Many farmers use walk-behind tractors to work in their fields. The adapter for the walk-behind tractor makes it possible to speed up its execution. This unit is used as a trailer that moves on wheels and is attached to a motor cultivator. You can add attachments to the device and mount a chair. Often gardeners make such a unit themselves.

Purpose

An adapter for a walk-behind tractor was created for the convenience of gardening. If you attach a hinge to it, you can expand the scope of application of the device:

- remove hay;

- level the soil surface;

- transport goods;

- harrow the ground;

- clear the area of snow.

An adapter is a device that is designed for movement on a motor cultivator. With it, you can control the unit while sitting in a chair, and at the same time cultivate the soil. The trailer for the Neva motor-cultivator is equipped with a steering control. It makes it easier to use the walk-behind tractor.

You can install different attachments for harvesting, a plow, a mower, etc.

This trailer speeds up work in the field. Using this design, you can increase the speed of the cultivator from 5 to 10 km/h. Let's look at the adapter device. The adapter for the motor cultivator consists of:

- frames;

- operator seats;

- two wheels;

- axles;

- coupling mechanism.

After attaching the adapter, the cultivator looks and is used like a mini-tractor. To create an adapter for a cultivator with front steering, you need a frame. The operator's seat is installed on it. The frame is fixed to the chassis.

The seat is fixed to the frame. This will make it easier for the operator to control the cultivator. The wheel system will help move the unit around the site. There are 2 types of wheels: metal (used in the field) and rubber (used for driving on the road).

The hitch for a walk-behind tractor is made of steel or cast iron by welding. She attaches the cart to the cultivator. The U-shaped fastening system is considered the best. With this design the device will be stable.

Specifications:

- The highest travel speed on a walk-behind tractor with a trailer is 12 km/h.

- Maximum load capacity - 100 kg.

- The track diameter is 67 cm.

- Dimensions are 130x70x71 cm.

- The weight of the device is 22 kg.

- The warranty period is 5 years.

What it is?

An adapter for a walk-behind tractor is a trolley, the main elements of which are a seat, a brake, a brake handle, footrests, a coupling mechanism and a frame with structural parts attached to it.

The brake of the device is located near the foot rest. Typically, such a device is equipped with two wheels, and the seat often has a lifting lever. The design of the adapter can be either universal or special: some of these varieties provide for additional fastening of various canopies.

Equipping the walk-behind tractor with an adapter practically turns the working unit into a mini-tractor with a seat that increases operator comfort.

Types of adapters for walk-behind tractors

The adapter for the walk-behind tractor comes in several types. The design is distinguished by the coupling method:

- Strong connection to the motor cultivator. The device has a separate steering wheel. Steering wheels are located at the front or rear (both options are possible).

- Movable connection. At the same time, the angle between the cultivator and the cart changes all the time. Turning requires a lot of effort due to the fact that the connection point is movable.

The devices are also divided according to the presence of drive wheels into:

- Front. The hitch assembly is located at the rear.

- Rear. The hitch assembly is located at the front.

Trailers are divided into:

- simple;

- universal.

In addition to garden work, universal ones are useful for transporting crops.

Trailers are divided according to the size of the drawbar:

- a short;

- long.

Structures with a short drawbar are attached to low-power walk-behind tractors. Trailers with a long drawbar are attached to powerful cultivators.

There are 2 types of trailers: on 1 axle or on 2 axles. These couplings are created by the manufacturer. The factory calculated such a design and mounted a tow bar on it. A spring was installed under the seat, designed to allow the vehicle to move smoothly on rocky surfaces.

The APM has special footrests and a brake that is pressed with the foot to stop the cultivator. Pneumatic tires were mounted on the adapter, which ensure smooth running at high speed.

You can buy the device in a specialty store unassembled in packaging. It's easy to assemble. There are instructions for this. To assemble the device, no additional knowledge or skills are required. Afterwards you need to check how the design works.

