Fan device and design

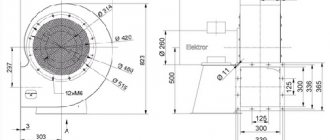

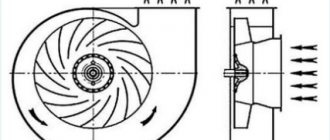

Radial fan operation diagram

Sometimes an impeller and a power unit are not enough to move air. In conditions of limited space, a special type of exhaust equipment design should be used. It has a spiral-shaped body that acts as an air channel. You can make it yourself or purchase a ready-made model.

To form the flow, the design includes a radial impeller. It connects to the power unit. The wheel blades have a curved shape and create a discharged area when moving. Air (or gas) enters it from the inlet pipe. When moving along the spiral body, the speed at the outlet increases.

Depending on the application, the centrifugal fan volute can be general purpose, heat-resistant or corrosion-resistant. It is also necessary to take into account the amount of air flow created:

- low pressure. Area of application: production workshops, household appliances. The air temperature should not exceed +80°C. Mandatory absence of aggressive environments;

- average pressure value. It is part of exhaust equipment for removing or transporting small fraction materials, sawdust, grain;

- high pressure. Forms an air flow into the fuel combustion zone. Installed in many types of boilers.

The direction of movement of the blades is determined by the design, and, in particular, by the location of the outlet pipe. If it is located on the left side, the rotor should rotate clockwise. The number of blades and their curvature are also taken into account.

For powerful models, you need to make a reliable base with your own hands to secure the body. The industrial installation will vibrate strongly, which may lead to its gradual destruction.

Types of impeller

The fan performance will directly depend on the shape, size and material of the impeller. It is also necessary to take into account the number and shape of the blades responsible for pumping pressure inside the cochlea. The main requirements for the material of the impeller and blades are corrosion resistance and ductility. Such a working body will withstand the chemical influences of an aggressive environment and increased vibration loads.

When choosing the shape and number of blades, aerodynamic loads and rotation speed are taken into account. When using powerful engines, the metal blades must be bent at right angles, which allows the formation of a stable air flow. But for low-power fans, it is preferable to use large straight blades, which make it possible to provide high pressure in large-sized volutes.

A well-made wheel should not vibrate during operation, as this can lead to rapid failure of the unit. Fan vibration increases the noise level, destroys the installation base and negatively affects the overall durability of the equipment. Oscillatory movements can be minimized by carefully balancing the shaft or using special shock-absorbing springs. They are mounted under the base of the housing, allowing them to dampen longitudinal and transverse parasitic vibrations of the unit.

Features of the snail hood

The memorable shape and distinctive operating principle make this type of ventilation stand out from similar ones. The most popular snail will be for rooms with a minimum area and free space. The design of the fan in the form of a spiral serves as an air duct in any warehouse or industrial premises.

There are different configurations available for your choice, but if you wish, it is quite possible to build a cleaning system with your own hands. How to install a snail and why is it better than other cleaning systems? The answers to these questions lie in the structural features of the device.

Calculation of paint booth ventilation

An important stage in arranging ventilation in a paint booth is its calculation. It is clear that such a harmful room, due to its technological purpose, must have multiple air exchanges. Its calculation is carried out according to the formula:

P= (t₁-t₂)хVх0.36, cubic m/h,

where t₁-t₂ is the difference in temperature outside and inside the paint booth,

V – room volume, cubic meters,

For example, let’s take a room with the following dimensions: length – 6.5 m, width – 5.0 m, height – 3.5 m. Since cars are mainly painted in the warm season, the largest temperature difference is about 13° C. Substituting all the values into the formula, we get:

The calculated indicator indicates how much air should be pumped into the box in 1 hour. It is clear that for this example, it is necessary to equip the chamber with supply and exhaust ventilation with mechanical drive. In addition, for such a fairly large room, the installation of an additional hood in the form of a grated floor is required.

Snail design

A standard volute (umbrella) consists of an impeller and a power unit. Your fan, depending on its assigned functions, may have protective properties against corrosion or be characterized by increased heat resistance.

The structure of the snail is selected directly for the room in which an additional cleaning system should be installed. When choosing a device, it is recommended to take into account the strength of the air flow, namely:

- low pressure flows;

- average pressure;

- high pressure flows.

