Oxygen cylinder reducer nut size

The parameters of nuts for gas cylinders are determined by GOST 949-73 standards.

The nominal thread diameter of the nuts is 27 (mm), the height of the nuts is 24 (mm).

The main dimensions of hexagonal brass nuts with a thread diameter of 27 (mm) with removable fittings, which are used to connect reducers to gas cylinders, in accordance with the manufacturers’ working documentation and the provisions of GOST 949-73 (Steel cylinders of small and medium volume for gases on P Additionally:

Maximum permissible deviations in dimensions, deviations in shape and location of surfaces of nuts for gas cylinders must comply with the provisions of GOST 1759.1.

The thread of the nuts for connecting reducers to gas cylinders must comply with GOST 24705 standards.

Technical requirements for the production of nuts must comply with GOST 1759.0.

Important: the material used for nuts with removable fittings for gas cylinders is brass, usually LTs40MtsZZh or LTs16K4 alloys in accordance with GOST 17711-93 (Copper-zinc (brass) casting alloys. Grades).

Detailed data on the main dimensions of hex nuts for gas cylinders are presented in the tables below.

| General view General characteristics of nuts for gas cylinders | d Nominal thread diameter in (mm) |

| Parameter Parameter of fitting |

Caution: The above data are official figures from manufacturers, but please note that the information is for reference only and is not guaranteed to be completely accurate.

Comments. Have questions? We will answer everything.

Source

Carbon dioxide cylinders 5 l, 10 l, 40 l, according to GOST 949-73

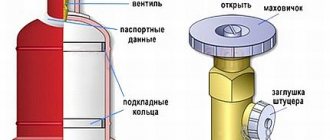

CO2 containers (cylinders) with a working volume of 5, 10 and 40 liters are designed for storage, transportation and technological distribution of carbon dioxide to consumers. New carbon dioxide cylinders must be equipped with:

- Oxygen valve VK, weighing 0.5 kg;

- Rubber transport ring – 2 pcs.;

- Support shoe, weighing 5.2 kg;

- A steel or re-certified cap, weighing 1.8 kg, or a fiberglass cap (safety), weighing 0.5 kg;

- Neck ring, weighing 0.3 kg.

The cylinders are made from the material “Structural high-quality carbon steel” grade 45D or “Structural alloy steel” grade 40KhGSA (cylinders with a capacity of 40 liters).

The body of the cylinder is painted black with the inscription “CARBON ACID” printed in yellow enamel. The weight of the cylinder is regulated without taking into account the weight of the valve, rubber rings, support shoe, safety cap and neck ring.

At the top of the cylinder there should be a “Carbon Dioxide Cylinder Passport”. Passport information is applied using the percussion method. In this case, the surface of the passport must be cleaned to a metallic shine and have an outer border in the form of a strip with an approximate width of 20-25 mm, applied with yellow enamel. The cylinder passport must contain the following information (from left to right along the perimeter of the intended circle):

- Date of manufacture of the cylinder, and the year of the next inspection;

- Working pressure “P”, MPa (kgf/cm2) and process hydraulic pressure “P” in MPa (kg/cm2);

- Capacity in liters;

- Empty cylinder weight in kilograms:

- The serial number of the cylinder and the product brand of the manufacturer;

- Brand of the company that carried out the Technical Examination of the cylinder;

- The mark of the Technical Control department of the cylinder manufacturer.

The thread in the neck of the cylinder is cut according to GOST 9909-81, and must meet the following requirements:

- Type – conical;

- The outer diameter in the plane of the neck end is 19.2 mm;

- The number of threads with a full thread profile is 7;

- There should be a thread left on the valve screwed into the neck - 2-5 and 1-2 turns of the visible threaded connection of the valve gland nut;

- The valve is installed on a sealing material, for example, a fluoroplastic sealant - FUM tape;

Oxygen reducer

The equipment used to reduce the oxygen pressure at the outlet of the storage vessel to the operating level and maintain it at the required level is called a reducer.

For each type of technical gas used in industry and everyday life, there are different equipment designs: for carbon dioxide one type, for acetylene another, for oxygen a third.

