Types of fittings

Due to the raw materials used and the manufacturing method, reinforcing bars are divided into two main groups: assembly and working.

- Assembly bars are used for the foundation of small buildings and for creating screeds. These are, most often, rods with a smooth surface and their diameter ranges from four to forty millimeters; they are not used for the construction of walls. They are classified as: class A1 (A240) fittings.

- Working steel is used as the main support of the walls, so the rods are thicker, their diameter is from six to eighty millimeters, and they have a corrugated surface, because it is on them that the main load is placed. They are classified as: A2 (A300); A3 (A400, A500); A4 (A600); A5 (A800); A6 (A1000).

They can also be divided by surface type, since reinforcement is used in various conditions, for example:

- Thermally strengthened, marked as T.

- Weldable, marked as C, such rods are best suited for creating structures.

- With an anti-corrosion coating, marked as K, such rods are not subject to rust.

Reinforcement can simultaneously possess several of these properties. Also, the steel used in the manufacture of rods can be:

- Carbonaceous, with varying amounts of substance, the more, the stronger. Designated as St and with an index from zero to six.

- Alloyed, with the addition of other metals.

Carbon steel (St) has varying degrees of deoxidation; it can be: calm - sp, semi-quiet - ps and boiling - kp.

The following are added to the alloy: carbon, manganese, silicon, nickel, chromium, copper, niobium, vanadium, vanadium nitrite, molybdenum, boron, titanium, aluminum, sulfur, phosphorus, arsenic, nitrogen and oxygen.

What is rolled reinforcing metal A1?

According to GOST 5781, A1 reinforcement is designated differently - reinforcement (reinforcing steel - hereinafter AC) AI (A240). This is a more correct name for this rolled metal and is used by all its manufacturers and professional consumers. In the technical language of GOST 5781, which classifies all types of reinforcing steel produced according to it for the reinforcement of conventional as well as prestressed various reinforced concrete structures, this designation stands for “class A1 reinforcement.”

The division into classes in this GOST is made according to one of the mechanical characteristics of the speakers - the yield strength. Its conditional value for product A1 is indicated in parentheses after the index A - the number 240. This is the value of the yield strength in kgf/mm2, but multiplied by 10. Thus, reinforcement A1 has a yield strength of 24 kgf/mm2 (corresponds to 235 N/mm2 ).

According to GOST 5781, AI speakers are manufactured only with a smooth profile - without corrugation of the surface of a regular round cross-section. Externally, depending on the nominal thickness, it looks like steel wire or rod.

Fittings without corrugation

AC A240 is produced hot-rolled and only from carbon steel. In this case, according to standard 5781, only brands St3sp, St3kp and St3ps are used. It is precisely because of this that A1 reinforcement, in contrast to smooth AC of other classes of GOST 5781 and produced in accordance with GOST 10884, is most in demand and is used both for reinforcement and as ordinary rolled metal - for the manufacture of various steel parts and structures. After all, St3 is the most flexible, ductile of all carbon and, especially, low-alloy grades and is better weldable than all alloys. Its chemical composition for finished AI fittings must meet the requirements listed in GOST 380.

The range of production of smooth AI speakers includes 14 standard sizes in diameter in the range of 6–40 mm. Products with a thickness of 6–12 mm are produced in rods or in the form of coils, and larger diameter A1 reinforcement is supplied only in rods. AS A240 rods are manufactured in lengths of 6–12 m. They are available in measured or unmeasured lengths. Together with the measured ones, unmeasured rods with a length of at least 2 m and in an amount equal to a maximum of 15% of the mass of the released batch can be supplied. The consumer can order the option he needs, and by agreement with the manufacturer, it is also possible to produce rods of 5–25 m.

Production of A1 fittings

There are 3 types of A1 rods, differing in production technology:

- hot rolled reinforcement;

- marked T - strengthened during heat treatment, hardening;

- marked B - cold-rolled, strengthened by drawing.

The material is produced in rolling mills using the method of deforming steel blocks. Source material - standard structural steel St3kp, St3ps or St3sp:

- low-carbon - for non-stressed reinforcement;

- high-carbon - for intense.

