1. Tightness of connections.

2. Relatively high strength (especially in relation to soldering and casting).

3. Reduced weight of the structure due to smaller processing allowances, a reduction in the number of overlap seams, and the absence of bolts and nuts.

4. Design and technological simplicity.

5. High degree of mechanization and automation of welding processes.

6. High productivity and low operating costs.

The widespread use of welding is limited by serious disadvantages:

1. Significant limitation on the list of applicable structural materials. Weldability is one of the main technological properties of metals. Not all of them have good weldability.

2. Negative effect of strong heating on the properties of the material in the weld area:

— the structure of the material changes;

— the plasticity of the material and the endurance of the structure are reduced;

— internal stresses arise in the weld area due to shrinkage of the material upon cooling.

3. As a consequence, the tendency of welded joints to warp, especially with asymmetrical seams.

4. Instability of the mechanical characteristics of welds, to a greater extent during manual welding.

Didn't find what you were looking for? Use the search:

Best sayings:

A scholarship can buy you something, but nothing more.

8952 — | 7227 - or read all.

188.64.173.93 © studopedia.ru Not the author of the materials posted. But it provides free use. Is there a copyright violation? Write to us | Feedback.

Disable adBlock! and refresh the page (F5)

very necessary

Source: studopedia.ru

Advantages and disadvantages of different types of welding

Any type of welding work has its advantages and disadvantages compared to others.

The advantages of the gas method of welding and cutting include low cost and simplicity of equipment, cheap consumables (hydrogen, propane, methane, ethylene, benzene, gasoline, acetylene), a simple way to regulate combustion, the possibility of any location of the burner in space, high manufacturability, independence from sources electric power supply.

The disadvantages of this method are the low efficiency of heating the metal, wide seams and a wide zone of thermal influence on the structures being welded, low productivity, and difficulties in automating the process.

The advantages of the electric arc welding method are high manufacturability, ample opportunities for mechanization or automation, a smaller heat-affected zone compared to the previous welding method, ease of process control, relatively cheap consumables (welding electrodes), and high process productivity.

The disadvantages are the need to use special welding converters (rectifiers, inverters) and welding transformers, energy dependence on the electrical network or generators, the need for preliminary preparation of edges (cutting, cleaning, fixing parts).

The advantages of electroslag welding include: the ability to weld thick-walled parts, no need for preliminary preparation of welded surfaces, lower flux consumption compared to arc welding, the ability to use electrodes of various shapes, improved macrostructure of the weld, high productivity, lower power consumption, small dependence of the gap on the thickness of the metal , the possibility of using this method for remelting steel from waste to produce castings, the ability to adjust the process in a wide range of welding currents 0.2. 300 A/sq.mm across the cross-section of the welding electrode, good protection of the weld pool from the influence of air, the ability to produce seams of variable thickness in one pass.

The disadvantages are: welding only in a vertical position (the angle of deviation from the vertical is no more than 30 degrees), mixing of the electrode metal with the base metal, coarse-grained structure of the weld metal, the need to use special technological equipment (forming devices, strips, starting pockets, etc.) , the impossibility of interrupting welding before the end of the process, since this creates defects that cannot be eliminated.

The advantages of the electron beam welding method are the following: high efficiency (up to 90%) of the conversion of the kinetic energy of accelerated electrons into thermal energy and high specific power of the beam, high temperature in the welding zone (up to 6000 degrees Celsius). Heat generation only in the welding zone, good penetration of deep seams, beam focusing reaches values up to 0.001 centimeters, the ability to use an electron beam for various types of work - drilling, welding, milling of almost any materials, a wide range of thicknesses of processed workpieces from 0.02 to 100 mm , high degree of automation.

Disadvantages include the presence of special equipment and highly qualified personnel, the presence of X-ray radiation and the need to protect operating personnel, and a reduced service life of the electronic cathode as a result of its high heating (up to 2400 degrees).

Strength calculation of welded joints

When calculating the strength of welded joints, it is assumed that the stresses in the sections are distributed evenly.

Typically, welded joints are loaded with forces acting parallel to the plane of contact of the parts being connected.

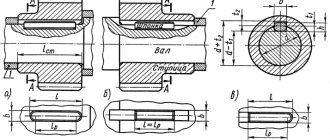

Calculation of butt welded joints for strength is carried out according to the nominal section without taking into account the thickening of the seams, depending on the type of acting loads (Fig. 5).

