Serebryanka is a paint with a metallic color or, simply put, aluminum powder, which is produced by finely grinding aluminum. Grinding is used in two different categories - PAP-1 and PAP-2.

Silver can be used for painting any surfaces outdoors, in conditions of elevated air temperatures (painting stoves, radiators), etc. Therefore, it is excellent for protecting surfaces from the effects of negative environmental factors. It also perfectly protects surfaces from corrosion and lays flat, but for this you need to dilute it correctly.

In what form is it produced?

Silverstone can be found on sale in the following forms:

- A powder that must be mixed with a suitable paint and varnish composition before use.

- Ready-made mixtures that need to be stirred before use and, if necessary, diluted with a suitable solvent to the required painting consistency.

Ready-made dyes can be sold:

Areas of use

Despite its versatility, silver is most often used to create protection against corrosion. It is often used for painting:

- various metal structures for industrial purposes (power lines, pipelines);

- automotive industry products: both for tuning a car and for giving its individual parts additional strength;

- galvanized or metal roofs;

- hangars and other utility rooms made of metal (not only the roof, but also the walls are painted to protect against overheating during the hot season);

- structures in constant contact with fresh or sea water.

In addition, much less often, silver dye is used to protect and decorate buildings made of concrete, stone or wood; it is possible to use silver dye based on acrylic enamel for painting plastic products.

A little theory

Initially, you need to understand the composition of silver paint in order to have at least the slightest idea of what you will have to work with.

Here are a few points to help you figure it out:

- It is a mistake to think that it consists of silver - it is not there in any form. It is present only in the name, but then the question is - why is the paint called that? Of course, because of the color it has, which, in turn, is obtained by finely grinding pure aluminum and its waste (mostly from waste, since solid aluminum is expensive to use).

- Before the preparation of silver paint begins, it is a powder (aluminum powder), which is diluted with special means.

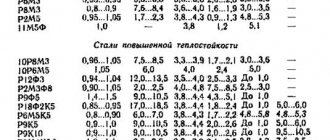

It is divided into two categories:

This is what the paint looks like in its original form before it was stripped

- PAP-1 is the first category, the powder particles are much larger.

- PAP-2 – second category, smaller fractions.

Note! The size of these very particles does not in any way affect the quality of the diluted paint. Categories are important for separating the industries in which silver is used.

- The pristine powder can be not just paint, but also have heat-resistant properties. Here, the material that serves as the basis for cooking plays an important role.

Important! Very often, unscrupulous manufacturers mix various “additives” into the paint, which deprive it of its original properties, so our advice is to make silver with your own hands. This makes the price lower and the quality higher, if, of course, it is prepared in the correct proportions.

We do it ourselves

The following will describe detailed instructions on how to make silver paint at home:

- After you buy the necessary materials, prepare dishes (containers) that you won’t mind throwing away, since it will be impossible to wash off the paint.

- Pour the powder into a container and pour in varnish or drying oil (this is the answer to the question - how to dilute silver for painting).

- The ratio should be 2 to 5.

- The varnish is poured gradually, with frequent stirring.

For your information! Builders prepare the mixture using a mixer, but at home you can use an ordinary oblong object, unless you have to stir vigorously for 10-15 minutes.

If the composition is too thick, you should add white spirit to it, but be careful, if you make the paint too thick, it will be unevenly distributed on the surface.

Important! Before preparing silver paint, protect your face and skin of your hands - glasses and rubber gloves are required when working with the solution.

Application of silverfish

Serebryanka has become widespread both in the domestic and industrial spheres. It is used in everyday life to a greater extent, for decorative finishing of products. It is used to apply it to the fences of houses to make them look more attractive. Interior items made of wood or metal are coated with such a paint and varnish substance to make them look more organic. Even swimming pools are covered with this paint.

On an industrial scale, the use of this paint is due to the need to protect equipment and other objects from corrosion.

As you know, this paint and varnish substance covers metal products with a dense film, which performs a protective function.

