Only a correctly selected torque wrench can ensure the assembly of mechanisms or building structures with a strictly specified torque. There are several varieties of it with different magnitudes of measurement error. This useful tool should be selected carefully, taking into account the complexity of the tasks.

What is a torque wrench?

We are dealing with a tool whose design makes it possible to limit the maximum tightening torque. A torque wrench is an advanced wrench with its own built-in torque gauge inside. Most models resemble devices with a union head and a ratchet, although there are varieties with a horn jaw. Externally, a torque wrench for a car is distinguished by the mandatory presence of a scale (arrow, electronic, or other type) for adjusting the amount of force.

Torque wrench device

Depending on the type of tool used, its design differs markedly. For example, the scale can be flat made of metal, electronic, engraved on the handle. As an example, consider a common typical wrench with a click type dynamometer. It consists of the following elements:

- rotating handle;

- frame;

- main scale on the body;

- auxiliary scale on the handle;

- spring mechanism;

- ratchet head;

- nozzle lock.

How does a torque wrench work?

If the torque applied to the handle is less than the values set on the scale, then the device is used as a simple wrench. The principle of operation of a torque wrench is to produce a signal at the required values that the required force has been achieved. Some models, for example, emit an audible click and cause the head to slip, which prevents the fastener from coming off. In the simplest products with a dial scale, control over the change in the tightening force value is carried out visually.

Dismemberment.

When turned on, all elements are displayed on the screen

Switching units of measurement is done by simultaneously pressing M

+

P/T

I also haven’t checked the calibration mode, but I suspect that the device will require a stable load of a certain force. I haven’t figured out how to do this yet, so I decided not to check what would happen.

In this regard, it was decided to ask for help from a friend who works in a service center. Such a mechanical sample was found with a force from 42 to 210 Nm

But there are several nuances here:

M

stores the currently configured signal strength into a memory location. There are 50 cells in total.

The keys are equipped with indicator and adjustment mechanisms, both with and without overtightening protection.

These keys have a similar operating principle to the arrow type, but a different appearance. The difference is achieving more accurate results. The tightening torque is fixed by a rotating mechanism with a spiral spring.

What is a torque wrench used for?

It is possible to tighten bolted joints “by eye” in non-critical joints, but often this practice ends in broken threads or crushed edges on the head of the product. If the force is insufficient, on the contrary, the fasteners in moving mechanisms become loose, which often leads to accidents. A wrench with a dynamometer with a built-in device for monitoring the amount of force applied helps to avoid this situation. In some models, the maximum torque is fixed; devices with an adjustable scale are more convenient to use.

Types of torque wrench

There are several types of tools with a built-in dynamometer of varying degrees of accuracy. When purchasing one, you need to understand that this is a torque wrench designed for a specific type of work, and it will not be suitable for everyday use in a home garage. Budget-friendly models are recommended for quick tightening; ultra-precise samples are used for particularly delicate and critical operations.

Torque wrenches are divided according to the following characteristics:

- Limit value of torque force.

- Indication type.

- Recommended area of use.

Electronic torque wrench

These models are equipped with a liquid crystal panel to display the amount of force. The digital torque wrench is very easy to use, in addition to the electronic scale, it has LEDs and an audible buzzer to indicate limit values. When the tightening is normal, the green light on the scale lights up. When the torque reaches a critical point, the red warning light comes on. The most important advantage of such a torque wrench is that force control can be carried out with the highest accuracy down to hundredths of values.

Arrow torque wrench

This variety is perfect for home use. These models are inexpensive and have a simple design. The pointer scale can be round (indicating torque wrench) or semicircular in shape with fastening at the handle itself (measuring wrenches). When changing values, the scale with the handle deviates in both directions, and the pointer remains in place, motionless. In samples with two arrows, one shows the current force value, and the second shows the limit value.

Disadvantages of switch models:

- A scale torque wrench has a relatively high error (about 6-8%).

- Due to its large dimensions, it is inconvenient for tightening in hard-to-reach places.

- The use of this model requires constant visual monitoring.

Open-end torque wrench

Devices with cap heads are not always convenient in cramped conditions; in some places it is more practical to use models with a horn-type mouth. Relatively quickly, samples of a universal type with interchangeable nozzles of both varieties appeared. If it is already clear what a torque wrench is, then there is no need to describe their device. The horn instrument differs only in the shape of the nozzle, otherwise its design is similar.

