In regions with harsh winters, sewage problems often arise. Due to prolonged and severe frosts, the system may freeze. In this case, the pipes, as a rule, become deformed or even burst. Let's look at how to connect a heating cable to communications to prevent an emergency.

Self-regulating cable Source artteplo.ru

Heating cable structure

The device is a conductor that converts electrical energy into thermal energy. There is no need for any additional equipment. To do this, simply connect the heating cable to a regular household network.

Heating wire is used for heating:

- water supply;

- inserting a pipe into the house from the wellhead;

- sewer communications;

- stormwater system;

- gas tanks;

- soil.

Heat-generating wires are made using special technology. And the result is a sealed device that is resistant to various external factors that negatively affect it. And the operating principle of the heating cable is based on the resistance of the material during the passage of alternating electric current. And the higher its parameters, the more heat will be released.

The heating cable consists of a conductor and a plug, which is needed to connect the device to the electrical network. The heating element covers the wires. It comes in two types: resistive and self-regulating.

Structure of a self-regulating heating cable Source uk-parkovaya.ru

To protect the conductor from the aqueous environment, at least a double layer of internal insulation is used. And food-grade plastic is used as the external environment of the device. This measure is necessary if it comes into contact with drinking water.

Without exception, all types of cable contain braided shielding. And in addition to protection against interference, it performs an additional grounding function. If the screen is connected to the neutral wire, this will allow the machine to disconnect the wire when it breaks.

Any heating cable must have feedback. Therefore, they are all equipped with temperature sensors. And in the simplest designs, the latter automatically change the current strength depending on the temperature of the environment.

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

Coupling installation

What materials will you need?

- self-regulating shielded cable

- plug with wire and grounding pin

The wire must be three-core, copper. The cross-section is selected depending on the current load (cable power).

Mistake #1

Moreover, according to the instructions, it cannot be less than 1.5mm2.

Even if you have a very short section of low-power cable.

- wire stripper

- crimper for crimping sleeves

- coupling set

It is important to note that heat shrink tubing comes with and without adhesive.

Mistake #2

Do not use thin-walled tubing without adhesive.

They will simply insulate the connection, but will not create the required tightness. It is also desirable that the tube be of mid-wall thickness.

Thin walls are very easily damaged by external influences.

- construction hair dryer

- stationery knife

Types of heating devices

Heating cables are available in two types. Resistive conductors can be single-core or double-core. The former are completely unsuitable for heating a pipeline. Therefore, a two-core design is used.

Twin-core heating cable Source tvergrandelektro.ru

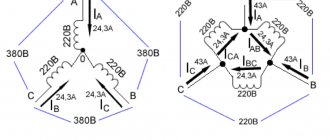

The heating cable is connected to a 220 V network through an automatic control unit. And since the resistive conductor emits only a constant temperature, a chromium-nickel alloy is used, which gives a stable high resistance.

The above conductors have been replaced by a self-regulating heating cable, the operating principle of which is based on the presence of an elastic matrix inside the device. It reacts to changes in ambient temperature and independently regulates the resistance of the conductor. Thereby reducing electricity consumption during thaws.

Wire PNVH-8000

PNVH-8000 wire is used to heat a specialized circuit of the evaporation system in modern electric refrigerators. High standards of protection with multi-layer composite insulation ensure the safety of the heater under conditions of a wide range of temperatures and vibration.

In this case, you will need to perform the following sequence of actions:

- Remove the protective layer of the cable using any available method.

- Fold the outer layer back over the previous one.

- Move the insulating layer a sufficient distance from the veins.

- The second cable needs to be worked following the procedure as described above.

- By soldering or pinching the contacts, connect the cores of two different wires.

- To insulate the resulting connection, use temperature-resistant tubing.

Expert opinion

It-Technology, Electrical power and electronics specialist

Ask questions to the “Specialist for modernization of energy generation systems”

How to connect a heating cable - 3 methods for heating a water supply Even when laying them in the ground below the freezing level, ice plugs form at the points where they come to the surface, connect to the foundation and in other unprotected areas. Ask, I'm in touch!

Laying methods

When heating any pipeline, a self-regulating cable for heating pipes can be placed either inside or outside. Moreover, none of the options is difficult to install. And for external use there are even two methods.

Linear

The simplest and most convenient method is in which the cable is pulled along the pipeline, tightly adjacent to it. You just need to protect the wire from possible mechanical damage. To do this, it is placed at the bottom of the pipe, and aluminum tape is used to securely fasten it.