When choosing a “Snail” fan, you should take into account the strength of the air flow

Professionals warn that the more powerful the ventilation unit, the more effort should be put into installing it. A homemade box or base will facilitate quick connection and correct operation of the entire device for a long time.

Description of equipment

Centrifugal fans are characterized by excellent efficiency, which is achieved due to the rapid rotation of a radial wheel with numerous blades. The working element is located in a spiral chamber, which ensures the highest possible air injection efficiency. The blades on the wheel are made curved, straight or in the shape of a bird's wing. Accordingly, the size of the equipment, its performance and purpose vary.

Depending on the air flow pressure indicators, it is customary to distinguish three classes of centrifugal fans:

- low pressure;

- medium power;

- heavy duty installations.

The pressure indicator can vary in the range of 0.1-12 kPa. The performance of the equipment will depend on the profile and number of blades, as well as on the electric motor used, which is responsible for rotating the working element. On sale you can find both fully mechanical devices and installations that are controlled automatically and have expanded functionality.

All snail coolers used today can work both to blow in and remove air from the room. To change the direction of rotation of the impeller, the phases of the current at the motor terminals are swapped. This is done using the corresponding switch toggle switch on the device control unit. Some models of ventilation equipment have the ability to change the rotation speed, which allows you to adjust the performance of the blowers.

Homemade snail

Before starting to create a homemade system, craftsmen recommend deciding on the functional purpose of the future device. A centrifugal fan, that is, an umbrella made from simple available materials, is suitable for partial cleaning of premises or complex equipment.

In cases where a do-it-yourself snail fan is intended for boilers, the body of the device must be made of heat-resistant steel sheets. A home-made centrifugal fan is made from old parts of a vacuum cleaner or cleaning system of a residential building. Fans such as a snail or an umbrella will serve well in small workshops, but for large-scale enterprises such devices will be of little use.

The entire process of creation and subsequent connection of the fan takes no more than two days, taking into account fast and high-quality work at all stages. First, calculate all the parameters of the future device, including the outer box and insulation. It would be a good idea to consider the option of additional gaskets that reduce the vibration effect from the operation of the snail device.

Homemade “Snail” fan is made from improvised materials

Next, the centrifugal fan is assembled from scrap materials or parts of an old device. Metal sheets or plastic are suitable for such purposes. Installation of the power unit requires special attention, so at this stage time is devoted to choosing a shaft or drive. The installed cooler will ensure timely cooling of the unit, extending the life of the entire device.

The centrifugal fan is mounted in the outer casing and mounted on a fixed base.

You can use a simple circuit to make and then connect a homemade device called an umbrella, supplement it and equip it with all the necessary elements for working in a given room. The main thing is to comply with all fire safety standards and use the snail for its intended purpose.

Air exchange calculation

Air exchange is calculated using the formula:

Where T is the difference in air temperature between that in the box and that supplied from the environment, Q is the volume of the box, and 0.36 is the air exchange coefficient.

In a large garage, air exchange should occur in proportion to the increase in the volume of the paint booth. This is important in cases where painting work needs to be done on bulky items, such as pickup trucks or even trucks.

An example of calculating the required air exchange

Let's say there is a rectangular paint box, 5x4 m. The ceiling height is 3 m. Painting is carried out in the autumn and the difference between the incoming and exhaust air is 10 degrees.

According to the formula, the following data is obtained: P = 5*4*3*10*0.36 = 216 cubic meters/hour.

If you want to assemble a spray booth with your own hands, it is better to make calculations based on the maximum and minimum air exchange parameters. Therefore, it is important to obtain the difference between inlet and outlet air for your climate zone. Because the average can reach -30 degrees in winter, and +50 in summer. Depending on how warm the room is, you can get a delta of 30-40. The adjusted calculation will require the performance of your ventilation system - 5*4*3*40*0.36 = 816 m3/hour. As you can see, the difference between autumn and winter operation can be more than 4 times.

In such conditions, the spray booth operator will not experience any discomfort and the spray mist can be eliminated effectively.

Centrifugal fan: equipment design

Ventilation systems equipped with this equipment have high potential even in difficult climatic conditions. A centrifugal fan is a structure consisting of several components:

- spiral body;

- impeller;

- impeller blades;

- electric motor.

All parts of the structure are connected by spot welding, rivets and bolts, which ensures reliability. The centrifugal fan often has a powder-coated stainless steel housing, which minimizes the possibility of corrosion. Indicators such as efficiency and vibration level depend on the direction of blade bending.