Snap torque wrench

The error of this tool is relatively high – up to 4%. Its main advantage is that the mechanic does not need to visually monitor the readings on the scale. Reaching the limit values is determined by a characteristic click, which is felt by hand and by ear; if you work carefully, the signal cannot be missed. The main and additional scales are engraved directly on the handle and body. There is no need to purchase a full set of torque wrenches; for a home car, a medium-sized model of 42-210 Nm is enough.

Main mistakes when making a key

Any high-precision tool cannot be manufactured completely without errors, since the master has neither accurate designs nor drawings at hand, and all this can lead to incorrect measurements and subsequent breakdown of car parts. However, many professionals have answers on this matter, offering car enthusiasts a number of recommendations in order to minimize errors and inaccuracies, in particular:

- You should not use soft metal as a lever, which can easily bend when pressed, because the force applied to the steelyard, without maintaining orthogonality, will not give the desired result, and the purpose of the device will be completely lost.

- You should not choose a cheap steelyard, because the accuracy of its measurements is very questionable, and the spring quickly stretches and fails. So, as of December 2022, the cost of scales should be in the region of 400-500.0 rubles. This is not much compared to the price of the torque wrench itself - about 3-4 thousand rubles, and it is better to change the low-quality component immediately.

- When attaching the nozzle to the nut, you need to take into account that it must be perpendicular to the axis of operation of the lever, otherwise the measurement will not work.

- Most steelyards have only an informational function and do not in any way limit the actions of the master, who can easily get distracted and tighten the bolt without paying attention to the scale reading.

You might be interested in this About High Jack jacks: features of the rack and pinion mechanism, selection criteria

Thus, when using a homemade product, the master bears much more responsibility, because the device cannot have the same automatic force reduction functions as a purchased analogue.

Service station

A homemade device is best used to control bolt tension if in doubt. If it is necessary to control the tightening on any complex component part, the car owner should still contact a service station for diagnostics and repairs, and should not replace important components in his garage, because unauthorized intervention can cost much more than the money saved on the key.

Which torque wrench should you choose?

When buying a tool, many people try to find one, but the most universal device. Other people purchase a set of several narrow profile products. Let's look at the main nuances of how to choose a torque wrench for your home:

- When determining the optimal key length and jaw shape, you need to take into account the configuration of the mechanisms being serviced.

- In poor lighting or cramped conditions, it is better to use a click torque wrench.

- Pointer devices do not require lengthy setup and are useful for working in open areas with constantly changing tightening values.

- If the accuracy of the torque of tightening the nut is important, then it is better to buy an electronic device.

- Switch budget key models have the lowest cost. If an error of 6-8% is satisfactory, then such a tool is suitable for relatively rare use in the home garage.

Torque wrench attachments

The use of these devices improves functionality and does not affect the accuracy of the tool. If you have to choose a torque wrench, it is better to purchase a kit with replaceable attachments. Their docking is carried out using a locking mechanism, replacement is simple and quick. The advantages of this choice are the following:

- A torque wrench with attachments is a universal tool, so there is no need to purchase several standard products.

- You can work with fasteners of different sizes.

- A tool with an appropriate attachment makes it easier to tighten fasteners in tight spaces.

Classification of nozzles:

- ratchets for socket heads;

- carob;

- caps.

GOST

GOST 33530-2015 has been developed for installation tools intended for standardized tightening of threaded connections, namely for torque wrenches and screwdrivers.

Verification is carried out in accordance with the State System for Ensuring the Uniformity of Measurements GOST 8.541-86 clause 2.1.2.

Torque wrenches from WERA, NORGAU, KING TONY, Jonnesway (Johnsway) and Tohnichi are certified in Russia and included in the state register of measuring instruments, so they can be used at sites where high demands are placed on torque accuracy and work with the most critical threaded connections, provided that the verification period has not expired.

As a rule, branded “speakers” are of higher quality, they have high performance and small errors, which are stated in the instrument’s data sheet.

Also, the number of documents attached to the measuring instrument must include certificates.

Certificates

Although this tool is called a key, at its core it is a measuring device that must have the appropriate documents: a device passport with a mark from the metrology laboratory about verification, certificates, etc.

