| Weight of 1 square meter of corrugated sheet quintet | Weight, kg |

| Weight of 1 m2 of corrugated aluminum sheet, 1.5 mm thick | 4,2 |

| Weight of 1 m2 of aluminum corrugated sheet 2 mm | 5,7 |

| Weight of 1 m2 of aluminum corrugated sheet 3 mm | 8,5 |

| Weight of 1 m2 of aluminum corrugated sheet 4 mm | 11 |

| Weight of 1 m2 of aluminum corrugated sheet 5 mm | 15 |

At Nevskaya Aluminum Company you can buy aluminum from a warehouse in St. Petersburg or order delivery throughout Russia.

The warehouse of the Nevskaya Aluminum Company is located at 266 Ligovsky Prospect, not far from the Moskovskie Vorota metro station, next to the freight highway - Vitebsky Prospekt, exits to the WHSD and the Ring Road. Loading documents are issued on site.

Source

Aluminum sheet weight

For the convenience of preliminary calculations of various designs, we bring to your attention the weight of aluminum sheets per piece and square meter in the table below. These sheets are widely used in industry. The weight of sheets made of other alloys can be calculated using conversion factors. To calculate the weight of AMg2 aluminum sheets, this weight must be multiplied by a factor of 0.992; Amg3 - 0.988; AMg5 - 0.981; AMg6 - 0.977; D16 - 1.03. Please note that the indicated weight of aluminum sheet is approximate and calculated using theoretical formulas. The weight of real sheets can fluctuate both up and down by several percent; this is due to technological variation during production. If the required sheet size is not in the table, you can use our non-ferrous rolled metal weight calculator

You may also need other calculation tables for other types of rolled aluminum

How much does a square meter of aluminum sheet weigh?

| Sheet size | Weight of 1 square meter, kg |

| Weight of 1 sq.m of aluminum sheet 0.5 mm thick | 1,4 |

| Weight of 1 sq.m of aluminum sheet 1 mm thick | 2,7 |

| Weight of 1 sq.m of aluminum sheet 1.5 mm thick | 4,1 |

| Weight of 1 sq.m of aluminum sheet 2 mm thick | 5,4 |

| Weight of 1 sq.m of aluminum sheet 2.5 mm thick | 6,8 |

| Weight of 1 sq.m of aluminum sheet 3 mm thick | 8,2 |

| Weight of 1 sq.m of aluminum sheet 4 mm thick | 10,9 |

| Weight of 1 sq.m of aluminum sheet 5 mm thick | 13,6 |

| Weight of 1 sq.m of aluminum sheet 6 mm thick | 16,3 |

| Weight of 1 sq.m of aluminum sheet 8 mm thick | 21,8 |

| Weight of 1 sq.m of aluminum sheet 10 mm thick | 27,2 |

Theoretical weight of sheets, kg, cut 1200x4000 mm

| Thickness, mm | Alloy grade and density, g/cm3 | |||||||||

| A5, AD0, AD1 | AMts | D16 | AMG2 | AMg3 | AMg5 | AMg6, 1561 | 1915, VD1 | 1105 | B95 | |

| 2,71 | 2,73 | 2,77 | 2,69 | 2,66 | 2,65 | 2,64 | 2,77 | 2,80 | 2,85 | |

| 0,3 | 3,90 | 3,93 | 3,99 | 3,87 | 3,83 | 3,82 | 3,80 | 3,99 | 4,03 | 4,10 |

| 0,4 | 5,20 | 5,24 | 5,32 | 5,16 | 5,11 | 5,09 | 5,07 | 5,32 | 5,38 | 5,47 |

| 0,5 | 6,50 | 6,55 | 6,65 | 6,46 | 6,38 | 6,36 | 6,34 | 6,65 | 6,72 | 6,84 |

| 0,6 | 7,80 | 7,86 | 7,98 | 7,75 | 7,66 | 7,63 | 7,60 | 7,98 | 8,06 | 8,21 |

| 0,7 | 9,11 | 9,17 | 9,31 | 9,04 | 8,94 | 8,90 | 8,87 | 9,31 | 9,41 | 9,58 |

| 0,8 | 10,41 | 10,48 | 10,64 | 10,33 | 10,21 | 10,18 | 10,14 | 10,64 | 10,75 | 10,94 |

| 0,9 | 11,71 | 11,79 | 11,97 | 11,62 | 11,49 | 11,45 | 11,40 | 11,97 | 12,10 | 12,31 |

