Reading time: 4 minutes

Alloy wheels are not only a stylish accessory for a car, but also significantly affect the ease of driving it. This is because they are made of lightweight material, which promotes rapid acceleration and braking of the car. But sooner or later the time comes when an alloy wheel becomes deformable. This happens when you fall into a hole at high speed or have a minor accident. And in such a situation, the car enthusiast asks the question: buy a new one or repair the damaged one?

As a result of deformation of the rim, not only its appearance, but also its geometry can be disrupted. And this is very serious, since with such a problem both the car and the person can suffer. A stamped disc is easier to repair, since the steel from which it is made is very malleable. Rolling a damaged rim on a special machine is not difficult. But with cast it is more complicated - ordinary rolling will not work here. For this procedure, only editing is used.

Alloy wheels

Editing car disks

For such a procedure, a special hydraulic press is used, which is available in car services. If the damage is not severe, then the disc will not need to be heated. And if they are significant, then you will need to preheat the deformed area, and then straighten it.

These recommendations are explained by the fact that when heated to high temperatures, the structure of the metal is damaged. It is not recommended to use such a disk, since with significant restoration it will not last long. Hitting a large pothole at speed can completely break it. And besides, such a rim is unsafe for further use.

The editing technology is as follows:

- The technician visually assesses the damage to the rim.

- For small dents, it is straightened without heating using a hydraulic press.

- When significant, heat, then adjust.

- The autodisk is fixed on the steppe and a hydraulic press is connected to it.

- The geometry is restored under the necessary force.

Microcracks may not appear immediately after deformation; they may become noticeable only after straightening. They are also fixed by welding.

Steel wheels can be easily straightened

Straightening is nothing more than the action of restoring the rim to its original shape. The process consists of eliminating all kinds of irregularities and deformations of the steel wheel that occur during everyday driving. For this purpose, special machines are used, which, due to the elasticity of the alloys, eliminate unwanted changes in shape.

It seems that everything is simple, but it is not. Depending on the alloy rim used for production and how it is made, the straightening procedure and heating temperature vary. Therefore, rim straightening should be done by someone who is experienced and knows what they are doing. Otherwise, you may do more harm than good.

Steel discs can be easily straightened - a broken disc is bent

The basket of straightening services usually does not exceed 900 rubles for one steel rim, but it all depends on both its size and the degree of damage.

Is it possible to edit car rims?

If we are talking about stamped models, then they can be corrected and restored, but only if the rim has not been severely damaged. But it is not recommended to repair cast ones, especially if they are severely deformed or cracked. Therefore, in some auto repair shops, masters ask the client to sign a consent to their repair.

This means that the person, knowing about all the possible consequences, still deliberately hands over the car disc for restoration. This procedure is not cheap, especially when it comes to cast models. If, despite all the warnings, the rim still needs to be straightened, then you should choose only specialized workshops with good equipment.

Rolling: return to former forms

During use, the car wheel may become deformed. Potholes on the roads, roadsides, curbs, emergency situations in which the car gets into, lead to the fact that the once round stamped or cast disk is damaged and, from being ideal, becomes bent in one or several places.

Cast drive

Since die-cast models are expensive, car owners prefer to repair them, if it is possible to correct defects, rather than purchase new ones, especially since finding one disc from a set can be problematic.

Returning a deformed cast disk to its initially correct geometric shape is called rolling. In essence, this is restoration work, which is performed by a specialist using equipment designed for this purpose.

It is unsafe to drive on wheels with a deformed disc, especially if the defect is severe, so it is not recommended to delay the restoration.

Do-it-yourself editing of alloy wheels

Minor damage can be repaired yourself. You can remove:

- chips;

- scratches;

- minor integrity violations;

Then a thorough inspection is carried out. If cracks are found on the surface, it will have to be boiled. To do this, you will need to take it to a car repair shop or process it yourself if you have argon-arc welding. But a welding machine is not the only thing you need; you will also need the ability to work with it and an understanding of the entire process of welding a disk. Otherwise, you should not do it yourself.