How can you simplify everything?

To reduce the cost of purchasing expensive equipment, using the box occasionally, you can increase the efficiency of even the simplest ventilation system. For this purpose, operation is provided in active and passive modes. Active mode is used to prepare the camera for operation, clean dust, and pump in fresh air. The second point is the removal of paint mist after processing the part and active ventilation for the operator. Passive mode is used during operation. Thus, you will not encounter large heat losses, and you will be able to quickly clean the room of toxic material residues, without large financial investments.

Centrifugal fan: operating principle of the design

The popularity of this equipment largely depends on efficiency and economic feasibility. The centrifugal fan is designed in such a way as to maximize these indicators.

The air, falling on the blades, is deflected at an angle of 90 0. Then it passes through the spiral casing of the centrifugal fan and only then enters the room. Thus, the most efficient circulation of air flows in the room is achieved.

You can buy a fan in our online store. Our catalog contains a large selection of different models: axial centrifugal air fan, centrifugal exhaust air fan, etc. Here you can easily choose a suitable centrifugal fan, the characteristics, price and quality of which will meet your requirements. We give our clients the opportunity to buy a centrifugal fan at a profit - the cost of the equipment will pleasantly surprise you.

How a paint booth works

To understand how important ventilation is in a car paint shop, you need to consider the operating principle of such a workshop. Considering the dyeing technology, the boxes in which it is produced are clean, closed rooms with a certain microclimate. One of the main criteria for high-quality painting is maintaining the specified temperature and humidity conditions.

The painting and drying processes require different room temperatures. Before starting the painting process, the car is placed in a box and the exhaust ventilation is turned on for maximum dust removal. Then, the inflow is turned on and coloring begins. At this time, air of a certain temperature and purified of all impurities enters the chamber from above, through air ducts, and “envelops” the car through special lattice openings.

Exhaust filters remove the resulting paint mist, saturated with solvents, paint, and varnish, through the filtration system into the atmosphere. In the floor, under the car, there are filter grids that also partially absorb falling heavy particles of coloring materials.

Upon completion of painting, the chamber is purged (about 5-7 minutes) - completely cleared of paint mist. The inflow is switched to a higher temperature, and the exhaust equipment is switched to recirculation mode. The microclimate required by the technology of painting with appropriate paints is created. The ventilation system in the painting booth operating in certain modes maintains the room temperature during this process at least 85°C.

Important! In order to avoid the formation of drafts, “vortices”, “dead zones”, and the extraction of air from adjacent rooms, it is necessary to correctly calculate the power of the system. Incorrect ventilation operation leads to poor quality results.

Types of centrifugal radial fans

There is no fundamental difference in design between radial fans. They are divided into several types according to purpose and power.

By power

The working pressure that the volute hood is capable of depends on the engine power of the device, the number and configuration of the impeller blades.

There are 3 types of radial fans according to this parameter:

- Relatively low pressure devices (up to 100 kg/cm²). These are small fans used to create forced ventilation in residential buildings, labeled as BP 80-75. In apartment buildings, such devices are mounted on the roof, in a common ventilation duct.

- Devices that operate in the medium pressure range from 100 to 300 kg/cm². They are used in ventilation systems of production workshops without special safety requirements. The general marking of hoods of this group is BP 300-45.

- Powerful (working pressure in the range from 300 to 1200 kg/cm²) snail hoods are installed in hazardous industries where there is a need for intensive removal of caustic, flammable and explosive gas mixtures. The general marking of this class is VR 12-26.

Which fan should be chosen for a given ventilation system is influenced by many parameters: the length of the channels, their branching, throughput, and the required air exchange rate per unit time. Such calculations are carried out by specialists at the design stage of the ventilation system.

Note! Centrifugal fans are installed not only for exhaust, but also for air supply, for example, in boiler rooms.

By purpose

The second classification system for radial fans divides them according to their purpose:

- General purpose snail hoods. They are operated at temperatures up to +80 degrees in an atmosphere where there are no specific or dangerous contaminants. Installed in residential or industrial sectors.

- Explosion-proof - the body and parts of the mechanism are made of materials that prevent the occurrence of sparks during operation. Used in rooms where there are explosive gas mixtures. The permissible operating temperature range is from -30 to +40 degrees.

