P

The industrial revolution in England in the 18th century is usually associated with the improvement of the loom and the invention of the steam engine.

These and other improvements and inventions created an urgent need to increase the production of new machines. The same was required by the development of shipbuilding and weapons production, due to the expansion of the British colonial empire and trade with the whole world. England became the "mistress of the seas."

The fleet then was sailing. The sails were controlled by a system of ropes passed through blocks. At the beginning of the 19th century, the British navy alone required more than 130 thousand blocks per year. The need for such a quantity of similar products could only be satisfied by mass production.

Henry Maudsley, 1827

Photo: gettyimages.ru

But the unprecedented demand for machines could not be satisfied as long as they were made by hand: the machines were created by skilled artisan mechanics, who often kept their manufacturing secrets secret. For this they were even often called arcanists

, that is, people who possess secret knowledge. The quality of the machines depended on the skill of the workers. So cars were rare and expensive.

It is known that the same James Watt was unable to manufacture the steam engine he invented for quite a long time, since he was unable to achieve the required precision in manufacturing the cylinder.

The manual production of machine parts excluded their interchangeability; as a result, each machine became unique, and its repair was impossible or required painstaking fitting of new parts. Similar problems arose in the manufacture of all complex devices. For example, the same weapon.

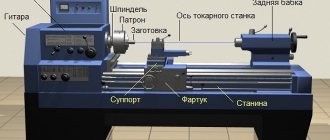

The main role in solving these problems was played by the improvement of the lathe carried out by the British mechanical engineer Henry Maudsley

(1771–1831). He can be considered the founding father of the modern machine tool industry - it was Maudsley who was the first to organize the production of machines by machines on an industrial scale, created a methodology for designing machines and developing technological processes, and introduced precision measuring instruments into the everyday practice of mechanical engineering.

The manual production of machine parts excluded their interchangeability; as a result, each machine became unique, and its repair was impossible or required painstaking adjustment of new parts

History of the lathe

History dates the invention of the lathe to 650.

