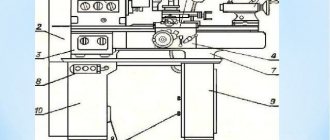

TV-16 or, in full, a screw-cutting lathe, is a small piece of equipment designed for working with small metal parts. Many people know him from school. The boys worked with him in labor lessons and often such devices were installed in training workshops to train mechanics. Indeed, at one time this machine trained many good professionals. Using the school machine is simple and practical.

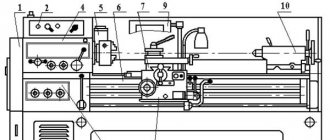

School lathe TV-16.

If you follow safety precautions, you completely eliminate the possibility of injury when turning metal parts. Unfortunately, this machine has long been out of production, because for industrial scale it could no longer cope with the volume of work and was supplanted by other, more modern analogues. Nevertheless, people have not stopped respecting it and wanting to buy it for their mini-workshop.

Description of turning and screw-cutting equipment

Replacement gears of the TV-16 machine.

This tabletop machine itself is a compact piece of equipment that will fit into any home workshop. After the equipment was discontinued from production, the models that were in reserve at the manufacturer's plant were bought up to meet the needs of small auto repair shops and other repair services that deal with the processing of metal parts during the production process.

The TV-16 machine itself made it possible to:

- Cut threads both inside and outside the part;

- Drill holes in the part with a high level of accuracy;

- Boring metal structures;

- Perform any basic turning work.

It was created with the sole purpose of developing the skills of young specialists to work on more complex equipment that was used in large enterprises. Therefore, the lathe can be mastered within 24 hours to the user’s level. It is not big, has compact dimensions:

- Height - 115 cm;

- Width - 60 cm;

- Length - 120 cm;

- Weight - 180 kg.

The machine was highly respected and valued for its productivity and small dimensions. Initially, the equipment was produced with a short beam, but later the plant began producing models with an extended version. This modification provided more opportunities, and the user could allow the production of high-precision parts in non-factory conditions in accordance with GOST, which then existed in the Soviet Union.

Performance indicators

Description of technical characteristics:

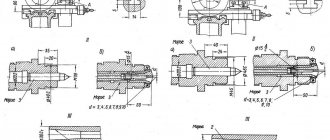

- center height – 8.5 cm;

- distance between centers – 25 cm;

- maximum cutting length – 25 cm;

- movement of the limb per 1 revolution – 3.2 cm (longitudinal); 0.15 cm (transverse);

- number of tools in the cutter holder – 4;

- spindle Morse taper – 3;

- spindle hole radius – 0.9 cm;

- tailstock Morse taper – 1;

- maximum movement of the quill – 6.5 cm;

- overall dimensions – 115x60x120 cm;

- weight – 0.18 t.

The maximum diameter of the part being processed cannot be more than sixteen centimeters above the supporting frame. Above the support element, the greatest distance is reduced to nine centimeters.

This is interesting: Do-it-yourself hydraulic press from a jack - how to make it, drawings, manufacturing options

Technical characteristics of the TV-16 machine

The machine had its own limiting capabilities, so the user could not process workpieces on it that were higher than the following dimensions:

- The diameter above the bed is more than 160 mm;

- The diameter above the caliper is no more than 90 mm;

- The maximum possible length of the workpiece is up to 250 mm.

Unlike its predecessor TV-4, the screw-cutting lathe model 16 had an increased hole width in the spindle - 18 mm.

The equipment passport has the following parameters:

TV-16 equipment passport.

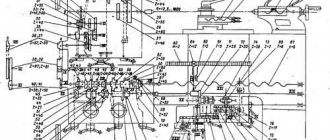

The equipment frame was made of cast iron, which provided support and a foundation for all other parts. The device has 3 longitudinal grooves that set the movement of the support and also ensure the fixation of the tailstock of the machine. The main chassis is represented by a screw, and the rack is located on the front area of the screw-cutting lathe.

The rotation of the workpiece inserted into the grooves is imparted by the headstock. The drive used for the machine is represented by an individual asynchronous motor. All equipment runs on electricity. Drive indicators:

- Power - 0.4-0.5 kW;

- Torque - 1,400 rpm.