| 1,0 | 13,0 | 13,1 | 13,3 | 12,9 | 12,8 | 12,7 | 12,7 | 13,3 | 13,4 | 13,7 |

| 1,2 | 15,6 | 15,7 | 16,0 | 15,5 | 15,3 | 15,3 | 15,2 | 16,0 | 16,1 | 16,4 |

| 1,5 | 19,5 | 19,7 | 19,9 | 19,4 | 19,2 | 19,1 | 19,0 | 19,9 | 20,2 | 20,5 |

| 1,6 | 20,8 | 21,0 | 21,3 | 20,7 | 20,4 | 20,4 | 20,3 | 21,3 | 21,5 | 21,9 |

| 1,8 | 23,4 | 23,6 | 23,9 | 23,2 | 23,0 | 22,9 | 22,8 | 23,9 | 24,2 | 24,6 |

| 1,9 | 24,7 | 24,9 | 25,3 | 24,5 | 24,3 | 24,2 | 24,1 | 25,3 | 25,5 | 26,0 |

| 2,0 | 26,0 | 26,2 | 26,6 | 25,8 | 25,5 | 25,4 | 25,3 | 26,6 | 26,9 | 27,4 |

| 2,5 | 32,5 | 32,8 | 33,2 | 32,3 | 31,9 | 31,8 | 31,7 | 33,2 | 33,6 | 34,2 |

| 3,0 | 39,0 | 39,3 | 39,9 | 38,7 | 38,3 | 38,2 | 38,0 | 39,9 | 40,3 | 41,0 |

| 3,5 | 45,5 | 45,9 | 46,5 | 45,2 | 44,7 | 44,5 | 44,4 | 46,5 | 47,0 | 47,9 |

| 4,0 | 52,0 | 52,4 | 53,2 | 51,6 | 51,1 | 50,9 | 50,7 | 53,2 | 53,8 | 54,7 |

| 4,5 | 58,5 | 59,0 | 59,8 | 58,1 | 57,5 | 57,2 | 57,0 | 59,8 | 60,5 | 61,6 |

| 5,0 | 65,0 | 65,5 | 66,5 | 64,6 | 63,8 | 63,6 | 63,4 | 66,5 | 67,2 | 68,4 |

| 5,5 | 71,5 | 72,1 | 73,1 | 71,0 | 70,2 | 70,0 | 69,7 | 73,1 | 73,9 | 75,2 |

| 6,0 | 78,0 | 78,6 | 79,8 | 77,5 | 76,6 | 76,3 | 76,0 | 79,8 | 80,6 | 82,1 |

| 6,5 | 84,6 | 85,2 | 86,4 | 83,9 | 83,0 | 82,7 | 82,4 | 86,4 | 87,4 | 88,9 |

| 7,0 | 91,1 | 91,7 | 93,1 | 90,4 | 89,4 | 89,0 | 88,7 | 93,1 | 94,1 | 95,8 |

| 7,5 | 97,6 | 98,3 | 99,7 | 96,8 | 95,8 | 95,4 | 95,0 | 99,7 | 100,8 | 102,6 |

| 8,0 | 104,1 | 104,8 | 106,4 | 103,3 | 102,1 | 101,8 | 101,4 | 106,4 | 107,5 | 109,4 |

| 8,5 | 110,6 | 111,4 | 113,0 | 109,8 | 108,5 | 108,1 | 107,7 | 113,0 | 114,2 | 116,3 |

| 9,0 | 117,1 | 117,9 | 119,7 | 116,2 | 114,9 | 114,5 | 114,0 | 119,7 | 121,0 | 123,1 |

| 9,5 | 123,6 | 124,5 | 126,3 | 122,7 | 121,3 | 120,8 | 120,4 | 126,3 | 127,7 | 130,0 |

| 10,0 | 130,1 | 131,0 | 133,0 | 129,1 | 127,7 | 127,2 | 126,7 | 133,0 | 134,4 | 136,8 |

How much does an aluminum sheet weigh?

| Aluminum sheet weight | Weight of 1 sheet, kg |

| Weight of aluminum sheet 1x1200x3000 | 9,9 |

| Weight of aluminum sheet 1x1500x3000 | 12,4 |

| Weight of aluminum sheet 1x1500x4000 | 16,5 |

| Weight of aluminum sheet 1x1500x6000 | 24,8 |

| Weight of aluminum sheet 1.5x1200x3000 | 14,9 |

| Weight of aluminum sheet 1.5x1500x3000 | 18,6 |

| Weight of aluminum sheet 1.5x1500x4000 | 24,8 |

| Weight of aluminum sheet 1.5x1500x6000 | 37,1 |

| Weight of aluminum sheet 2x1200x3000 | 19,8 |

| Weight of aluminum sheet 2x1500x3000 | 24,8 |

| Weight of aluminum sheet 2x1500x4000 | 33 |

| Weight of aluminum sheet 2x1500x6000 | 49,5 |

| Weight of aluminum sheet 2.5x1200x3000 | 24,8 |

| Weight of aluminum sheet 2.5x1500x3000 | 30,9 |

| Weight of aluminum sheet 2.5x1500x4000 | 41,3 |

| Weight of aluminum sheet 2.5x1500x6000 | 61,9 |

| Weight of aluminum sheet 3x1200x3000 | 29,7 |

| Weight of aluminum sheet 3x1500x3000 | 37,1 |

| Weight of aluminum sheet 3x1500x4000 | 49,5 |

| Weight of aluminum sheet 3x1500x6000 | 74,3 |

| Weight of aluminum sheet 4x1200x3000 | 39,6 |

| Weight of aluminum sheet 4x1500x3000 | 49,5 |

| Weight of aluminum sheet 4x1500x4000 | 66 |

| Weight of aluminum sheet 4x1500x6000 | 99 |

| Weight of aluminum sheet 5x1200x3000 | 49,5 |

| Weight of aluminum sheet 5x1500x3000 | 61,9 |

| Weight of aluminum sheet 5x1500x4000 | 82,5 |

| Weight of aluminum sheet 5x1500x6000 | 123,8 |

| Weight of aluminum sheet 6x1200x3000 | 59,4 |

| Weight of aluminum sheet 6x1500x3000 | 74,3 |

| Weight of aluminum sheet 6x1500x4000 | 99 |

| Weight of aluminum sheet 6x1500x6000 | 148,5 |

| Weight of aluminum sheet 8x1200x3000 | 79,2 |

| Weight of aluminum sheet 8x1500x3000 | 99 |

| Weight of aluminum sheet 8x1500x4000 | 132 |

| Weight of aluminum sheet 8x1500x6000 | 198 |

| Weight of aluminum sheet 10x1200x3000 | 99 |

| Weight of aluminum sheet 10x1500x3000 | 123,8 |

| Weight of aluminum sheet 10x1500x4000 | 165 |

| Weight of aluminum sheet 10x1500x6000 | 247,5 |

At Nevskaya Aluminum Company you can buy aluminum from a warehouse in St. Petersburg or order delivery throughout Russia.

