 180° and a second bead is deposited on the opposite side. Afterwards, the product is rotated 90° and the third bead is fused, and after 180° - the fourth. Next, a fifth bead is deposited, which overlaps the first. It should be noted that before applying the next roller, the previous ones must be cleared of slag.

The second method implies that the part must rotate around its axis during the entire working process. The latter option is especially convenient in the case of mechanized surfacing, in which the part rotates uniformly .

2. Automatic submerged arc surfacing ensures a wear-resistant layer. This method can be carried out with welding or flux-cored wire, strip electrode, flux-cored tape. Here two methods should be distinguished: deposition is carried out along a generatrix or along a helical line.

To restore flat products, it is necessary to cover large areas with minimal penetration of the base metal . A short video of surfacing with a plowshare will give you an idea of the operation.

to repair flat surfaces :

Narrow rollers are used; each subsequent roller is located overlapping the previous one by 0.3-0.4 of its width; slag is removed immediately from all weld beads.

Laying narrow rollers at a certain distance from one another is one of the simplest methods. The slag should be removed after applying several beads. After this, the beads are also fused in the gaps.

Wide-layer surfacing is a more advanced technology. Transverse oscillatory movements are imparted to the electrode.

Multi-electrode surfacing and electrode strip surfacing are characterized by increased productivity.

To obtain a wear-resistant layer, surfacing should be performed using flux-cored wire and open-arc tape. In this case, transverse vibrations with the required range are imparted to the electrode. This case is characterized by the absence of a slag crust of significant thickness.

In electroslag surfacing, flux-cored wire or solid wire can be used as the electrode material. [ads-pc-4][ads-mob-4]

Manual arc surfacing: GOST and technical conditions

As a result of its implementation, the applied material may have the same properties as the base one, or others, thus changing the performance characteristics of the part. It all depends on the electrodes, and if in the first case they correspond to the interstate standard 9467-60, then in the second they correspond to 10051-62.

In standard situations, preference is given to “E” and “F” type rods. Particularly interesting are the options with calcium fluoride coating from the U and UONI series. Because they produce a fine-grained material characterized by high impact strength, and this is the key to the absence of cracks.

Please note that the technology of manual arc surfacing of steel depends on the chemical composition of the part. If the proportion of carbon in it is no more than 0.25%, work can be done at any temperature. But the higher the percentage of carbon, the more likely it is that hardening structures will appear at points of thermal impact. Therefore, products containing 0.25-0.5% C must be heated to 120-350 0C.

How many layers should I do? It depends on the overall thickness that needs to be maintained. It is important to ensure that their distribution is correct - so that the new one goes along the upper third of the previous one. Why? Because it is in this section that there are the fewest pores and foreign inclusions, which means it is best suited for creating a strong seam.

At what current is manual welding and surfacing of parts carried out? This is influenced by a number of factors, in particular, the brand and diameter of the selected electrode, the quantity, weight and height of the final coating. The smaller the product, the lower the amperage should be, and vice versa.

Deformations that arise during labor can be reduced; to do this, it is enough to make one or more (depending on the situation) of the following rational decisions:

- • heat the part to 200-400 0C;

- • bend the product in the opposite direction;

- • immerse the object in water, but do not wet the work surface;

- • arrange the rollers symmetrically (thereby balancing the force effects);

- • rigidly fix the workpiece in a jig or similar device - so that it can be removed only after cooling is complete;

- • correctly distribute the additive over problem areas, for example, in a spiral, with application on the reverse side, with a breakdown of large planes;

- • relieve internal stresses using high-temperature tempering - with heat treatment at 650 0C.

Surfacing of metal-cutting tools and dies

Restoration of metal-cutting tools and dies is performed by arc surfacing in three ways: manual, automatic and semi-automatic.

The first option involves the use of electrodes. Metal-cutting tools and dies operate during cold and hot stamping, so they should be restored using the following grades of electrodes: OZI-3; OZI-5; OZI-6; TsS-1; CI-1M. The layer deposited with such materials has a high level of resistance to abrasion and crushing under heavy loads and high temperatures (up to 650-850°C). The product must be heated to 300-700°C before fusing. Fusing is carried out in 1-3 layers, the thickness is 2-6 mm.

We invite you to watch a video demonstration of the Zeller 769 electrode surfacing test.

Automatic and semi-automatic methods are carried out with alloyed wire using fluxes or pastes.