- Fire-resistant or heat-resistant hoods are installed in industries that use increased temperature in the technological process. The devices are made of carbon steel and coated with heat-resistant compounds. Operate at temperatures up to +200 Celsius.

- With enhanced anti-corrosion protection. These are fans that are installed in chemical plants with aggressive environments.

- Dust (marked VRP) – fans for removing air masses with suspended particles. The devices have a larger gap between the housing and the impeller and a reduced number of blades so that the device does not become clogged with waste during operation. Design features here lead to a drop in the efficiency of the device. It is necessary to choose a hood with a reserve of operating power.

- For smoke removal (marking VRDU). These fans are installed to remove smoke if a fire occurs. The devices operate in the temperature range of 400-600 degrees.

Housing material

The purpose and power indicators of the device will largely depend on the material from which the cooler is made. The industrial volute for ventilation is made of steel and other heavy-duty alloys, taking into account the degree of aggressiveness of the environment of use. Fan models designed for operation with non-aggressive gas mixtures and oxygen can be made of carbon and galvanized steel.

When the device is used to move aggressive gas mixtures and acids, it is necessary to choose chemically resistant steels, which ensures reliable and trouble-free operation of the equipment.

Standard modifications of exhaust fans are designed for use with air masses and gases whose temperature does not exceed 90 °C. On sale you can find highly specialized models used to work with gases with temperatures up to 200 °C. Such units are made of special heat-resistant steel, which is resistant to acids.

There is also an explosion-proof version of the hood, made of aluminum, copper alloys and other ductile metals. These snails use a special electrical wire that eliminates sparking, which is the main cause of explosions and fires.

If it is necessary to use centrifugal fans in conditions of high humidity, modifications protected from corrosion processes are used. The volute body is made of special galvanized steel, and the presence of rubberized gaskets prevents the penetration of moisture into the protected housing where the electric motor and control automation are located.

If the technological process involves active dust formation and the presence of sawdust and other mechanical mixtures in the air, then it is not possible to use standard modifications of radial fans. It is necessary to choose special dust-proof installations that do not have an additional front disk on the impeller, and the number of blades on the shaft reaches 6-8 pieces.

Another feature of this type of equipment is the presence of a large gap between the suction port and the impeller. This design allows you to cope with dust without reducing the efficiency of the equipment.

General information about centrifugal (radial) fans

Coil fans have a dual designation (marking): VR and VC, that is, radial and centrifugal. The first indicates that the blades of the working part of the equipment are located radially relative to their rotor. The second is the designation of the physical principle of operation of the device, that is, the process of intake and movement of air masses occurs due to centrifugal force.

It is centrifugal fans in ventilation systems that have shown themselves on the positive side due to the high efficiency of air removal.

Operating principle

As already mentioned, fans of this modification operate based on the action of centrifugal force.

- The blades attached to the rotor of the device rotate at high speed, creating turbulence inside the housing.

- The inlet pressure drops, which causes the suction of nearby air, which rushes inward.

- Under the action of the blades, it is thrown to the periphery of the space, where high pressure is created.

- Under its action, the air flow rushes to the outlet pipe.

This is how all centrifugal models work, which are installed not only in ventilation systems, but also in smoke removal systems. About the latter, it must be said that their body is made of aluminum alloy or steel, coated with heat-resistant materials, and is equipped with an explosion-proof electric motor.

Design Features

As already mentioned, the main design feature is the snail. It is also necessary to indicate the shape of the blades. Fans of this brand use three types:

- with straight slope,

- with a backward tilt

- in the form of a wing.

The first position is small fans with high power and performance. That is, they can create conditions in which other models require a large body. At the same time, they operate with low noise levels. The second position is an economical option that consumes 20% less electricity than other positions. Such fans can easily withstand loads.

As for the design that relates to the electric motor, there are also three positions:

- the rotor is fixed directly to the motor shaft through a coupling and bearings;

- through a belt drive using pulleys;

- The impeller is mounted on the electric motor shaft.

And one more feature is the connection points between the fan and the air ducts of the ventilation system. The inlet pipe has a rectangular hole shape, the outlet is round.

Restrictions on use

It is advisable to install radial fans to move large volumes of gas-air masses, provided that they do not contain:

- explosives;

- fibrous materials and sticky suspensions in an amount of more than 10 mg/m3;

- explosive dust.