Rice. 5. Welds

A straight butt weld (Fig. 5, a) is stretched (compressed) by a constant force F. The permissible force on the seam is determined by the formula

where Lδ is the cross-sectional area of the seam, where the height of the seam is taken equal to the thickness of the sheet - δ, h ≈ δ[σ'p] is the permissible tensile stress in the seam itself.

When calculating compression, take the permissible compressive stress [σ'compress], which usually exceeds the permissible tensile stress (Table 8).

Table 8. Allowable stress for base metal

| Welding method | When stretched [σ'p] | When compressed [σ'compress] | When cutting [τ'sr] |

| Automatic, manual electrodes E42A, E50A | [σp] | [σp] | 0.65[σp] |

| Electrodes of ordinary quality E42, E50 | 0.9[σp] | [σp] | 0.6[σp] |

| E34 electrodes with ionizing coating | 0.6[σp] | 0.75[σp] | 0.5[σp] |

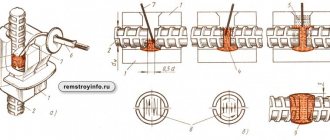

The lap joint (Fig. 5, b) can be frontal when the force F is perpendicular to the seam, flank when the weld bead is parallel, and combined when there are oblique seams.

Angular connection of two parts, the welded edges of which are located at any angle (usually 90°).

T-joint is a connection between the ends of one part and the planes of other parts.

Lap, corner and T joints are formed by a fillet weld (Fig. 5).

A fillet weld connection is accompanied by the action of a static tensile force F (Fig. 5, b).

Rice. 6. Corner joints

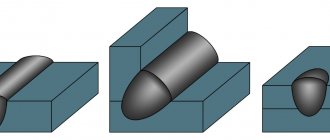

Calculation of fillet welds of all types (convex and concave) is carried out for a cut in a dangerous section 1–1, passing through the bisector of a right angle (Fig. 6; a, b) of an isosceles triangle without taking into account the convexity of the seam: with side K = δ. In this section, in addition to tangential stresses, normal stresses also arise.

Cutting area with a seam length equal to the strip width

where b1-1 = δcos45° ≈ 0.7δ.

Assuming that the force F is distributed evenly along the entire length of the seam, the permissible force for a one-sided seam

where δ is the thickness of the sheet, mm (or the value of leg K); b – sheet width (or seam length), mm; [τ'sr] – permissible stress at seam shear (Table 2).

When calculating compression, the permissible compressive stress [σ'compress] should be substituted into the formula.

When calculating the strength (tension-compression) of other welded corner joints, the same calculation formula is used, only instead of b the total length of all seams L is substituted, and we obtain:

where K = δ, mm; LΣ – total length of all seams; [τ'sr] – permissible stress on seam shear.

The total length of the weld LΣ = Σli is the sum of all sections of the weld. So, in Fig. 5, and LΣ = L = b; in Fig. 5, b total length of the seam LΣ = 2lф + la; in Fig. 7, a – LΣ = 2l1 + 2l2 + 2B.

Rice. 7. Scheme for determining the total length of welds

Taking into account possible defects in seams (lack of penetration at the beginning and along the length, craters at the end of the seam), sometimes the actual length of individual seams is increased by 5...10 mm to ensure the strength of the connection.

When connecting structures with flank seams to parts of an asymmetrical profile (angles, channels), welded using gussets (Fig. 7, b), the total length of the seams l1 and l2 are taken equal to the product of the total length of the seam LΣ by the size inversely proportional to the distances from the flank seams to the line centers of gravity of an asymmetrical section profile of a part:

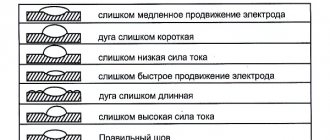

The essence, advantages and disadvantages of manual arc welding with coated electrodes

The essence of the process: The arc burns between the electrode rod and the base metal. Under the influence of the heat of the arc, the electrode and the base metal melt, forming a metal weld pool. Drops of liquid metal from the molten electrode rod are transferred into the bath through the arc gap. Together with the rod, the electrode coating melts, forming a gas shield around the arc and a liquid slag bath on the surface of the molten metal. The metal and slag pools together form the weld pool. As the arc moves, the metal of the weld pool hardens and forms a weld. As liquid slag cools, it forms a solid slag crust on the surface of the weld, which is removed after the weld has cooled (Figure 1).