Surfacing of parts exposed to abrasion with impact loads and without impact loads

Products operating under conditions of intense surface wear and high shock loads must be overlaid with electrodes of the following brands:

Welding electrodes for surfacing OZN-400M

Advantages of OMG-N: they comply with state standards, deposition can be carried out with direct and alternating current of reverse polarity.

TsNIIN-4 is one of the most popular and popular brands.

Metal deposited with OZN-7M rods during multilayer deposition has increased resistance to cracking.

Advantages of OZN-400M: high productivity, deposited metal is characterized by increased hardness.

Advantages of OZN-300M: the deposited metal has increased stability of wear resistance and hardness; surfacing is performed with direct and alternating current of reverse polarity.

An example of such parts is elements of construction and earth-moving equipment.

For surfacing parts exposed to abrasion and without shock loads, the following grades of electrodes are used.

To obtain a deposited layer of special hardness, it is necessary to use surfacing electrodes T-590 and T-620. These brands are intended for repairing parts subject to intense abrasion. Thanks to a special coating, which includes ferrochrome, ferrotitanium, ferroboron, boron carbide and graphite, the hardness of the deposited metal can reach 62-64 HRC. Metal deposited with T-590 and T-620 materials is brittle and prone to cracking, and is therefore not intended to withstand significant shock loads. Fusing is carried out in 1-2 layers.

Repair of products made of various metals and alloys also has its own specific characteristics.

Wear factors

There are a large number of wear factors that appear both in pure form and in combination with each other. Therefore, to ensure maximum hardening efficiency, the filler metal must be carefully selected.

The grade of reinforcement metal should be selected as a compromise between each wear factor. Therefore, when the wear mechanism is studied, it is determined which factor is the main one and which is the secondary one.

Experience shows that in order to select the optimal metal for hardfacing, you need to know the following:

1. what are the main factors of wear; 2. what grade of base metal of the part being hardened; 3. what welding methods are preferable to use; 4. what final machining of the part is required.

If the primary wear factor is abrasive wear and the secondary wear factor is impact wear, then the reinforcing metal should be used such that it has good resistance to abrasive wear as well as sufficient resistance to impact wear. To simplify the general understanding of wear factors, they can be divided into characteristic types.

Metal-on-metal friction wear or adhesive wear

This type of wear occurs when one part rubs against another, for example: when shafts rotate in bearings, when sprockets come into contact with chains, when a pair of gears operates, etc. Martensitic alloys resist metal-to-metal wear well. Austenitic-manganese and cobalt alloys also resist this type of wear well. Cobalt alloys are used for parts operating at high temperatures and in oxidizing environments.

Typically, contact between surfaces of materials of the same hardness produces excessive wear. Therefore, materials of different hardness are chosen for the friction pair.

Impact wear

Metal parts are deformed, partially broken and even completely destroyed if their surfaces are not protected from impact wear. Impact wear occurs in crushing and grinding equipment where rock or gravel is crushed. In this case, small abrasive particles are formed, so the surfaces of the equipment must be simultaneously protected from abrasive wear.

Austenitic-manganese steels, when surface hardened, offer great resistance to pure impact wear due to their high surface hardness and relatively soft core. Martensitic alloys also resist moderate impact wear, but to a lesser extent than austenitic-manganese alloys. Crusher plates, impact hammers, railway crosspieces and rails are subject to intense impact wear.

Abrasive wear caused by small mineral particles

This type of wear occurs when sharp particles slide across a metal surface at varying speeds. Wear occurs by grinding down the metal with particles that are like small cutting tools. The heavier the particle and the sharper its shape, the more severe the abrasion.

This type of wear occurs in earth-moving equipment, agricultural tools, and when transporting minerals. Due to the absence of shock loads, brittle high-carbon chromium steels and carbide-containing alloys are excellent at resisting this type of wear.

Intense abrasive wear in the presence of pressure

This type of wear occurs when small, hard abrasive particles are crushed and ground between two metal parts. Typical parts subject to this type of wear are nozzles, rotary crushers, mixer blades, and scraper blades. To strengthen such parts, austenitic-manganese, martensitic and carbide-containing alloys are used. Carbide alloys usually contain small titanium carbides, evenly distributed throughout the volume, which resist this type of wear well.

High temperature wear

When metals are exposed to high temperatures for long periods of time, they tend to lose strength. As a result of operating at high temperatures, thermal fatigue cracks appear. Thermal shock caused by cyclic thermal stresses is observed in forging and hot working tools and dies. When working in an oxidizing environment, the metal surface is covered with an oxide film, which is destroyed upon cooling and the oxidation process is repeated. Martensitic steels containing 5-12% chromium have good resistance to thermal fatigue wear. Alloys with chromium carbides offer excellent wear resistance at temperatures up to 600°C. To operate at elevated temperatures, nickel- or cobalt-based alloys are often used. Rolling rollers, dies, guillotine knives, punches, dies for hot metal processing, etc. operate at high temperatures.