A calibration certificate, also known as a verification certificate, indicates that the instrument has been tested in laboratory conditions to determine the accuracy and error of the device.

The test is carried out using different tightening forces, as a result of which the real values are established.

Wrenches suitable for international use, including the EU region, must comply with the calibration procedures of ISO 6789, Type I, Class B.

Error

Manufacturers claim an error of 3-4% for high-quality branded torque wrenches, which indicates a fairly high accuracy of such devices.

The accuracy of some models of this instrument reaches 99%.

Calibration and verification

All measuring instruments included in the Russian Register must be verified within the time limits established by the standards; it is unacceptable to use them without verification.

By average standards, torque wrenches are required to be calibrated once a year or after every thousand operating cycles.

Important!

A tool that requires verification must be calibrated independently, and tampering with its design is prohibited.

At the same time, nothing prevents you from calibrating devices used in conditions where verification is not necessary.

Torque Wrench Rating

Among the existing assortment, the following popular models should be highlighted:

- JTC 4933

– the scale is located behind the glass, the on-screen magnifying effect makes it easy to recognize data, 3/8 square, range 10-100 Nm, chrome-vanadium material, length 405 mm. - Torque wrench Jonnesway T04060

– square head 1/4″, working range DR 5-25 Nm, product length 272 mm. - Berger BG-13 STW

- universal, includes 6 heads, has an extension, 1/2 square, range 28-210 Nm, length 450 mm. - Alca450000

– complete with extension and adapter, ratchet type, you can use two types of socket bits, 1/2 square, range 28-210 Nm, length 463 mm. - JTC-1203

– high calibration, error no more than 3%, 1/2 square, chrome vanadium, range 28-210 Nm, length 465 mm.

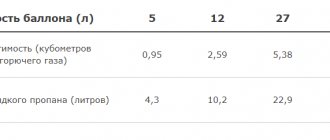

Tightening force values for different types of bolts (table)

For a more convenient and accurate perception, a table is presented for tightening bolts with a torque wrench.

| Thread | Strength class, Nm | Head, mm | |||||||

| 3.6 | 4.6 | 5.8 | 6.8 | 8.8 | 9.8 | 10.9 | 12.9 | ||

| M5 | 1.71 | 2.28 | 3.8 | 4.56 | 6.09 | 6.85 | 8.56 | 10.3 | 8 |

| M6 | 2.94 | 3.92 | 6.54 | 7.85 | 10.5 | 11.8 | 14.7 | 17.7 | 10 |

| M8 | 7.11 | 9.48 | 15.8 | 19 | 25.3 | 28.4 | 35.5 | 42.7 | 13 |

| M10 | 14.3 | 19.1 | 31.8 | 38.1 | 50.8 | 57.2 | 71.5 | 85.8 | 17 |

| M12 | 24.4 | 32.6 | 54.3 | 65.1 | 86.9 | 97.7 | 122 | 147 | 19 |

| M14 | 39 | 52 | 86.6 | 104 | 139 | 156 | 195 | 234 | 22 |

| M16 | 59.9 | 79.9 | 133 | 160 | 213 | 240 | 299 | 359 | 24 |

| M18 | 82.5 | 110 | 183 | 220 | 293 | 330 | 413 | 495 | 27 |

| M20 | 117 | 156 | 260 | 312 | 416 | 468 | 585 | 702 | 30 |

| M22 | 158 | 211 | 352 | 422 | 563 | 634 | 792 | 950 | 32 |

| M24 | 202 | 270 | 449 | 539 | 719 | 809 | 1011 | 1213 | 36 |

We will also present a table of tightening torques for inch threads according to the standard used in the United States.

| Inches | Nm | Lb |

| 1/4 | 12±3 | 9±2 |

| 5/16 | 25±6 | 18±4.5 |

| 3/8 | 47±9 | 35±7 |

| 7/16 | 70±15 | 50±11 |

| 1/2 | 105±20 | 75±15 |

| 9/16 | 160±30 | 120±20 |

| 5/8 | 215±40 | 160±30 |

| 3/4 | 370±50 | 275±37 |

| 7/8 | 620±80 | 460±60 |

How to test a torque wrench at home?

Devices of this type are invented for precision work. Even the Soviet torque wrench in the old days underwent periodic mandatory calibration. It is better to carry out this work in specialized workshops using proven, certified equipment. If the task is to do the test at home, then we carry it out using a relatively accurate household canter.

