A high-quality grill is the key to a successful barbecue. The material of construction directly determines how evenly the meat will be fried, how long the coals will smolder, and how the smoke will be distributed. Choosing the right metal will help the device last for many years. Unsuitable material, on the contrary, will lead to rapid corrosion, can spoil the taste of food and lead to poisoning. That is why when buying or making a barbecue with your own hands, you should take this issue responsibly.

Carbon steel grill

In production, in 99% of cases, barbecues are made from carbon steel (that is, where the carbon content is no more than 2.14%). For example, grades ST-3, ST-5 (classification: regular quality steel) or ST-15, 08-PS (classification: high-quality steel) (the latter products are stronger, more wear-resistant, but also 20 percent more expensive). The listed brands are affordable, have good performance characteristics and can be welded without restrictions. Their disadvantage is that they are susceptible to corrosion and can be deformed during heat treatment. These shortcomings are compensated for by the thickness of the sheet of the structure being welded (preferably from 2 mm) and covered with an anti-corrosion coating.

Here is a barbecue made of carbon steel grade 08PS - in industry this steel is also used for gaskets, washers, pipes, as well as parts subjected to chemical heat treatment - bushings, eyes, rods.

Various experts and sofa analysts consider ST-45 carbon steel to be the ideal option for a brazier. Its characteristics are such that it is used in shafts, gears, cylinders, and structures subject to surface heat treatment, which require increased strength. The difference in price compared to ST-3 is small, but it is difficult to weld steel. In order to weld it correctly, it is necessary to heat it to 200-300°C and subsequent heat treatment - annealing, so that there are no cracks, which makes the finished structure more expensive.

– What material is your grill made of? - Black metal. / For reference, iron and any alloys based on it (steels, ferroalloys, cast irons) are called ferrous metals /

Mobility

First of all, you need to decide in what conditions you are going to cook on coals. Will it be a solid structure for a summer house or a country house, the location of which is strictly defined? Or do you need a mobile product for regular outings? In terms of mobility, all barbecues can be divided into three main types:

- Collapsible grill . For transportation it requires constant assembly and disassembly from scratch. Compact, lightweight, usually inexpensive and varied in design. Suitable for occasional trips into nature, but short-lived and does not hold heat well.

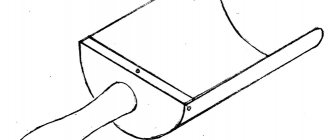

- Folding grill . The main elements of the box are connected into a non-separable, but compactly folding structure. The layout of such braziers is very diverse, but more often the coal box, consisting of plates with movable joints, is transformed into a small suitcase. A good option for frequent trips into nature with a car, they “unfold” quickly, are more durable and reliable than collapsible products. It costs noticeably more, but still does not hold heat well.

- Stationary grill . Completely integral, welded, non-separable structure made of thick-walled metal. Heavy, durable, heat-intensive. It is purchased for many years of use in “home” conditions. Stationary barbecues are usually more thoughtful, multi-functional and generally better suited for cooking. Their prices are higher and there is practically no mobility, but this is not required of them. Moreover, there are semi-stationary products with a pair of wheels for convenient movement around the site.

Corten steel grill

There are manufacturers who make barbecues from Corten steel; this is an alloy steel that is used in bridge construction, shipbuilding, industrial and civil construction as a structural material that does not require painting or other types of additional corrosion protection. Once covered with rust, such steel forever retains its brownish color.

Brazier made of Corten steel.

Brazier made of Corten steel. Photo https://www.labottegadelfuoco.it/barbecue-acciaio-corten/

Brazier made of Corten steel. Photo https://www.espositoforni.com/barbecue-mod-classic-corten/

Brazier made of Corten steel. Photo https://www.espositoforni.com/barbecue-mod-classic-corten/

Brazier made of Corten steel. Photo https://www.espositoforni.com/barbecue-mod-classic-corten/

Corten steel grill. Photo https://www.grillsymbol.com/shop/bbq-smokers/bbq-smoker-q-1250/

Corten steel grill. Photo https://www.grillsymbol.com/shop/bbq-smokers/bbq-smoker-q-1250/

Corten steel grill. Photo https://www.grillsymbol.com/shop/bbq-smokers/bbq-smoker-q-1250/

Brazier made of Corten steel. https://www.grillsymbol.ee/ru/shop/charcoal-grills-ru/grillsymbol-soegrill-chef-xl/

Technical specifications

It is important to pay attention to the design characteristics:

- material;

- general dimensions;

- bottom shape;

- number of holes for air flow;

- the presence of a lid, holes for skewers;

- wall thickness.