Read also: History and traditions of Port wine

Silver paint is often used to cover moats and various fences. It significantly increases the resistance of objects to environmental conditions, which are not always favorable.

Painting with silver is a fairly simple process. After all, it has a fairly dense structure and practically leaves no streaks or streaks. It lays down in an even and neat layer.

First, the paint must be thoroughly mixed. After this, you can begin preparing the surface for painting. If it is metal, you should first thoroughly clean it of roughness and rust, if any. If necessary, a primer must be applied to create a smooth material. Only after it has dried should you start painting.

If the surface is wooden, you must first level it with sandpaper to sand off all the unevenness. After this, apply paint.

The paint must be applied using a roller, brush or special sprayer. In any case, you can do this in one layer or in several. In each individual case, the number of layers is determined individually and depends on the condition of the surface.

Read also: Medical features of healthy nails

Pros and cons of silver

People have been using silver paint for more than a century, and during this time no one has had time to get tired of the paint. On the contrary, it is used more and more often for various needs. What is the secret of such popularity? It's all about the huge number of advantages it has:

- Silver does not flake and is quite durable and at the same time thin material. But at the same time, if you need to, you can easily get rid of the paint.

- The paint turns into a protective layer for the surfaces it is applied to. It creates a thin but even, smooth layer, fully displaying the surface texture.

- It is used on various materials - from wood to concrete and metal.

- Long service life, so the paint does not deteriorate in water for 3 years, nominally about 7 years, but in reality even longer.

- Not afraid of high temperatures.

- Invulnerable to corrosion.

- Non-toxic.

- Dries quickly.

- Painted in a pleasant silver color.

- With its help, you can achieve different shades of metal using pigments.

Of course, in addition to its advantages, this paint has its disadvantages, the main one of which is the risk of explosion. Therefore, such powder should be stored in a dry place and in a tightly sealed container, away from possible sources of fire and direct sunlight. You should not keep the paint near food, as the silverfish smell will quickly be absorbed.

It is also worth noting that the paint is incompatible with oil and alkyd paints. In addition, silver should not be applied on top of NBC and nitro-enamel paints, since in combination with such a coating the paint will not last long on the surface, will quickly come off and, possibly, swell with bubbles.

Types and form of release

On sale you can find two types of silverware, which differ in the production method and properties:

- Heat resistant paint. Finished products obtained by mixing bitumen varnish and aluminum powder. The coloring composition is resistant to high temperatures. The layer maintains its integrity when heated to 400°C.

- Classic silver. It is suitable for application to wooden and concrete surfaces. Does not withstand high temperatures. Not suitable for application to the surfaces of radiators and heating pipes.

Heat-resistant silver paint for metal is used for various purposes:

- painting batteries;

- painting metal pipes;

- protecting metal from overheating and moisture.

It is often used for painting metal household products. On sale you can find both ready-made formulations and powder in packages that need to be diluted.

Batteries painted silver (Photo: Instagram / kirti__store)

Composition and properties

Despite the name, this paint does not contain silver. It is made from aluminum powder. The resulting metal dust is diluted with a thickener.

Properties of silver for painting metal:

- After application, a durable metal film is formed on the painted surface. It protects the material from the destructive effects of moisture and chemicals.

- Protects against exposure to ultraviolet rays. Painted surfaces do not heat up in the sun.

- The surfaces are leveled, the texture becomes pleasant to the touch.

You can buy the dye at any construction market. Additionally, you will need varnish or drying oil.

Release containers

Serebryanka is sold in different types, which makes it possible to purchase what is necessary in each specific case:

- Powdery. Before painting, it must be mixed with the dye or varnish used.

- Ready-made mixtures that can only be used after shaking them well (if they are too viscous, you can dilute them using a solvent).

As for ready-made coloring agents, they are sold:

- In buckets (sometimes these are jars).

- In aerosols. The compositions in cans are very convenient both to use and to store. Their shelf life, if all rules are followed, is much longer than their counterparts in other consistencies. When spray painting surfaces, you also do not need any tools, which greatly simplifies the process. The paint is applied in a thinner and even layer, which, among other things, increases its service life. If necessary, you can purchase water-based acrylic or alkyd paint compositions in cans.