Surfacing of stainless steels

The most popular electrodes for surfacing corrosion-resistant steels are grades TsN-6L, TsN-12M-67. The core of such materials is a stainless high-alloy wire. The deposited metal has the following characteristic features: high corrosion resistance, resistance to scuffing. The second property allows these electrodes to be used for surfacing reinforcement products. The need for preheating (up to 300-600°C) and subsequent heat treatment depends on the brand of materials used.

The features of the welding process of stainless steels can be found in the article “Welding stainless steel”.

Surfacing of cast iron and its alloys

The most popular brands of electrodes for surfacing cast iron are:

Electrodes TsCh 4.

OZCH-2 are designed for surfacing ductile and gray cast iron.

MNCh-2 electrodes ensure the density and cleanliness of the deposited layer (after processing).

OZZHN-1 and OZZHN-2 are used for working with gray and high-strength cast iron.

TsCh-4 electrodes have good welding and technological characteristics: ease of ignition and stability of the arc, low spatter.

Some grades are universal; they can be used to weld various types of cast iron: malleable, gray, etc. Most are intended for certain types of alloys. A complete list of electrodes for welding cast iron can be found in the corresponding section.

Equipment used

Surfacing equipment operates using the same heating sources and methods as welding equipment. It differs in that it has auxiliary devices that ensure the supply and distribution of additives over the surface of the product.

For surfacing, welding devices are often used, which can be supplemented with the necessary devices and equipment. Surfacing equipment is divided according to the shape of the working surfaces: for bodies of revolution, for flat parts, for complex profiles.

The additive is applied using classical methods (for example, spraying, rods, wire) or special ones (centrifugal distribution, spiral laying, etc.).

Surfacing equipment is equipped with devices for preheating the product (from 500 to 700 degrees). The market offers small-sized units for home use that work with metals up to several millimeters thick.

Surfacing of copper and its alloys (bronze)

Products made from technically pure copper are deposited using Komsomolets-100 electrodes or filler rods, the composition of which is close to the composition of the base metal. It is recommended to use preheating to 300-500°C. If the copper temperature exceeds 500°C, then the deposited layer must be forged.

If it is necessary to surfacing bronzes, it is better to use OZB-2M electrodes. The deposited metal has high surface wear resistance.

Surfacing of copper and its alloys is carried out using direct current of reverse polarity exclusively in the lower spatial position.

The brands of electrodes intended for welding copper and its alloys can be found in the corresponding section.

Manual arc surfacing modes

You need to choose one of them based on a number of parameters - additional and basic, which ultimately determine the size and quality of the seam.

The main characteristics are:

- • current strength - in general, it should be higher, the thicker the diameter of the electrode and the base metal;

- • arc voltage (length), defined as the distance from the end of the rod to the surface of the workpiece - it is important to keep it short and stable;

- • speed – the faster the work is done, the less spreading of the material, but the higher the risk of lack of penetration, so it is necessary that the process occurs evenly;

- • type and polarity of the current – reverse is relevant for thin-sheet and high-alloy items (so as not to burn or overheat them), direct – for massive parts.

Additional parameters include the number of passes, the thickness and chemical composition of the applied layer, and the location of the joint.

Surfacing of aluminum and its alloys

OZA-1 electrodes.

The most effective restoration method is arc surfacing. Electrodes of the OZA, OZANA and UANA brands are intended for products and structures made of aluminum and its alloys.

Consumables OZA-1 ensures the production of metal with high corrosion resistance.

The special coating of OZANA-1 electrodes allows you to normalize the process and destroy the oxide coating formed on aluminum products during work.

To regulate the structural composition of the deposited metal, powder electrodes should be used. Electrodes of this type make it possible to create not only a deposited layer of equal strength to the base metal, but also a layer with significantly improved characteristics.

A complete list of electrodes for welding aluminum and its alloys is presented in the corresponding section.

Equipment for manual arc surfacing

The power source can be a step-down transformer: at a low output voltage it will give a large amperage, which is convenient. Rectifiers are also often chosen: by converting them, instead of the standard “mains” 220 V and 50 A, it is quite possible to get 600 A at 17-45 V. Inverter machines are also quite popular - due to their relatively small weight and size. Electric generators are becoming portable connection points, but they are quite expensive to operate, which limits their relevance.