The main function of the machine is to adjust the longitudinal feed for thread cutting. To ensure the movement of the tool holder in the direction from the lead screw to the equipment support, an apron is used. The entire machine operates in two modes - automatic and manual. To use the first, you need to turn on the apron nut, and by turning it off, the movement of the tool holder will be performed manually by the equipment operator. To do this, just rotate the flywheel with the dial.

Thanks to the support, the cutting elements are fixed and moved. If the operator has to process large workpieces or make a hole, the tailstock comes to the rescue. It is mobile - that is, if necessary, it can be removed from the machine and thereby facilitate work with small parts. If you need to process large ones, then one front one will not be enough. The tailstock has a trident-shaped mount, which allows you to more securely fix and rotate the part.

If you need to make a hole in a part, then place a suitable tool on the tailstock, using a drive, the workpiece begins to rotate and move towards this tool. The operator then controls the depth of the groove.

The TV-16 machine installation itself is mounted on a regular wooden table. According to the instructions, fixation is performed using screws. The engine together with the drive will be located in a special cabinet. As a rule, its location will be to the left of the table.

To protect the equipment from short circuits, measures are taken to ground the device, and while working on it, it is better for the operator to place a rubberized mat under his feet, which will act as a dielectric. If a short circuit suddenly occurs and there is a risk of electric shock, it will pass through a lower resistance and exit through the grounding wire or rod. This is a small but important point when working on a screw-cutting lathe 16.

Peculiarities

Setting up mechanisms and components

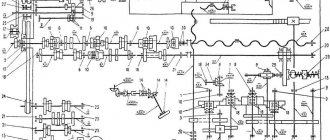

The spindle bearings are secured using a nut. Proper selection of spacer bushings will help eliminate the occurrence of axial play. It is important to create the correct tension on the V-belt drive belts, not too much, but it is unacceptable for them to slip on the pulleys. The adjustment is made using an eccentric mechanism, followed by fixation.

Before installing the TV-16 lathe, the gears are cleaned and lubricated. Using wedges and screws, gaps in the guides of the caliper carriage, upper and transverse slides are adjusted.

Conical processing of the product in the centers involves a shift of the tailstock body relative to its plate. Using screws helps you fine-tune the desired location.

Installation features

The initial installation phase involves moving the machine to its final location and then unpacking it. The table is supplied in additional packaging. For the most accurate fixation, you need to secure the machine to the wooden surface of the table with 6 screws, which secured it in the shipping box. The drive belt should be installed on the drive pulley. Particular attention is paid to the correct connection of the grounding wire; it should be routed through specially designed holes in the frame and secured with a bolt.

Proper installation involves leveling the horizontal using a level. Using fuses, cable wiring should be carried out from the group distribution board. The final stage consists of carefully removing the anti-corrosion lubricant from all components and surfaces.

Support TV-16

Before starting operation, it is important to carry out a detailed inspection and check of all parts and assemblies. The initial check of correct operation occurs both idle and with load applied.

User manual

The equipment cannot be used or serviced unless you have unplugged it. The machine must be maintained at least once a month. This means that if you decide to purchase such equipment for yourself, you should clean it and inspect it for condition every 30 days.

Also watch the video regarding the operation of TV-16.

Equipment contacts are made from materials that contain silver. Consequently, the operator is not required to carefully care for their condition. There is no need to adjust them either, and if they suddenly wear out, they simply replace them with new ones. If you clean the contacts, blackening will occur, which will undoubtedly affect the performance of the equipment.

To prevent rust on the surface of the machine, the interface between the core and the armature should be coated with machine oil. After this, everything is wiped with a dry cloth so that the oily substance does not provoke gluing of the armature and the core.

Important! The spindle should not create any play during operation.

A complete inspection of equipment and repair of components must be performed at least once a year. Bearing lubricants are changed after 40,000 operating hours. It is better to use lubricant grade 158 TU 38 101320-77. In order for all bearings to function normally, the operator should fill the oil reservoir to 2/3 of its volume.

Advice! Preventive inspection of the unit should be carried out once every 6 months.

Preventive repair of the machine.

In addition to routine inspection, you need to periodically review the condition of the switch, look at the surface of the nuts and other joints to monitor how they are in working condition.

- If the connection points are clogged, you should clean them so that later the bolts can be easily unscrewed without tension and the risk of stripping the threads.