The characteristics of rods (strength, geometry, ratio of weight and cross-sectional diameter) are regulated by GOST 5781-82, GOST 2590-2006, DSTU 3760-98, as well as other current regulatory documents. The permissible deviation of the actual parameters of the finished product is 3...9%.

Standard sizes of fittings A1

Products are classified according to two basic indicators:

- Length - 6-12 m for measured products or arbitrary for non-measured fittings. The length of the measuring rod is determined by the diameter (the reference parameter is 10 mm).

- Cross-sectional diameter - 6-40 mm. The production step is 2-3 mm.

Class A1 materials are supplied in the form of rods or coils (coils) weighing from 1.5 tons. Wire with a diameter of up to 10 mm is rolled into coils.

Features and Benefits

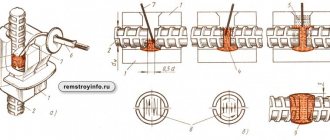

A1 reinforcement forms contact with concrete in a number of ways:

- during adhesion (for example, when concreting a steel element into a block);

- during compression (for example, with reinforced concrete after concrete shrinkage);

- in shear bond zones;

- during friction;

- electrochemically - when the cement solution interacts with the surface of the steel.

At the low price of A1 reinforcement per meter and ton, the material has a considerable number of advantageous characteristics:

- flexibility, elasticity;

- hardness, strength;

- ease of welding;

- resistance to corrosion, exposure to chemically aggressive environments (chlorine, natural gas);

- durability.

The second marking of reinforcement A1 - A240 - indicates the fluidity index, or the stress value, above which metal deformation begins.

Areas of application

- Construction: Reinforcement of beams, columns, floors, foundations, framing frames.

- Formation of cast and metal structures, reinforced concrete blocks.

- Strengthening the strength of monolithic structures - tunnels, bridges.

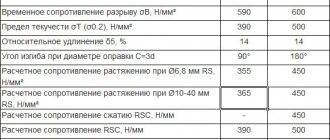

Class comparison table

| Reinforcement class | Rod type | Rod diameter (mm) | Tensile strength (MPa) | Elongation at break (%) | Grade of steel used |

| A1 or A240 | Smooth | From 6 to 40 | 373 | 25 | St3kp, St3ps, St3sp. |

| A2 or A300 | Fluted | From 10 to 40 From 40 to 80 | 490 | 19 | St5sp, St5ps, 18G2S. |

| A3 or A400 | Fluted | From 6 to 22 | 590 | 14 | 35GS, 25G2S, |

| A3 or A500 | Fluted | From 6 to 40 | 600 | 14 | 32G2Rps. |

| A4 or A600 | Fluted | From 6 to 8 From 10 to 18 From 10 to 32 From 36 to 40 | 883 | 6 | 80С, 20ХГ2Ц. |

| A5 or A800 | Fluted | From 6 to 8 From 10 to 32 From 36 to 40 | 1030 | 7 | 23ХГ2Ц. |

| A6 or A1000 | Fluted | From 10 to 22 | 1030 | 7 | 22Х2Г2АУ. |

A3 marking, range, weight and technical characteristics

The standard marking of class A3 reinforcing steel is written on one line in the following order:

- a number indicating the diameter of the rod in mm;

- letter “A” and class indication “III”;

- in brackets (A400) - international classification;

- GOST 5781-82.

For example, the standard marking for A3 with a diameter of 20 mm is: 20-A-III (A400) GOST 5781-82.

According to GOST 5781-82, no additional letters are used for marking A3.

A3 is produced according to a standard range of the following nominal diameters:

∅6÷∅40 mm, weight of 1 meter is regulated by GOST 5781-82:

| Diameter | Weight, kg/1 m.p. | Number of meters in 1 ton | Diameter | Weight, kg/1 m.p. | Number of meters in 1 ton | Diameter | Weight, kg/1 m.p. | Number of meters in 1 ton |

| 6 | 0,222 | 4504,50 | 16 | 1,580 | 632,91 | 28 | 4,830 | 207,4 |

| 8 | 0,395 | 2531,65 | 18 | 2,000 | 500,00 | 32 | 6,310 | 158,48 |

| 10 | 0,617 | 1620,75 | 20 | 2,470 | 404,86 | 36 | 7,990 | 125,16 |

| 12 | 0,888 | 1126,13 | 22 | 2,980 | 335,57 | 40 | 9,870 | 101,32 |

| 14 | 1,210 | 826,45 | 25 | 3,850 | 259,74 |

For the production of A-III reinforcing steel, low-alloy steel grades 35GS, 25G2S, 2G2Rps are used.