If all components work well, you can start operating the device. When purchasing a design, you also need to choose a soft lining for the seat. Then the driver's work will become more convenient. The HorseAM IS 1 adapter for the Magnum walk-behind tractor, and adapters for the PNO-1, AM-3 K, BUM-3, KTZ-03 cultivators are very popular among farmers.

With steering

A high-quality adapter with a steering wheel for a walk-behind tractor makes it easier to control the cultivator. In terms of its functions, such a walk-behind tractor is comparable to a mini-tractor, only it is more economical in fuel consumption. The standard APM unit does not have a steering wheel.

Control is carried out using the cultivator steering wheel. But other manufacturers produce units with steering. The trolley is designed for more convenient work on the cultivator, so the presence of a steering wheel will make control easier.

With movable joint

When a trailer is movably coupled to a motor-cultivator, the angle of the vertical axis between the cart and the cultivator changes. It is easier to make such a device, but when turning it will be necessary to apply more force. This type of trailer is inferior in geometric characteristics: the turning radius becomes larger.

Front and rear adapters

There are several types of trailers depending on which wheels are driving:

- Front-wheel drive. The unit is fixed at the back of the walk-behind tractor. This is the simplest and most popular modification. It makes it possible to easily control the cultivator and perform a large amount of work.

- Rear drive. The unit is located in front of the cultivator. This design makes it possible to perform work when using a hitch located at the rear of the cultivator.

- Four-wheel drive. The trailer can be located either in front or behind the cultivator. This design differs from the previous ones in that not 2 wheels rotate, but all 4 at once. This device performs the functions of a mini-tractor. At the same time, the maneuverability of the structure, its maneuverability increases, and additional traction with the soil is provided. The 4x4 drive is considered the most efficient.

The rear adapter is the most common type of trailer for a walk-behind tractor. It can be used as a trolley (load capacity about 100 kg), for mounting with attachments for plowing, mowing, snow removal, etc.

A trailer with steering allows maneuvers on various terrain, making the operator's work easier. Operating the structure using the steering wheel of the cultivator itself can be inconvenient and dangerous. When working on a field with uneven terrain or in a vegetable garden, it is better to use a trailer with a steering wheel for a walk-behind tractor, as it is easier to control.

In order to make a rear adapter with your own hands, readily available materials are suitable. The basis of the trailer design is the frame; it can be made of metal profiles or metal pipes. The hitch assembly can be movable or rigid. In the second case, the cultivator itself will need to be modified, so creating a movable hitch is less complicated.

The rear adapter is used for work that requires constant supervision (hilling up beds), so the design necessarily includes a seat for the convenience of the operator. The work is also facilitated by the presence of a steering control, which is made from the steering mechanisms of any vehicles.

Advantages and disadvantages

Adaptive steering of a walk-behind tractor is convenient because:

- eliminates the need to walk behind motor vehicles;

- the traction potential of the walk-behind tractor is fully realized;

- the functionality of agricultural equipment increases;

- transportation of the unit to a specific processing area is simplified;

- easier control - no longer requires a lot of operator effort;

- the structure can be disassembled if necessary;

- sufficient balance is achieved on all axes.

The disadvantages include an increase in fuel consumption, which after modification takes one and a half times more. However, these losses are justified by the ease of management and saving a colossal amount of time that the gardener spends when working with the land.

How to make an adapter for a walk-behind tractor with your own hands

A gardener or farmer who wants to increase the volume of work can make an adapter for a walk-behind tractor with his own hands. Let's look at how to make a front adapter with a steering wheel yourself. To do this, a frame is made, a lever is welded to it, then a coupling unit is created, after that the trailer rotation mechanism is made, then the braces need to be welded.

In this way, you can make a homemade all-wheel drive trailer for both small and heavy walk-behind tractors. Let's look at step-by-step instructions for making a trailer yourself below.