- If the bolts are loose, the operator needs to tighten them, otherwise the machine may rattle, which will affect the accuracy of sharpening or turning the part.

- Carbon deposits and other traces of work should be removed from working surfaces to avoid problems with the machine later.

All these precautions will enable you to significantly increase the service life of such a machine and improve the quality of the parts processed on it.

See information about Easton hockey sticks on our website.

Important! To avoid problems with damage to wires, it is recommended to clean the electrical cabinet from dust that accumulates there once every 3-4 months.

Safety precautions

Following safety precautions helps prevent injury when operating equipment.

To prevent accidents from occurring, the following rules must be followed:

- It is not allowed to perform cleaning and lubrication work on equipment components during its operation.

- It is not allowed to leave the equipment turned on and move away from it; you must first disconnect it from the electrical network.

- It is necessary to ensure good lighting of the work area.

- If a breakdown occurs, you must stop working immediately.

- In the event of an emergency, you must immediately disconnect the equipment from the electrical network.

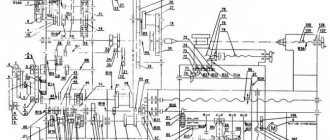

Electrical equipment

All electrical equipment of screw-cutting lathe 16 is designed for the use of power units. It is connected to a three-phase network. To ground the device, an ordinary neutral wire is used. It helps protect not only from short circuits, but also from network overload, as well as a number of other factors of electric current breakdown. The complete connection diagram is visible in the photo below.

To provide contacts, relay contact equipment is used. It hides in the electrical cabinet, which is located on the back of the machine. You can see it on the headstock housing of the equipment.

Before making a test run, you should make sure that the network frequency and voltage fully comply with all TV-16 parameters. It is permissible to connect equipment to the network using copper wires, which in cross-sectional diameter are equal to those of the conductors in the machine circuit. The grounding is connected using a bolt, and before starting, the operator needs to make sure every time that everything is fine with the connection.

TV-16 electrical circuit diagram of the machine

Symbols for the TV-16 electrical circuit.

Operating rules

Before you start sharpening parts, you need to adjust the speed of the product. The specifics of the processing being carried out determine which gearbox gears need to be installed. A chuck or faceplate is fixed to the spindle component. The tools are mounted and fixed on the cutter holder. The workpiece that is being processed is fixed in a chuck or centers. When processing centers, you need to bring the tailstock. The lathe-screw-cutting device is started after a special key is pressed. The machine is turned off with the “Stop” button.

If it is necessary to reverse the spindle component, the switch handle is set to the “backward” position. It is worth noting that at the “Stop” mark only the electric motor is turned off. In view of this, upon completion of processing, in order to safely de-energize the device, you need to move the handle to the “off” position.

Excessive heating of the spindle component indicates that the lubricant needs to be changed and the quality of the connections checked. It is necessary to regularly check the condition of the bearings in order to troubleshoot problems in a timely manner.

Only a professional who understands the technical intricacies should service a screw-cutting lathe. To prevent injury, the following safety precautions must be observed:

- Do not clean or lubricate machine parts while the device is operating;

- It is forbidden to leave the device running. Before leaving, you need to turn it off or stop it completely;

- the workplace should be well lit;

- if any problems occur, you must immediately stop processing the part and contact the service technician;

- in the event of an accident, you must immediately disconnect the device from the network;

- the machine must be reliably grounded.

Where to buy and what to look for when choosing

Since the machine has been discontinued, buy it only from the reservation of some enterprise, or from private individuals. In any case, when purchasing this used for a home workshop, you should take a number of the following measures:

- Check the serviceability of the machine on site with the current owner.

- Assess the condition of the parts.

- When purchasing, it is recommended to go through all the parts to look again and assess their condition.

buy such equipment on Avito for around 20,000-40,000 rubles. And most often it is taken for personal use, for small turning workshops or to meet the needs of a car service center.

Main varieties and explanation of modifications

The TV-16 machine is one of the universal models of the TV series, produced in Soviet times for educational institutions. The series also includes the following models with similar equipment and a fairly simple electrical circuit:

- TV-2 , model with three feeds and three types of thread cutting. Available in two versions with different headstock covers. Motor power 500 W, spindle speed 900 rpm.

