Cylinder color

Externally, unpainted acetylene containers differ only in the width of the neck. They have a diameter of 210 mm and a standard support shoe. After painting with enamel in preparation for work, the acetylene cylinder is white . In the upper quarter of the cylindrical part the word “Acetylene” is written in red. Letters 60 - 100 mm high should occupy at least half the circumference of the container.

There is a marking on the cone near the neck. It includes:

- manufacturer's trademark;

- factory mark;

- individual number;

- brand of the organization that carried out the technical examination;

- date of manufacture;

- year of next maintenance;

- operating pressure;

- capacity in liters;

- weight in kg.

The marking is stamped onto clean metal, outlined around the perimeter with red paint and coated with varnish to protect the surface from corrosion..

What's the pressure?

According to GOST, pressure is determined at a temperature of + 20⁰C. Limit value 19 kgf/cm2. Typically, acetylene in cylinders has 14 - 16 kgf/cm2.

Gas pressure depends on temperature changes. For example, 19 kgf/cm2 at 20⁰ when cooled to -4, a total of 13.4 kgf/cm2, at 35⁰ a critical value of 26 kgf/cm2 is reached. Therefore, a pressure reserve is created in case of heating.

You can determine the amount of gas filled by a simple calculation. You need to subtract the weight of the empty cylinder from the weight after refueling and multiply by 1.09 - that’s how much a liter of gas weighs.

Storage

Oxygen and acetylene cylinders are stored separately from each other. The conditions are the same:

- containers must stand vertically;

- place the cylinders in special stands and fix them;

- the room temperature should not exceed 25⁰C;

- should not be placed near heating devices or open flames;

- batches at the warehouse should not exceed 20 pieces.

Valves on containers with argon in the non-working position must be closed with special caps. As for acetylene cylinders, they are also sorted by volume.

You cannot keep a container nearby that is larger or smaller than the main group.

Device

The acetylene gas cylinder is made from seamless pipes in accordance with GOST 949-73 . Wall thickness 7 – 8 mm. The ends of the container are spherical. The top part has a hole into which the valve is screwed. A cylindrical shoe is placed on the lower part, giving the container stability.

The neck in acetylene cylinders is wider than in others where gas is stored. Through it, the container is filled with a porous mass: cast porous filler, activated birch carbon and basalt fiberglass. The loose substance absorbs acetone well and promotes uniform dissolution of acetylene in it.

Foreman of the acetylene cylinder filling section of the SpetsBallonMash plant Kurnikov A.I.: “The Americans fill the inside of an acetylene cylinder with asbestos cord. At the end of the last century, the Russian Federation abandoned such material as carcinogenic. Small particles of asbestos evaporate along with argon. In Russia, they switched to natural materials that absorb acetone: silk, leather, mineral wool, sawdust. Currently, some manufacturers use asbestos in small quantities as an additive to quartz sand and calcium hydroxide. In Germany, charcoal is mixed with magnesium carbonate and kieselguhr. When purchasing a cylinder, you should pay attention to its filling. Asbestos causes lung cancer."

Storage of acetylene - general provisions.

Due to the fact that acetylene is explosive not only when mixed with air or oxygen, but also in a pure state, there is a possibility of the cylinder exploding if a backfire occurs or if it is accidentally heated by a burner. Acetylene is stored in transport and small-capacity cylinders of a special design.

To prevent the spread of a blast wave in an acetylene cylinder, it is filled with a special cast porous mass, which most often is activated carbon, pumice, or asbestos fiber. Acetylene pumped under pressure fills all the pores of the material; to increase the gas volume, the filler is impregnated with acetone, which increases the absorption of the material. For example, up to 13 liters of acetone are poured into a transport acetylene cylinder, one liter of which can hold up to 23 liters of gas. In total, the transport cylinder can hold up to 6 kilograms of acetylene. This design of the cylinder allows the filler to dampen the resulting shock waves from an acetylene explosion, which significantly increases work safety.

Cylinders for acetylene storage are painted with white enamel, the inscription “Acetylene” is applied to it, under it are the letters “LM”, which indicates that the cylinder is filled with a cast porous mass. These inscriptions must be red.

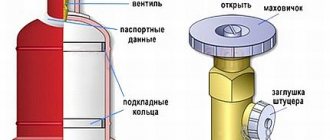

Valve

The locking device is made of steel. With prolonged contact with copper and bronze, a chemical reaction occurs and acetylenide is formed - a combination of copper with carbon and the release of hydrogen. Copper acetylene can cause an explosion .

The valve is connected to the neck with a clamp. The thread on the fitting is left - counterclockwise.

There are no taps usual for other gas tanks. The valve is opened with a special socket wrench by rotating a square spindle located in an axis along the entire length of the body. The clamp pressure screw has a small hole on one side for the outlet fitting.

How much is 40l?

The volume of acetylene in a fully filled gas container is calculated using a simple formula:

40 × 15 × 9.2 = 5520 l;

Where: 40 l – cylinder volume;

15 kg/cm2 – pressure;

9.2 gas solubility coefficient in acetone;

5520 l = 5.5 m3 amount of acetylene.

This formula calculates the amount of acetylene that can be filled into any size cylinder. In the formula, only 40 – the number of the container’s volume – changes to 5, 10 and others .

Cylinder explosion

The main disadvantage of acetylene is its explosiveness. Gas can detonate for many reasons:

- achieving a critical mass of gas;

- high pressure;

- residue in the flammable gas cylinder;

- contact with lubricant or calcium carbide;

- electrification of the neck by the gas itself, passing at high speed;

- heat;

- leakage and air connection;

- impacts on the weakened walls of the container.

The gas becomes explosive if it is collected in large volumes and when the acetylene pressure in the cylinder exceeds 2 kg/cm2. To reduce the risk of spontaneous explosion, a special porous mass is placed inside the gas container. It divides all the gas into small particles, allowing it to move freely. Pure acetylene can be pumped with a maximum pressure of 25 kg/cm2.

Refueling

Acetylene is produced by combining water and carbide . Acetylene cylinders are filled through the neck, determining its quantity by weight. Standard full cylinder 65 kg, empty 53 – 58 kg. The weight of the container with filler is indicated at the marking on the neck and is determined by weighing.

The acetone partially evaporates along with the gas. At each refill, add 130 - 150 ml.

If you fill a 5 liter container from a 40 liter cylinder, the gas in it will run out very quickly. In order for acetylene to dissolve in acetone, high pressure must be created. When pumping at home, it is impossible to create it .