The specialist performing the work must protect himself from accidental injuries - wear gloves and a mask with a “chameleon” light filter, which protects the eyes from the harmful effects of UV radiation.

Materials for manual arc surfacing deserve special attention. These are either electrodes, or wires and tapes, or hard alloys. We have already considered the first two options, let's take a look at the third.

Most often these are boride- and carbide-forming metals such as manganese, chromium, titanium, tungsten, combined with iron, nickel, boron, cobalt, both in powder and cast form. A typical representative of the first category is stalinite, the second is rod sormite.

Cases in which they are relevant:

- • restoration of machine tools and production mechanisms;

- • creation of stamps;

- • repair of parts used under severe wear conditions.

Consumption of materials

To determine the cost of the finished product, it is important to correctly calculate the consumption of surfacing materials. Calculations are carried out in accordance with accepted standards for each specific type of work and materials. Also, knowing the exact quantity of necessary consumables can ensure process continuity and create reserves of materials.

Calculation of deposited metal during welding is one of the main indicators. There is a special formula to determine the value of this coefficient. The mass is calculated per 1 meter of weld. How to determine the mass of deposited metal during welding will be analyzed further:

G = F * y * L, where: F – cross-sectional area of the weld (in mm2) y – specific gravity of the metal (g/cm3) L – length of the weld is 1 meter.

Thanks to this formula, any performer will be able to calculate the mass of deposited metal during welding.

Calculation of electrodes for surfacing is also a significant quantitative parameter. The performer does not need to perform calculations to determine this value. Each brand of welding materials has its own indicator - electrode consumption during surfacing of 1 kg. metal varies from 1.4 to 1.8 kg.

to calculate the mass of deposited weld metal per linear meter. According to GOST, each form of weld made of carbon and low-alloy steels, performed by manual electric arc welding with a metal consumable electrode and welding in carbon dioxide, has an average value of this parameter.

Surfacing electrodes

Manufacturers and sales companies offer a wide range of special electrodes for surfacing. The most popular surfacing materials are electrodes from the following manufacturers: “SpetsElektrod” (Moscow), “LEZ”, “SpetsElektrod” (Volgodonsk), “SZSM”, ESAB, Lincoln Electric. The wide range of consumables offered allows the contractor to choose the best option for electrodes to perform specific work. A complete list is presented in the section “Electrodes for surfacing surfaces of layers with special properties.”

Surfacing Services

Many companies operating in the metal processing industry offer related services. Companies provide surfacing services at a professional level, using specialized and modern equipment, and employees with extensive experience and knowledge. Craftsmen can process products of various sizes. Therefore, if the performer cannot carry out the fusing procedure independently, it is more advisable to turn to specialists. This will help significantly save money and time spent.

other services

Restoration of diesel fuel equipment parts Restoration of plunger surfaces Restoration of bearing seats Surfacing of valves Restoration of parts by spraying Restoration of parts by surfacing Restoration of cast iron parts Restoration of parts by welding Repair of stamps and molds Restoration of parts of printing equipment Restoration of food industry parts Repair of shafts Spraying of shafts Restoration of shafts Restoration of parts and components Restoration of parts by metallization Restoration of parts with repair dimensions Restoration of metal parts Restoration of surfaces of parts Restoration of steel parts Restoration of car parts

"Plasmacenter" offers

- services for restoration of parts, coating, vacuum sputtering, microplasma sputtering, electric spark alloying, plasma processing, coating certification, titanium nitride sputtering, shaft repair, corrosion coating, protective coating, hardening of parts;

- supply of equipment for the processes of finishing plasma hardening, welding, soldering, surfacing, spraying (for example, gas-thermal, gas-flame, microplasma, high-speed and detonation spraying), electric spark alloying, control devices, powder dispensers, plasma torches and other equipment;

- supply of consumables such as welding wire, electrodes, welding rods, spraying powders, surfacing powders, additive manufacturing powders, surfacing wire and other materials for welding, surfacing, spraying, additive manufacturing and hardening processes;

- conducting R&D in the field of surface engineering, coating tribology, plasma processing methods, selection of optimal coatings and methods of their application;

- training, consulting in the field of surfacing, sputtering, hardening, modification, hardening.

Contact us by phone: +7 (812) 679-46-74, +7 (921) 973-46-74, or write to us by email.

Our managers will tell you in detail about the technologies we have for coating, hardening, restoring, imparting surface properties, as well as the cost of the company’s services.