- TV-4 , an improved model with a more powerful engine, spindle speed up to 1,500 rpm, and six speeds.

- TV-6 , a model identical to the previous one, is distinguished by an engine power of 1.1 kW, 1,400 rpm, the appearance of an electrical panel on the right cabinet and a modified configuration of carbolite handles.

- TV-7 . A completely modernized model with a modified gear shift method and expanded functionality.

Product marking means:

- number 1 - group (lathe equipment);

- number 6 - type (screw-cutting lathe).

Messages [ 21 ] 172 [Closed]

1 Topic from Andrey1989 04/14/2016 22:27:55 (3 years 11 months ago)

- Andrey1989

- Participant

- Topic author

- Inactive

- Experience: 5 years 7 months

- Messages: 1 891

- Reputation: [ 11 | 2]

Topic: I will buy spare parts for the TV-16 lathe

subject

Edited by Andrey1989 (08/05/2016 17:56:55, 3 years 7 months ago)

2 Reply from RCB 04/15/2016 09:27:38 (3 years 11 months ago)

- RCB

- Participant

- Inactive

- Experience: 12 years 4 months

- Messages: 1 163

- Reputation: [ 21 | 1 ]

Re: Buy spare parts for a TV-16 lathe

In what condition and at what price are you planning to buy?

3 Reply from Andrey1989 04/19/2016 21:02:16 (3 years 11 months ago)

- Andrey1989

- Participant

- Topic author

- Inactive

- Experience: 5 years 7 months

- Messages: 1 891

- Reputation: [ 11 | 2]

Re: Buy spare parts for a TV-16 lathe

In what condition and at what price are you planning to buy?

well, preferably in working order, but the buyer says the price

4 Reply from -=HUNTER=- 04/19/2016 21:07:00 (3 years 11 months ago)

- -=HUNTER=-

- Participant

- Inactive

- Experience: 10 years 5 months

- Messages: 4 714

- Reputation: [ 83 | 8 ]

Re: Buy spare parts for a TV-16 lathe

I’ll take this opportunity to buy a school machine or a bigger one

5 Reply from RCB 04/19/2016 21:26:55 (3 years 11 months ago)

- RCB

- Participant

- Inactive

- Experience: 12 years 4 months

- Messages: 1 163

- Reputation: [ 21 | 1 ]

Re: Buy spare parts for a TV-16 lathe

Schoolchildren on Avito often skip around 30. And on TV-16, for example, a person sells https://www.chipmaker.ru/index.php?app=a … lot=857325, I bought some spare parts from him. I have a TV-16, but in a disassembled state you will need to use your hands accordingly and the price will be lower. That’s why I asked about the price: take it more expensive to work right away or cheaper but tinker with it.

6 Reply from Andrey1989 04/20/2016 13:40:55 (3 years 11 months ago)

- Andrey1989

- Participant

- Topic author

- Inactive

- Experience: 5 years 7 months

- Messages: 1 891

- Reputation: [ 11 | 2]

Re: Buy spare parts for a TV-16 lathe

I’ll take this opportunity to buy a school machine or a bigger one

7 Reply from -=HUNTER=- 04/21/2016 07:42:43 (3 years 11 months ago)

- -=HUNTER=-

- Participant

- Inactive

- Experience: 10 years 5 months

- Messages: 4 714

- Reputation: [ 83 | 8 ]

Re: Buy spare parts for a TV-16 lathe

Schoolchildren on Avito often skip around 30. And on TV-16, for example, a person sells https://www.chipmaker.ru/index.php?app=a … lot=857325, I bought some spare parts from him. I have a TV-16, but in a disassembled state you will need to use your hands accordingly and the price will be lower. That’s why I asked about the price: take it more expensive to work right away or cheaper but tinker with it.

yes you can put your hands on it

link does not work

Edited (04/21/2016 07:43:25, 3 years 11 months ago)

8 Reply from barbarian 04/21/2016 08:05:17 (3 years 11 months ago)

- barbarian

- Participant

- Inactive

- From: Barnaul

- Experience: 9 years 9 months

- Messages: 3 667

Re: Buy spare parts for a TV-16 lathe

A purely desktop TV-7m was hanging out on Avito for 40,000, a TV-16 is not a schoolboy, but a normal machine, if you need to cut threads, look for it. But as a former owner of all of the above, I highly recommend taking industrial crayons. a machine with RMC 500 (30 thousand on Avito) and with the rest of the money, rent a garage where you can put it.