The key document defining the requirements for gas reducers is GOST 13861-89. This document defines the general conditions for products of this type.

Purpose of the oxygen reducer

Oxygen is an integral component of the so-called gas welding or metal cutting. It is delivered to the work site in cylinders made of steel and painted blue.

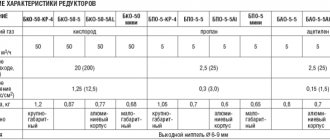

To ensure the supply of oxygen under operating pressure, reducers are used. In accordance with GOST 13861-89, these devices are marked as follows - BKO, SKO, RKO. The first abbreviation means that the reducer is used for installation on oxygen cylinders, single-stage (D - two-stage). The second is a network Product, and the third is a ramp Product.

Several types of these devices are produced - BKO 25 and BKO 50. The first type provides oxygen supply up to 25 cubic meters per hour, the second 50. The maximum operating pressure parameter of the first model is 0.8 MPa, for the second 1.25 MPa.

A union nut is used to connect the oxygen reducing device.

The gearbox uses the following principles in its operation:

- The gas passes through the filter and is supplied to the high pressure chamber. Rotation of the regulator transfers the force of the installed spring through the disk, diaphragm and pusher directly to the valve. It is he who regulates the flow of oxygen into the working volume.

- The unit in which the pressure changes occurs is a separate assembly unit consisting of a seat, a valve with a spring and an EF-5 filtration device. To increase safety, a valve is mounted on the device body, designed to release gas when a critical pressure level in the working chamber is reached from 16.5 to 25 kgf per square centimeter.

Oxygen reducer pressure gauge

As part of the oxygen reducer, pressure gauges are used, one shows the pressure value in the cylinder (network), and the second shows its output parameter. The oxygen mixture is supplied to the welding zone through a hose with a diameter of 6 mm or more. The hose is connected to the fitting, and a cutter or burner is installed at the other end.

Cylinder valves

Oxygen valve VK-94 (Compressed air, nitrogen and other non-aggressive gases)

| Options | VK-94-01 | ||

| isp.07 | |||

| Du, mm, no less | 4,0 | ||

| Working pressure, MPa (kgf/cm2) | 20 (200) | ||

| Dimensions, mm | 60x62x120 | ||

| Weight, kg | 0,55 | ||

| Connection dimensions | |||

| at the inlet - external thread | W27.8 | W19.2 | |

| at the outlet - external thread | G3/4 -B | ||

Diaphragm valve VBM-1 (for inert gases: helium, nitrogen, argon and other non-aggressive gases)

| Options | VBM-1 | ||

| Du, mm, no less | 4,0 | ||

| Working pressure, MPa (kgf/cm2) | 20 (200) | ||

| Dimensions, mm | Ø62x130 (without filter) | ||

| Weight, kg | 0.65 | ||

| Connection dimensions | |||

| at the inlet - external thread | W27.8 | W19.2 | |

| at the outlet - external thread | G3/4 -B | ||

Membrane valve KVB-53 (oxygen, helium, carbon dioxide, compressed air, nitrogen)

| Options | KVB-53 | |

| Du, mm | 4 | |

| Working pressure, MPa (kgf/cm2) | 20 (200) | |

| Dimensions, mm | 63x63x110 | |

| Weight, kg | 0,56 | |

| Connection dimensions | ||

| at the inlet - external thread | W27.8 | |

| at the outlet - external thread | G3/4-B | |

Hydrogen valve BB-88

| Options | BB-88 | ||

| isp.03 | |||

| Du, mm, no less | 4,0 | ||

| Working pressure, MPa (kgf/cm2) | 20 (200) | ||

| Dimensions, mm | 66x62x120 | ||

| Weight, kg | 0,60 | ||

| Connection dimensions | |||

| at the inlet - external thread | W27.8 | W19.2 | |

| at the outlet - external thread | SP 21.8-14 threads per 1″ left | ||

Ammonia valve (Angle pin valve for chlorine cylinders)