BC e. The machine consisted of two coaxially installed centers, between which a workpiece made of wood, bone or horn was clamped. A slave or apprentice rotated the workpiece (one or more turns in one direction, then in the other). The master held the cutter in his hands and, pressing it in the right place against the workpiece, removed the chips, giving the workpiece the required shape. Later, a bow with a loosely stretched (sagging) bowstring was used to set the workpiece in motion. The string was wrapped around the cylindrical part of the workpiece so that it formed a loop around the workpiece. When the bow moved in one direction or the other, similar to the movement of a saw when sawing a log, the workpiece made several revolutions around its axis, first in one direction and then in the other. In the 14th and 15th centuries, foot-driven lathes were common. The foot drive consisted of an ochep - an elastic pole, cantilevered above the machine. A string was attached to the end of the pole, which was wrapped one turn around the workpiece and attached to the pedal with its lower end. When you press the pedal, the string is stretched, forcing the workpiece to make one or two turns, and the pole to bend. When the pedal was released, the pole straightened, pulled the string up, and the workpiece made the same turns in the other direction. Around 1430, instead of an ochep, they began to use a mechanism that included a pedal, a connecting rod and a crank, thus obtaining a drive similar to the foot drive of a sewing machine, which was common in the 20th century. From that time on, the workpiece on the lathe received, instead of an oscillatory movement, rotation in one direction throughout the entire turning process. In 1500, the lathe already had steel centers and a steady rest, which could be strengthened anywhere between the centers. On such machines, quite complex parts were processed, which were bodies of rotation, right down to the ball. But the drive of the machines that existed at that time was too low-power for metal processing, and the forces of the hand holding the cutter were insufficient to remove large chips from the workpiece. As a result, metal processing turned out to be ineffective. it was necessary to replace the worker's hand with a special mechanism, and the muscular force driving the machine with a more powerful engine. The advent of the water wheel led to an increase in labor productivity, while having a powerful revolutionary effect on the development of technology. And from the middle of the 14th century. water drives began to spread in metalworking. In the mid-16th century, Jacques Besson (died 1569) invented a lathe for cutting cylindrical and conical screws. At the beginning of the 18th century, Andrei Konstantinovich Nartov (1693-1756), a mechanic for Peter the Great, invented an original lathe-copying and screw-cutting machine with a mechanized support and a set of replaceable gears. To truly understand the global significance of these inventions, let's return to the evolution of the lathe. In the 17th century lathes appeared, in which the workpiece was no longer driven by the muscular power of the turner, but with the help of a water wheel, but the cutter, as before, was held in the hand of the turner. At the beginning of the 18th century. lathes were increasingly used for cutting metals rather than wood, and therefore the problem of rigidly fastening the cutter and moving it along the table surface being processed was very relevant. And for the first time, the problem of a self-propelled support was successfully solved in A.K. Nartov’s copying machine in 1712. The inventors took a long time to come to the idea of mechanized movement of the cutter. For the first time, this problem became especially acute when solving such technical problems as thread cutting, applying complex patterns to luxury goods, making gears, etc. To obtain a thread on a shaft, for example, markings were first made, for which a paper tape of the required width was wound onto the shaft, along the edges of which the outline of the future thread was applied. After marking, the threads were filed by hand. Not to mention the labor intensity of such a process, it is very difficult to obtain satisfactory quality of carving in this way. And Nartov not only solved the problem of mechanizing this operation, but in 1718-1729. I improved the scheme myself. The copying finger and support were driven by the same lead screw, but with different cutting pitches under the cutter and under the copier. In this way, automatic movement of the support along the axis of the workpiece was ensured. True, there was no cross-feed yet; instead, the swing of the “copier-workpiece” system was introduced. Therefore, work on the creation of the caliper continued. In particular, Tula mechanics Alexey Surnin and Pavel Zakhava created their own caliper. A more advanced support design, close to the modern one, was created by the English machine tool builder Maudsley, but A.K. Nartov remains the first to find a way to solve this problem. In general, cutting screws has long remained a complex technical task, since it requires high precision and skill. Mechanics have long thought about how to simplify this operation. Back in 1701, the work of C. Plumet described a method for cutting screws using a primitive caliper. To do this, a piece of screw was soldered to the workpiece as a shank. The pitch of the soldered screw had to be equal to the pitch of the screw that needed to be cut on the workpiece. Then the workpiece was installed in the simplest detachable wooden headstocks; the headstock supported the body of the workpiece, and a soldered screw was inserted into the backstock. When the screw rotated, the wooden socket of the tailstock was crushed into the shape of the screw and served as a nut, as a result of which the entire workpiece moved towards the headstock. The feed per revolution was such that it allowed the stationary cutter to cut the screw with the required pitch. A similar kind of device was on the screw-cutting lathe of 1785, which was the immediate predecessor of the Maudsley machine. Here, the thread cutting, which served as a model for the screw being manufactured, was applied directly to the spindle, which held the workpiece and caused it to rotate. (A spindle is the name given to the rotating shaft of a lathe with a device for clamping the workpiece.) This made it possible to do cutting on screws by machine: the worker rotated the workpiece, which, due to the thread of the spindle, just like in the Plumet device, began to move progressively relative to a fixed cutter that the worker held on a stick. In this way, the product received a thread that exactly matched the spindle thread. However, the accuracy and straightness of the processing here depended solely on the strength and firmness of the hand of the worker guiding the tool. This was a great inconvenience. In addition, the threads on the spindle were only 8-10 mm, which allowed only very short screws to be cut.

Childhood and youth

Henry Maudsley was born on August 22, 1771 in Woolwich, eight miles from London, the fifth child in a large family of a carpenter at the local arsenal. Nothing is known about the childhood years of the future machine tool builder, except that he, the son of a carpenter, was barred from going to school. Apparently, he mastered reading and writing on his own and quite late. Like other children from working-class families, Henry was sent to work at the age of twelve. He joined the same arsenal as a cartridge stuffer - in England such workers were called powder monkeys,

"powder monkey" Two years later he was transferred as an apprentice to a carpenter's workshop. And a year later he himself asked to be an apprentice at the forge, where, on his own initiative, he also worked as a mechanic. By the age of eighteen, Maudsley had become not only the best blacksmith of the arsenal, but also a mechanic, as evidenced by the measuring instruments he made himself while working at the Woolwich Arsenal.