9 Reply from Andrey1989 04/23/2016 10:04:20 (3 years 11 months ago)

- Andrey1989

- Participant

- Topic author

- Inactive

- Experience: 5 years 7 months

- Messages: 1 891

- Reputation: [ 11 | 2]

Re: Buy spare parts for a TV-16 lathe

Edited (04/24/2016 08:59:54, 3 years 11 months ago)

10 Reply from BUYER 04/24/2016 16:37:03 (3 years 11 months ago)

- BUYER

- Participant

- Inactive

- From: Mirny Boulevard 37

- Experience: 11 years

- Messages: 961

- Reputation: [ 53 | 1 ]

Re: Buy spare parts for a TV-16 lathe

I recently purchased a TS-3 Votkinsk station wagon and have been looking for it for a long time in good condition. True price tag.

11 Reply from Andrey1989 04/24/2016 18:57:41 (3 years 11 months ago)

- Andrey1989

- Participant

- Topic author

- Inactive

- Experience: 5 years 7 months

- Messages: 1 891

- Reputation: [ 11 | 2]

Re: Buy spare parts for a TV-16 lathe

I recently purchased a TS-3 Votkinsk station wagon and have been looking for it for a long time in good condition. True price tag.

Yes, I would take the tsh too, but it’s too big, I have nowhere to put it. )

12 Reply from BUYER 04/24/2016 19:53:45 (3 years 11 months ago)

- BUYER

- Participant

- Inactive

- From: Mirny Boulevard 37

- Experience: 11 years

- Messages: 961

- Reputation: [ 53 | 1 ]

Re: Buy spare parts for a TV-16 lathe

I recently purchased a TS-3 Votkinsk station wagon and have been looking for it for a long time in good condition. True price tag.

Yes, I would take the tsh too, but it’s too big, I have nowhere to put it. )

Only the hourly one is smaller, approximately 70cm

Edited (04/24/2016 19:55:05, 3 years 11 months ago)

13 Reply from Andrey1989 04/29/2016 08:16:19 (3 years 11 months ago)

- Andrey1989

- Participant

- Topic author

- Inactive

- Experience: 5 years 7 months

- Messages: 1 891

- Reputation: [ 11 | 2]

Re: Buy spare parts for a TV-16 lathe

Edited (05/17/2016 21:26:43, 3 years 10 months ago)

14 Reply from Barnauletz 05/17/2016 21:39:51 (3 years 10 months ago)

- Barnauletz

- Participant

- Inactive

- Experience: 7 years 1 month

- Messages: 10 021

- Reputation: [325 | 2]

Re: Buy spare parts for a TV-16 lathe

I see that the title of the topic has changed a little. Can I congratulate you on your purchase?

Purchased, but incomplete?

15 Reply from Andrey1989 05/17/2016 22:02:12 (3 years 10 months ago)

- Andrey1989

- Participant

- Topic author

- Inactive

- Experience: 5 years 7 months

- Messages: 1 891

- Reputation: [ 11 | 2]

Re: Buy spare parts for a TV-16 lathe

I see that the title of the topic has changed a little. Can I congratulate you on your purchase?

Purchased, but incomplete?

I bought it, went all the way to Biysk to get it, searched for a long time, for a whole year, it’s a good option, but in order to bring it to fruition, more details are needed. but in general, so that it is complete. You’re unlikely to find one like this, and it’s unlikely anyone will sell one like this. there are so many weird things out there. well, or the price is like a shuttle - which is also not ice)

85 ads found

Want to sell faster? Find out how

Lathe TV-16

Business and services » Equipment

20,000 UAH.

Lathe TV-16

Business and services » Equipment

20,000 UAH.

Lathe TV-16

Business and services » Equipment

15,000 UAH.

Kyiv, Darnitsky Today 10:52

Stand on TV-16

Business and services » Equipment

1,500 UAH.

TV-16 lathe

Business and services » Equipment

14,000 UAH.

Tabletop screw-cutting lathe TSA-16, TV-16

Business and services » Equipment

25,000 UAH.

Spare parts lathe TV 16

Business and services » Equipment

250 UAH

Dnepr, Amur-Nizhnedneprovsky 6 September.

