Even in conditions of widespread Bulgarians and other types of metal-cutting hand tools traditional hacksaws for metal have not sunk into oblivion. Sometimes it is much easier, faster and safer to cut metal manually, using an ordinary saw blade.

The main difference between saws for metal and wood is the height of the teeth. In hacksaws for cutting metal, the teeth have a height of 1-1.5 (mm). For cutting wood, higher teeth are used, from 2 to 5-7 (mm) and even more.

A hacksaw is a saw designed for cutting metal workpieces. This tool consists of a frame and a saw blade. Unlike the vast majority of saws for wood, in saws for metal the blade is rigidly attached. The only exceptions are hand saws for metal with one-sided fastening.

Of course, today the position of hacksaws for metal has been greatly replaced by grinders and band saws . When performing voluminous work, that is, cutting a large number of workpieces, it makes sense to use the same grinder. When you need to make only 1-3 cuts, then very often craftsmen give preference to a hand hacksaw for metal .

Let's talk about the types of hacksaws for metal.

Characteristics and purpose

The main purpose of a hacksaw is to cut various materials. The main one is metal, but since there are many small teeth on the blade, it can be used to separate:

- plastic;

- ceramics;

- polyvinyl chloride;

- Styrofoam;

- particle boards;

- laminate;

- plexiglass;

- tree.

When choosing a hand tool, you need to pay attention to the blade. Blades are manufactured according to the requirements of GOST R 53411-2009. This document describes the standards by which hacksaw blades are divided into three groups, differing in size:

- Double. The distance between the holes for fastening into clamps is 300 mm (permissible error 2 mm). Blade length - 315 mm. The height of the teeth is 20 mm. Thickness - 0.8 mm.

- Single. The distance between the mounting holes is 300 mm. The permissible error is 2 mm. Total length - 315 mm.

- Single shortened. The distance between the mounting holes is 250 mm. Total length - 265 mm.

The height of single panels is 12.5 mm, thickness is 0.63 mm.

Plexiglas in packaging (Photo: Instagram / rezka_stekla_soln)

Design

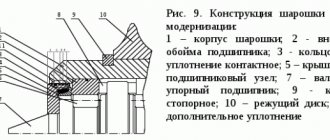

The hacksaw consists of several parts:

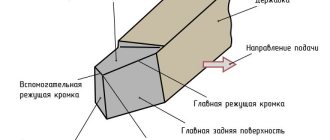

- Blades for hacksaws for metal. This is a removable item. It is used to cut workpieces made of different materials. It is a metal strip on which wedge-shaped teeth are located.

- Machine or frame. It is an arc that is made of different metals and alloys. The frame is needed to secure the canvas. It can be standard cast or sliding.

- Handles. It can be located in different places.

Modern hand tools can be equipped with additional mechanisms to increase comfort during work and expand functionality.

Hacksaw blades (Photo: Instagram / enerteh.by)

Design features of a hacksaw for metal

Widespread use is largely determined by the design of a hacksaw for metal. It is represented by a C-shape, between the two edges of which there is a special canvas. When considering what the tool consists of, we note the following:

- Lever. Today, the handle of a hacksaw for metal is in most cases made of two different components, which ensure a long service life. The shape should be quite convenient, and the element itself should be placed at the top of the structure or on the side. The upper location is used in most cases when it is necessary to process hard-to-reach areas.

- Frame. It is designed to bear the load, as well as dampen vibration during operation. Today, various materials are used in the manufacture of such tool elements. In order to process hard-to-reach places, the design often has an element through which the tilt of the blade is adjusted. The frame is made solid or sliding; the second version allows installation of products with different lengths.

- The canvas is represented by a tape made of hard alloys. This element is considered the thinnest and most fragile; it is represented by a combination of small teeth located relative to each other at a certain distance and angle. When carrying out work, you should be careful, as even minor mistakes can lead to damage. When choosing, attention is paid to the fact that the surface must be hardened, since otherwise the required level of wear resistance cannot be ensured. To increase productivity, a blade with a rare tooth is selected, to increase the quality of the cut with a frequent one. Recently, bimetallic fabric has become widespread.

The design features of a hacksaw for metal determine the very wide distribution of the tool. The main part determines the duration of use and other aspects; the cutting speed and quality of the cut depend on the installed blade.

Types of hacksaws

Varieties:

- Household. Standard hand tools for occasional household tasks. The handle is made of wood, and an adjustment screw is installed on the front of the frame.

- Hand saws. A compact tool designed for sawing metal in hard-to-reach places. Suitable for securing broken saw blades.

- Professional models. Their main difference is the high quality of materials from which the main parts of the structure are made.

You also need to pay attention to the division of hacksaws by drive type. They are electric and manual. Electric ones are divided into battery and network. The former allow you to work without connecting to the mains, which makes them more versatile, but the batteries gradually discharge and require charging, which reduces the time you use the power tool. Battery models are equipped with special systems to suppress vibrations.

Household hacksaw (Photo: Instagram / ploskogubtsy.ru)

Types of instruments

Currently, there are three types of tools for metal carving:

Homemade. The most popular and inexpensive option, which is well suited for simple household work (cutting seams, grooves) and is distinguished by a high level of convenience during use. Quite often, such tools are supplemented with wooden handles, which are placed longitudinally to the blade.

Professional hacksaws. They are used to carry out long-term work and obtain precise cuts; thanks to them, it is possible to cut metal into non-standard sizes. Supplemented with a comfortable rubberized handle.