The capabilities of the barbecue and the features of its use depend on the technical characteristics.

Brazier with lid (Photo: Instagram / kovka_and_metall_krd)

Manganese steel grill

On the forums you can find recommendations that in barbecues it is necessary to use alloyed manganese steels, for example, 09G2S, 10G2, 17GS, due to the fact that these steels were created to work at temperatures from -70 to +425 ° C under pressure for parts of steam boilers, production pipes (the latter is popularly called “boiler steel”). That is, the advantage is that such steel is wear-resistant and does not lend itself to temperature deformation in the calculated ranges. (For reference only, larch and oak burn hotter, producing heat up to 900°C; pine and spruce firewood burn at 620-630°C.) There are enough examples of the use of these steels on the market; just google for “barbecue 17GS”.

Brazier made of steel 17GS

Type of fuel

Progress does not stand still. Coal and wood are not the only fuel options for grilling shish kebab. Modern roasters are:

- Solid fuel . Traditional barbecues use wood or coal, fuel is widely available. Easy to use and use, with a familiar and understandable cooking principle. The disadvantages of such braziers are obvious: a long time to put into operation (burning wood, igniting the hive), difficulties with adjusting the heat and cleaning, the ability to use only outdoors or indoors with a powerful hood.

- Gas . Gas grills are good to use because they offer instant heating, fine temperature control, the ability to be used indoors, and the absence of soot, soot and ash. Among the disadvantages: the absence of smoke changes the cooking principle (dishes lose their characteristic “smokiness” in taste), a more complex and, as a result, expensive design. They are also characterized by limited mobility - such fryers run on gas cylinders, and this is a noticeable addition to your luggage (and a hit on your pocket).

- Electrical . Such barbecues incorporate all the advantages and disadvantages of gas braziers, but are completely unsuitable for use in field conditions. However, they are safer than gas ones and more compact, because their operation requires not a bulky gas cylinder, but a regular outlet.

Stainless steel grills

Barbecues made of so-called “stainless steel” excite men and women better than any aphrodisiac. Of course, stainless steel is an alloy steel that is resistant to corrosion in the atmosphere and aggressive environments. This does not mean that it does not corrode or deform at all. Not every welder knows how to weld stainless steel. And it costs two to three times more than carbon steels. The brands AISI-304, AISI-409, AISI-430 are often used. The latter is popularly nicknamed “mirror stainless steel” and is allowed to be used for the production of products in contact with food.

Brazier made of mirror stainless steel

Brazier made of mirror stainless steel

Brazier made of mirror stainless steel

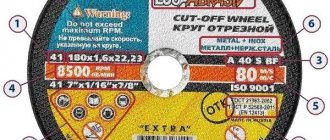

Is metal processing necessary?

It is better to additionally protect a steel grill from corrosion, then it will last even longer than usual. For this purpose, you can use powder enamels and paints with heat-resistant properties. The first coating you come across will not work - burnt paint will ruin the kebab and lead to poisoning with toxic secretions.

Special compounds can withstand heat above 600°C. They look beautiful and enhance the appearance of the structure. Heat-resistant paint in aerosols can be purchased at specialized and automotive stores. They do not emit harmful substances, but silicone paints also protect against rust, plaque, accumulation of soot and ash. Some of their varieties require baking, which may be indicated in the instructions.

In the factory, the metal structure is further strengthened by bluing and oxidation. The surface is cleaned, degreased, and a black heat-resistant film is applied on top. The steel is kept in a sodium solution at 140 °C or in water vapor with oxygen. Electrochemical processing is also possible. It is very difficult to carry out these processes on your own, but if there is an opportunity, it is better to take advantage of it. Compositions for such procedures are often sold at gun stores.

IMPORTANT. Painting is carried out only on the outside.

Making or purchasing a high-quality barbecue requires certain knowledge, time and effort. You should not neglect the characteristics of the metal if you plan to use it for a long time. Bad steel can harm your health and inevitably lead to unnecessary expenses and the purchase of a new device.