At that time, in Pimlico, a suburb of London, Joseph Bramah, a famous mechanic and inventor, a pioneer in the field of hydraulics and metalwork, owned a large workshop. He was literate and could draw well.

Brama initially installed water closets in London. He came up with a completely new device for them, for which he took out a patent. Since then, Bram's invention has undergone only minor changes.

Brahma then improved the door lock. He developed a new mechanism design that surpassed everything known before him in quality and reliability. The correct operation of the new lock depended on the precision of the parts. And Brama began to look for a skilled mechanic to whom he could entrust this work. But I didn’t want to pay a lot. Maudsley turned out to be such a person: the young guy was happy about the interesting work and did not demand much payment.

Henry Maudsley's original screw-cutting lathe

Photo: gettyimages.ru

He soon became the best worker in the workshop. Brahma appointed him as a master and entrusted him with the mechanization of the manufacture of parts of his castle. Along the way, Maudsley mastered literacy and learned to draw. Work with the lock was carried out secretly, in a separate, always locked room, which gave Maudsley additional opportunities for independent in-depth work.

Some of the machinery and equipment from Joseph Bram's secret workshop survives, including a power saw, a spring winding machine, and a drilling template. The power saw has prismatic guides, the use of which in the designs of later lathes created by Maudsley is considered one of his most important improvements. And in the design of the machine for winding springs, in addition to prismatic guides, there is a caliper, mechanized using a “screw-nut” pair, and a set of replaceable gears. In other words, the set of all those devices that formed the basis of future lathes were developed by Maudsley during the period of his work at Bram.

Years of study and work in Bram's workshop largely prepared Maudsley for his future work. Bramah carried out many of his orders with the participation of Maudsley, who learned from Joseph not only the art of a mechanical engineer, but also business acumen: he began to understand in the production of which consumer products mechanization and automation are most effective.

Bramah owed Maudsley a lot, but still did not want to increase his salary. This prompted Maudsley to leave his stingy owner.

Moreover, every factory worker had a cherished dream - to become the owner of a workshop himself. They approached this gradually, little by little they personally made blacksmithing, plumbing and measuring tools for themselves. Maudsley began doing this while still at the Woolwich Arsenal. While working for Brahm, he continued to accumulate stock. Over time, these tools became very useful to him.

Cruelly saving on the essentials, Henry saved a small amount and in 1797 rented a small workshop and an abandoned forge with it. So Maudsley left Brahm after working for him for eight years.

Henry Maudsley Lambeth plant

Photo: gettyimages.ru

When did the first CNC machine appear?

The first CNC (Numerical Control, NC) machine was invented by the son of the owner of Parsons Inc, John Parsons.

The first CNC (Numerical Control, NC) machine was invented by the son of the owner of Parsons Inc, John Parsons, who worked in the engineering department of the company owned by his father. This company specialized in the production of propellers, blades and related parts for helicopters.

Persons Jr. was the first to patent the idea of using a machine that processed materials for propellers and other parts using a program that was executed by reading the necessary information from punched cards.

Parsons and his first CNC machine

Tools

For wood processing, tools are used that are divided into three groups:

- Cutting - semicircular chisel, jamb. With their help, the top thick layer of material is removed.

- Marking and control tools - compasses, vernier calipers and calipers - measure parts.

- Accessories for the machine - a body with a fork center, a chuck and a faceplate.

Some numbers

The story was like this:

- In early 1949, the United States Air Force began funding Parsons Inc. to develop and further manufacture a machine that could contour mill complex shaped parts produced for helicopters, airplanes, and other aircraft. But, contrary to the expectations of the Air Force, Parsons Inc was forced to ask for help from the Massachusetts Institute of Technology, namely from its laboratory specializing in servomechanics.