If there are no cracks, then restoration can continue. Using sandpaper, you need to level the surface and remove all resulting dust from it. Then you will need to apply a two-component epoxy paste. After it has dried, you need to sand the surface again with fine-grain sandpaper. Next, the car disc should be coated with a primer in several layers, each drying for about 20 minutes. Professionals recommend letting the primer dry for at least 24 hours. This way it will dry completely and the disc will be ready for further restoration. And the next stage is painting it and opening it with varnish.

Restoring steel wheels

If your rims aren't looking their best, might it be better to do a full regeneration with sandblasting and painting? Then they will return to their ideal appearance, which will benefit the entire car.

Sandblasting of steel wheels is carried out in an automatic sandblasting machine. Has a speed regulator that prevents damage to the coating. After this treatment, the rim must also be additionally protected with anti-corrosion liquid.

Steel discs can be easily straightened by rolling the disc on a machine

Then it's time for sanding to remove any scratches or dents, followed by powder coating. There are many colors to choose from, so you can really stand out.

Painting steel wheels starts with a powder coating and then electrostatic powder paint is applied. The part is then sent to an oven where the paint is cured at 180°C. If the chosen color requires it, the rim can also be coated with a clear varnish.

It is worth noting, however, that painting and sandblasting a steel rim costs from 1,700 to 2,700 rubles, which, combined with the cost of straightening, may not be profitable.

What is straightening alloy wheels and how is it done?

If you decide to straighten alloy wheels, you should definitely contact only good specialists

who know exactly how to do their job correctly. Often, motorists remain dissatisfied with straightening alloy wheels and subsequently complain about this procedure only because they encountered an unqualified specialist who could not cope with his task.

How to straighten alloy wheels:

- First of all, specialists carry out the necessary diagnostics

. Do not forget that each case is individual, and workers must understand in detail the problem that your car is facing. Also, if you are present during the inspection of your car, please note that the wheels must be “stripped”, that is, the tires must be removed from them, otherwise it is unlikely that it will be possible to find out the cause of the problem. - Next, specialists determine the nature of the damage

and begin to draw conclusions about how they will work with it. - Alloy wheels are often difficult to repair

, so they are more expensive to repair. However, do not forget to pay attention to the equipment that the employees of the repair shop or center have. It is alloy wheels that require special care and handling. - Before starting repair work, specialists thoroughly wash the discs

and then begin work.

Please note that straightening alloy wheels is not a cheap service, especially if the repair center or salon uses special equipment (and this equipment is necessary for a good repair).

Rolling out stamped and steel wheels

The following modifications can be rolled out at a tire shop:

Rolling is the same as rolling, that is, restoring its correct geometric shape. Rolling out a steel or stamped version can be done independently, when you need to straighten one disc, or simultaneously with repairing the car's chassis.

It is possible to restore the geometry offset:

For example, they repair damaged sides or “cure” “curb disease.”

Geometry measurement

Rolling out stamped options is as follows:

- The surface is cleaned.

- The rolling machine is adjustable for a specific model.

- The element is installed in the machine.

- The rollers of the machine roll the entire rim or the area that is subject to restoration.

To roll out a steel model, special equipment is not enough. The result of the work depends on the experience and skill of the worker. The master straightening the steel element must control the straightening process so that during operation of the equipment the rim does not bend or problems arise that could lead to complete damage.

What's good about straightening alloy wheels?

Of course, before you understand whether your car needs this or that procedure, you first need to determine all the pros and cons of this process. Of course, you can not edit alloy wheels, but simply buy a new disk (or disks) and make a replacement. However, this will cost much more, so it’s better to see what good and useful repairs to your car’s wheels will give you.