Source of the article: https://villadacha.ru/barbecue/metall-dlya-mangala.html

Braziers made of copper

Copper is a metal that has been tested for thousands of years. Now barbecues made of copper and its alloys have lost popularity. It is a soft metal with good thermal conductivity, easily oxidized, which, if not polished, becomes covered with a greenish coating. It seems like there are still such specialists in Turkey who are engaged in the production of copper barbecues.

Brazier made of copper. Photo https://www.bakirhome.com/bakir-ocakbasi/

Brazier made of copper. Photo https://www.bakirhome.com/bakir-ocakbasi/

Brazier made of copper. Photo https://www.bakirhome.com/bakir-ocakbasi/

Brazier made of copper. Photo https://www.bakirhome.com/bakir-ocakbasi/

What do the sizes depend on?

When determining the optimal size of the barbecue, as well as its design features, it is necessary to take into account:

- Number of people. The length of the kebab maker depends on this indicator, allowing you to simultaneously cook kebab for the whole company.

- Cooking method: skewers, barbecue grill. The width and length of the device depends on it.

- Distance from coals to skewers. The depth of the fryer, as well as thermal radiation, depends on this indicator.

Gold brazier?

What about gold? – the reader who has read up to this point will ask. Gold is a metal that is quite expensive and softer than copper. History knows one example of a barbecue coated with 24-karat gold. It was made by the Australian company BeefEater, specializing in the production of grills. The barbecue was sold in 2009 for $165,000 (~4.5 million rubles at that rate, that is, now, taking into account inflation, such a unit would cost ~5.5 million rubles).

BeefEater Gold BBQ. Photo https://www.dailymail.co.uk/news/article-1392750/BeefEater-Barbecues-golden-grill-plated-24-carat-gold–165-000.html

BeefEater Gold BBQ. Photo https://www.dailymail.co.uk/news/article-1392750/BeefEater-Barbecues-golden-grill-plated-24-carat-gold–165-000.html

Accessories

Often barbecues come with individual accessories or entire sets of them. Some should be purchased immediately, others are better purchased separately.

- Skewers . It’s great if they come complete with a barbecue. Firstly, you don’t have to buy them separately, and secondly, the number and size of the “native” skewers should definitely match the parameters of the selected fryer. Obviously, cheap barbecues are equipped with cheap skewers made of thin steel. In this case, it is better to refuse additional equipment and order skewers separately - those with a rectangular cross-section and made of stainless steel will be just right.

- Grill grate . By analogy with skewers, the “original” grill is already adjusted to the dimensions of the grill. Meanwhile, this is a very functional accessory that actually turns the grill into a barbecue grill. However, choosing such a grille separately will not be a problem, so there is no need to focus on this.

- Skewer . A useful accessory that allows you to grill large pieces of meat or whole animal carcasses. Roasters from the premium segment are equipped with an electric spit - a convenient, but not cheap, addition. Equipping a barbecue with a spit yourself will not be easy, so immediately think about its necessity and draw the appropriate conclusions.

- Other . A fan, a poker, a dustpan, tongs, all kinds of spatulas and forks, cleaning tools - all this is needed, it increases the comfort of cooking and operating the barbecue, but it is secondary and not as important as the barbecue itself.

Brazier made of heat-resistant and heat-resistant steels

If you make a barbecue from steel grades KhN32VT, KhN35VT, KhN38VT, KhN60VT, KhN78T, 33NK, 06KhN28MDT, KhN65MVU, then it will be essentially eternal - these are heat-resistant and heat-resistant steels (this is the official name of the class of steel, and not an invention of marketers). They were created for the rocket and space industry, elements of gas turbine engines of aircraft, combustion chambers of furnaces and other products operating at high temperatures, usually from 500 to 1350 °C. The price is approximately 1300-1700 rubles per kilogram. That is, the cost of the material for the barbecue alone can be 60-80 thousand rubles. We have heard nothing about the mass production of such barbecues; there are not even examples of finished products on the Internet for anyone to brag about. Maybe somewhere, through connections and for a lot of money, someone sells it. Everything is possible.

What design elements are required?

L.B.: For a barbecue to be considered correct, several nuances must be taken into account.