- Parsons' company worked with MIT until the 50s of the last century. In the same year, the Massachusetts Institute bought a company producing HydroTel brand milling equipment and stopped cooperating with Parsons Inc. Immediately after the contract was terminated, the institute awarded a contract to develop the first program-driven milling machine to the United States Air Force.

- Already in September 1952, the HydroTel milling machine was shown to people at an exhibition, and a little later the whole world learned about it thanks to an article from Scientific American magazine. This was the first automatic device, which was controlled using a perforated tape.

The first machine with Numerical Program Control was different from the others in that it had a much more complex design and control, and therefore its use in industry was difficult, and sometimes even impossible.

- The very first CNC machine was designed and manufactured by Bendix Corp. in 1954, and just a year later (in 1955) these devices began to be used en masse in machine tool building and in the refurbishment of old equipment in production. Equipment with PU slowly gained its popularity in the world, since many people were quite skeptical and distrustful of this new product of technological progress. In order to prove the opposite, the United States Department of Defense manufactured 120 copies of CNC machines at its own expense. Subsequently, these machines were leased to private and government firms involved in processing various materials and producing products from them.

- After a short period of time, in 1958, the first symbolic programming language was developed, called APT (Automatically Programmed Tools).

Introduction of CNC machines into domestic production

The first CNC machines made in Russia, or more precisely, made in the USSR, for use in industry, were the 2K63PU screw-cutting automatic lathe, as well as the 1541n rotary turning machine. They were developed and began to be mass produced in the 60s of the last century.

These machines were controlled using both PRSZK systems (working together with them) and other industrial equipment control systems. A little later, CNC vertical milling machines were invented and put into production, called 6H13 and which were equipped with the Kontur-ZP system, with the help of which the machine was directly controlled.

By the end of the 70s of the last century, 2P22 and Electronics NTs-31 systems, which were also produced by domestic manufacturers, began to be installed on CNC turning equipment.

Modern CNC machines

Nowadays, PU equipment is a part without which it is impossible to imagine any production facility producing high-quality products.

The main advantage of devices with CNC systems is not only that it becomes possible to process parts and workpieces of complex shapes, but also that the entire production process becomes more and more automated every day.

Currently, companies use equipment produced in different periods of time. For this reason, numerical control systems have significant differences both in design and in the method of programming and further work with them. Basically, if they have the financial opportunity, companies try to replace outdated CNC systems with new, modern ones, so even machines of the same model, released at the same time, can differ significantly in the software and electronic parts associated with numerical control.

Who invented the first automatic machine?

PREREQUISITES FOR CREATION OF AUTOMATIC EQUIPMENT

The automatic lathe was created in the USA, where the development of metal processing technology began later than in Europe.

The first metal-cutting machines made in this country were very imperfect compared to the machines of G. Model and his students. In the first half of the 19th century. The beds of American machines were wooden, with iron guides attached to them. The lack of experienced machine tool builders and the need to use metal-cutting machines at enterprises that produce products with interchangeable parts (primarily weapons factories) led to the introduction of simple machines and devices designed specifically for performing a single specific operation.

The first most advanced machines, which in their characteristics were close to European models, were built using the experience of English machine builders. Thus, a lathe, manufactured in 1853 in New York and having good technical characteristics, was built by A. M. Freeland, who was a follower of Whitworth and used his experience [6].

The quality of American machine tools in the second half of the 19th century. was already quite high. The machines were mass-produced, and complete interchangeability of parts and units of machine tools from the same company was introduced. The moving parts were fitted not one to one, but to special templates that ensured their identity. If parts broke, it was enough to order a similar one from the factory and replace it without the slightest adjustment. To reduce manual labor (if it was impossible to eliminate it completely), the parts were pre-processed on machines. For example, on the plane for the support of lathes, they were first milled, then planed and then “scraped” to the templates.