Selling lathe TV-16

Business and services » Equipment

12,000 UAH.

Turning TV 16 (schoolboy

Business and services » Equipment

13,000 UAH.

Metal lathe TV 16

Business and services » Equipment

14,000 UAH.

Selling Lathe TV-16

Business and services » Equipment

10,000 UAH.

Support, small longitudinal feed of lathe TV-16, TV-4

Business and services » Equipment

4,000 UAH.

Selling turning machine TV-16 complete, with stand, motor, pulleys

Business and services » Equipment

12,000 UAH.

Krivoy Rog, Dzerzhinsky 4 Sep.

Pinol TV16

Business and services » Equipment

800 UAH

machine TV 16

Business and services » Equipment

8,000 UAH.

Nikolaev, Central 4 Sep.

Lathe TV16

Business and services » Equipment

25,058 UAH.

Metal lathe TV16, 16T04A (not a set), wood lathe STD120

Business and services » Equipment

15,000 UAH.

Selling lathe 1M63, 1k625, 1a616, TV320, 1a62g, 1v62g (16k20)

Business and services » Equipment

55,000 UAH.

Kropyvnytskyi, Kirovsky district 3 September.

Stanina TV 16

Business and services » Equipment

Lathe TV 16 and NGF-110

Business and services » Equipment

1,000 UAH

Selling lathe TV 16 “SHKOLNIK”

Business and services » Equipment

15,500 UAH.

Lathe TV 16

Business and services » Equipment

14,000 UAH.

Lathe TV-16

Business and services » Equipment

10,000 UAH.

Selling lathe TV 16

Business and services » Equipment

15,167 UAH.

Selling machine TV16

Business and services » Equipment

11,000 UAH.

Guitar TV16

Business and services » Equipment

2,300 UAH.

Zaporozhye, Zavodsky 1 Sep.

Lathe TV 16

Business and services » Equipment

16,000 UAH.

Kharkov, Chervonozavodskoy 1 Sep.

headstock of lathe TV 16

Business and services » Equipment

3,000 UAH.

Smart Tv Box Sunvell H3 2/16GB Andro > Business and services » Equipment

649 UAH

Kharkov, Chervonozavodskoy 31 Aug.

Gears of lathe TV-16 TV-4 TV6

Business and services » Equipment

250 UAH

TV 16 counter drive

Business and services » Equipment

600 UAH.

Selling school lathe TV16 Almaty ideal USSR

Business and services » Equipment

22,000 UAH.

Selling lathe TV16

Business and services » Equipment

15,000 UAH.

Lathe TV16

Business and services » Equipment

9,000 UAH

Lathe tool holder tool holder riztsetrimach TV 4 -7 -16 16u

Business and services » Equipment

600 UAH.

lathe TV16

Business and services » Equipment

6,500 UAH.

Lathe TV 16

Business and services » Equipment

6,500 UAH.

Lathe TV-16. Spare parts

Business and services » Equipment

900 UAH

tool holder on TV16

Business and services » Equipment

500 UAH

General design and operating principle

The device consists of the following components:

- cast base;

- rear and front nodes;

- tool holder;

- feed and drive mechanisms;

- set of gears, cutters and other tools.

The operating principle of these parts is as follows. The part, mounted on the spindle in a horizontal position, can be rotated; with the help of a sharpened moving cutter, a certain layer of chips is removed from the metal product.

Additional equipment in the form of drills, grinding discs and cutters used for work significantly expands the functionality of the equipment.

A unit of separately rotating and fitted parts, securely fixed to the frame, makes up the internal structure of a screw-cutting lathe.

Modern analogues

The obvious advantages of the TV-16 machine belong to their analogues, they are not inferior in quality of equipment, service life, and even win in the number of modes, power and automation of the process, and accessibility.

- Swiss JET BD-7 or BD-X7.

- German Optimum TU1503V.

- Joint production of the Czech Republic and China - Proma SM-300E.

- Russian TRIOD LAMS-02/300.

- Czech MN-80A.

- Polish TSA-16.

Despite the fact that the TV-16 is no longer in production, it is a competitive model. Initially designed for training beginners. Suitable for semi-finishing and finishing of parts, unsuitable for mass production of metal products.