An ideal fryer should not be hollow, otherwise you can forget about uniform temperature distribution and well-cooked kebab. The best option is a grate , with slots or a grate at the bottom of the roasting pan.

Brazier with grate

The slots or holes will provide:

- A uniform flow of oxygen into the coal mass, which will support their combustion and create uniform heating over the entire area. Moreover, an excellent result will be obtained regardless of weather conditions (for example, wind), which seriously complicate cooking in barbecues with perforated walls.

- Removing ash through grate openings. The only thing you need to provide is a box for collecting it.

- Easy temperature control. A metal flap covering part of the slots or grate will allow you to achieve optimal cooking conditions.

Quality is in the details

According to the expert, you can tell that paint will withstand high temperatures by its appearance. It is baked in an oven at a temperature of 1100 degrees, and there should be no traces left on the paint when it comes out. If there are traces, this means that the grill was painted with ordinary brushes. “However, it is impossible to understand experimentally in a store how the paint was applied. This can only be done at home by scratching the grill on the corner. If the seller convinced you that the grill was painted directly in the oven, but the paint suddenly began to peel off, you were deceived,” continues Dmitry Alekseev.

To protect yourself and make sure that the grill is of high quality, you can pay attention to the corners of the brazier. So, on a proper grill there will be no traces of welding in the corners, the welding seam will pass only in two places - on the right and left walls, and on the back and front the metal should be bent.

The walls and bottom of the grill less than 2 millimeters will instantly burn the kebab, but a thickness of 4 mm will make the meat juicy and cooked. The height of the grill should range from 10 to 18 mm.

Let's go on a picnic: how to choose skewers and dishes Read more

Brick products for cooking on coals

Stone is usually used to make high-quality stationary buildings - barbecues, stoves, gazebos or entire barbecue pavilions. They choose for them some shady place surrounded by greenery in the garden or on a personal plot and build such an ensemble. Its center, of course, is the grill and stove for the gazebo, made of brick. In such an oven you can cook shish kebab, grill vegetables, or pilaf in a cauldron. There is a massive table and chairs nearby. Lighting has been installed so that you can breathe fresh air in the evenings in the circle of warm company. We gave examples of such corners for relaxation in the article “How to properly place a garden barbecue oven with barbecue.” Advantages of brick

: • durability; • wear resistance: not afraid of corrosion or high temperatures; • good heat capacity: retains heat for a long time, allowing you to save fuel; • low cost.

However, this barbecue material also has its drawbacks. The structures made from it are massive, it is impossible to move them, and for picnics on a hike you will have to purchase an additional small grill. It requires painstaking work and knowledge of the laws of physics: if the same pipe is built incorrectly, instead of good traction you will get soot and just torment during cooking.

Material

When choosing a material, you need to consider that the metal must withstand exposure to open flames. It is also important to pay attention to its environmental friendliness.

To make a grill you can use:

- Cast iron. Tolerates temperature changes well. When used outdoors, surfaces quickly become rusty. Transportation is complicated by the large specific gravity.

- Steel. The best varieties are 45, 10G2, 16GS. Often used to make various tools.

- Stainless steel. The most popular material for making barbecues. Withstands temperature changes and prolonged exposure to moisture. Weighs less than cast iron.

Ferrous metal is often used in the manufacture of barbecues.

Selection principles

When choosing a metal grill you need to consider:

- Availability of free space on the site.

- Dimensions of the fryer.

- Possibility of moving the structure.

- Complete set. For example, you can buy a grill with a metal cauldron or a full-fledged barbecue oven.

Advantages and disadvantages

The strengths of barbecues depend on the material from which they are made. General benefits include:

- durability, reliability, wear resistance;

- large selection of models;

- mobility (collapsible structures can be taken with you outdoors).

Flaws:

- If the metal is chosen incorrectly, the surfaces will quickly become covered with rust.

- Cast iron products have a lot of weight. They are difficult to transport.

- Thin walls burn out quickly.

If the choice of material is made correctly, most of the weaknesses can be eliminated.

Cast iron grill (Photo: Instagram / raslovokladka)

Manufacturers and cost

Russian manufacturers:

- Mangal-ASK;

- Super-manga;

- MOS-Mangal.

The average price of a collapsible structure is 1,500 rubles, a stationary one is 8,000 rubles.