Due to the fact that forging work was poorly mechanized and automated at that time, American machine tool builders preferred cast parts. If possible, all control knobs were placed on the apron of the machine. The inclusion of forward and reverse motion from the belt drive was ensured by simple movement of the friction clutch, which was engaged with one of the drums rotating in opposite directions. To switch the feed to the opposite direction, a conventional bit with a satellite gear was used.

Turret lathe 1850 (USA)

In the second half of the 19th century. elements were introduced that ensured complete mechanization of processing - an automatic feed unit in both coordinates, a perfect system for fastening the cutter and the part. Cutting and feed modes changed quickly and without significant effort. The lathes had elements of automation - automatic stop of the machine when a certain size was reached, a system for automatically controlling the speed of frontal turning, etc.

However, the main reason for accelerating the progress of the American machine tool industry was not the development of the traditional lathe, which in general could no longer be fundamentally improved, but the creation of its modification - the turret lathe.

The need to create such a machine was associated with the transition at the end of the first half of the 19th century. from flintlocks to percussion cap weapons. It required a large number of screws, and for their production S. Fitch, who took a contract from the government to produce 30 thousand pistols, designed and built in 1845 a turret machine with 8 cutting tools in the turret head. In 1858, G. Stone proposed another design for a turret machine. Note that this equipment made it possible to get by with a small number of experienced adjusters and use unskilled labor while maintaining high productivity.

The main advantage of turret machines was a sharp reduction in the time required to change cutting tools. Turret lathes of the 19th century. They usually had two supports - one cutting, which had only one transverse feed, and the second - a through one, which had only a longitudinal feed. A revolver cartridge was attached to the second, carrying (at that time) up to 10 tools. After one cutting operation and retraction of the cutter to its original position, the chuck had to be rotated to engage the new cutter. In general, the worker’s function includes turning the cutting chuck, feeding and securing the material and cutting tool. The movement of the longitudinal support was usually limited by stops and therefore did not require highly qualified workers. All technological operations here are simple and could easily be replaced by automated units. Consequently, the turret machine could relatively easily be turned into an automatic machine.

The headstock of an American-made turret lathe of the second half of the 19th century. is of no interest, with the exception of the spindle and chuck, which are almost always drilled (for feeding bar material). The chuck is equipped with a workpiece clamping mechanism, which can be clamped and released without stopping the machine. The operation of these mechanisms was blocked with the mechanism for automatically feeding the workpiece. In 1871, E. Parkhurst patented a collet chuck and a clamping mechanism of this kind. The prototype of this collet chuck was the Whitworth collet. Subsequently, various models of chucks with cams were used that clamped and released the bar while the machine was operating (without stopping it). The supply of material was ensured at first (since 1861) simply by a load, which was attached to the rod through a block and pushed it to the stop, fixed in the revolving chuck, at the moment the jaws opened. With a large mass of the rod, however, a strong impact occurred, which upset the machine. In order to avoid such an impact, a throttle-type brake or other device was used.

In the United States, the ratchet rack was most often used in turret lathes. For workpiece diameters larger than 2-3 inches, feeding methods using special mechanisms were used on powerful machines. The rotation of the turret at the end of the operation and the need to change the instrument was also automated (since 1861).

Consequently, on various turret and lathes it was possible to automatically, without stopping the machine, carry out the advance of the workpiece and its clamping, processing (with mechanical longitudinal and transverse feed), removal of the finished part and subsequent repetition of the cycle. However, until the 70s of the XIX century. Only some of these devices were used, i.e., individual technological operations performed on the machines were automated.

Automation trends in metal cutting equipment in the United States have been driven by a number of factors. Among them, economic factors occupied a dominant place. The ease of operation of these machines made it possible to use unskilled and cheap labor - women and teenagers who could operate several machines at the same time. It was also important that during the civil war of 1861-1865. The demand for firearms increased, and a shortage of skilled workers held back the growth of firearms production. The way out of this situation was the creation of automatic machines. The success of automation of individual elements of metalworking lathes and turrets allowed us to hope for a successful solution to this problem, especially considering that in the 40s of the 19th century. Woodworking automatic machines were designed and successfully used (K. Wipple, 1842; T. Sloan, 1846).