Home test of torque wrench:

- We set the tightening torque on the key to the required value.

- We tighten the bolt or nut until it clicks.

- We position the key handle vertically.

- We hook the canter hook on top of the key, holding the device at a right angle.

- We pull the canter with our hand in the direction of tightening until it clicks, visually monitoring its readings.

- We measure the length of the tool handle with a tape measure to determine the leverage.

- We calculate the magnitude of the moment using the formula (M = F*r). For example, with a canter reading of 8.5 kg and a key length of 32 cm, we obtain the following data: (8.5x9.81)x0.32 = 26.7 Nm.

How to set a torque wrench?

If the device has recently been repaired or it has not been working correctly since the factory, then it needs to be calibrated. At home, we do the task of how to set a torque wrench according to the following instructions:

- Calibration requires setting the exact moment of force. At home, this can be done using a canter, as described in the previous section, or using a load with a precise weight (dumbbells, kettlebells).

- We set the handle to the desired moment and check the key in operation.

- If the click occurs before the load moves, the calibration sleeve must be tightened.

- If the weight rises without a click, the calibration sleeve is loosened.

- The torque wrench is adjusted until the load barely rises at the moment of clicking.

- When the required parameter is set, the locking knob is tightened.

- The locknut is installed and tightened to secure the calibration sleeve.

How to use a torque wrench?

Depending on the type of tool, the operating instructions may differ. For example, click-type models should be set to the minimum value at the end of work to weaken the adjustment mechanism. We will describe the main nuances of how to properly use a torque wrench, which are suitable for any model of device, regardless of type:

- It is not recommended to use this tool to unscrew nuts, otherwise you may lose settings or break the mechanism.

- Do not set force values beyond the setting limits.

- Clean the tool delicately, without completely removing the factory lubricant.

- When the lock nut is tightened, it is prohibited to rotate the handle.

- If the torque wrench has been stored without use for a long time, do not try to immediately set a large force on the scale; first check it in operation at a small torque value.

- It is prohibited to use pieces of pipe as extensions and to use a torque wrench as an impact tool.

- It is recommended to install only standard attachments.

- Throwing the tool on the ground or hitting the torque wrench is prohibited.

- The products are stored in a dry, clean place, and sent for long-term preservation in a lubricated form.

- During operation, the spring mechanism weakens, so periodically the keys should be checked independently or sent for calibration.

Purpose, device and characteristics

Torque wrenches are designed for standardized tightening of screw connections; most often this tool is used in car repairs, for example, for tightening spark plugs, when tightening wheel bolts, fastening the cylinder head and for other objects where it is recommended or required to take into account the tightening torque.

Torque wrenches are also used in the installation of refrigeration equipment, air conditioners, in the assembly of construction equipment, in the construction of railways, bridges, oil and gas pipelines and other structural objects where controlled tightening of screw connections is necessary.

The use of torque wrenches, thanks to their design, prevents the possibility of licking off the edges of bolts and nuts, and also prevents stripping of threads or damage to the fasteners themselves, because tightening is carried out in accordance with established standards.

Thus, using this precise tool, screw connections are tightened with the required force, which eliminates the possibility of overtightening or undertightening.

Attention!

It is unacceptable to use a torque wrench as a wrench.

In other words, you cannot use this tool to unscrew stuck, rusted, or simply overtightened, and especially overtightened, threaded fasteners.

If the “speaker” is not used for its intended purpose, its service life will be very short or even end in an instant.

The body of this tool is made of specialized metal alloys; the device is mainly cylindrical in shape, inside of which there is an adjustment spring.

The spring is adjusted by turning the handle to the right or left to set the required force.

The handle is located at one end of the device, just after the lock nut, if equipped, some models use a special lock to secure the position of the handle.

The handle is movable; it is designed to adjust the tightening torque by rotating it to the right or left.

On the opposite side, an elastic mechanism is built into the core of the torque wrench.

The limit torque coupling is the main mechanism in which the articulated joint is installed; it is the one that is activated when the set tightening torque is reached.

The ultimate torque clutch has a ratchet or ratchet mechanism built into it that allows rotational movements in confined spaces.

The limit coupling can be either an integral part of the torque wrench or a separate attachment installed in the socket end or in the rectangular cavity of the base, depending on the model of the tool.