An important operating condition is the ambient temperature: it should not go beyond -40 0C to +45 0C. In addition, the composition of the passing gas-air masses should not contain corrosive agents that contribute to the accelerated destruction of the fan flow part.

Of course, for use in some industries, fans are produced with a high degree of corrosion resistance, protection against sparks and temperature changes with casings and internal components made of high-strength alloys.

How does a snail hood work?

The device operates from the mains. Sizes range from household (main body diameter 25 cm) to industrial (diameter 150 cm).

The fan “rakes” air with small blades that rotate at high speed. The air flow is directed into the housing, makes a turn and is removed into the outlet hole. Passing through the curls, the flow loses speed and creates pressure.

Note! If the fan inlet is hermetically connected to a closed channel, then the volute hood will work like a vacuum pump.

Ventilation functions in car painting booths

Supply ventilation of a paint booth for cars requires particularly careful selection. Before the air from the street, drawn in by the supply fan, enters the spray booth, it passes through three filter elements.

- The first, coarse cleaning, is located immediately behind the fan, ridding the air masses of dust and heavy particles.

- The second (after-treatment) is located behind the heating equipment.

- The third (fine cleaning) – finally cleans the air and is located directly in front of the air duct of the spray booth.

Important! The location of the filters should be such that they are easy to maintain - replace if dirty. Filter elements “clogged” with dust affect the speed of air movement, and, accordingly, the quality of car painting.

The presence of heating equipment allows you to regulate the temperature of the air flow from 30 to 85°C and above. Ventilation ducts placed on the ceiling have holes through which air enters the paint booth at a certain speed.

Self-production

radial fan for boiler

First of all, you should decide on the functional purpose of the centrifugal fan. If it is necessary for ventilation of a certain part of the room or equipment, the housing can be made from scrap materials. To complete the boiler, you will need to use heat-resistant steel or make it from stainless steel sheets yourself.

First, the power is calculated and the set of components is determined. The best option would be to dismantle the snail from old equipment - a hood or vacuum cleaner. The advantage of this manufacturing method is the exact match between the power of the power unit and the body parameters. A snail fan can be easily made with your own hands only for some applied purposes in a small home workshop. In other cases, it is recommended to purchase a ready-made industrial-type model or take an old one from a car.

Procedure to make a centrifugal fan with your own hands.

- Calculation of overall dimensions. If the device will be installed in a confined space, special damper pads are provided to compensate for vibration.

- Manufacturing of the body. If there is no ready-made structure, you can use plastic sheets, steel or plywood. In the latter case, special attention is paid to sealing the joints.

- Installation diagram of the power unit. It rotates the blades, so you need to choose the type of drive. For small structures, a shaft is used to connect the motor gearbox to the rotor. In powerful installations, a belt type drive is used.

- Fastening elements. If the fan is installed on the outer casing of, for example, a boiler, mounting U-shaped plates are made. With significant power, it will be necessary to make a reliable and massive base.

This is a general scheme according to which you can make an exhaust functional centrifugal unit with your own hands. It may change depending on the availability of components. It is important to comply with the requirements for sealing the housing, as well as to ensure reliable protection of the power unit from possible clogging with dust and debris.

The fan will make a lot of noise during operation. Reducing this will be problematic, since vibration of the housing during the movement of air flows is almost impossible to compensate with your own hands. This is especially true for models made of metal and plastic. Wood can partially reduce background noise, but at the same time it has a short service life.

In the video you can see the process of manufacturing a case from PVC sheets:

How to make it yourself

One of the features of such snails is their different price range. The minimum price for a snail hood will be about 3 thousand, but such devices, as a rule, are not very powerful and are very limited in size. The average price of a high-quality unit will exceed 20 thousand rubles.

Therefore, for domestic needs, it is more advisable to make a homemade snail for extractor hood. The standard design of such a housing will consist of two parts: the engine will be located in one zone, and the blowing blades in the other .

The casing for the snail can be purchased at hardware stores. If you are going to make it yourself, purchase the motor and other parts in advance, since the dimensions will have to be adjusted. It is better to make the case from metals (for example, aluminum and steel). Plastic will be less resistant to mechanical damage, and wood will quickly catch fire in the event of a malfunction.

The fan in such a system will operate at high speed. Therefore, incorrect design of the hood can have bad consequences. Check the quality and reliability of not only the base itself and fastening mechanisms, but also the motor, impeller and fan.