The warehouse of the Nevskaya Aluminum Company is located at 266 Ligovsky Prospect, not far from the Moskovskie Vorota metro station, next to the freight highway - Vitebsky Prospekt, exits to the WHSD and the Ring Road. Loading documents are issued on site.

Source

Theoretical weight of sheets, kg, cut 1500x3000 mm

| Thickness, mm | Alloy grade and density, g/cm3 | |||||||||

| A5, AD0, AD1 | AMts | D16 | AMG2 | AMg3 | AMg5 | AMg6, 1561 | 1915, VD1 | 1105 | B95 | |

| 2,71 | 2,73 | 2,77 | 2,69 | 2,66 | 2,65 | 2,64 | 2,77 | 2,80 | 2,85 | |

| 0,3 | 3,66 | 3,69 | 3,74 | 3,63 | 3,59 | 3,58 | 3,56 | 3,74 | 3,78 | 3,85 |

| 0,4 | 4,88 | 4,91 | 4,99 | 4,84 | 4,79 | 4,77 | 4,75 | 4,99 | 5,04 | 5,13 |

| 0,5 | 6,10 | 6,14 | 6,23 | 6,05 | 5,99 | 5,96 | 5,94 | 6,23 | 6,30 | 6,41 |

| 0,6 | 7,32 | 7,37 | 7,48 | 7,26 | 7,18 | 7,16 | 7,13 | 7,48 | 7,56 | 7,70 |

| 0,7 | 8,54 | 8,60 | 8,73 | 8,47 | 8,38 | 8,35 | 8,32 | 8,73 | 8,82 | 8,98 |

| 0,8 | 9,76 | 9,83 | 9,97 | 9,68 | 9,58 | 9,54 | 9,50 | 9,97 | 10,08 | 10,26 |

| 0,9 | 10,98 | 11,06 | 11,22 | 10,89 | 10,77 | 10,73 | 10,69 | 11,22 | 11,34 | 11,54 |

| 1,0 | 12,2 | 12,3 | 12,5 | 12,1 | 12,0 | 11,9 | 11,9 | 12,5 | 12,6 | 12,8 |

| 1,2 | 14,6 | 14,7 | 15,0 | 14,5 | 14,4 | 14,3 | 14,3 | 15,0 | 15,1 | 15,4 |

| 1,5 | 18,3 | 18,4 | 18,7 | 18,2 | 18,0 | 17,9 | 17,8 | 18,7 | 18,9 | 19,2 |

| 1,6 | 19,5 | 19,7 | 19,9 | 19,4 | 19,2 | 19,1 | 19,0 | 19,9 | 20,2 | 20,5 |

| 1,8 | 22,0 | 22,1 | 22,4 | 21,8 | 21,5 | 21,5 | 21,4 | 22,4 | 22,7 | 23,1 |

| 1,9 | 23,2 | 23,3 | 23,7 | 23,0 | 22,7 | 22,7 | 22,6 | 23,7 | 23,9 | 24,4 |

| 2,0 | 24,4 | 24,6 | 24,9 | 24,2 | 23,9 | 23,9 | 23,8 | 24,9 | 25,2 | 25,7 |

| 2,5 | 30,5 | 30,7 | 31,2 | 30,3 | 29,9 | 29,8 | 29,7 | 31,2 | 31,5 | 32,1 |

| 3,0 | 36,6 | 36,9 | 37,4 | 36,3 | 35,9 | 35,8 | 35,6 | 37,4 | 37,8 | 38,5 |

| 3,5 | 42,7 | 43,0 | 43,6 | 42,4 | 41,9 | 41,7 | 41,6 | 43,6 | 44,1 | 44,9 |

| 4,0 | 48,8 | 49,1 | 49,9 | 48,4 | 47,9 | 47,7 | 47,5 | 49,9 | 50,4 | 51,3 |

| 4,5 | 54,9 | 55,3 | 56,1 | 54,5 | 53,9 | 53,7 | 53,5 | 56,1 | 56,7 | 57,7 |

| 5,0 | 61,0 | 61,4 | 62,3 | 60,5 | 59,9 | 59,6 | 59,4 | 62,3 | 63,0 | 64,1 |

| 5,5 | 67,1 | 67,6 | 68,6 | 66,6 | 65,8 | 65,6 | 65,3 | 68,6 | 69,3 | 70,5 |

| 6,0 | 73,2 | 73,7 | 74,8 | 72,6 | 71,8 | 71,6 | 71,3 | 74,8 | 75,6 | 77,0 |

| 6,5 | 79,3 | 79,9 | 81,0 | 78,7 | 77,8 | 77,5 | 77,2 | 81,0 | 81,9 | 83,4 |

| 7,0 | 85,4 | 86,0 | 87,3 | 84,7 | 83,8 | 83,5 | 83,2 | 87,3 | 88,2 | 89,8 |

| 7,5 | 91,5 | 92,1 | 93,5 | 90,8 | 89,8 | 89,4 | 89,1 | 93,5 | 94,5 | 96,2 |

| 8,0 | 97,6 | 98,3 | 99,7 | 96,8 | 95,8 | 95,4 | 95,0 | 99,7 | 100,8 | 102,6 |

| 8,5 | 103,7 | 104,4 | 106,0 | 102,9 | 101,7 | 101,4 | 101,0 | 106,0 | 107,1 | 109,0 |