Reinforcement with a diameter of ∅6 mm÷∅40 mm is made from steel grades 35GS, 25G2S. In addition, fittings with a diameter of ∅6 mm÷∅22 mm can also be made of steel 32G2Rps.

Popular classes of reinforcement and their application

Reinforcement classes A1 and A2 are used to create reinforcing ties, since this type of rod is characterized by increased elasticity, but class A2 is more dense in structure.

Reinforcement class A3 (A400, A500) is considered the most popular, as it has a durable structure and inexpensive cost. Such rods are used in the construction of building walls.

Reinforcement class A4, most often used in the creation of reinforced concrete structures. Such rods are less easily welded, so they are usually tied up in frames.

Reinforcement classes A5 and A6 are the most expensive, but also the strongest, so they are used to strengthen and create large spans, for example, in the construction of factories or factories.

What is it made from?

This metal product is produced from low-alloy carbon steel. The high carbon content in it makes the frame more elastic and resistant to stress. When manufacturing fittings, manganese, titanium, chromium and silicon can be added to the raw materials. These additives form the main technical characteristics of the product. Depending on the manufacturing method, there are three types of rolled metal A3:

- Hot rolled type.

- Thermally strengthened. After manufacturing, this type of reinforcement is subjected to special heat treatment - hardening. This additional processing makes it possible to increase the strength of metal rods.

- Hood reinforced type. When using this technique, the product is processed by cold stretching.

Visual comparison

The first class of reinforcement always has a smooth profile of the rod; very rarely it can be the second class, but all other classes have only a corrugated surface. Also, different classes differ in diameter, weight and length.

Reinforcement of the third and fourth classes are similar in characteristics, but the bars of the fourth class are larger, since higher quality steel is used in their creation. Reinforcement of the fifth and sixth classes is easier to recognize; the rods are much larger and longer, and they are also much more expensive.

This knowledge will help when choosing fittings, but you can simply contact a sales consultant.

- < Back

What to look for when purchasing?

In addition to intermediary markups, the cost of products is also affected by:

- Rolled metal class.

- Brand.

- The diameter of the rods and their length.

- Type of packaging and other characteristics.

Therefore, carefully study the information on the product page and compare it with your tasks. If you don’t know how to choose an A3 for specific purposes, contact one of our employees. He will clarify the nature and scope of the work ahead of you, and then recommend a product with optimal characteristics.

Buy a3 fittings: metallbase.com/production/armatura/klass-a3/#ves

Specialized fittings A3 35GS

One of the varieties of A3 rolled metal is A3 35GS. This is a very durable reinforcement with a round cross-section and a corrugated surface. It is made from low-alloy structural steel to create welded structures. The diameter of this product can be in the range of 6-36 mm, and the length of the rods should not exceed 11.7 m. Sometimes the length indicator is changed upward. But this is done exclusively on an individual basis.

As a rule, this type of rolled metal is used in road construction. This involves laying conventional road surfaces and concrete slabs. This scope of application is associated with the high strength of the products, high-quality adhesion to concrete and resistance to frost. The latter characteristic is due to the presence of manganese in the raw material, which tolerates low temperatures well. A3 35GS products can be installed longitudinally or transversely in concrete. If the rods are laid longitudinally, they take on tensile stress. In the case of transverse laying, the compressed section is tied and coupled. But, regardless of the location of the reinforcement, in both cases the risk of the formation of inclined cracks is reduced.

Despite all its advantages, this product also has a disadvantage. It is associated with the inability to use manual arc welding. If you need to use this method of welding metals, use another type of A3 - 25G2S rods. They also contain manganese, so they are immune to severe frosts.