High-quality, correctly selected fittings are the key to the reliability and durability of any constructed structure. Popular varieties include A2 fittings, also known as A300. Its use increases the strength and reliability of constructed concrete structures. For what reasons is this type of fittings in such demand?

What is she like?

To begin with, class A2 fittings are made from specially designed steel. Two brands are used for this. Firstly, St5sp(ps) is a carbon steel of ordinary quality, used in the manufacture of reinforcing bars and in riveted structures. Secondly, ST18G2S is a low-alloy steel used in the manufacture of welded structures. The ability to assemble a structure from metal rods is extremely important. It is undesirable to weld most analogues, as this leads to a decrease in the strength and durability of the finished structure. You have to use a special knitting wire, which holds the rods in the desired position, but does not give the frame high strength. However, the use of a special grade of steel allows us to solve this problem, obtaining a high-quality and durable frame.

Diameter may vary. Today it is produced with a diameter from 10 to 80 millimeters, depending on the grade of steel used for its production. Rods with a thickness of 12 millimeters or less can be supplied in coils, which simplifies storage, transportation and use. The thicker ones are metal rods of various sections.

What does reinforcement class mean?

Based on the fact that the very essence of reinforced concrete is a combination of a reinforcing frame inside with concrete pouring, products of different shapes and with different loads placed on them should use reinforcing bars of different cross-section and composition as reinforcement. Classification of reinforcement is a way to unify and simplify the processes of manufacturing reinforced concrete.

To facilitate orientation in the types of reinforcement, there are tables of classes, thanks to which the selection of the required cross-section and metal composition of the rod is carried out.

The main parameters indicated in the tables:

- Weight (mass)

- Applicable diameter limit

- Load and resistance that the bar can withstand

- Possibility of integration into stressed parts of a structure

- Relative extension

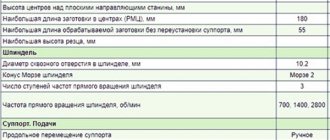

| Class | Rod diameter, mm | Tensile strength, MPa | Relative extension, % | steel grade |

| AI (A240) | 6-40 | 373 | 25 | St3kp, St3ks, St3sp |

| AII (A300) | 10-40, 40-80 | 490 | 19 | St5sp, St5ps, 18G2s |

| AII (Ac300) | 10-32, (36-40) | 441 | 25 | 10GT |

| AIII (A400) | 6-22, 6-40 | 590 | 14 | 35Gs, 25G2s, 32G2Rps |

| AIV (A600) | (6-8),10-18, 10-32, (36-40) | 883 | 6 | 80С, 20ХГ2Ц |

| AV (A800) | (6-8), 10-32, 36-40 | 1030 | 7 | 23ХГ2Ц |

Pay attention to the first (left) column.

It contains old and new designations. The first also means the Soviet GOST 5781-75 (which, nevertheless, can often be found in reference books). In order not to be disoriented, you need to know the compliance of old GOSTs and updated ones. Numerical and letter values according to the current GOST 34028-2016 are indicated in brackets. Let's look at the presented labeled samples in more detail:

- A 240 is a smooth-profile reinforcement of class A1, which does not have corrugated hooks on the outer edge in the form of a “spiral” or “herringbone” with a longitudinal edge. This smooth profile is used for the manufacture of non-stressed reinforcing mesh in reinforced concrete products not intended for load-bearing structures, or as clamps. Their adhesion to concrete is weak and their strength is low.

Basically, such reinforcement is used when reinforcing plaster in walls, when the plaster mortar is spread with a trowel and then leveled with tools designed for this purpose, and when pouring floor screeds. In addition, smooth reinforcement can be used as thick wire for tying together large-sized metal structures - because only such rods, acting as fastening wire, can reliably fix frames made from profiles with a diameter of 40 mm or more.

- A300 and Ac300 are class 2 fittings. It has a corrugated profile, with a rod diameter starting from 10 and ending with 80 mm. Adhesion to concrete is higher. Application - in the construction of low-rise buildings (with the number of floors not exceeding 3).

- A400, or AIII – class 3 fittings. The most popular profile that can be used in capital (including multi-story) construction and to solve almost all construction problems. It has a unique combination of stress resistance and strength; there is always a corrugation on the surface. It is durable, strong, and the cost is only slightly higher than the cost of the A1 and A2 brands (A 240, A 300 and Ac 300). A3 is a hot-rolled profile with a periodic surface.

- A600 Corrugated fittings class 4. It has slightly greater strength and stress resistance characteristics than A 400, and the metal contains alloying additives that increase the durability of reinforcement structures inside reinforced concrete, or another indicator of carbon content. Such rods are joined into a reinforcing mesh by welding. A600 is mainly used in support blocks or foundation slabs, as it is stronger and more durable.