Note: aluminum dyes in powder form or formulations in cans are more popular among consumers. They are presented in a wide range of colors, which helps you choose the most suitable shade without coloring yourself.

How to paint

Painting with silver paint, no matter using an aerosol method or using a painting tool, is carried out in exactly the same way as for most dyes:

- Surfaces are cleaned of remnants of old decor and degreased.

- A primer is applied to the cleaned base (one layer is enough for silver).

- After the primer has dried, paint is applied in several layers.

Easy to use and durable silver will protect structures from the aggressive influence of external factors, and its durability will allow you to significantly save on repairs, because subsequent repair and restoration work will not be required soon.

Source

Advantages and disadvantages

- Easy to apply. The silver paint is applied in a perfectly even layer, and no smudges form even when painting vertical surfaces;

- Versatility of use. As a rule, metal structures are painted with silver to protect against corrosion, but it can be used to paint almost any surface, for example, wood or concrete;

- Strength. A thin film forms on the treated surface, which does not peel off over time;

- Harmlessness. Aluminum powder does not emit toxic substances, so painting with silver is absolutely safe. Silverfish can only acquire properties harmful to human health if it is diluted with toxic enamel. If non-toxic paints and varnishes are used to prepare the composition, then it is quite possible to paint the internal walls of residential buildings;

- Aesthetic aspect. After the paint dries, the surface on which it is applied acquires a pleasant silver color, but if necessary, you can add color of any desired shade. This is easy to do, since a wide range of different colors are sold on the finishing materials market;

- Long service life. Painted surfaces do not require renewal for a period of 6-7 years, however, if the paint is applied to an object that is in constant contact with water, the service life will be up to three years, without loss of the original appearance or the appearance of cracks.

It is worth noting that, like any paint and varnish material, in addition to the advantages listed above, aluminum paint also has a number of disadvantages.

- First of all, this paint and varnish material should not be applied over other types of paintwork materials. Before painting with silver paint, it is imperative to clean the surface from any remnants of old paint. If you neglect this recommendation, the applied layer may crack, swell and not last even half of the period stated by the manufacturer.

- The second significant drawback is the increased risk of fire and even explosion of silverware in undiluted form. This factor must be taken into account when storing and preparing aluminum powder, therefore it is necessary to observe all precautions and safety measures when working with the material.

Wash

During operation, paint may get on surrounding objects. To prevent this, you need to cover the surrounding surfaces with plastic film.

If paint gets on the floor or walls, it can be washed off in several ways:

- Place a few drops of sunflower oil on the painted area. Wait 10–15 minutes. Wipe the surface with any dry cloth.

- Buy nail polish remover without acetone. Apply it to the stain with a brush. Wait 5 minutes. The paint will become wet and cracks will appear. Wipe off the stain with a rag. Wash off any remaining nail polish remover with plenty of water.

When working with silverfish, you need to wear a work uniform, gloves, safety glasses, and a respirator. They will protect the respiratory tract, eyes and body from metal dust.

Silver paint has not lost popularity for several decades. This is due to its unique properties and low price. In order for the painted surface to maintain high strength and an attractive appearance, you need to take into account some nuances when preparing and applying the coloring composition.

Metallic paint technology

Painting is carried out in a room with good ventilation. It is not recommended to begin applying aluminum paint without preparing the surface.

- Using sandpaper or a metal brush, rust and peeling old paint are removed from the metal. The wooden surface is also sanded. The coating of lime and chalk is removed from concrete and brick.

- The surface is primed to enhance the tenacity of silver, although it is already at a high level. It is enough to apply the primer once. This stage is a recommendation for concrete and brick. A primer is required if the old layer of paint cannot be removed from the surface. In addition, the number of paint layers is reduced.

- Poorly removed old paint can cause the silver to peel off.