| Options | 15ls93bk | |

| Du, mm, no less | 5 | |

| Nominal pressure, MPa (kgf/cm2) | 1,6 (16) | |

| Weight, kg | 0,52 | |

| Connection dimensions | ||

| at the inlet - external thread | W27.8 | |

| at the outlet - external thread | G1/2 |

Acetylene valve VAB-97

| Options | VAB-97 | |

| Du, mm, no less | 3,5 | |

| Working pressure, MPa (kgf/cm2) | 3,5 | |

| Dimensions, mm | 123x41x39 | |

| Weight, kg | 0,6 | |

| Connecting thread | W27.8 |

Acetylene valve VBA-1

| Options | VBA-1 | ||

| isp.03 | |||

| Du, mm, no less | 4 | ||

| Working pressure, MPa (kgf/cm2) | 3,5 (35) | ||

| Dimensions, mm | 110x45x45 | ||

| Weight, kg | 0,65 | ||

| Connection dimensions | |||

| at the inlet - external thread | W30.3 | W19.2 | |

| at the outlet - boring for a fitting with a clamp | Ø10xØ20x5.5 | ||

Balloon valve Cavagna group (Italy)

Types of oxygen reducers

Gearboxes can be divided into two large classes – ramp and stationary. The former are distinguished by high gas throughput, reaching 120 cubic meters per hour. That is why they are installed to supply oxygen to combined welding stations. The second oxygen reducers are intended for personal use. They guarantee gas consumption ranging from 5 to 25 cubic meters per hour. It should be remembered that in appearance oxygen reducers are similar to each other.

GOST 13861-89 defines the following types of products for reducing oxygen pressure:

- On the cylinders - BKO, BKD and BPO.

- In the backbone network - SKO, SAO, SPO, SMO.

- Universal - U.

- Ramp ones - RKZ, RAD, RPD.

- Central action - CDC.

The key parameters of an oxygen reducing device are the ability to pass a certain volume of gas per unit of time and maintain a given gas pressure in the container.

Oxygen reducer BKO 50-4

Thus, BKO 50-4 provides a gas supply of 50 cubic meters per hour and with a pressure of 4 atm. BKO 50 – 12, at the same flow rate, maintains a pressure of 12 atm. By the way, devices of these models are most often used to equip working gas welding stations.

Oxygen reducer RKZ 500-2 (collection diagram)

RKZ 500-2 (ramp oxygen reducer) is designed for simultaneous supply of gas to several gas welding stations. These devices operate in a temperature range from -5 to +50 degrees Celsius. By the way, experts recommend equipping oxygen devices of this class with additional filters.

Design and principle of operation of an oxygen reducer

Reverse-acting devices have become widespread in practice. The reason for this is their minimal dimensions and the design simplicity of the product.

Oxygen reducer design

The body of this device contains two consecutive vessels. The first is a high-pressure container, it receives gas from a cylinder or from a gas supply line. A valve is mounted between the containers, controlled by two springs acting on the membrane. The valve stroke directly depends on the force developed by these springs.

The spring installed in the first chamber is adjusted using an adjusting screw. It adjusts the stroke of the control valve. To close it, just turn the screw all the way.

The low pressure chamber is directly connected to the burner (cutter), that is, the pressure level in the container determines the level of gas pressure on the burner (cutter). If the gas flow exceeds the volume supplied, the pressure in the first tank will drop. In this case, the spring will press on the membrane with great force and as a result the valve will open to a greater extent and the volume of gas supplied will increase. If the flow rate is reduced, the spring will return the valve to its place. Thus, automated regulation of operating parameters in the reduction device occurs.

Pressure gauges are mounted on the body of the oxygen reducer. The first sensor shows its numerical value in the cylinder, the second shows it on the working element (cutter, burner).

How much gas is in the cylinder?

The level of its consumption will directly depend on how much gas the cylinder contains. The amount of gas depends on the pressure inside the container and the type of contents.

In the case of supplies from our company, the distribution is as follows:

- Propane. 50 liter cylinders hold 10 cubic meters. m / 42 liters of liquid gas / 21 kg of liquid gas

- Acetylene. In a 40-liter cylinder with an indicator of 19 kgf/cm2 you will find 4.5 cubic meters. m / 5.5 kg of gas in a dissolved state.