The first universal automatic lathe was invented by Chr. Spencer in 1873. It was structurally simple, its main feature was the cam shaft. X. Spencer is the author of several more advanced types of automata.

The invention and serial production of automatic lathes of various types meant that the machine tool industry had reached a high level of development and that one could expect the release of automatic machines of other technological types of metal-cutting equipment. Thus, the machine tool industry entered a new stage of its development - the stage of improving automatic metal-cutting machines.

Technological progress. History of metalworking machines.

Today it is impossible to imagine life without metalworking machines. Be it a car or an ordinary screw, all this would be impossible to create without machines. No one knows for sure who first created metalworking machines. It is known that the first mention of metal-cutting lathes was somewhere in the first half of the 18th century, but since there were no mass orders for products yet, these machines did not become widespread. The history of the development of metalworking machines can be divided into several stages:

The first screw-cutting lathe in the world. The beginning of the era of metal-cutting machines.

In 1718, the Russian scientist and mechanic Andrei Konstantinovich Nartov was sent by Peter I to European countries to study turning. After analyzing and studying metal processing methods, Nartov decides to improve the machines used in his workshop and creates the world's first screw-cutting lathe in the world, which had a mechanized support and a set of replaceable gears. However, the fate of this invention (like many Russian inventions) was very sad. It was forgotten after the death of the scientist and was reinvented by Henry Maudsley in 1800.

A little later, inventor Eli Whitney created the world's first milling machine, thanks to which he was able to fulfill an order from the US government to produce 15,000 guns in record time (2 years).

Thanks to these inventions, it became possible to create more complex mechanisms, steam engines (including the first steam locomotives).

The advent of mass production.

Thanks to steam engines, by the mid-19th century, groups of lathes and milling machines were powered by steam power, ushering in large-scale production.

At first, industry satisfied only military needs (firearms, artillery, steam engines for warships, etc.). However, by the end of the 19th century and the beginning of the 20th century, the automotive industry was actively developing and electrification was being carried out everywhere. In order to make the car mass-produced and affordable, all parts and components began to be produced on production lines with metal-working machines, which at one time allowed Henry Ford to produce 15 million Ford T cars.

After the First World War, a new round of development began in the manufacturing industry. Enterprises are beginning to massively use turret machines.

In such machines it is possible to produce parts with a pre-configured tool, which saves time on changing tools. Which provided the prerequisite for the creation of the first computer numerical control (CNC) machines.

The era of production automation. CNC machines.

In the 50s of the 20th century, the productivity of universal machines hit a practical ceiling. Humanity is faced with the question of production automation. In addition, such complex units as a jet engine began to appear, and aircraft construction, which uses parts of complex aerodynamic shapes, is actively developing. To address these challenges, a CNC milling machine made by Bendix Corp. is making its first appearance in the United States.

The introduction of these machines did not go smoothly. Entrepreneurs were distrustful of the new technology. All executing programs were started from punched tapes.

The first CNC machines were incompatible with each other and transferring a program from one machine to another was very problematic. To solve this problem, the Electronic Industries Alliance developed the universal programming language G-code in the early 1960s. After 1965, due to the rapid wear of obsolete tools, new materials for cutting tools were developed, which increased their service life.

In the USSR, CNC machines became widespread in the 1980s with the development of the Electronics NTs-31 (for lathes) and 2P22 (for milling machines) control units.

In the 1990s, due to the rapid development of electronics and the mass introduction of replaceable multifaceted cutting inserts, machine tools received new development. A modern machine does not have a gearbox. Everything is controlled electronically.

Since the 18th century, humanity has made a huge technological leap. Now many people underestimate blue-collar jobs and consider them unprestigious. But do not forget that thanks to the work of specialist machine operators, you enjoy all modern benefits, be it a personal car, public transport, or a washing machine.