The fan dimensions are selected taking into account the area and degree of contamination of the room. Industrial designs are large.

Important! When installing the motor inside the box of such a hood, make sure that the design includes cooling holes. High temperature stress on the system can lead to an explosion.

Pay special attention to the choice of internal materials. Fan operation can be affected not only by temperature, but also by the power of air flow, the amount of debris and dust.

When air with large impurities is sucked in, the blades of the rotating wheel may be damaged. And in order to thoroughly clean the air, the unit must operate at high speed and under high pressure - this creates additional stress on the entire internal structure. Therefore, it is better to choose parts made of durable materials, such as steel or aluminum .

Compliance with the following recommendations will allow you to create a high-quality and safe hood with a long service life:

- choose the right size and power of the motor : take into account the maximum load on the structure, as well as the required operating speed of the hood;

- When mounting such a system vertically, carefully check the reliability of the fan and wheel fastening : with rapid air flows, they can jump off or change their location;

- materials adjacent to such a hood must be fireproof , as are all parts used in its assembly;

- observe the proportions between the individual hood zones : in the standard models offered in stores, the optimal ratio of the length and width of the structure is taken into account;

- If you are not sure that the assembled hood is safe, contact specialists who will check its serviceability .

Please note that hoods are rarely used in living rooms . Firstly, they take up a lot of space, and secondly, in rooms like a kitchen, the flow of polluted air can have different directions, so it is best to install such a hood in a ventilation shaft, where all the air coming from the apartment is concentrated.

The design of such structures will also play an important role in living rooms, but it is not diverse and does not always harmonize with the interior.

Tip: When placing such a hood in an open environment (outdoors), make sure that weather conditions will not affect its functionality.

Ventilation hoods can be used not only for air purification . In domestic conditions, they will do an excellent job of heating the room, and will also affect the humidity in the room .

The cost of equipment intended for domestic and industrial needs will differ significantly, but, in any case, such units have sufficient power for full operation.

For an example of designing a snail hood, see the attached video.

Types of ventilation systems

Based on the number of fans in the ventilation system, there are:

- Single-motor ventilation - when fresh air comes from ceiling ducts, and under pressure all pollutants settle on the floor, where, due to natural circulation, they are removed outside the room through ducts in the floor.

- Dual-motor ventilation - two motors are used. Above the object, and built into the floor channel.

In all cases, the installation of filter elements is provided, however, under heavy loads and when the filters are dirty, the dual-motor system proves to be more efficient.

Due to the fact that ventilation calculations are made for a fairly large volume of air, it is worth paying close attention to the supply ventilation.

Professional systems provide heating. With air exchange up to 1000 cubic meters per hour, the temperature in the box begins to play an important role. Some people use recuperators, but at such productivity and low temperatures it will simply stop working. What is the way out? Reduce ventilation performance to an acceptable minimum and organize safe air heating. For high-quality surface treatment, a certain temperature regime is required. Gentle drying while heating will allow freshly painted items to dry evenly.

Electric motors used

The industrial snail hood is equipped with explosion-proof electric motors, durable housings and covers. Most often, asynchronous mechanisms with a fixed rotation speed are used as a drive. This unit quickly reaches maximum performance and is reliable and durable. The disadvantages of asynchronous electric motors include the inability to adjust the speed of rotation of the working shaft, which somewhat limits the possibilities of using such equipment.

The presence of dimming in the electric motor and an automatic control unit allows you to regulate the rotation speed, significantly expanding the functionality of the use of volute fans. The disadvantage of using such motors with variable speed control is their high cost, as well as reduced reliability of units in which the electronics that control the operation of the drive often fail.

Sources

- https://StanokGid.ru/osnastka/ventilyator-ulitka-svoimi-rukami.html

- https://vozduhstroy.ru/vytyazhka/ventilyator-ulitka-svoimi-rukami.html

- https://www.RoomKlimat.ru/section/5/64-tsentrobezhnye-ventilyatory/

- https://TopVentilyaciya.ru/ventilyaciya/vytyazhka-ulitka.html

- https://AeroClima.ru/dymoudalenie/ventilyator-ulitka/

- https://ru-remont.com/kvartira/kuhnya/tehnika/krupnaya/vytyazhka/vidy/ulitka.html

- https://spk-kovka.ru/stanki/ventilyacionnye-ulitki.html

[collapse]