Positive aspects of straightening alloy wheels:

- This procedure will be cheaper than buying a new alloy wheel

(which are the most expensive). Car owners often have to spend money on their car, so it won’t hurt anyone to save money sometimes. - Of course, damage to alloy wheels varies

. There are also problems that make it pointless to go to a repair shop or salon. But if, for example, your wheel simply no longer looks beautiful and attractive due to driving on not very high-quality roads, then the wheel can simply be painted. And, what is very convenient, this can be done at home! Why buy a new drive when you can fix the old one right in your garage? - If your disc is damaged a little more, then you can contact a repair shop or center for the next procedure - rolling

. Rolling plays one very important role and provides one very important service - it rids the wheel of excess unnecessary weights and gives it a round shape. What does it mean? This means that your car's movement will now become smoother and more balanced. This way, you will ride more comfortably and feel safer. - Sometimes car owners who don't know much about cars start to panic and exaggerate the problems their car is facing, so they rashly decide that they absolutely need to understand their alloy wheel. But if you go to a repair shop or auto detailing center, you may find that your problem isn't as big

as you think. Diagnostics is undoubtedly an important thing. - Your wheels will be washed

. What's not a plus? Car owners often don’t have enough time to finally get their wheels in order after a long drive on dirty roads.

The process of rolling and painting alloy wheels

Rolling cast wheels differs from rolling steel and other models in that cast modifications cannot be heated (even spot-on). During heating, destruction of the crystal lattice of the material may occur. As a result, the material completely changes its structure and cannot cope with the loads that the car puts on it. The consequences can be different: the geometry will change again during operation, and there is also a risk of losing the wheel while driving due to a broken spoke or other part of the structure.

Special attachments, which are used during the straightening process on special professional machines, ensure that the material is not disturbed or put out of working condition.

A pressing question arises: is it possible to roll a cast disc? Since heating cast models is prohibited, severe flaws can be corrected manually by tapping the bent sections of the rim before rolling on the equipment. But not every master can do such work, since it is labor-intensive. And such a service will cost the client a pretty penny.

How does the process of rolling a cast wheel take place:

- The surface is cleaned of dirt and dust.

- Examined for the presence of cracks.

- It is established what kind of damage led to the deformation: axial or radial runout.

- If an element has a crack at the base of the spokes or landing grooves, then this option cannot be restored.

- The sample to be restored is installed on special equipment and, with the help of special rollers, rotates and undergoes straightening.

Painting

A restored wheel can be painted if the center offering such a service has good professional equipment. Restoration of the paintwork is carried out after eliminating defects, on a disk completely cleared of old paint. After painting, according to the standards, the element must be placed on the equipment to check for imbalance and, if any, correct it.

Disadvantages of straightening alloy wheels

If you come across reviews from motorists who have already adjusted alloy wheels, then most likely you will be surprised how many people speak extremely negatively about this procedure. However, there are objective disadvantages that are definitely worth paying attention to.

Why you can’t straighten alloy wheels:

- It is not safe

. Indeed, no one can give you a guarantee that the disk will serve you for a long time and will work absolutely as it should. Also, no one guarantees you that problems cannot arise with the disk that will lead to an accident right on the road. - The discs still take their original form

. Of course, you can be happy that your alloy wheel has finally been patched up and now looks decent (almost exactly the same as before). However, no matter what they do with your discs in the salon, after some time they will still take their original shape (the shape in which you brought your disc to a repair shop or car service center). - In the end, you will spend a lot more

. Of course, the procedure itself will cost you less than buying a new alloy wheel (and they are very expensive), but the repair will most likely not last long, and the wheel will bring new problems to the car owner. Then you will have to either go to a repair shop or service again, or buy a new wheel. - After heating, the cast disk will be much more susceptible to various kinds of dangers

. Any bump or hole, any collision with various kinds of obstacles can lead to a wheel split. Who knows what consequences this may have? - The threat of getting to a bad master

. If you end up with a bad mechanic who doesn’t have the slightest idea how to properly handle alloy wheels, then you may end up in some kind of trouble on the road in the future.

Expansion of steel rims

... of course, you need to take into account additional costs, and this is not so small. Depending on the size of the rim, the price for a set can be up to 12,000 rubles.

Widening steel wheels for tuning?