Classes V and VI fittings are practically not used in civil engineering, and are used mainly for the construction of large hydraulic structures, airfields receiving large-capacity aircraft, dams for large reservoirs and other strategic objects.

The main types of profiles (except for class A 240, smooth and need no introduction):

a) circular; b) double-sided crescent; c) crescent-shaped quadrilateral

Where is it used

Due to the excellent properties of the reinforcement, it can be used in a wide variety of construction areas:

- construction of private and multi-storey houses;

- construction of bridges, dams, dams;

- laying the road surface;

- construction of warehouses, hangars, industrial premises.

Almost every construction site uses this material, which has won the trust of experienced specialists.

In addition to the cases listed above, metal rods are widely used in the production of reinforced concrete slabs in factories. The high strength of the material allows it to be used in the manufacture of conventional reinforced concrete products (reinforced concrete products), as well as prestressed ones. The latter are more difficult to manufacture - the reinforcement is subjected to tension, after which the mold is filled with mortar. The hardened concrete is held in place by a tension rod, and the finished product is able to withstand high bending and tensile loads.

You can often hear another name from experts - A300. Indeed, the brand of fittings A2 is completely identical to A300. There are no differences in purpose, properties and material used in their manufacture. This will be useful to remember for every person involved in construction.

Such a wide scope of application is one of the main advantages of reinforcement, which has made it such a popular building material.

The difference between class A3 reinforcing steel and class A1

These types of reinforcing steels, manufactured in accordance with GOST 5781-82, have four main groups of differences:

- Dissimilar surface profiles

- all diameters A1 (∅6 mm÷∅40 mm) are manufactured SMOOTH, without longitudinal and transverse grooves. A3, on the contrary, has two longitudinal ribs and projections along helical lines between them. - Various steel grades

are used for production : A3 is made from low-alloy steels with the addition of manganese (35GS, 25G2S), manganese and boron (32G2Rps). For the production of A1, carbon steels (without alloying additives) St3kp, St3ps, St3sp are used. - Various mechanical characteristics

.

| Reinforcement class | Yield strength kgf/mm² | Relates. length % | Bending test (c - thickness of the post, d - ∅ reinforcement) |

| A-I(A240) | 24 | 25 | c=d |

| A-III(A400) | 40 | 14 | c=3d |

- The areas of application differ.

A3, thanks to its corrugated surface, has excellent reinforcing properties and is used for reinforcing concrete structures for various purposes in the construction of monolithic buildings and structures made of reinforced concrete (in contrast to smooth A1, which is suitable for reinforcement only in certain, special cases, for example, cylindrical reinforcement cages , for road reinforcement). But class A1 reinforcement is more in demand in the manufacture of auxiliary metal structures (excluding highly loaded ones).

Sources

- https://spbrmk.ru/klassy-i-marki-stali-armatury/

- https://armaturniy.ru/arm/vidy/klassy-armatury.html

- https://tutmet.ru/armatura-klassa-a1-xarakteristiki-osobennosti-profilya.html

- https://www.mirmt.ru/metalloprokat/armatura-a1/

- https://www.balashiha.z-felix.ru/armatura/a3/

- https://metallicheckiy-portal.ru/articles/prokat/armatyra/armatura_klassa_a3-ee_osnovnie_xarakteristiki_osobennosti_i_primenenie

- https://www.atlantmetall.ru/company/spravochnik/armatura/a3/

Why does the profile shape differ?

When working with this material, every observant person will notice that the shape of the rods varies. Products with ring, crescent and mixed profiles are available for sale. You should pay attention to this - the main purpose of the rods depends on the shape.

Profile types: 1 – ring; 2 – sickle-shaped; 3 – mixed.

For example, a ring profile provides better adhesion - finished reinforced concrete products will be able to bear bending loads without harm. The crescent profile gives reinforced concrete high tensile strength. The mixed reinforcement profile is the newest of those listed - it appeared on sale relatively recently. It combines the advantages of both types of reinforcement, but the high cost narrows the scope of use - it is usually used only in cases where the increased strength of reinforced concrete products is important - in the construction of dams and bridges.

Reinforcement profile shape A300 according to GOST.