| 9,0 | 109,8 | 110,6 | 112,2 | 108,9 | 107,7 | 107,3 | 106,9 | 112,2 | 113,4 | 115,4 |

| 9,5 | 115,9 | 116,7 | 118,4 | 115,0 | 113,7 | 113,3 | 112,9 | 118,4 | 119,7 | 121,8 |

| 10,0 | 122,0 | 122,9 | 124,7 | 121,1 | 119,7 | 119,3 | 118,8 | 124,7 | 126,0 | 128,3 |

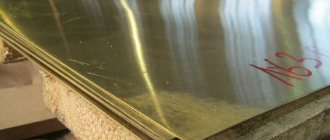

Corrugated aluminum sheet 2x1200x3000 AMg2N2R quintet - price

When ordering up to 0.1 tons - RUB 319,900/piece.

When ordering up to 1 t. - RUB 319,900/piece.

When ordering more than 1 ton - RUB 305,300/piece.

Retail cost - 6815 rubles/pcs.

Detailed information about prices, volumes, availability and delivery times can be obtained from your personal manager.

Aluminum corrugated sheet measuring 2x1200x3000 mm from AMg2N2R alloy with quintet surface type. The product is manufactured in accordance with GOST 21631-76.

Aluminum corrugated sheet 2x1200x3000 AMg2N2R quintet has all the necessary documents of conformity and certificates (Issuance of a package of documents is carried out directly when issuing invoices upon shipment or receipt, as well as for previously shipped goods, at the request of the client.).

There is a system of personal discounts depending on the volume, terms of payment and delivery of the order.

Our clients have access to services related to additional processing, as well as the manufacture of products and metal structures.

To place an order, use the appropriate forms directly on the website or contact representatives of our company in any way convenient for you. All contact information is located in the corresponding section of the site.

| Material: | AMg2N2R |

| Regulatory document: | GOST 21631-76 |

| Length: | 3m |

| Thickness: | 2 mm |

| Width: | 1200 mm |

| Size: | 1200x3000 mm |

| Number of square meters in 1 piece: | 3.6 m² |

| Weight 1 sq.m.: | 5.38 kg |

| Weight 1 piece: | 19.368 kg |

| Number of sq.m. in ton: | 185.874 |

Please note that the table contains reference data about the product “Aluminum corrugated sheet 2x1200x3000 AMg2N2R quintet”; they may differ from the characteristics of the actual product. Some product characteristics may vary depending on the manufacturer, and may also vary in each specific delivery.

You can always check the characteristics of the product you are interested in with your personal manager.

Source

Quintet aluminum sheet

Prices, rental range:

* The website presents wholesale prices for orders over RUB 90,000. The cost of products depends on the order volume, payment terms and place of shipment (check with the manager for information). Prices on the website are for informational purposes only and do not constitute a public offer.

Filter

The price is valid and updated as of 06/30/2021.

Availability of rental products in warehouses:

We offer all types of rentals wholesale and retail (from 1 piece to a wagon)!

For regular customers, deferred payment for up to a month. Non-cash, cash payment.

The next day after payment. (Own vehicle fleet, delivery throughout Russia by transport company).

We weigh the products in front of you. Loading into the car is free. Loading 1 position takes 5-15 minutes (5-6 positions - about an hour).

Corrugated aluminum rolled metal is one of the most popular products. sells aluminum sheets with a thickness of 1 to 4 mm both in regular factory sizes (3500×1500mm, 3000×1200mm, 3000×1500mm) and in individual ones: the company provides metal cutting services, so customers have the opportunity to purchase the product in the desired size size.

Aluminum corrugated sheet: types and features of choice

Along with strip, profile, rod and other semi-finished products made of aluminum and its alloys, aluminum sheet has become widespread.

Its use allows solving an extremely wide range of technical problems. Approximately 40% of all aluminum produced in the world is used in sheet form. Corrugated sheets occupy an important place in the range of aluminum sheets. Corrugated aluminum sheet is a flat semi-finished product of rectangular cross-section, which got its name due to the presence on the surface of a convex pattern formed by regular rows of protrusions located at an angle to each other. This is the so-called riffles, literally translated from English - gutters, grooves.

Dimensions and weight of corrugated aluminum sheet

Sheet thickness excluding the height of the convexities: 1.2; 1.5; 2; 2.5; 3; 4 millimeters. There are corrugated aluminum sheets with a thickness of 5 millimeters.

The standard size of corrugated aluminum sheet is 1.2×3.0; 1.5x3.0 meters. By ordering a cutting service, you can buy corrugated aluminum in the sizes you require.

The weight of a corrugated aluminum sheet depends not only on its size, but also on the grade of the alloy. For example, the weight of rolled aluminum metal with dimensions of 1.5 × 1200 × 3000 millimeters: AMG2 - 16.15 kg, and VD1 - 15.26 kg. One of the most popular is aluminum corrugated sheet 2 mm. You can buy rolled aluminum AMg2N2 in sizes 1200×3000 and 1500×3000, the weight of the sheets will be 21.07 and 23.34 kg. And the weight of a 4 mm sheet, cut to 1500×3000 mm, is 45.52 kg.