Hacksaw-handle. Characterized by a special shape in the form of a bracket, it is used for processing hard-to-reach areas. Well suited for internal cuts.

If you wish, you can see the photos of the presented variants of hacksaws for metal.

Types of hacksaw blades

The hacksaw blade is considered the main part of the hand tool. The performance of the tool and the cutting accuracy depend on its type.

Metal cloth

It has a large number of small teeth. Large teeth will not cut metal.

Blade length - 150–300 mm. The canvas can be made from different materials:

- carbon steel;

- cobalt steel;

- carbon and high-speed steel.

Tungsten filament

Strings are made from tungsten carbide. Their length is 30 cm. They are suitable for fastening within standard hacksaws. String diameter - 2.7 mm. With its help you can make precise cuts. The string is suitable for straight and curved cuts, cutting out circles.

Diamond string

The basis of such a string is alloy steel, onto which diamond coating is applied. Coating thickness - 2 mm. The string is secured in the clamps using rings.

A high-quality diamond wire should quickly cut through various materials. When working, its surfaces and working area must be moistened with water to avoid overheating.

It is better to choose an arc with a handle and attach a diamond string to it. Such a hacksaw is cheaper than a professional hand tool, but it can be used to cut metal, concrete, stone, ceramics, etc.

Diamond string (Photo: Instagram / abraziv_ykt)

Types and areas of use of the tool

The purpose of this tool is to cut products from durable metals, cut grooves and seams, trim metal blanks, etc. Among other things, using a hacksaw you can cut metal alloys, and, for example, ceramics, plastic, foam, wood and organics.

There are three types of metal saws:

- Models for home use are the most affordable and popular option, suitable for solving simple household problems. Characterized by ease of use. In most cases, such devices are equipped with screws and a wooden handle, which is located longitudinally to the cutting blade.

- Professional-grade hacksaws can work for a very long time, creating high-quality cuts. Professional hand saws for metal are often equipped with a comfortable and durable handle and allow you to set the blades at a certain angle, which is required to create cuts of unusual shapes.

- “Handle” - has a special shape that resembles a staple. This allows you to use this type of hacksaw in hard-to-reach places. This tool is perfect for internal cuts.

Selection principles

When purchasing a hacksaw for metal, you need to consider a number of criteria. It is important to study the strengths and weaknesses of the instrument and understand the manufacturers.

Criteria

Criterias of choice:

- The material from which the handle is made. Comfort when working with a hacksaw will depend on this. It is better to choose handles with rubber pads.

- The shape of the teeth, their size. They should not be large in order to cut metal without problems.

- Canvas size. Depends on the length of the workpieces being cut.

It is better to put aside a tool with a hollow handle, since it will break if pressed hard.

Mini hacksaw for metal (Photo: Instagram / wedotools)

Advantages

Positive sides:

- simplicity of design and maintenance;

- light weight;

- performing work in any conditions;

- reliability, durability;

- possibility of sharpening;

- application for sawing various materials;

- ease of use.

Manufacturers and prices

Manufacturers:

- "Enkor"

- Stanley;

- STAYER;

- GROSS;

- Top Tools.

The average price is 500 rubles.

Assortment of hacksaws (Photo: Instagram / stroi_it)

Tool selection criteria

In order to choose a reliable and easy-to-use tool, you need to know the criteria that will help you make the right choice:

- for manual models:

- The hacksaw frame must be made of solid metal, because tubular structures are not able to withstand long-term loads;

- the size of the frame must correspond to the size of the saw blades used;

- the handles must have a special coating that prevents slipping during operation;

- the ability to saw at an angle other than the vertical plane expands the functionality of the tool, but negatively affects its cost.

During use, the hacksaw should fit comfortably in the user's hand.

- for reciprocating saws:

- the technical characteristics of the reciprocating saw must allow processing metal of the required size and at the required speed;

- the reliability of electric models is guaranteed by the manufacturer’s brand, so you shouldn’t chase cheap products offered by little-known companies;

- The type of tool (corded or cordless) determines the nature of its use.

Thanks to the variety of models, both manual and electric, you can always choose the right one in accordance with the nature of use and other selection criteria.

Operating principles

To make cutting metal with a hacksaw more effective, when working with hand tools you must adhere to some rules:

- You need to hold the tool with both hands so that the blade does not bend. It is better to secure the workpieces in a vice.

- The ease of use of the tool can be increased by changing the cutting angle.

- The pressure must be increased when moving forward, and decreased when moving backward.

- It is important to practice in advance in securing the canvas in the clamps. It is important that it does not move when sawing.

Before you start working with a hacksaw, you need to check the sharpness and integrity of the teeth, their location relative to each other. If there are irregularities, the teeth move in different directions, the blade needs to be replaced.

Cutting a metal pipe (Photo: Instagram / ekb_tools)

Manufacturing

Any person without practical skills can make a homemade metal hacksaw. It is important to study in advance the structure of hand tools and how to connect the main parts.

A handle with an arc can be made from large-diameter wire, fittings, metal strips, profiled or plastic pipes. All that remains is to think about fastening the canvas.

A hacksaw is a hand-held tool for sawing workpieces made of different materials. To create high-quality cuts, you need to learn how to choose blades. We must not forget about the rules for choosing a frame with a handle. It is important that the tool is comfortable to work with and that the blades are securely held in the clamps.