- Carbon dioxide. The 40 liter capacity contains 12 cubic meters. m / 24 kg.

For gases such as helium, oxygen, argon, nitrogen, as well as for welding mixtures, which are supplied in 40-liter cylinders at a pressure of 150 atmospheres, the figure will be 6 cubic meters. m / helium 1 kg, and for other compressed gases - 8–10 kg.

Oxygen reducer characteristics and design features

In addition to the key parameters in the form of flow and pressure, gearboxes have the following additional characteristics:

Oxygen reducer characteristics

- Number of pressure reduction stages. Manufacturers produce devices with one or two stages of regulation. In the first, the main role is played by the spring. In models with two stages, adjustment is carried out using intermediate air chambers. These products guarantee the operation of the gas welding workplace in conditions where the temperature is below zero. In addition, these reducers guarantee a stable gas supply. But they differ in design complexity and, accordingly, cost.

- All oxygen reducers are connected to the gas source using a union nut. Clamps and other fastening devices must not be used. This is caused primarily by the explosive properties of oxygen, which require high-quality sealing of the connection.

- Another parameter of oxygen reducing devices is the climatic design. This indicator is important. The fact is that a drop in pressure leads to an increase in its volume. This leads to overcooling of the reducer and gas, which can lead to damage to the device.

Oxygen reducer device features

The two-stage oxygen reducer is distinguished by a valve manufactured with high precision and a membrane assembled from two layers of material. Synthetic rubbers are used for its manufacture. This allows the device to remain operational at temperatures below 0 and pressures up to 200 atm.

What is the thread on the carbon dioxide cylinder?

Any CO2 balloon system has the same structure. Many modules are optional, some can be combined, but in the end the structure is still the same: The cylinder is a source of gas. Often a metal container containing gas under (high!) pressure. They are divided into refillable or disposable. Disposable cylinders - often available in branded systems with an interesting price. The downside is that the cylinders themselves are thrown away after the gas is used up. To work further, you need to buy the same cylinder (without the system) - which is cheaper than a ready-made system, but often still expensive. Or you can look for options for converting the remaining system for replacement cylinders. Evaluate the feasibility of the purchase by calculating the cost of maintaining this system. My personal opinion is that compact systems with disposable cylinders have a right to life, for example in micro aquariums. Refillable cylinders are the most interesting option in terms of long-term operation. Allows you to reuse them. Divided into . As it turns out, the difference is quite significant for our country. They often don’t want to refill branded cylinders because they are “non-standard”, they don’t have certification, etc. Before purchasing a system with a branded cylinder, make sure you find where to refill it. “Our” cylinders are made according to the standards of our country. Can be certified and tested (gas under pressure... the life of relatives is always more expensive than even the most beautiful aquarium). They are checked and refueled at special stations. There are “carbon dioxide”, “oxygen”, converted fire extinguishers, oxygen from medical systems, etc. In essence, they are the same. They differ in size, shape, weight. Oxygen - have greater wall thickness, since oxygen is under greater pressure and have a greater margin of safety. As a rule, CO2 cylinders are made with a margin of safety and, if properly filled and used, are no worse than oxygen cylinders, and at the same time significantly lighter. A further difference between all cylinders is the valve. In fact, it is a tap with a thread that serves to connect to the “REDUCER” cylinder. The size of the valve thread is important when choosing a reducer, it is not directly related to the volume of the cylinder, but, as a rule, the following sizes are used: 1. Thread 12″ or 21.8mm (W21.8×1/14) – used in carbon dioxide cylinders 0.5-5 liters Most imported cylinders use the same thread (in my opinion, the most promising cylinders). 2. Thread (12 mm - not sure) - used in oxygen cylinders. 3. Thread 34″ or 27.8 mm - standard for “large” cylinders (7 liters or more). 4. Some imported systems may have their own thread size in order to bind the buyer to their equipment. In principle, you can look for adapters between systems.

A thread of one size can easily be converted to another using a special adapter. Advice - if possible, do not use adapters. If “this has already happened”, do not use homemade or tap water ones, but buy a special one for high pressure.