Theoretical weight of sheets, kg, cut 1200x3000 mm

| Thickness, mm | Alloy grade and density, g/cm3 | |||||||||

| A5, AD0, AD1 | AMts | D16 | AMG2 | AMg3 | AMg5 | AMg6, 1561 | 1915, VD1 | 1105 | B95 | |

| 2,71 | 2,73 | 2,77 | 2,69 | 2,66 | 2,65 | 2,64 | 2,77 | 2,80 | 2,85 | |

| 0,3 | 2,93 | 2,95 | 2,99 | 2,91 | 2,87 | 2,86 | 2,85 | 2,99 | 3,02 | 3,08 |

| 0,4 | 3,90 | 3,93 | 3,99 | 3,87 | 3,83 | 3,82 | 3,80 | 3,99 | 4,03 | 4,10 |

| 0,5 | 4,88 | 4,91 | 4,99 | 4,84 | 4,79 | 4,77 | 4,75 | 4,99 | 5,04 | 5,13 |

| 0,6 | 5,85 | 5,90 | 5,98 | 5,81 | 5,75 | 5,72 | 5,70 | 5,98 | 6,05 | 6,16 |

| 0,7 | 6,83 | 6,88 | 6,98 | 6,78 | 6,70 | 6,68 | 6,65 | 6,98 | 7,06 | 7,18 |

| 0,8 | 7,80 | 7,86 | 7,98 | 7,75 | 7,66 | 7,63 | 7,60 | 7,98 | 8,06 | 8,21 |

| 0,9 | 8,78 | 8,85 | 8,97 | 8,72 | 8,62 | 8,59 | 8,55 | 8,97 | 9,07 | 9,23 |

| 1,0 | 9,8 | 9,8 | 10,0 | 9,7 | 9,6 | 9,5 | 9,5 | 10,0 | 10,1 | 10,3 |

| 1,2 | 11,7 | 11,8 | 12,0 | 11,6 | 11,5 | 11,4 | 11,4 | 12,0 | 12,1 | 12,3 |

| 1,5 | 14,6 | 14,7 | 15,0 | 14,5 | 14,4 | 14,3 | 14,3 | 15,0 | 15,1 | 15,4 |

| 1,6 | 15,6 | 15,7 | 16,0 | 15,5 | 15,3 | 15,3 | 15,2 | 16,0 | 16,1 | 16,4 |

| 1,8 | 17,6 | 17,7 | 17,9 | 17,4 | 17,2 | 17,2 | 17,1 | 17,9 | 18,1 | 18,5 |

| 1,9 | 18,5 | 18,7 | 18,9 | 18,4 | 18,2 | 18,1 | 18,1 | 18,9 | 19,2 | 19,5 |

| 2,0 | 19,5 | 19,7 | 19,9 | 19,4 | 19,2 | 19,1 | 19,0 | 19,9 | 20,2 | 20,5 |

| 2,5 | 24,4 | 24,6 | 24,9 | 24,2 | 23,9 | 23,9 | 23,8 | 24,9 | 25,2 | 25,7 |

| 3,0 | 29,3 | 29,5 | 29,9 | 29,1 | 28,7 | 28,6 | 28,5 | 29,9 | 30,2 | 30,8 |

| 3,5 | 34,1 | 34,4 | 34,9 | 33,9 | 33,5 | 33,4 | 33,3 | 34,9 | 35,3 | 35,9 |

| 4,0 | 39,0 | 39,3 | 39,9 | 38,7 | 38,3 | 38,2 | 38,0 | 39,9 | 40,3 | 41,0 |

| 4,5 | 43,9 | 44,2 | 44,9 | 43,6 | 43,1 | 42,9 | 42,8 | 44,9 | 45,4 | 46,2 |

| 5,0 | 48,8 | 49,1 | 49,9 | 48,4 | 47,9 | 47,7 | 47,5 | 49,9 | 50,4 | 51,3 |

| 5,5 | 53,7 | 54,1 | 54,8 | 53,3 | 52,7 | 52,5 | 52,3 | 54,8 | 55,4 | 56,4 |

| 6,0 | 58,5 | 59,0 | 59,8 | 58,1 | 57,5 | 57,2 | 57,0 | 59,8 | 60,5 | 61,6 |

| 6,5 | 63,4 | 63,9 | 64,8 | 62,9 | 62,2 | 62,0 | 61,8 | 64,8 | 65,5 | 66,7 |

| 7,0 | 68,3 | 68,8 | 69,8 | 67,8 | 67,0 | 66,8 | 66,5 | 69,8 | 70,6 | 71,8 |

| 7,5 | 73,2 | 73,7 | 74,8 | 72,6 | 71,8 | 71,6 | 71,3 | 74,8 | 75,6 | 77,0 |

| 8,0 | 78,0 | 78,6 | 79,8 | 77,5 | 76,6 | 76,3 | 76,0 | 79,8 | 80,6 | 82,1 |

| 8,5 | 82,9 | 83,5 | 84,8 | 82,3 | 81,4 | 81,1 | 80,8 | 84,8 | 85,7 | 87,2 |

| 9,0 | 87,8 | 88,5 | 89,7 | 87,2 | 86,2 | 85,9 | 85,5 | 89,7 | 90,7 | 92,3 |

| 9,5 | 92,7 | 93,4 | 94,7 | 92,0 | 91,0 | 90,6 | 90,3 | 94,7 | 95,8 | 97,5 |

| 10,0 | 97,6 | 98,3 | 99,7 | 96,8 | 95,8 | 95,4 | 95,0 | 99,7 | 100,8 | 102,6 |

Standard requirements

Rolled aluminum sheets with a corrugated cross-section profile, as specified in GOST 21631-76, are produced in the form of rectangular-shaped products, on which protrusions are specially applied, located at an angle to each other and forming a specific pattern. Such protrusions, as well as the very low weight of sheet aluminum, are precisely the most significant features of such a material.