Why are the disks expanded? Well, it's a matter of taste. Some say the extension looks better on sports cars or classic cars. They also have the advantage of being able to fit wider tires, which improve traction and make the car better on the road. Others who see such discs have mixed feelings.

Steel wheel flaring starts at 1 inch wide and then at intervals of every 0.5 inch. The next step is to finish the edge so that it looks good after welding. You should also remember to straighten first and then expand.

Is it worth adjusting alloy wheels?

Of course, the final decision will still be yours, but it’s still worth looking at all the positive and negative sides of this procedure.

However, it is best to try to take care of your safety and try not to resort to straightening alloy wheels, as this may actually lead to some kind of danger. Of course, buying a new wheel is expensive, but your life is more valuable.

Many car enthusiasts in Russia are well familiar with such a service as straightening alloy wheels. Everyone knows the condition of our roads, so even an experienced driver can “catch” a hole or bump while driving. Because of this, even a cast disc can lose its original shape.

For example, after severe damage, the metal part of the wheel is deformed from a circle to a figure eight. In this case, any adequate driver sends the product for restoration to a service center or buys a new kit.

In this article we will talk about the most popular types of rims, consider their advantages and disadvantages. We will also briefly describe how damage is repaired at a service station.

Is it even possible to roll alloy wheels?

At some service stations, to increase the ductility of the aluminum alloy, the surface of the car disk at the rolling site is heated. Plasticity naturally increases, but at the same time the probability of disruption of the structure of the material increases when a certain temperature limit is exceeded, which can lead to a loss of strength. What conclusion can be drawn from all of the above? Probably, everything depends on the skill of a specialist who can correctly assess the degree of damage and apply rolling in doses with or without heating. The main thing is the desire of the car owner to risk making repairs in a way that is not the most optimal for correcting damage to light alloy cast wheels.

More details about this technology: ...

Varieties

Manufacturers produce several main versions of disk products, which are usually divided according to material and manufacturing method:

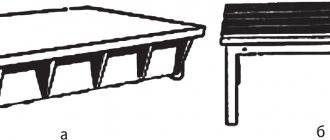

- Stamped steel is the simplest option. Such wheels are made of steel using stamping technology. Advantage in price and maintainability. For example, when hitting a hole, the steel rim does not split, but bends. Such dents can be easily rolled on a special machine. The main disadvantages of stampings are their heavy weight and unpresentable appearance. Increased weight leads to increased fuel consumption, reduces vehicle controllability, and excessively loads the chassis components. In addition, the car owner has to regularly paint the stamping with an anti-corrosion compound and use plastic caps.

- Cast - the most popular option on the market. Aluminum or magnesium alloys are used to make light-alloy rims. Molten metal is poured under pressure into a special mold. Once the product has cooled, it is removed for machining on machines. To increase strength, manufacturers roll the billet while it is still hot. This technology is called “flow forming”. The advantages of a light alloy rim are low weight and high strength. This allows you to reduce fuel consumption and reduce the load on the suspension. In addition, casting technology allows us to produce products of different designs for any car. However, such wheels are very difficult to repair. Often, after damage, microcracks appear on the rim, which lead to subsequent splitting even with minor impacts.

- Forged - the most durable and lightest option. The rim is made from aluminum alloys. The manufacturing technology is essentially stamping a solid workpiece followed by machining. Advantages: strength, low weight. As a rule, when struck, the rim does not split, but bends. You can straighten almost any damage, just like stamping. Disadvantages: high cost, limited design.

Next, we will consider whether it is possible to straighten a cast wheel and how damage is corrected in a car repair shop.

How to align alloy wheels

An alloy rim is much stronger than stamping, so restoring the original wheel geometry is a rather labor-intensive procedure. If the damage is small, then rolling the wheel rims can be done “cold”. In case of significant deformation - for example, the rim is bent in a figure eight, the damaged areas are leveled only after pre-heating.

If cracks appear after a strong impact, argon-arc welding is used to restore the integrity of the rim. With its help, the tear points are welded. Microcracks can also be corrected using welding.