Scheme and design elements

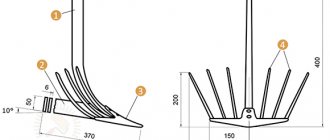

To make an adapter with your own hands, you must first complete the drawings and diagrams of this device. And using a ready-made diagram indicating all the parts, assemblies, structural elements and their dimensions, it will be easier to start making the unit yourself.

Required materials and tools

Let's consider what is needed to create the device.

Materials and tools:

- Two wheels with an axle. The radius of the wheels should be 15-18 inches. You can take wheels from a car.

- Bearings for wheel and steering systems. Metal profile corner or channel, metal pipe.

- Nuts, screws, washers.

- Lubricant: grease.

- Welding machine, drill with drill bit, wires, disks.

- Bulgarian.

- Screwdriver, wrench, screwdriver.

- Frame for turning the cultivator using the steering wheel.

Drawings and dimensions

First you need to complete the drawing. First of all, the kinetic scheme is calculated. Then they carry out the basic diagram, which shows the dimensions of all parts. All parts, components and fasteners of the structure will be manufactured according to this scheme. Before you start creating the unit, you need to clarify all the data available on the diagram and check their compliance with the indicators of all workpieces.

Do-it-yourself steering wheel for a walk-behind tractor

The adapter for a walk-behind tractor with steering makes it easier to maneuver and makes the structure more stable. Making a steering wheel for a walk-behind tractor with your own hands is quite easy if you have basic welding skills.

You can create a design from a steering mechanism from a car; it is better to use a steering column with a bipod from trucks and tractors. The bipod can be used as a rear adapter coupling to the cultivator. The steering bipod is indispensable if the trailer design does not include steering arms. When making an adapter with a steering wheel for a walk-behind tractor, you can make a ball joint that allows the wheel to rotate freely in a horizontal plane.

If the equipment is used for plowing the ground or other complex work, then it is better to make the steering and the mechanism for connecting the trailer and walk-behind tractor independent, since there will be a large load on the coupling unit.

Assembling an adapter for a walk-behind tractor

First they make the frame. It is made from pieces of metal of the required length. The metal is cut with a grinder and the parts are connected by welding or screws.

Then they do the chassis. When the cultivator motor is located at the front, then the track width is determined by the base wheels. The rear ones are attached to the frame using an axle. It must be made from a pipe of the required diameter. Bushings with bearings are attached to its ends.

Then wheels are mounted on them. When the cultivator motor is at the rear, the track width must be wider. Otherwise, the structure will not be able to maintain balance during operation. Then the base wheels of the cultivator need to be removed and fixed to a wide axle.

To make your own steering wheel, you do not need to remove the car handle. If you use a handle from a cultivator, you can control the entire structure using a motorcycle handlebar. But it will be difficult to go back. Therefore, it is best to mount a durable steering column.

Let's consider making a frame for a motor-cultivator trailer. If you take a frame made of solid metal, control will be directed to the front axle of the unit. You can make a frame on hinges, in which case the steering column will rotate completely onto the front frame. To achieve this, a gear should be mounted to the front frame.

The second gear is mounted on the steering column. Then a seat for the tractor driver is made. It can be taken from the car. The seat is placed on the frame by welding. It can be adjusted. This is especially necessary for the front type of device. The driver's seat is now attached.

To attach the trailer to a walk-behind tractor with a plow, you must install a bracket. To operate the mower, you need to make a hydraulic system. To work on the device, you need to weld the tow bar from the car to the rear part, where the metal frame is located. The pump can be borrowed from any unit for agricultural work.

The hitch for the cultivator is U-shaped. For this you need a channel profile. The hitch is installed under the steering column. In this case, you need to drill the holes that are marked on the drawing. The bracket and pin are mounted through them. The components are made of high quality steel. You can also make a caterpillar mechanism.