You can familiarize yourself with the GOST requirements for sheet aluminum by downloading the document in pdf format from the link below.

GOST 21631-76 Sheets of aluminum and aluminum alloys. Specifications

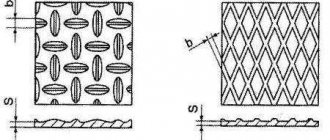

The projections formed on the surface of the aluminum sheet are called corrugations. The corrugated surface consists of groups of adjacent protrusions formed from varying numbers of corrugations. Thus, a sheet whose corrugated surface is formed from groups of protrusions, each of which contains five corrugations, is an aluminum sheet quintet, two corrugations are a duet, one is a diamond. It is not difficult to distinguish sheets with different types of corrugation; to do this, just look at the photo of the product.

Types of corrugation of aluminum sheet

GOST specifies the basic geometric parameters of corrugated aluminum sheets:

- length of finished sheets – 200–600 cm;

- width of sheet products – 100–150 cm;

- thickness of rolled aluminum sheets – 1.5–4 mm (it should be borne in mind that this parameter does not include the height to which the corrugations rise above the sheet).

The weight of one linear meter of corrugated aluminum sheet is calculated using a special formula. It is necessary to know the following geometric parameters of such a product: the maximum and minimum dimensions of the sheet in terms of its thickness and width and the density of the alloy from which such a sheet is made. The provisions of GOST provide the following method for determining the weight of one linear meter of corrugated rolled aluminum sheets of various types.

- The largest and smallest values of sheet thickness are added together, and the total is divided by two.

- The average sheet width is calculated by adding the minimum and maximum values of this parameter and dividing the resulting amount by two.

- Then, to determine the average volume of one linear meter of corrugated aluminum sheet, the obtained values are multiplied.

- The result of this multiplication must be multiplied by the density of the aluminum alloy from which the sheet in question is made, and then divided by 1000.

Approximate weight of 1 m2 aluminum sheet

In the event that it is necessary to calculate the weight of corrugated aluminum sheets made from alloys of grades B95, B95-1 and B95-2, the formula takes into account the density of the material equal to 2.85 g/cm3. When calculating the mass of corrugated aluminum sheets from material of other grades, the following conversion factors are used:

- 0.947 – for AB grade alloys;

- 0.937 – AMg3;

- 0.926 – AMg6;

- 0.94 – AMg2;

- 0.95 – AMg5;

- 0.954–0.982 – D1, D12 and D16;

- 0.97 – AKM;

- 0.958 – AMts, AMtsS and MM;

- 0,972 – 1915.

All of the above indicators of conversion factors are stipulated by the provisions of GOST 21631-76, the link to which is presented above.

The practicality of sheet aluminum, as a rule, is used for purely utilitarian purposes

Advantages and characteristics of corrugated aluminum

Operational and physical-chemical characteristics that determine the popularity of this type of rolled aluminum:

— high resistance to corrosion;

— long service life;

— relief pattern that prevents slipping even on a wet surface;

— presentable appearance;

— environmental safety of the product;

— resistance to many aggressive factors of the operating environment;

— affordable price of corrugated aluminum.

The most common brands you can buy are: AMg2N2, 1105ANr, AMg2Nr, and AMg3N2. The letter H indicates that the alloy is hard-worked. This material is more durable and hard. There are several types of cold-working: semi-hard-working (H2), cold-working (H), one-third cold-working (H3) and one-quarter cold-working (H4). Cold-worked sheets (H) have the greatest strength. The letter P is added to the marking of products obtained by cold rolling.

If you need to additionally process the product using bending, welding, and the product will be used outdoors, it is better for you to buy AMG2N2R (semi-hardened corrugated steel) or AMG2NR (cold-cold rolled steel). When used indoors, on a flat surface without distortion, the cheaper imported analogue GALAXY is also suitable.

Characteristics and advantages of the material

A metal sheet that has specific bulges on the surface, consisting of 5 parallel strips - corrugations - is called a “quintet”.

The relief pattern is applied at a certain angle: each “group” of riffles is located perpendicular to each other. This not only gives the product a beautiful appearance, but also provides an anti-slip effect. Other benefits:

- immunity to negative external influences;

- light weight;

- long service life;

- environmental Safety;

- affordable price.

Rolled aluminum with a “pattern” can be produced from different alloys, but the most practical are AMg2N2, AMg2NR, AMg3N2, AMg5ANR, 1105ANR. Each of them has increased resistance to corrosion, has good ductility and weldability, and is not prone to sparking during friction.

All products are manufactured in accordance with state quality standards.

Production methods

Aluminum sheets having a corrugated cross-section profile are produced using hot or cold rolling. In this case, corrugated sheets, the thickness of which is 3–4 mm, are made by hot rolling, and products with a smaller thickness are made using cold technology.

