Grover washer - the history of the creation of a new type of locking connection according to Gosstandart

At the end of the 19th century, the mechanical engineering field began to develop at a fairly high speed, which required new, more reliable connection methods. The quality of threaded connections at that time was low, and conventional versions could not withstand oscillatory loads and strong vibration. Due to this effect, the strength of the connection is significantly reduced, and other common problems associated with loss of tightness could arise. The situation was significantly improved by a spring washer, which significantly increased the strength and reliability of connections in the event of a vibration load.

The new type of connecting element is quite simple, which determines low cost and reliability in use. GOST 6402-70 spring washers determines the use of certain materials in their production. The key points are:

- Reminds me of a regular spring coil.

- The gap diverges in the direction opposite to the movement of the nut, thereby eliminating the possibility of unscrewing.

- The rotation is fixed due to a special edge of the grower, which digs into the surface.

Download GOST 6402-70

When designating and marking a spring washer, it is indicated what material is used and the diametrical size. It is worth considering that not all materials are suitable for the manufacture of the product in question, since it is necessary to ensure high performance characteristics.

Design

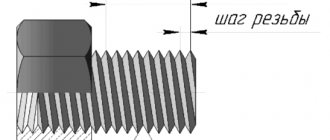

The spring washer is similar in appearance to an incomplete turn of a spiral. The location of its ends, located in different planes, is of fundamental importance.

In the working position, the gap is oriented in the direction of the rotational movement carried out when tightening the fastener. This design solution reduces the possibility of loosening the connection to a minimum, since the washer acts as a stopper.

Grover washer options

Most often, the product in question is used to ensure a reliable bolted connection. At the same time, it is often installed with a conventional design to significantly increase the contact area. Due to this, the reliability of the connection is significantly increased. Looking at the product drawing, two different versions can be noted:

- The first one is considered the simplest. Considering the din 127 spring washer, we note that it has a different hole diameter, as well as coil thickness. In this case, a certain angle of deviation of the turns from the central axis is noted.

- The second version is characterized by greater complexity in production. However, due to the complexity, the mechanism can withstand large dynamic and multidirectional loads.

The din127 m8 galvanized washer has become quite widespread. Due to special treatment, the protection of the surface from environmental influences is significantly increased. Also sold is a din 7980 m6 washer, which is characterized by its own specific features.

Most products have right-hand winding, due to which the production of hardware is carried out in a clockwise direction. But some versions are made with a left-hand turn.

What do you put under the nut?

Roofing types of washers have sealing gaskets made of rubber or rubber. ... Washers with claws are a kind of stopper. They are used to fix the fastening device in order to prevent the nut from turning with the backing when exposed to dynamic and vibration loads.

Interesting materials:

Is it possible to move the word Oleg? Is it possible to transfer the word streams? Is it possible to move the word ate? Is it possible to move the word quarrel? Is it possible to move the word Saturday? Is it possible to transfer the word notebook? Is it possible to move the word dinner? Is it possible to transfer the word jam? Is it possible to translate the word bindweed? Is it possible to translate the word snake?

Disadvantages of the Grover Washer

Before paying attention to the disadvantages, we first note the main advantage - the simplicity of production technology and low cost. However, there are also several serious disadvantages that need to be taken into account:

- In some cases, the force of the spring washer is not enough due to the high dynamic loads that arise during operation of the mechanism.

- A large tension force causes the grower to turn into a regular plate. Fixation is provided only to a small extent.

- In almost all cases, the connecting element in question cannot be reused due to severe deformation.

When creating conventional devices, a spring washer is used due to its low cost. In some cases, the possibility of replacing it with another product with a similar scope is considered.

Comparison of different types of washers

Above, information was presented about the main types, advantages and disadvantages of available methods of locking threaded fasteners. However, which one is better? In particular, which washers are more appropriate to use in specific conditions?

The answer to this question can only be given by comparative tests. To assess the endurance of bolted connections under dynamic load conditions, special vibration stands are used. The measuring complex includes a platform on hydraulic supports, an external electric motor (for loading the platform - creating vibration) and control sensors, information from which is sent to a PC for subsequent processing and demonstration of the results.