Fig. 1 Scheme of the process of manual arc welding with a covered electrode

The main advantages of this welding method:

§ possibility of welding in all spatial positions and installation conditions;

§ relative simplicity, reliability and mobility of welding equipment;

§ the ability to weld a different range of metals (carbon steels, non-ferrous metals, copper, etc.) and thicknesses;

Allowable stress for welds

When calculating machine-building structures made of low-carbon, medium-carbon and low-alloy steels, the permissible stresses for welds under static loads are taken depending on the permissible tensile stress of the base metal [σp] (Table 2).

The value [σp] is obtained from the dependence

where σт – yield strength for the base metal (welded parts), MPa; [n] – safety factor, [n] = 1.3…1.6 for low-carbon steels, [n] = 1.5…1.7 for low-alloy steels. Smaller [n] values are recommended for low-critical connections and under light operating conditions, and larger values are recommended for critical connections and under severe operating conditions (Table 9).

Table 9. Yield strength for the base metal (σт) (sample)

| steel grade | St3 | St4 | St5 | Steel 30 | Steel 35 | Steel 45 |

| σt, MPa | 235…216 | 255…235 | 255 | 294 | 250 | 280 |

Example. Determine the length of the flank seams that ensure the strength of the connection between the equal-flanged (equal-sided) corner and the gusset (Fig. 7, b), if the cross-sectional dimensions of the corner (its profile): a) 70x70x6, b) 50x50x4; material – steel StZ. Manual welding with E42 electrode.

Calculation

According to the reference table for an equal-flange (equal-sided) corner of a profile 70x70x6 we take b = 70 mm, t = 6 mm, SL = 813 mm2,

Cx = 19.3 mm.

We calculate the permissible tensile stress of the base material, taking it from the table. 5 for steel StZ σт = 225 MPa and [n] = 1.45:

Based on the equation of the tensile strength of the angle σр = F/SL≤[σр], we determine the permissible value of the tensile force:

Using this force, we calculate the conditions for the equal strength of the corner in tension and the seam in shear.

Using the table 4 we calculate the permissible weld stress during shearing:

From the equation for the strength of seams, we determine their total length, taking k = t = 6 mm:

By formulas

with b = 70 mm and Cx = 19.3 mm, we determine l1 and l2:

Taking into account the possibility of technological welding defects, we finally accept l1 = 240 mm, l2 = 100 mm.

The main pros and cons of gas-shielded welding

The specific environment has a significant impact on the final result of the work. Thus, the properties of the arc and the characteristics of the seam will differ markedly from those of electric welding. The type of gas used plays a big role.

For example, argon allows you to create a figured seam due to the softness of the arc. And helium is used when it is necessary for the welding site to be practically invisible, as well as when processing thin sheets of metal. However, helium is used less efficiently due to its low weight.

When it is necessary to maintain a balance between efficiency and invisibility of the seam, carbon dioxide is used. By the way, it is almost universal. With its help you can weld products from almost any alloy.

It is worth noting that the type of gas has no effect on the choice of electrode. It may or may not be melting. However, due to the high degree of danger of gases, extra care must be taken during the welding process.

So, the general advantages of this technology:

- high quality seams;

- versatility in terms of processed materials and their thickness;

- independence of the result from spatial position;

- visual inspection of the seam during its formation;

- there is no need to fill up and remove flux and slag;

- efficiency;

- possibility of automation;

- cheapness.

There are also disadvantages of gas shielded welding. Thus, these include the presence of light and thermal radiation from the arc. The operator must be reliably protected from these negative factors, which requires additional financial costs. But the repair of such welding machines is generally no different from others.

is now an authorized LEEK Service Center. We repair voltage stabilizers of any model under warranty and for a fee.

Our service center will soon open in St. Petersburg!

Dear Clients! So we have passed the 40,000 order mark. For more than 6.5 years of daily work, we have repaired a total of about 40,000 units of welding equipment of various types and manufacturers. We are grateful to you for choosing ours. Every day we work fruitfully to provide you with services as efficiently and quickly as possible. We also make mistakes, but we always try to accommodate the client.

Source: welding-zone.ru