Thus, all the necessary parts and components of the adapter for the cultivator have been manufactured. Now you need to assemble the entire structure. After this, it needs to be checked and tested in operation. If all components operate normally, then you can begin operating the unit.

Recommendations for use

Regardless of the type of assembled and connected product, you need to start working with it by taking into account safety regulations. Before starting the engine, you need to conduct a visual inspection of the equipment to eliminate visible damage and malfunctions. Do not add fuel to the fuel tank while the engine is running.

If you hear an unusual noise when you turn it on, you need to stop the engine and identify the cause of the problem.

Do not use gasoline of inappropriate brands or fuel mixed with oil and other impurities. Before each start, you need to check the oil level, since this is often the reason the engine stops.

In order to extend the service life of motorcycles, a new product must be run-in. It will contribute to the trouble-free functioning of the walk-behind tractor.

During this process, the working surfaces of the parts are usually worked out. The duration of running-in, as a rule, varies for products of different brands and modifications. In some varieties it can be up to 20 hours or more. At this time, you should not load the equipment to the maximum extent.

See also: Benefits of fire doors

One recommendation is to change the oil after the first five hours of operation. As for warming up the engine, this should be done at medium speeds without load for about three minutes.

Based on the modification of the walk-behind tractor, for the first hours of its operation it is necessary to operate the unit in first gear (with the gas lever in the middle position). It is important to try to avoid not only maximum, but also minimum speed . At the end of using the equipment, you need to check the tightness of the threaded connections.

As for the cultivated soil, it is better to cultivate simple soil in the first hours. In addition, you need to take into account that rolling in is not done on rocky and clay soil.

Before work, you need to inspect the area and remove stones and large debris. In general, when working with motorized equipment, you need to constantly monitor its cleanliness and check the fastening strength of the accessible elements of the adapter and walk-behind tractor, including attachments.

Don't forget to tighten any loose fasteners. You also need to remember about timely maintenance.

Maintenance and storage

As a rule, you need to check the oil level every time you turn it on, and replace it at least once every six months. The air filters are checked before turning on the unit. Clean it when it gets dirty or once every three months.

The sump tank is cleaned every six months. If it is necessary to replace consumables, they try to buy original parts or those with similar quality characteristics.

They will help extend the life of agricultural equipment and will not cause engine failure. As for cleaning the air filter, this is necessary to maintain the working condition of the carburetor.

Do not use a solvent with a low flash point for this, as this is flammable and can lead not only to a fire, but also to an explosion. You cannot use equipment without an air filter, because this causes accelerated engine wear.

Repairs are carried out in a well-ventilated area with the engine turned off. In this case, it is necessary to ensure a sufficient level of ventilation in the work area. Exhaust gases are hazardous to human health and inhalation can be fatal. Motor vehicles should be stored in a dry, ventilated area .

During the summer season, it is not recommended to leave it outside, especially if the base of the operator’s seat is made not of plastic, but of wood. In order to extend the quality and performance characteristics, when storing the unit outdoors, you need to cover it with a tarpaulin cover.

If you do not plan to use agricultural machinery for more than three months, gasoline is poured out of the fuel tank, it is cleaned, and the position of the gas lever is checked. If necessary, disconnect the wheels.

Sources

- https://stroy-podskazka.ru/motobloki/adapter/

- https://sadovaja-tehnika.com/motobloki/navesnoe-oborudovanie/adapter/

- https://MoyMotoblok.ru/navesnoe-oborudovanie/samodelnyj-adapter-dlya-motobloka-svoimi-rukami-chertezhi/

- https://vsemotobloki.com/navesnoe-oborudovanie/dlja-svoimi-rukami.html

- https://stroy-podskazka.ru/motobloki/adaptery-s-rulevym-upravleniem/

- https://vsemotobloki.com/motobloki/neva/adapter-na-motoblok-neva.html

Did the article help you?

Andrey

Ask questions

Ask questions and write answers in the comments