- Apply a thin layer of paint 2-3 times to pre-dried walls. It is better to work with a roller or spray gun. If you work with a brush, then the actions must be quick. The paint hardens very quickly and the coating layer may not be even. Each subsequent layer is applied to the dried previous one. The time interval between application of layers is short.

Serebryanka dries completely in 4 hours, the setting speed is even faster. If there are defects in the work, then you need to have time to correct them before drying.

Watch the video to better reinforce the material:

Advice: to increase the service life of the protective and decorative layer of silver, it is recommended to cover it on top with the varnish that was used in the process of making the dye.

Random drops of silver are removed with a solvent. Damp drops can be easily removed by applying vegetable oil to them and wiping them off shortly. Nail polish remover is used for the same purposes.

Preparing the surface for silver coating

The surface should be cleaned of grease stains, rust and dust. Serebryanka rejects most paints, especially oil and nitro enamels. Therefore, all remnants of the old coating must be removed.

Silver paint for wheels

Apply paint only to a well-dried surface. You can use a brush and a spray gun. Standard drying time is 16 hours. The second layer is applied after 6 – 8 hours.

If you need to renew the silver coating, you don’t have to remove the old paint. It is enough to wash and degrease the surface well. Over time, after 15–20 years, the layering will begin to swell. Then the old coating is removed with a wire brush, the residue is removed with acetone and painting begins again.

Areas of use

Serebryanka is a universal paint, the composition of which can be applied to almost any type of substrate. But at the same time, it is most often used to paint planes made of metal or iron due to its anti-corrosion properties.

Mostly paint is used:

- For application to surfaces and structures in the industrial sector (e.g. pipelines).

- For painting cars or its individual elements.

- Serebryanka is suitable for application on galvanized and metal roofs.

- It can also be used to cover walls and metal bases in hangars, garages or other outbuildings (prevents overheating of surfaces in the summer).

- Suitable for use on foundations and structures that are operated in conditions of high humidity or are often in contact with water.

- Much less frequently, but still, surfaces made of concrete, stone and wood are coated with silver dye. It can also be used to paint plastic structures.

Cooking at home

In order to prepare silverware at home, you must first decide which surface to paint.

Options:

- metal heating surfaces are painted;

- paint equipment or objects at normal temperatures;

Heat-resistant enamel

To prepare heat-resistant silver, use PAP-1 powder and add BT-577 varnish or other recommended thermal varnish. You can use ready-made paint BT-177. You need to decide what you will use to paint the surface: brush, roller, spray gun. For brushes and rollers, a thicker consistency is required so that there are no smudges and the paint is evenly distributed.

It is better to do a few test strokes to decide if the thickness is sufficient. If necessary, make the composition less often by adding a solvent.

If you use a spray gun, you make thinner paint. Solvents are added to the finished BT-177: solvent, turpentine, white spirit in equal parts. For 1 portion of paint add 1 portion of solvent.

Subsequence:

- Wear protective equipment (clothing, respirator, goggles, gloves).

- Prepare a container for dilution and ingredients in the required proportions (powder and varnish).

- Powder and varnish are added in parts. Knead well until a homogeneous composition is obtained (the paint should have an oily consistency).

- Dilute the paint with solvent to the desired thickness. It is recommended to use a construction mixer for better mixing.

On video: making heat-resistant paint.

Serebryanka on drying oil

How to make silver for non-thermal surfaces? The composition is prepared in the same way as for thermal paint, but the only difference is that varnish or synthetic drying oil is used to dilute aluminum powder.

Preparation and breeding

If silver metal paint was purchased in powder form, it must be prepared before application. Varnish or drying oil is suitable for diluting the dye. When choosing the second option, you need to buy only synthetic fluid.

After purchasing a liquid for diluting silverfish, you need to learn how to properly mix the dye components. Features of paint thinning PAP-1:

- Prepare varnish BT-577. Mix it with silver powder in a ratio of 5 to 2.

- When mixing components, use a mixer set to low speed.

The resulting composition can be applied to radiators and heating pipes. It can withstand heat up to 400°C.

Features of paint dilution based on PAP-2:

- Any varnish is suitable for mixing this type of silver powder.