All such products, regardless of what type of corrugation needs to be applied to their surface, are produced according to the following technological scheme.

- Quite massive ingots are made from aluminum alloy, weighing 2–3 tons.

- Various preparatory operations are carried out with ingots.

- The resulting billets are subjected to hot rolling, which can be followed by cold rolling if necessary.

- Then the corrugated sheets are subjected to heat treatment and finishing operations, the technology of which depends mainly on what type of aluminum alloy was used for their manufacture.

An excellent, detailed video about all the nuances of the production of rolled aluminum sheets.

According to the technical specifications (TU), additional technological operations can be used for certain types of aluminum corrugated sheets. In particular, technical conditions have been specially developed for the production of aluminum sheets, on the surface of which “lentil” corrugation is applied. It is quite easy to determine the type of such corrugation even from a photo: its elements have a pronounced diamond-shaped configuration.

For the production of aluminum sheets with corrugation, the following grades of alloys of this metal are most often used: AMts and AMg. The preference of these alloys as a material for corrugated sheets is due to their high resistance to corrosion, which allows the successful use of products made from them in cases where they are exposed to high humidity and other aggressive environments.

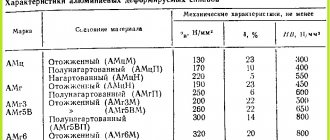

Characteristics of aluminum wrought alloy grade AMts

Additional advantages of using aluminum alloys belonging to the AMts category are:

- good ductility, which greatly facilitates the processing of such materials by plastic deformation methods;

- good weldability ensured by the use of aluminum electrodes;

- light weight;

- decent mechanical characteristics.

Meanwhile, it should be borne in mind that aluminum alloys containing manganese cannot be subjected to heat treatment, which could improve their mechanical properties. Products made from these alloys are subjected to a technological operation such as cold hardening, which, although it reduces the plasticity of the material, can significantly increase its hardness.

Application of Aluminum Corrugated Sheet

Corrugated aluminum is an extremely popular and sought-after metal product that can be used everywhere. Among the areas of application of corrugated aluminum sheets are construction, production sites (including stairs, flights of stairs, passages, etc.), automotive and instrument making, agriculture, aircraft manufacturing and many others.

Due to their high resistance to corrosion, aluminum corrugated sheets can be used both outside and indoors, used as a finishing material and floor coverings. Very often, corrugated aluminum is used for lining refrigerated vans and car vans. In the food industry, corrugated aluminum is used for flooring.

The main function that makes corrugated aluminum so popular is the formation of an anti-slip coating. But today, very often, corrugated aluminum sheets are used for decorative purposes, for example, for tuning cars, motorboats, boats and other vehicles, as decorative elements. You can’t do without corrugated aluminum in the production of refrigeration rooms, installations, as well as many household appliances.

Supplier: LLC RTG "MetPromStar"

Main aluminum alloys

Pure aluminum is not suitable as a material for the manufacture of corrugated sheets, so alloys are more often used. The main feature of alloys is alloying additives, which give the final product certain properties (corrosion resistance, strength, ductility, etc.). The better the quality of the alloy, the higher the price of corrugated aluminum sheet.

AMg2 - Material containing from 2 to 4% magnesium. Gives the product ductility, strength and resistance to corrosion, and is easy to weld. The alloy is suitable for the use of sheets in critical structures, equipment creation and mechanical engineering. Often amenable to additional processing.

VD1 - Contains an admixture of copper from 2 to 5%, as well as 0.4 - 1.6% magnesium. This composition gives the alloy ductility, strength and resistance to impact loads.

AMts - The composition containing up to 1.5% manganese is perfectly weldable, has high ductility and is suitable for creating various products. Due to its low strength, it is not suitable for critical structures.

Aluminum sheet with corrugation

Aluminum is a lightweight, corrosion-resistant metal that has gained popularity in households and industrial production.

Physical properties of metal:

- density - 2.7 g/cm3;

- plastic;

- resistivity 0.027 Ohm • mm2/m;

- thermal conductivity 203.5 W/m • K;

- melting point 660ºС.

Due to their light weight, aluminum sheets are preferable to rolled steel in reconstructed and repaired buildings, since aluminum puts less load on foundations and other supporting structures.

Plasticity and low melting point make it possible to easily process metal and give products complex shapes. The lack of brittleness at ultra-low temperatures has expanded the field of application to cryogenic technology.

In industries associated with the formation of flammable and explosive gases, aluminum is used as a spark-proof material in the construction of floors, panels, and enclosures of lifting and transport equipment cabins.

Aluminum's ability to conduct heat is 3 times higher than that of steel; it is widely used in heat exchangers with high and low temperatures, as well as kitchen utensils and air conditioners.

Its electrical conductivity is less than that of copper, but due to its lower specific gravity it conducts 2 times more electricity than copper wire with equal weights. This characteristic is used in conductors, transformers, and high-voltage power lines.

Alloys with other metals

Perhaps the only negative quality of aluminum is its low strength, but modern metallurgy has found a way to overcome this characteristic: alloys with copper, magnesium, manganese, chromium, silicon, and other metals are comparable in strength to some types of steel.

An oxide film forms on the surface of aluminum products. Thanks to it, the metal exhibits unique anti-corrosion qualities. In combination with nickel and iron, the protection weakens; in combination with manganese, it increases. Corrosion resistance expands the possibility of using aluminum structures and products in the chemical industry and transportation of aggressive liquids. Contact with halogens, chlorine and bromine, weak nitric acid, alkalis, mercury leads to the destruction of oxide protection.