The tests are carried out as follows. Fasteners (bolt, nuts and washer) are installed into the hole on the platform and tightened with a primary torque (for example, 8 kN). The engine turns on and the platform begins to vibrate. After some time, the connection will “float”, i.e. the nut will begin to unscrew spontaneously and the primary tightening torque will decrease - perhaps even to zero (the fastener will completely loosen).

Which washer locks the connection better? Obviously the one with which the primary tightening torque under the influence of vibration will last longer! The relationship “moment – loading time” allows us to draw a conclusion about the durability of the washers. And at the same time, compare them with each other - under the same experimental conditions.

Such a test is called the “Junker vibration test” (the test procedure is regulated by DIN 651512002). The test shows that the lock (wedge) washer has the greatest resistance - the primary tightening torque is maintained almost 100% (while, for example, with a lock washer it drops to zero by the end of the test!).

How can I replace a spring washer on a Grover?

You can fix the nut using a variety of elements; quite a lot of them have been produced. Grover, another name for a spring washer, is often replaced with the following:

- The nut is self-locking. This product is characterized by the fact that in the upper part there is a plastic rate, which is responsible for damping the vibration load and unwinding. It is worth considering that difficulties in manufacturing the product cause a significant increase in its cost, but the effectiveness of such a nut is quite high.

- Disc type washer. It can also be installed instead of the original grower, and is characterized by lower cost and greater reliability.

- There is also a crown nut. It is required when drilling a counter fastening element and then placing a cotter pin. The reliability of the connection in this case is quite high, but it is characterized by steps.

- Gear type flange. The flange has notches that are fused with the nut. The notches ensure reliable fixation of the connection.

- Lock washer. During its manufacture, a large number of teeth are created that provide fixation.

- Plates with antennae. In this case, one of the tendrils is selected into the part, and the rest are folded over the turns. There are simply a huge number of similar versions on sale, so it is possible to choose the most suitable one.

- Wire locks. This fixation option has become widespread due to its low cost.

As a rule, the choice is made depending on the operating conditions.

Varieties

The production of spring washers in our country is regulated by the provisions of GOST 6402-70. It establishes 2 options for the execution of these hardware.

The first execution is simple. The second option is more complicated. Grovers of this design are used in connections subjected to high loads, including vibration and those of a pulsed nature - shock.

This regulatory document clearly states that spring washers must be produced of the following types.

- Lungs. The cross section of the turns of such parts is rectangular. They are designated by the letter “L”.

- Particularly heavy. The cross section is square. The designation is: “OT”.

- Heavy. The cross-sectional configuration is the same as in the previous case – it is square. The letter "T" is used for designation.

- Normal. The cross section of the turns is also square. Indicated by the letter “N”.

The table shows the nominal dimensions of the parameters, which are shown on the execution drawings, for growers suitable for forming connections using appropriate rod fasteners. The unit of measurement is millimeters.

| Dn.st.e | d | Types of spring washers | ||||||||||

| O.T. | T | H | L | |||||||||

| The values of parameters b and s are the same | s | b | ||||||||||

| * | ** | * | ** | * | ** | * | ** | * | ** | * | ** | |

| 48,0 | 48,5 | +1,0 | — | ____ | — | —— | 12,0 | ± 0,215 | 7,0 | ± 0,18 | 12,0 | ± 0,215 |