That's all, dear readers. Subscribe to my channel or give it a thumbs up.

History test Industrial Revolution 8th grade

History test Industrial Revolution: achievements and problems for 8th grade students with answers. The test includes 2 options, each option has 7 tasks.

1 option

1. Which of the following is characteristic of the final stage of the industrial revolution?

1) the transition from manual labor to machine labor 2) the transition from manufacture to factory 3) the creation of industrial equipment using machine tools 4) the excess of income from agriculture over income from industry

2. Automatic loom invented

1) G. Models 2) T. Makaley 3) J.M. Jacquard 4) J. Stephenson

3. A sign of the completion of the agrarian revolution in England in the first half of the 19th century. is

1) predominance of farms 2) predominance of traditional farming methods 3) development of fair trade 4) subsistence nature of farms

4. The rotary furnace - convector - for smelting steel was invented in 1856.

1) Emile and Pierre Martin 2) Henry Bessemer 3) George Stephenson 4) Henry Model

5. The railroad boom was not

1) development of subsistence farming 2) development of international trade 3) expansion of economic ties 4) invention of the steam engine

6. Select two names that are redundant in the list of car manufacturer names. Write down the numbers under which they are indicated.

1) Ernst Siemens 2) Oliver Evans 3) Richard Trevithick 4) Etienne Montgolfier 5) Karl Benz 6) Gottlieb Daimler

7. Who is being talked about in the above passage?

“He was a professional artist, but became carried away by the achievements of the industrial revolution and left painting. The telegraph he invented made it possible to build the world's first telegraph line and establish telephone communication between Washington and Baltimore in 1844. His first message transmitted over this line consisted of the words: “What a miracle the Lord has performed!”

The history of the creation of the first machine in the world

The history of the appearance and development of the lathe dates back to 650 BC. e. This is documented by an engraving found by archaeologists. It depicts people in tunics watching master Fyodor work on a foot-operated lathe. The part was fixed between 2 centers and driven by a lever.

The workpiece in such a machine rotated alternately several revolutions towards the tool, then back, away from it. The cutter was held in the hands. The cutting force was weak and the accuracy was low. On such a machine they could process:

Historians have found jewelry made using similar equipment.

First mentions

The first images of lathes were found in ancient Egypt. The beam drive mechanism is clearly visible on the frescoes. The string was wrapped around a part clamped in the center at one end and pulled onto the bow. The slave moved the device back and forth, rotating the wooden piece in one direction or the other. The master sits on the floor and guides the tool.

Main details

Turning technology has been developing for a long time, acquiring new skills and increasing the level of skill. Thanks to this, today all wooden products are distinguished by a smooth surface, conciseness and completeness. And their appearance will not leave anyone indifferent.

All samples of wood turning work are divided into several parts:

- torus;

- cube;

- parallelepiped;

- cone;

- ball;

- pyramid.

Almost all of these figures can be obtained by turning. Before placing a piece of wood on a lathe, the bark is first removed from it and the cracks are cleaned out. In order for the processing to be carried out correctly, the prepared solid piece is securely fixed to the device with special devices. After all the work has been completed, the craftsmen do expressive painting on the products according to ancient traditions (its magnificence can be judged by the famous Khokhloma and Russian nesting dolls).

What features did early models have?

Early models had a common drive for all. Rotation was transmitted through belt drives. The number of revolutions of the workpiece could not be set accurately. The longitudinal and transverse movement of the caliper depended on the number of shaft revolutions and was regulated by rearranging the gears in the feed box. The spindle rotation speed was set by throwing the belt onto a pulley of the required diameter.

The accuracy of the transverse and longitudinal feed of the tool was 0.1 mm - the error of manual movement along the dial. It was not possible to automate the machining process on early models and produce large batches of parts with high accuracy of fit.

The lathe has a long history. It reflects the technical level of development of peoples, their desire to simplify the manufacture of parts and create beautiful things of the correct shape.