The presence of a protective film complicates welding; it is performed with tungsten electrodes, and the procedure itself is carried out in an inert gas environment.

Aluminum does not form compounds harmful to human health, does not participate in the metabolism of warm-blooded creatures, and therefore is widely used in the manufacture of packaging for long-term storage of food products.

Pure aluminum has low strength and is plastic; alloys are used in almost all areas of production and everyday life, and sheets of alloys are corrugated - a three-dimensional pattern is applied, which makes them anti-slip and decorative.

Hot and cold rolled

Aluminum corrugation is produced by hot or cold rolling with or without further processing.

Hot rolling consists of annealing large-sized ingots in a shaft furnace to give the metal a uniform structure, and then passing it between paired cylindrical shafts, reducing the clearance between them and simultaneously applying relief. The hot method produces sheets with a thickness of over 3 mm. The disadvantage of hot-rolled products is the uneven geometric dimensions.

The technology for producing hot-rolled corrugated aluminum includes 5 operations:

- Ingots weighing 3-8 tons are cast from alloys obtained by alloying aluminum.

- The workpieces are transported to a shaft furnace, where homogenizing annealing is carried out for 4-5 hours at a temperature of 20-40ºC to obtain metal with a homogeneous structure.

- The prepared ingots are sent to rolling mills with cylindrical rolls with a relief installed in pairs, and the gap between them gradually decreases, giving the sheet the desired shape and relief pattern.

- The resulting sheets undergo heat treatment (annealing) to relieve internal stress.

- The final finishing of the sheet consists of grinding, cutting to specified sizes, and applying coatings.

Cold rolled products are produced without preheating using more powerful equipment. The sheets have a constant geometry with a clear corrugation pattern. Rolled products are heat treated to relieve internal stresses in the metal, then the sheets are ground and cut to specified sizes.

Treatment

- Thermal or its absence, products without heat treatment do not have a marker; heat-treated (or annealed) sheets receive the letter “M” in the brand. The entire range of aluminum grades, except VD1, can be annealed.

- The annealing procedure is used to eliminate excess strength of the sheet, which it may acquire during processing.

- cold-worked (H) - with an outer layer compacted by special machines or shot peening;

- semi-hardened (H2) - with a lower degree of compaction;

Cold-worked or semi-hardened metal under the influence of high pressure in a low-temperature environment is strengthened with a partial loss of ductility. At higher pressures, a high degree of hardening is achieved.

Products made from cold-worked material cannot be welded or bent due to the possibility of cracks, but they are used in high-strength building structures.

Semi-hardened sheets are welded and bent.

Hardening and aging

Tempering gives corrugated aluminum sheets additional tensile strength. The technology consists of sudden cooling after high-temperature exposure:

- a hardened and naturally aged sheet receives the letter “T”, the natural aging process takes 4-5 days without heat treatment;

- hardened and artificially aged - “T1”, aging is forced, at t = 150ºC for several hours;

- cold-worked after hardening and artificial aging - “TN”.

Surface finish quality

Corrugated aluminum sheet may have:

- high finish with the designation “B”;

- increased finishing - “P”;

- regular trim that is not marked.

High finishing involves the use of A7 grade aluminum as a raw material for the production of corrugated sheets; A6; A0; AD00; AD0; AD1; HELL; AMts grade alloys; AMg2. Advanced and regular finishes do not have requirements for the grade of metal or alloy.

The surface texture of the sheet can be glossy or matte.

Alloys used in the production of aluminum sheets

For the production of sheets, aluminum grades A0, A5, A6, A7 are used (the chemical composition is regulated by GOST 11069-74), as well as AD, AD0, AD00, AD1 (according to GOST 4784-74). The range also includes products made from heat-strengthened and non-heat-strengthened alloys of the following types:

- high strength;

- weldable, standard strength;

- normal strength (duralumin);

- highly plastic, medium strength (magnalia);

- highly plastic, low strength - with and without alloying.

Production capabilities

| Aluminum/alloy grade | No heat treatment | M | H2 | N | T | T1 | TN |

| A0 | + | + | + | + | |||

| A5 | + | + | + | + | |||

| A6 | + | + | + | + | |||

| A7 | + | + | + | + | |||

| HELL | + | + | + | + | |||

| AD0 | + | + | + | + | |||

| AD1 | + | + | + | + | |||

| AD00 | + | + | + | + | |||

| AMts | + | + | + | + | |||

| AMtsS | + | + | + | + | |||

| AMg2 | + | + | + | + | |||

| AMg3 | + | + | + | ||||

| AMg5 | + | + | |||||

| AMg6 | + | + | |||||

| AMg6B | + | + | |||||

| AMg6U | + | ||||||

| AB | + | + | + | + | |||

| D1A | + | + | + | ||||

| D16A | + | + | + | + | |||

| D16B | + | + | + | ||||

| D16 | + | + | + | ||||

| D16U | + | + | |||||

| B95-1A | + | + | + | ||||

| B95-1 | + | ||||||

| B95-2A | + | + | + | ||||

| V95-2B | + | ||||||

| VD1A | + | + | + | ||||

| VD1B | + | + | + | + | |||

| VD1 | + | + | + | + | |||

| AKMA | + | + | + | + | |||

| AKMB | + | ||||||

| AKM | + | ||||||

| B95A | + | + | + | ||||

| 1915 | + | + | + | ||||

| D12 | + | + | |||||

| MM | + |