- Mixing proportions: 3-4 parts varnish, 1 part silver.

- When making a coloring composition, you need to constantly stir the solution.

The resulting paint will be very thick. Before applying it to a metal surface, you need to wait 10-15 minutes.

To apply the finished coloring composition you can use:

- synthetic brushes;

- spray;

- roller

Attention should also be paid to preparing metal surfaces before applying paint. To do this, you need to perform several steps:

- Clean the surface with a metal brush.

- Sweep away the dust with a broom or sponge.

- Remove rust using special chemical compounds.

Preparing the Paint

Secrets of applying silver paint

There is nothing complicated about applying silver. In order to begin this process, you must first thoroughly clean the working surface from the previous layer of paint, metal, lime, etc. The metal surface should be cleaned of rust and scale. If you can’t remove layers of old paint, the surface can be primed.

If you are going to coat wooden materials with silver, you should first sand them thoroughly. For painting, you can use any tools that are more convenient for you to work with - a sprayer, a brush, a roller. Silver should be applied to the surface in two, or better yet, three layers. When choosing a brush as a tool for painting, you should remember that you need to be very dexterous and nimble, because if you hesitate even a little, the paint may have time to dry. As a result, everything will be painted unevenly.

Painting silver metal or wood surfaces

Ideally, painting should be done on a perfectly clean surface. However, if this is not possible, then you need to remember that silver cannot be applied to all paintwork. For example, it is not used with nitro enamel, oil paints or NBCH enamel.

If the surface was previously treated with a primer, then fewer layers of silver will be required. Each new layer is applied only after the previous one has completely dried. With this type of paint, the wait is less because it dries faster. For the same reason, paint must also be applied quickly.

Is it possible to make a silver coin with your own hands?

You can often be faced with the question of making your own dye at home. The answer is yes, it is quite possible.

To do this, you will need to take into account the following information:

- Powder grinding (PAP – 1 or PAP – 2). All information about the dilution method and proportions should be indicated on the container with the dye and experimentation in this case is not recommended. Because this will directly affect the final result.

- Staining technique. You also need to consider what tool the paint will be applied to the surface with (roller, brush, aerosol). If an aerosol is used, the solution must be made more liquid by mixing silver with water-based compounds. After drying, such surfaces not only look aesthetically pleasing, they are harmless, dry quickly, and also have a high level of strength.

- Silver should not be used if it is necessary to dilute nitro-enamel or oil-based dyes. They do not interact well with aluminum surfaces.

If a uniform consistency is required, then the mixing algorithm will be as follows:

- The required amount of powder is poured into a separate container.

- Next, you need to add paint to it and mix everything well until a thick consistency is formed.

- Afterwards, you need to gradually add paint to the existing mixture, stirring the solution.

Note: upon completion of mixing, you need to inspect the consistency and, if it is too thick, dilute it using a solvent. It must be remembered that if a spray can is used for painting, the mixture should be liquid, and vice versa - thicker if used with a roller or brush.

How to prepare yourself

When planning to make silver paint yourself, you should pay attention to the following:

- Grinding character (PAP-1 or PAP-2). The ratios for dilution with paints and varnishes are always indicated on the packaging of aluminum powder, and it is not recommended to violate these proportions.

- Method of application to walls: aerosol, using a spray gun or roller. For the aerosol method, the composition should be made more fluid, using acrylic or other water-based varnishes. Acrylic paint and varnish mixtures are not only convenient for aerosol application - after drying, all acrylic paints provide high protection from adverse influences.

- Do not use nitro enamels or oil paints for dilution - they do not combine well with the aluminum base.

To obtain a homogeneous mass, mixing must be carried out according to the following scheme:

- Measure out the required amount of powder and pour into the prepared container.

- Add a little paint base and stir until a thick paste forms.

- Add the remaining varnish to the resulting slurry, gradually stirring.

Next, you should evaluate the thickness and, if necessary, dilute with a solvent suitable for the base: for the aerosol method it will be larger, but for application with a painting tool you will need a thicker mixture.