Special properties

Also, fittings are distinguished by purpose. In relatively rare cases, a metal rod must have a number of properties that make it suitable for the application. This is achieved in different ways - by adding special impurities to the alloy or by special processing. In any case, the fittings acquire unique characteristics. The presence of special properties is indicated by the letter at the end of the encoding. The following designations are usually found:

- C – weldable. Usually, when assembling a frame from reinforcement, the use of welding is extremely undesirable - overheating reduces strength and, in addition, reduces resistance to corrosion. But there is a special metal that contains additives that increase its ability to withstand negative consequences;

- K – resistant to corrosion. Thanks to special additives (chrome, tungsten and others), the fittings are able to work for many years not only in conditions of high humidity, but also in contact with an aggressive environment - alkaline, acidic, with a high oxygen content;

- SK is a reinforcement that has both of the above properties. It has a high cost, so it is used relatively rarely, only when the usual one cannot cope with difficult operating conditions.

Of course, there is a special GOST for this product that imposes special requirements on it.

Manufacturing method

However, the characteristics listed above are not the only ones. It is equally important to know the manufacturing method. Today, hot-rolled and cold-drawn manufacturing methods are used. The performance characteristics of the material, as well as the scope of application, depend on this.

They are easy to distinguish upon external examination. Cold-drawn rods have a smoother surface - there are no differences. Possessing increased plasticity, they are able to withstand enormous loads without harm to themselves.

Hot rolled ones have slight changes in diameter. This is primarily due to the fact that it is impossible to heat the entire mold and steel to the same temperature, at least in factory conditions. However, the differences are minimal and the finished material fully complies with all GOST requirements. In addition, the finished material has a lower cost, which allows you to reduce costs when purchasing fittings.

As you can see, A2 fittings have a number of important advantages that make it a good choice in a number of cases. Understanding its parameters and having an idea about the most popular varieties, you can easily choose the material you need.

A400 and A500 fittings according to GOST 34028-2016

GOST 10884-94 and GOST 5781-82, discussed above, are things of the past. Both designated documents were replaced by GOST 34028-2016, created on the basis of GOST R 52544-2006. We'll talk about it further below.

So, now A3 reinforcement is designated only by its yield strength, that is, as A400 reinforcement. This also can conditionally include such a type of long products as A500 reinforcement. The main direction of use is still the same - reinforcement of prefabricated and monolithic reinforced concrete structures. Let’s say right away that in practice the scope of application is much wider. We will consider this issue in a little more detail below.

As before, the reinforcing bars we are considering are now of periodic profile. That is, the same A3 corrugated reinforcement, but with a different sauce, the name only indicating the yield strength.

Reinforcing bars of periodic profile

We hope the title is clear. Now for the assortment. The release form is the same - skeins and rods. The delivery of rods can be carried out in measured, unmeasured or measured lengths with unmeasured lengths. Their length is from 6.00 to 18.00 meters, unmeasured length is from 6.00 to 12.00 m. The length is agreed upon in the order and may be different. Delivery in coils is carried out with a nominal diameter of rolled products up to 22.00 mm (previously A3 reinforcement up to 10.00 mm).

Please note that rentals differ depending on the type of profile (4f, 1f, 3f, 2f). The differences are in the height of the transversely located ribs, their pitch, angle of inclination, total, total distance between the two ends. The profile shape is specified in advance when ordering. In short:

- 1f – two ribs placed longitudinally, there are transverse ribs with an inclination to the axis, annular type of section, equal to the thickness of the half rings;

- 2f - distinguished by a crescent-shaped cross-section of ribs located longitudinally on 2 sides, opposite to each other along the perimeter;

- 3f – no ribs placed longitudinally, transverse crescent ribs, placed evenly on 3 sides, along the perimeter;

- 4f – there are no ribs placed longitudinally, there are ribs with a segmental cross-section placed transversely symmetrically on 4 sides.

Areas of use

Due to its properties, this material is used in many areas , including:

- Reinforced concrete reinforcement;

- Reinforcement of higher class steel reinforcement;

- For mutual fixation and hardening of the surface of the product;

- As a means of monolithic construction such as dams, mines, bridges, airfields and other objects.

If the load on the reinforced concrete allows, then the steel reinforcement product is used independently. It is usually used to strengthen columns, foundations, beams and panels. A thin product with a diameter of 6 and 8 millimeters is used as a wire for tying and fastening building meshes, reinforced frames, reinforcement of concrete screeds and floors, as well as plaster.

In addition, fittings of this brand are actively used for the production of decorative, load-bearing, frame and other metal structures, parts for them and various equipment and technological equipment. It is used wherever ordinary rolled metal made of St3 steel is used.

A1 reinforcement is known for its mechanical and technological properties, as well as strength characteristics. This allows this material to be used in various construction and industrial applications, including strengthening reinforced concrete and foundations. Independent use of reinforcement is also allowed subject to permissible loads and high-quality manufacturing.