| 10,0 | ± 0,18 | |||||||||||

| 45,0 | 45,5 | 9,5 | ||||||||||

| 42,0 | 42,5 | 12,0 | ± 0,35 | 10,0 | ||||||||

| 9,0 | ||||||||||||

| 39,0 | 39,5 | — | ± 0,29 | 8,5 | 6,0 | ± 0,15 | 10,0 | ± 0,18 | ||||

| 36,0 | 36,5 | 12,0 | ± 0,35 | 10,0 | 9,0 | |||||||

| 8,0 | ||||||||||||

| 33,0 | 33,5 | — | ± 0,29 | — | 7,0 | |||||||

| 30,0 | 30,5 | 10,0 | 9,0 | 8,0 | 9,0 | |||||||

| 6,50 | 8,0 | |||||||||||

| 27,0 | 27,5 | +0,84 | 9.0 | 8,0 | 7,0 | 5,5 | 8,0 | |||||

| 6,0 | ± 0,15 | 7,0 | ||||||||||

| 24,0 | 24,5 | 8,0 | 7,0 | 6,0 | 5,0 | 7,0 | ||||||

| 5,50 | 4,8 | 6,5 | ||||||||||

| 22,0 | 22,5 | 7,0 | 6,0 | ± 0,24 | 5,50 | 4,5 | 6,0 | ± 0,15 | ||||

| 5,0 | ||||||||||||

| 20,0 | 20,5 | 6,0 | ± 0,24 | 5,5 | 5,0 | 4,0 | 5,5 | |||||

| 4,50 | ||||||||||||

| 18,0 | 18,3 | 5,50 | 5,0 | 4,50 | 3,5 | 5,0 | ||||||

| 4,0 | ||||||||||||

| 16,0 | 16,3 | +0,70 | 5,0 | 4,5 | 4,0 | 3,2 | 4,5 | |||||

| 3,50 | ||||||||||||

| 14,0 | 14,2 | 4,50 | 4,0 | 3,50 | 3,0 | ± 0,125 | 4,0 | |||||

| 3.20 | ||||||||||||

| 12,0 | 12,2 | 4,0 | 3,5 | 3,0 | ± 0,125 | 2,5 | 3,5 | |||||

| 10,0 | 10,2 | 3,50 | 3,0 | ± 0,125 | 2,50 | 2,0 | 3,0 | ± 0,125 | ||||

| 2,5 | ||||||||||||

| 8,0 | 8,2 | +0,58 | ____ | ____ | 2,5 | 2,0 | 1,6 | 2,5 | ||||

| 2,0 | ||||||||||||

| 7,0 | 7,2 | — | 2,0 | 1,6 | 2,0 | |||||||

| 6,0 | 6,1 | 2,0 | 1,6 | 1,4 | 2,0 | |||||||

| 1,4 | 1,2 | 1,6 | ||||||||||

| 5,0 | 5,1 | +0,30 | 1,6 | 1,4 | 1,2 | 1,6 | ||||||

| 1,2 | 1,0 | 1,2 | ||||||||||

| 4,0 | 4,1 | 1,4 | 1,2 | 1,0 | 1,4 | |||||||

| 1,0 | 0,8 | ± 0,08 | 1,2 | |||||||||

| 3,5 | 3,6 | — | 1,0 | 0,8 | 1,0 | |||||||

| 3,0 | 3,1 | 1,0 | 0,80 | ± 0,08 | 0,8 | 1,0 | ||||||

| 0,6 | ± 0,07 | |||||||||||

| 2,5 | 2,6 | +0,25 | 0,8 | ± 0,08 | 0,60 | ± 0,07 | 0,6 | 0,8 | ± 0,08 | |||

| 2,0 | 2,1 | 0,6 | ± 0,07 | 0,50 | 0,5 | |||||||

Parameter “k” (see Version 2) is relevant only for light and normal type washers. Its value varies in the range 0.15 mm ≤k≤0.8 mm.

The following designations are used in the table:

- Dn.st.e. – diameter (nominal) of a suitable fastening rod element;

- symbol “*” – “Nominal value”;

- symbols “**” – “Limit deviation”.

Varieties, material and manufacturing methods

The product in question is manufactured taking into account the standards established in GOST 6402-70. It specifies what materials and methods should be used. Among the features of the choice of metal, we note the following points:

- It is allowed to use steel, as well as bronze and some other non-ferrous alloys.

- Hardness should vary from 40 to 48 HRC when using common steel grades. If bronze is used, the value is at least 90 HRC. The weight and some other indicators largely depend on the type of material used.

- During production, various methods can be used, but the appearance of cracks, scale, burrs and other defects is not allowed. In some cases, only minor defects are acceptable that do not affect the performance characteristics of the product.

- To identify the main qualities, a flat washer is subjected to various tests.

A situation often occurs when, in the manufacture of a spring washer, special spring steel is used, which has special performance characteristics.

To achieve the required properties, heat treatment is carried out, due to which the hardness increases and the brittleness decreases.

Washer compliance with GOST 6402

The grower is manufactured as specified in GOST (spring steel 65G), followed by heat treatment. This reduces the internal stress of the metal, increases its strength and resistance to external influences, and also reduces the fragility of the product.

Grover washers can be produced with or without coating. The applied coating improves the anti-corrosion properties, and the chrome coating also gives greater hardness to the washer and increases service life.