Almost all modern models of torque wrenches have a flag switch, the so-called reverse, designed to change the direction of tightening clockwise or counterclockwise, so you can tighten in any direction.

Some models of this tool are produced with a double drive square located on two opposite sides.

This modification is also designed to quickly tighten screw connections in two directions.

The tightening torque is determined using an existing scale, on a liquid crystal display, or by a characteristic click that occurs in the limit coupling, depending on the device of the model.

Using the scale of a torque wrench, you can accurately determine how much force was applied to tighten a bolt or nut, which is why some craftsmen call this tool an accurate wrench.

Drive types

The design of the tip (drive) of torque wrenches for attachments comes in two types:

- A convex square tip (outer tetrahedron), designed for installing socket heads and special attachments on it.

- A hollow rectangular tip into which horn heads, split, cap, ratchet and other inserts/attachments are installed.

Nozzles and inserts are mated to the tip of the torque wrenches, and secured in it (on it) using a locking mechanism, if provided by the manufacturer.

The design of older models differs from modern ones; read more about it below in the description of each type of torque wrench.

Dimensions

The dimensions of the drive on which or into which nozzles and inserts are installed depend on the type of seat.

Square shank dimensions for bits in inches:

- Square 1/4

- Square 3/4

- Square 1/2

- Square 3/8

Dimensions of rectangular cavities for inserts:

Rectangle: 9x12mm;

Rectangle: 14x18 mm;

The size range of nozzles and socket heads ranges from 6 to 19 mm, followed by the following sizes:

- 21 mm;

- 22 mm;

- 24 mm;

- 26 mm;

- 27 mm;

- 29 mm;

- 30 mm;

- 32 mm;

- 34 mm;

- 41 mm.

Each size is designed for a certain force applied during operation.

An effort

The unit of force of torque wrenches in the CIS countries is measured in newton meters and is called the moment of force, which is denoted by two Cyrillic letters Nm, at the international level the designation is by Latin letters Nm.

One newton meter is equal to 0.101972 kilogram-force meter.

One kilogram-force meter is equal to 9.80665 newton meters.

Where high accuracy is not required, to simplify the perception of these numbers, for example, in secondary schools and in everyday life, it is generally accepted that one newton meter is equal to one kilogram of meter force.

The force range of different models of this tool can be from 0.1 to 1000 Newton meters.

NOTE:

In car repair instructions for the most important fasteners, as a rule, it is indicated with what exact force it is necessary to tighten a particular bolt, nut, or stud.

General standards for tightening threaded connections are contained in the guidance document RD 37.001.131-89 dated July 1, 1990, which describes the classes of threaded connections and the requirements for them.

How to do without a torque wrench?

In field conditions, it is difficult to find an accurate calibrated instrument. There is an original way to replace a torque wrench if you urgently need to tighten the nuts. The work can be done using kitchen scales according to the following technology:

- A reliable key and a relatively accurate spring canter are required.

- Ideally, the tightening torque should correspond to the force applied to a 1 m long lever.

- To simplify the calculations, you can use a meter section of pipe as a force arm.

- If you use a wrench without an extension cord, then measure its length. With a length of 25 cm, divide 1/0.25 = 4. For example, a force of 2 kgf*m is required. Next, we multiply the resulting value by the required force: 4x2 kgf*m=8 kg.

- This means that with a short arm of 25 cm, you need to get a reading of 8 kg on the scale, and with a long arm of 1 m, a reading of 1 kg.

- We install our key on the fastener vertically, and fix the canter hook on top of the handle.

- Pull the scale ring from the other end until the required weight is reached.

Replacing the oil pressure sensor

To install a new sensor, you will need the following tools and consumables: two wrenches for “21”, an open-end wrench for “22” with an adapter, a rubber protective cap, an O-ring and block (usually included in the kit), a wire terminal for the sensor contact. Before replacement, you must remove the negative terminal from the battery. Operating procedure:

Remove the rubber protective cap from the top of the sensor and disconnect the wiring terminals. Unscrew the sensor from the fitting using a “21” wrench, carefully holding the tip of the fitting with a key of the same size. Remove the sensor. An O-ring and a metal washer are installed at the connection between the sensor and the fitting, which must be replaced if they are worn. The new sensor is installed in the reverse order.