Spiral laid heating cable Source gizbar.com

Spiral

With this method, the wire is wound around the pipe in a spiral. And the density of turns can increase the heating effect. Moreover, it is possible to carry out winding either completely close to the communication or with a slight sag. And to secure the conductor, the same aluminum tape is used.

Interior

If there is no access to the external sides of the communications, then a self-regulating cable for heating the pipes is placed inside the system. To do this, a special tee is cut into the highway in the right place. And wires are laid through it. Upon completion of the operation, the connection is carefully sealed.

Additional Tips

Following the manufacturer's recommendations increases the service life of the heating system. It is necessary to periodically inspect the wire located on the surface of the pipe and replace damaged areas. If you intend to install the cable on a rough surface, then heat transfer can be improved by wrapping the pipe with metal tape. It is recommended to purchase ready-made kits from major manufacturers.

Saving on components results in the need to install a new circuit after 2–3 years of operation.

Network connection

Let's look at how to connect a self-regulating heating cable to the network without involving a specialist. The process is not particularly complicated, but there are certain nuances when laying a cable inside a pipe. Let's analyze all the stages in more detail.

When the conductor is located externally, installation work is reduced to the following:

- The ends of the cable are cut with a ladder, at different distances. Each one must be freed from insulation to a length of 10 mm.

- A general-purpose heat-shrink sleeve is placed on the cable. And each of the conductors is equipped with a separate coupling.

Connecting wires using a heat-shrinkable sleeve Source kvt-pro.ru

- A special sleeve is used to connect the wires. The ends of the conductors are inserted into its sockets and crimped with pliers.

- First, each connection is tightened with its own coupling, then the installation site is closed with a common one. Each coupling is heated with a hairdryer so that it tightly compresses the contact.

If a self-regulating cable is used, its end is sealed using a special heat-shrinkable end sleeve. As a rule, the heating wire is first fixed to the pipe, and then it is connected to the network. When the conductors are located inside the pipe, the connection of the heating cable to each other, that is, to the supply wire, is carried out first.

Installation is no different from the previous one. And in order to place the prepared cable inside the pipe, you must use a pass-through kit. It contains a special oil seal. And for its correct connection, it is always sold with detailed instructions.

In order to control the temperature, you will need to purchase a thermostatic regulator. It is installed near the electrical panel. And to increase safety, an RCD (automatic circuit breaker) is installed in the circuit. It will interrupt power to the heating cable if there is a short circuit on the line.

How to properly connect two different parts of a self-regulating heating cable?

Heating cables are allowed to be connected according to certain rules. Given the right conditions, a customized system will work properly for many years.

To connect two different wires, follow this algorithm:

- Cut the top insulating layer of the cable. Remove the inner insulation.

- The semiconductor part will need to be heated. For this you will need a hairdryer. After this it will become soft. Expose thin wire strands.

- Repeat the first two steps for the other cable.

- Use the compression or soldering method to connect two different wires.

- To insulate the veins, use heat-resistant plastic tubing.

Briefly about the main thing

When choosing a heating cable for utilities, you must first decide on the method of its connection. If it is external, you will need aluminum tape for secure fastening. When the wires are laid inside the pipe, you need to additionally purchase a special tee and a pass-through kit for easy placement of the wires.

When connecting conductors to each other, it is better to use special sleeves and heat-shrinkable sleeves. Reliable sealed contact will be the key to the overall safety of the device. For additional protection, it is necessary to take care of installing circuit breakers to turn off the power in the event of an electrical circuit break.

Write in the comments what you think - is it worth using a self-regulating cable? After all, it is much more expensive than the usual resistant one. Isn't it better to just turn on the heating during severe frosts and turn off during thaws?

Why is it necessary to use cable heaters?

Many extended structures located outside are susceptible to ice formation, followed by an emergency:

- roof eaves . Ice and icicles spoil the roofing, and if they fall, they are dangerous for people below;

- drainage system . Icing causes deformation or breakage of gutters, and moisture drainage is also impaired;

- porch, walking paths . Become slippery, which leads to injury to people;

- water supply, sewerage, other pipelines, tanks. An ice plug clogs the line, and if there is severe icing, the structure collapses (water expands when it freezes).

Heated floors are installed using heating cables. Unlike water heated floors, this system is easier to install and does not cause leaks.