Grover disc is available in four types: light, normal, heavy and extra heavy. GOST describes all the indicators that spring washers must have, and also presents a table of dimensions of the washer-grower. The type of disk is influenced by the profile of the wire rod.

The sharp edge of the disk also stops spontaneous unscrewing due to the emphasis on the metal, therefore, when it is necessary to unscrew the fastener, mechanical damage (scratches) usually remains on the nut from the sharp edge as if from a carver.

It is not recommended to use the disk in an assembly with fasteners a second time, and when this recommendation is ignored, the fasteners are unscrewed at the most inopportune moment.

How to install the Grover washer?

In general, the product in question does not differ significantly from the usual version. That is why the installation features include the following:

- Located between the nut and the main element.

- Can be supplied with a regular nut.

It is the ease of operation that determines the wide distribution of the product in question.

What you need to know about the profession

It is very important to know what functional responsibilities an engraver has:

- be able to create models for an object;

- select the right material for the job;

- choose the right processing methods and methods, as well as the necessary tools;

- carry out engraving of any complexity;

- be able to bring work to perfection;

- sharpen engraving tools;

- carry out adjustment and adjustment of all necessary machines and devices necessary for engraving.

It is important to know where a specialist can work:

- various public or private jewelry workshops;

- in art workshops;

- in stores that sell gifts;

- in enterprises related to printing, textiles, or pulp and paper mills;

- in organizations where funeral services are provided, in particular, the production of monuments.

Application of spring washers and operating features

The scope of application of hardware and the spring washers in question is quite wide. This is due to the fact that they are easy to manufacture and last for a long period. Among the operating features we note:

- Over time, the basic properties decrease.

- Mechanical damage can cause failure.

- Exposure to heat also negatively affects the basic properties.

It is allowed to use a washer of this type in mechanical engineering and other fields. This takes into account that the degree of fixation is relatively low.

Advantages and disadvantages

Spring washers have both advantages and disadvantages. The advantages include:

- versatility. Grovers, when installed correctly, work perfectly in threaded connections of any type;

- resistance to the negative effects of moisture. Even if non-corrosion resistant 3X13 steel was used to produce the washers, such parts made of carbon alloys are usually galvanized. Therefore, when working in conditions of high humidity, iron oxide - rust - does not appear on their surface;

- ease of use;

- low cost even compared to other budget fasteners;

- fairly high wear resistance;

- excellent strength characteristics.

Spring washers have significantly fewer significant disadvantages:

- if the groover is used in conjunction with fasteners made of soft metal, its edges may harm their threaded knurling;

- When left in a tightly tightened threaded connection for a long time, residual deformations occur. For this reason, reuse is often not possible;

- When a spring washer is subjected to increased loads, it can change from a helical configuration to a flat configuration over time. This phenomenon causes a significant decrease in the tensile force.

Technical requirements

GOST 6402-70 also prescribes the rules that must be followed by the manufacturer of spring washers. Below are just some of them.

- The raw material for the manufacture of these products must be wire that meets the requirements of GOST 11850, adopted in 1970. It is also allowed to use blanks made from alloys of the following grades: heat-resistant, corrosion-resistant high-alloy structural steel 3X13; spring-spring structural steel 65G; unalloyed spring structural carbon steel 70; bronze grade BrKMts3-1 or other non-ferrous alloys.

- The hardness index, determined by the Rockwell method: steel spring washers, must be in the range of 40.0...41.5≤HRC≤48.0...49.5; bronze growers must have at least 90HRB

The hardness of growers made from grade 70 steel can be increased to 50.0≤HRC≤51.5.

- The surface of the products should not contain traces of corrosion, signs of cracking, flash residues - burrs, as well as scaly particles - scale. At the same time, the remains of inseparable scale do not classify the product as defective.

- The cut at the ends of the turns of the washers should be flat. Metal chips that do not bring the value of parameter “m” (see design drawing No. 1) beyond the limits of permissible deviations are not included in the number of rejection criteria.

- The edge formed by the supporting surface of the product and the cutting plane should be as sharp as possible.

- The trapezoidal configuration of the cross-section of the spring washer, which does not go beyond the parameters “s” - in the drawing this is the height of the coil, is not considered a defect.

- The bushing should not crack or break if the ends are bent at an angle of 45°.