The gearbox, as a rule, is the most expensive element of the system. Purpose – reducing gas pressure to “acceptable” values. Roughly speaking, gearboxes are divided into aquarium and industrial (for beer, welding, etc.). Industrial ones have the ability to very roughly control the gas flow and require additional equipment, such as a “fine-tuning valve”. Among the positive features of industrial gearboxes are their maintainability and “brutality” - they are often not so fragile. Industrial gearboxes come with all three thread types. Aquarium gearboxes are designed for more precise adjustment and a small volume of gas that passes through them. Suitable for connection to CO2 equipment without additional devices. As a rule, aquarium gearboxes are much more compact, but more expensive compared to industrial ones. When buying “our” gearbox, decide what you need from it and immediately try to order it with a hose, a fine-tuning tap and, if necessary, a solenoid valve - so that the seller can connect it all at once

How to work with an oxygen reducer

When working with oxygen reducers, it is necessary to carry out several preparatory operations.

- Check the serviceability and integrity of the pressure sensors. The arrows must be set to zero and not change their position when turning the gearbox.

- Before connecting the gas supply hoses, it is necessary to check whether the operating screw that regulates the closing of the valve is turned out.

- After connecting the hoses, it is necessary to configure the device to supply the pressure necessary to perform the work.

Working with an oxygen reducer

In addition to the above operations, it is necessary to check the gearbox for leaks. To do this, the screw must be unscrewed completely.

Check the threaded connection for traces of oil and grease; if found, they must be removed immediately using a solvent.

By the way, you can check the tightness by applying soap foam to the threaded connections. If bubbles appear, work must be stopped and the gearbox must be sent in for repair.

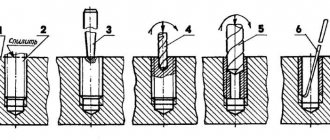

The valve structure on a gas cylinder and how to replace it if necessary

Cylinders are universal equipment for storing and transporting gaseous substances for domestic and industrial purposes. The shut-off valves in them do not last forever, so over time the valve on the gas cylinder needs to be replaced. You can do it yourself, following a number of safety rules.

We will tell you how to choose the right valve for equipping a gas cylinder. For independent craftsmen, we provide detailed instructions on how to change a worn-out device. Here you will learn what safety measures must be observed when installing a shut-off device on a gas tank.

What else you should know when working with a gearbox

As you know from a school chemistry course, oxygen is a strong oxidizing agent and therefore work with it must be carried out in strict accordance with the requirements of safety and labor protection rules. In particular, oxygen and oils must not be allowed to come into contact; such contact will result in an explosion.

Gas is often delivered to workplaces in cylinders with a pressure of 14.7 MPa. Therefore, when handling them, certain safety rules must be observed. In addition, the cylinder must not be dropped, hit, stored from fire, etc. The oxygen reducer installed on it must be covered with a durable casing.

Filled 50 liter propane cylinder for welding

» Articles » Refilled 50 liter propane cylinder for welding

Propane gas is used to ensure the operation of cooking stoves, heating residential, industrial and warehouse premises, refueling cars, gas welding and metal cutting. In our country, steel propane cylinders with a capacity of 5, 12, 27 and 50 liters are most often used for domestic gas supply. Such containers are easy to distinguish from others - they are always painted red. The word "PROPANE" must be written in white capital letters approximately 6 cm high.

In order to order a propane cylinder, you just need to call us or fill out the feedback form on the website. Our consultants will be happy to provide comprehensive information on any issue related to gas equipment. Our offers are transparent and profitable, just like propane gas itself.

Causes of gearbox failures

Like any technical device, the oxygen reducer is susceptible to problems that arise during operation. Thus, oxygen leakage may occur due to the fact that the seal between the valve and the chambers is broken. This may be because the hard rubber seat seal has worn out, or because foreign particles have entered the valve mechanism.

When operating in winter, the oxygen reducer may freeze. To prevent this phenomenon, the valve of the cylinder must be closed and blown with warm air. This will remove both ice and excess moisture. By the way, it is strictly prohibited to use fire to heat the gearbox.

There are frequent cases when the gearbox becomes clogged with foreign particles. To prevent this, the filter must be periodically blown or washed.